Plasterboard thickness for walls

Drywall is a building material widely used for repair work.

They use it to line walls, create partitions, arches, and ceilings of incredible beauty. It is suitable for creating shelves, niches, and interior products. The thickness of the gypsum board for walls plays an important role.

How to choose the correct dimensions of the material, what determine the selection parameters?

How to properly build a plasterboard wall

The room temperature must be maintained above 10°C. Before installation, drywall must be kept in the room being repaired for 2 - 3 days so that it accepts its air humidity and temperature. Which drywall is best to install depends on the climate in the room. In rooms with normal and dry temperature and humidity conditions, gypsum boards are installed.

For rooms with high humidity, GKLV.S is used. If the unevenness of the walls is more than 20 mm, pre-glue strips cut from plasterboard 100 mm wide with Perlfix glue and then glue plasterboard slabs onto them with Fugenfüller putty.

- maintains the desired microclimate in the room;

- environmental friendliness: drywall is completely harmless and does not have a detrimental effect on human health;

- high sound insulation;

- the possibility of subsequent finishing with painting, plastering, tiles, wallpaper and other materials;

- low cost of plasterboard - allows it to be used even in low-budget construction;

- the ability to create structures of any complexity, including round ones.

Drywall is often used to finish walls and ceilings. Installation of drywall is carried out before laying the final floor covering. In order for the walls and ceiling to support the drywall, they must be strong and not delaminate. Drywall cannot be glued to plaster. If the wall material is wood, it is permissible to choose fastening the gypsum boards with tar paper nails with large heads.

The nails are recessed, and the recessed areas are puttied. Glue is first applied to uneven walls. A comparative analysis of the price factor of using plasterboard or plaster to level walls showed that neither method has a significant advantage, except for the case when plasterboard with glue is used instead of plaster.

In the process of wall repair, both specialists and novice finishers are trying to figure out: what is better, plaster or drywall on the walls? Each technology option has its pros and cons. The final decision is influenced by the slightest nuances that you don’t pay attention to in everyday life. At the corners of the edges of this crossbar, cuts are made to the marked depth.

Only the front part of the profile is left intact, and the side shelves in the cut area are bent at a right angle - they must fit inside the frame. They are secured with pliers, a riveter or self-tapping screws. For example, to tidy up walls using plaster mortar and beacons, you need to have certain skills and dexterity that only come with practical experience.

And when working with drywall, it is enough to be diligent, careful and accurately follow all technological recommendations. The process will go faster if all the necessary materials, elements and consumables for installing the structure and tools for work are at hand. Very often, when a complete interior decoration of a room is carried out, it becomes necessary to level the walls. This situation is especially common in multi-storey buildings. The advantage of the first option is that there is no need to carefully prepare the surface, since all its shortcomings will be completely hidden. In addition, all communications and sound insulation can be hidden in the space between the gypsum board and the ceiling.

Material advantages

Before purchasing GC sheets, you need to familiarize yourself with the pros and cons of the material:

- Thermal insulation. A leveled surface with material saves on heating costs. This is especially true if insulation is laid under the gypsum board.

- Flexibility. Drywall bends under a certain radius, this allows you to make decorative elements.

- Fire resistance. If a room catches fire, only the top layer that is not covered with a gypsum board finish will burn out - the gypsum does not burn.

- There are certain types of material used in the kitchen, bathroom, and balcony.

- When leveling the wall with material, communications, wiring and other cables are carried out behind the sheets.

With all the advantages of gypsum boards, there are disadvantages:

- fragility of the material. It breaks and crumbles, so installation work is carried out with caution;

- if you install the usual gray color in the kitchen or bathroom, it will absorb a lot of moisture and subsequently become deformed;

- before installing gypsum board on the surface, it is necessary to determine how thick it should be and whether the wall will be weighted;

The listed advantages show that the use of plasterboard is beneficial for leveling surfaces and creating other surfaces.

What are the advantages of drywall?

Using drywall to level walls (without a frame or using the frame method) with your own hands is a proven opportunity to reduce this process in time and make it less messy.

Covering walls with plasterboard does not require careful preliminary preparation. More often, leveling with plasterboard is carried out using a metal profile.

Advantages of leveling walls with plasterboard:

- allows you to hide internal communications;

- apply insulation or soundproofing membrane;

- the material is convenient for interior work: hanging pictures, shelves, hiding additional light sources.

The disadvantages of leveling walls with plasterboard include the ability of this material to hide the volume of the room; it is not so significant as to become decisive in the choice of leveling methods; it is not even noticeable to the eye.

Which plasterboard is better to cover the walls in a room: characteristics

Before answering the question, it is necessary to list the external factors influencing the future design.

- Humidity in the room. If there is high humidity in the room: kitchen, bathroom, attic, corridor, use a moisture-resistant sheet - green plasterboard.

- Temperature conditions. With sudden changes in temperature, drywall can shrink and expand. This will lead to cracks. The leaf will burst.

- If the wall is located next to an active fireplace, it is necessary to install it with fireproof material. It resists high temperature and will not change the original appearance.

The purpose of the surface matters. If decorative finishing with gypsum board with figured elements is intended, then one sheet thickness of 12.5-9.5 mm is used. But, taking into account the hanging of shelves, a TV, a picture, a large mirror, a different material with a certain thickness of up to 24 mm is used. In some cases, the sheathing is installed in 2 layers.

How best to level walls

To give the wall the desired flawlessness, use the wet and dry leveling method. In the first case, the plaster solution is applied in several thin layers, each of which is primed.

However, leveling walls with plaster presents certain difficulties. In particular, to obtain perfectly smooth walls, the mandatory installation of beacons is required.

The use of plasterboard sheets (GKL) with an ideal working surface, specified in factory production conditions, not only simplifies the problem of wall alignment, but also solves a number of new design problems in changing the space of the room, supplementing it with arches, niches, and protrusions according to the designer’s plan.

Gypsum filler, sandwiched between layers of building cardboard, is a relatively inexpensive material that can be mechanically affected (cut, sawn, drilled) and interacts well with finishing materials.

It is used to level walls in two main ways:

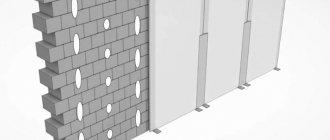

- frame - based on a frame made of metal profiles or wooden slats;

- frameless - based on fastening to the wall using special adhesives and putties.

If you plan to create a partition in a room with high humidity, then you should pay attention to another type of drywall - gypsum board (moisture resistant) or even gypsum fiber sheets (GVL).

Which is better to choose and use drywall thickness

The material used for repairs is divided into types. Each type is applicable for its intended purpose, but there are options when the finishing material is used in a place other than what it was produced for.

- Wall gypsum board. Suitable for leveling indoor walls. With its help, partitions are created, both decorative and permanent interior structures.

- Ceiling gypsum board. The main difference is thickness. Thin sheets that have less weight should be mounted on the ceiling.

- Arched type. Plasterboard, which has flexibility due to its thickness. We can use it not only for creating arched openings, but also for the production of decorative figured elements on surfaces, partitions, and ceilings. Sometimes a beautiful butterfly made of arched material is mounted on the corner between the ceiling and the wall.

- Moisture resistant – gypsum plasterboard green tone.

- Fireproof – GKLO pink color.

- Regular - plasterboard gray color.

- Moisture-resistant fireproof – GKLVO red tone.

Depending on the purpose of the building material, a certain type is used.

What are the sizes of gypsum boards?

Each type of material has its own dimensions.

| No. | Type of gypsum board | Manufacturing plant | Its width, length, mm | Area, m2 | Weight, kg |

| 1 | Wall | KNAUF Lafarge | 1200-2500, 1200-2500 | 3 26 | |

| 2 | Ceiling | 1200 to 3600 | 3 36 | ||

| 3 | Arched | 1200-2500 | 3 | 17.1 |

What is the thickness of the plasterboard - such a weight. Each manufacturer creates mounting sheets in sizes that differ from the standard by millimeters.

What is the sheet thickness

For covering surfaces, 12.5 mm material is used. This sheet will withstand a certain load.

Drywall 15-24 mm is used for covering surfaces on which heavy objects will be hung - a TV, shelves with books, a water heater.

Wall sheets, regardless of type (regular, moisture resistant) have a thickness of 12.5 mm.

The ceiling view has a thickness of 9.5 mm.

Arched gypsum board – 6.5 mm.

Sometimes, when constructing a permanent partition, double wall cladding is used. They create this for structural strength that can withstand heavy weight.

What width is better to choose

All types of drywall have the same width - 1200 mm. A frame base of profiles is mounted under the gypsum plasterboard, which contains the exact dimensions for fixing the profile. This applies to both the ceiling and other surfaces.

If you need smaller drywall, it is cut with a construction knife or a router.

Moisture-resistant gypsum board: description of material features

Sheets of moisture-resistant plasterboard have a number of features that distinguish them from other finishing materials. Before purchasing and starting repairs, you should carefully read the characteristics of this material. When purchasing, you need to pay attention to the quality of the material and the presence of a certificate, which increases consumer confidence in the product.

Moisture-resistant drywall is divided into classes, the choice of which determines the quality of finishing work.

Drywall sheets of this type should be selected depending on the type of space in which the finishing will take place. It is important to determine goals that will help you choose the class of material, its size and thickness. The slabs can have a standard size or can be made to order.

Material Features:

- The slabs are light green or pink in color.

- The marking is applied to the back of the sheet using blue color.

- When producing sheets, a special impregnation is used, which performs a protective function against the penetration of moisture and fungi into the material.

Professional craftsmen choose moisture-resistant drywall, as it has high performance and reliable properties. It is convenient to work with it, since the material is quite flexible. However, its cost is considered low.

Features and Recommendations

Before choosing gypsum boards for leveling walls, you need to determine the manufacturer. Common ones are KNAUF, Volma. Before purchasing sheets, you need to check its dimensions.

Attention. The dimensions of the sheet affect the installation carried out indoors. When choosing the length of one sheet and making your own calculations, there may not be enough material. You shouldn't overpay either.

When installing thin sheets, it is necessary to limit the wall in advance from hanging any objects on it. Even creating a niche on such a wall can negatively affect the entire structure.

Stages of leveling walls with plasterboard without a frame

- Lay out the gypsum board sheets indoors for 2-3 days.

- Make markings.

- Prime the back side of the plasterboard and let the layer dry.

- Place the sheets vertically, starting from the corner of the room.

- Leave a gap at the floor equal to the thickness of the plasterboard, taking into account the elongation of the sheet after drying.

- Apply glue around the perimeter of the sheet with a notched trowel.

- Apply glue in the center in the form of small patches using a regular spatula.

- Align the glued sheet by lightly tapping it with a rubber mallet.

- Fix the plasterboard with dowels (flush) screwed into pre-drilled holes to preserve the integrity of the plaster.

- Tape the seams with sickle mesh

- Seal the joints of the outer corners with counterseals.

- Prime all uneven surfaces, joints, and screw heads.

- Fill uneven areas and seams.

- Sand the putty areas.

- Apply primer under the topcoat.

Plasterboard thickness for walls

The correct choice of material is the key to obtaining a high-quality and durable surface. For quick leveling of vertical bases, the most preferable option is gypsum plasterboard slabs, but to perform the cladding, you need to choose the correct sheet size. The thickness of the drywall is determined based on the characteristics of the structure being created.

Frame and frameless installation of plasterboard on walls

Today we will look at popular types of finishing materials and note under what conditions their use is allowed. We will choose which plasterboard is best suited for walls, and also discuss possible methods and technologies for its installation. For finishing wall surfaces, sheets with a length of 2500-3000 mm are mainly used. The width of the slabs is 1200 mm, and the thickness of plasterboard for walls can be 9 or 12.5 mm. The length of gypsum board sheets of all types can be 2000; 2500; 3000; 3500 and 4000 mm, and their most common width is 1200 mm.

There is no standard size for wall plasterboard: for example, the thickness of the slab depends on the type of material and the features of its application and can vary from 6.5 to 24 mm. We know that installing gypsum plasterboard is the simplest and most effective way to finish and level wall ceilings in a room. The most common are two options for installing drywall: Each type of our finishing material has certain characteristics and has special properties that must be taken into account when choosing it for a particular room.

Types of material

GCR is divided into categories depending on the functions and characteristics performed:

- Ordinary. It is used in residential premises, offices, service rooms. According to the standard, objects must have a constant positive temperature and humidity no more than 65%. A simple board consists of plaster, lined on both sides with cardboard. The products are gray in color and marked according to GOST.

- Moisture resistant. GKLV refers to special materials that are used for covering walls and constructing partitions in rooms with high humidity. This is an excellent solution for a bathroom and shower room, hallway, loggia. Improving the quality of the material is achieved through additives in the composition. Additional components also increase resistance to fungus and mold. Impregnation of the outer coating helps neutralize the harmful effects of water, but the sheets are not able to maintain their structure during prolonged direct contact with liquid. The products have a greenish tint.

- Fire resistant. The material is used for cladding areas that experience constant temperature effects. The product is suitable for cladding areas prone to fire and evacuation corridors. Such properties are achieved by adding reinforcing fibers to the composition, which significantly strengthen the structure of the slab. But the integrity of gypsum boards when in contact with very high temperatures or open flames is maintained for a short time (from 30 to 60 minutes). The exact values are indicated on the labeling. The fire-resistant material is pink in color.

- GKLVO. A universal variety that combines high levels of moisture resistance and fire safety. The product is the optimal solution for attic spaces and ventilation. The material has a green tint and red markings.

- Arched. A special type that bends well is used to create complex architectural forms.

There are many varieties of plasterboard sheets, but the most popular are simple, waterproof and fire-resistant plasterboard, other models are considered highly specialized and are used for special work

Regardless of the category, the main purpose of plasterboard material is to level the bases. The slabs are laid on the frame, or less often they are glued directly to the surface. The resulting coating is suitable for any finishing process.

Advantages and disadvantages of gypsum plasterboards

If you compare drywall with other building materials, you can find both advantages and disadvantages.

- Low price. The material is accessible to almost all segments of the population.

- Ease. On average, a sheet weighs 29 kg; even one person can work with it. Therefore, gypsum board is widely used in the construction of high-rise buildings, because it significantly reduces the load on load-bearing structures.

- Ease of processing. Cutting plasterboard sheets does not require expensive special equipment. This can be done with a jigsaw, a hacksaw, and even an ordinary mounting knife.

- Flexibility. This property is used in the construction of arches and vaults.

- Environmental friendliness. The material is absolutely non-toxic, because it is made only from gypsum and cardboard without the use of any synthetic additives. Therefore, it can be used in children's and medical institutions.

- Smooth surface. Thanks to this feature, gypsum board is widely used for leveling walls and ceilings, since it is much easier and less expensive than doing the same work with plaster and putty.

- It is a good basis for any type of finishing. After sealing the seams, it looks perfectly smooth and is suitable for painting, wallpapering or tiling.

- Fire properties. Since the middle layer consists of gypsum and crystalline bound water, when a fire occurs due to an increase in temperature, moisture is released. This prevents the plasterboard wall from catching fire for at least 20 minutes, and when using a special fire-resistant type, up to 1 hour.

- Purity. Due to the fact that the installation of plasterboard structures is carried out “dry”, without the use of building mixtures, cleaning the premises after renovation is greatly simplified.

- Diversity. To satisfy all consumer needs, types of drywall have been developed, adapted to perform a variety of tasks.

- Relative fragility. With strong mechanical stress, dents and even breaks remain on the surface of the sheet;

- Low water resistance. Drywall cannot withstand prolonged direct exposure to water and is not recommended for use in rooms with humidity above 85%.

We advise you to study - User ratings of ovens for electric and gas models

So, despite the presence of shortcomings, this material has much more advantages, which has ensured its constantly growing demand. Depending on the scope of application and the composition of the gypsum layer, there are different types of plasterboard.

Standard sheet thickness

The dimensions of the gypsum board slab are determined by regulatory documents: width - 120 cm, length - from 2 to 3 m in increments of 50 cm. This is the optimal gradation, which allows you to quickly make the necessary calculations.

Particular attention is paid to thickness, since it is this indicator that affects the weight and strength of the structure. Products are conventionally divided into ceiling and wall products. The first group includes products with a thickness of 9.5 mm, which is explained by the need to reduce the load. The second type includes several variations:

- Regular gypsum board. The standard value is 12.5 mm. This thickness of gypsum board slabs for walls is used for simple finishing of vertical surfaces. The cladding has good stability and contributes to sound insulation.

- Moisture resistant variety. Has similar dimensions. The material is used in small spaces, so the thickness is minimal.

- GKLO boards are characterized by increased strength even at 12.5 mm, but for objects that need more protection, sheets with a thickness of 15 and 18 mm are produced. Working with such products is much more difficult.

- GKLVO. The dimensions of the variety are standard, but some manufacturers produce products with a thickness of 1.5 cm for situations where it is necessary to increase reliability.

- Arched. This option is used to sheathe certain areas of the walls where it is necessary to create a complex geometric shape, so the thickness of the material is minimal - 6.5 mm.

The markings, which must be present on the outer covering, indicate all the parameters.

On a note! Although product sizes are standard, it is recommended to purchase products from the same manufacturer.

Three ways to level walls with plasterboard without lathing yourself

The main motive for choosing a method for such improvement of walls may be the curvature of the surface revealed by hanging (using a plumb line). It should not exceed 4 cm. Exceeding this value is a reason to choose the frame cladding method.

Changes in unevenness will also determine the choice of adhesive: with a curvature of 5 mm, even putty or spot application of glue will be effective. In places where heavy objects are attached, gypsum board slabs are glued to the wall with their entire surface, and even fastened in several places with dowels, with the heads recessed into the structure of the slab.

The difference on the wall does not exceed 4 mm

In the process of leveling the walls with plasterboard, Fugenfüller (or an analogue) is applied with a spatula along the center of the sheet and along the perimeter (not quite to the edge) in equal piles, forming rows. There can be more than three rows. If the wall will be subject to load, the entire surface must be covered with glue.

From gypsum board scraps, pads are made on the floor to form the necessary gap to take into account future deformation of the length of the glued sheet.

The sheet is placed vertically on a backing made of scraps, pressing it against the wall and aligning the marks near the ceiling along the horizontal lines.

This is how they lay sheet by sheet, cutting holes for window and door openings along a plumb line.

On a wooden wall, in addition to glue, plasterboard is attached flush with tar paper nails.

Drop 4-20 mm

Apply piles of Perlfix glue (or an analogue) as more reliable, higher than the depressions in the wall, onto the gypsum board sheets with a calibrating spatula. The distance in the rows decreases (up to 30cm), and the diameter of the glue piles increases to 10-15cm. The process then repeats the first option.

Drop 20-40 mm

In this case, you cannot do without temporary linings, which are made from 10-centimeter gypsum board strips glued to the wall in 40-cm increments.

Vertically aligned strips form a frame, to which, after 2-3 days, sheets of plasterboard are glued using Fugenfüller putty, which has good adhesion and high resistance to cracking. At the next stage, the joints are puttied.

Plasterboard cladding is a process that allows a combination of options that are acceptable for different levels of surface curvature. Because on one wall there may be minimal depressions and serious irregularities.

The use of temporary linings, in this case, can be removable, when after drying the linings are removed and the voids are sealed with a special compound.

Finishing work on drywall

To cover a room with plasterboard, standard sheets alone are not enough. Interwindow partitions and parts of walls above doors will require fragmentary inserts, and those - joints and seams. Therefore, an essential step in completing the leveling of walls with gypsum board sheets is putty.

Putty is produced in the form of dry mixtures (polymer, cement, gypsum), which, after thorough mixing in an aqueous solution, reliably strengthen joints, edges, and mask the places where dowels are used.

For greater reliability, the puttying process includes the application of a serpyanka mesh and counter-shoulders - thin profiles made of perforated steel for forming corners.

During this technological period, the gap left at the floor is also sealed using underlay pieces of gypsum board.

After drying, the putty is sanded until the front surface of the plasterboard sheet is smooth, primed and puttied for decorative finishing.

The frameless leveling method is somewhat more complicated than the frame method, but significantly saves the usable volume of the room. It is in demand in small rooms and can be successfully used on the walls of modern buildings made of large and small blocks of reinforced concrete and brickwork.

How to choose drywall

Conventional cladding for leveling surfaces differs from the construction of partitions, so it is necessary to proceed from the specific situation.

Optimal options for walls:

- For rooms with stable humidity, a standard type of gypsum board with a thickness of 12.5 mm is used. Such cladding must be carried out in compliance with certain requirements.

- Rooms with high humidity are sheathed with moisture-resistant products of the same thickness. The structure of the material is quite durable and can withstand the weight of ceramic tiles.

- Vertical surfaces that need to be protected from fire are finished with fire-resistant sheets 12.5 mm thick, difficult areas - 15 mm.

Increasing the strength of the partition is possible due to a thicker sheet or creating a multi-layer structure from plasterboard of standard thickness

Partitions can perform several functions and experience different loads, so the following rules must be taken into account:

- Simple dividing structures (including decorative ones) are lined with 12.5 mm thick plasterboard.

- If the expected load per 1 m2 is up to 50 kg, it is recommended to choose a thickness of 15 mm.

- When the impact exceeds 70 kg, 18 mm sheets are used.

Partitions are strengthened by increasing the number of layers of drywall.

Materials and tools

- Drywall sheets (GKL) 12.5 or 9.5 mm thick;

- glue or putty (“Perlfix”, “Fugenfüller”);

- primer (“Betonokontakt” or “Tiefengrund for hygroscopic walls”);

- plumb and level;

- a set of spatulas for gypsum boards (notched, truncated, for internal and external corners);

- drywall file or knife;

- self-tapping screws;

- screwdriver;

- rubber mallet;

- contraschultz;

- serpyanka mesh.

Which drywall is best to use for walls?

Modern industry produces several types of gypsum sheets. They all differ in their operational and technical characteristics. To choose the right drywall for a particular room, you should become more familiar with its properties.

The most massive gypsum boards up to 5 cm thick are used to level floors as a basis for finishing floor coverings that require a perfectly flat surface: laminate, linoleum, parquet. The thickness of plasterboard for a wall is selected depending on its functional purpose. This wall is intended for use in finishing rooms with high humidity. It has a single frame and is sheathed with a triple layer of moisture-resistant plasterboard.

To improve thermal insulation and sound absorption, drywall can be used in combination with mineral wool filler. The mass of m 3 walls is about 75 kg. Gypsum fiber sheets (GVL) are a special group of gypsum finishing material.

GVL slabs are made from a mixture of gypsum and cellulose fibers in a ratio of 5 to 1. The distinctive quality of gypsum fiber sheets, compared to gypsum plasterboard, is their increased strength. Thanks to this, fairly heavy suspended structures can be attached to the wall. Also, the thin sheet is excellent for the manufacture of various decorative elements of interior design - arches, niches, curved structures.

This is due to its low rigidity and ability to bend to take the desired shape. Wall finishing is a preliminary stage of work before further finishing. Thanks to the flexibility of the material, the walls can not only be leveled, but can be made in any configuration.

Installation takes place in several stages.

- To fasten the slats to the wall, dowels and a drill are used. If there is a gap between the slats and the wall, fill it with scraps of wood or plasterboard.

- Horizontal spacers must be installed between the vertical slats.

Moisture-resistant plasterboard adhesive: which one to choose

The purchase of adhesive should be made at the time of purchasing drywall. Store managers will help you choose high-quality glue that will provide reliable adhesion to surfaces. It is important to pay attention to the brand and cost of the glue.

It is best to use glue when the finishing surface is as smooth as possible.

If the surface is not smooth enough, it is better to apply the glue to a thick layer of substrate. The glue is applied to the back of the drywall, and the wall or ceiling must be treated with water. After connecting the surfaces, the dowels are fixed.

Types of glue:

- Volma-montage;

- Unifix;

- Pearlgip;

- Quild Mural;

- Perflix.

You can prepare glue for gypsum board yourself. To do this, you need to add a certain amount of gypsum to simple glue. Homemade cooking will save you a lot of money.

Read more about the use of glue for gypsum boards here:.

Which drywall is best to use for walls in a wooden house?

If you decide to carry out under-frame insulation, but you don’t have external insulation, you should abandon this idea, or first carefully calculate the dew point. In addition, a perfectly leveled surface allows you to come up with various original interior options. You can make paintings or panels, paint or wallpaper, create different variations of ceilings or use tiles.

- Calculate the plasterboard panels so that the edge of each of them falls on the middle of the shelf of the rack profile. If you need to trim, use a pencil to draw a mark on their surface and make a cut along it in the top layer of sheets.

- Then break the panel where the cut is made at an angle (so that the gypsum core bursts) and cut through the back cardboard side.

When calculating the number of bars required to construct the frame, you need to take into account the need to secure horizontal guides under the ceiling and on the floor. It is to them that the vertical posts will be attached later. This is a complete base on which wooden walls are covered. Insert rack profiles into the slots of the lower and upper guides, every 40–60 cm and secure with piercing screws with a 13 mm press washer. Pull the horizontal control threads (with a distance between them of 100–120 cm) to control the level, and, focusing on them, screw the profiles to the hangers (bent in the shape of the letter “P”) with metal self-tapping screws.

Bend the excess edges of the hangers back so that they do not protrude beyond the outer surface of the profiles. All sheets are a kind of “sandwich” made of two layers of durable cardboard and a solid gypsum core. Impregnating the coating with special solutions and adding various additives to the core makes it possible to achieve various functional characteristics.

To know how to choose the right plasterboard for walls, you need to familiarize yourself with its main types: We know that installing gypsum plasterboard is the simplest and most effective way to finish and level wall floors in a room. The most common two options for installing drywall:

- fragility of the material. It breaks and crumbles, so installation work is carried out with caution;

- if you install the usual gray color in the kitchen or bathroom, it will absorb a lot of moisture and subsequently become deformed;

- before installing gypsum board on the surface, it is necessary to determine how thick it should be and whether the wall will be weighted;

All types of drywall have the same width - 1200 mm. A frame base of profiles is mounted under the gypsum plasterboard, which contains the exact dimensions for fixing the profile. This applies to both the ceiling and other surfaces. Companies produce panels with thicknesses: 6.5, 9.5, 12.5, 15, and up to 24 millimeters.

The length of the sheets ranges from 2000 to 4000 mm, and the width can be 600, 900, 1200 mm. Everything is clear about the purpose of the material; the type is selected according to the basic conditions, but questions may arise with the thickness of the slab (you can choose from 6.5 to 24 mm). What options to choose for wall decoration? Before work begins, the installation of electrical wiring and pipelines, which are planned to be hidden under the plaster, is completed.

Distribution boxes need to be made protruding from the wall by approximately 20 mm. Gluing plasterboard to walls and ceilings is done with putties and adhesives like Perlfix, Fugenfüller and the like. To improve the adhesion of walls that do not absorb moisture, they are treated with Betocontact primer or similar.

Hygroscopic walls, for example, if wood was used for their manufacture, are treated with primers that reduce the absorption of moisture from the glue, such as Tiefengrund, Ricombigrunt.

- well processed to create complex shapes: arches, convexities, concavities.

- It is convenient to lay communications inside the frame, which is sheathed with gypsum board.

- Easy installation.

- The wall turns out smooth and does not require additional leveling.

- If you mount the frame on top of the floor screed, the plasterboard wall can be dismantled and rebuilt as needed.

- Very light material, gives very little load on the floors.

Dimensions of the gypsum fiber sheet are 2500 x 1200 x 10/12.5 mm, weight 36/42 kg. More often, a thickness of 10 mm is used for interior partitions. The metal frame is sheathed with GVL sheets in one layer, unlike gypsum plasterboard.

To improve sound insulation, you can make two layers, but then it is better to combine: one layer of gypsum fiber board, the other of gypsum plasterboard. Today, drywall is made by a variety of manufacturers. Among the highest quality suppliers of products, we should separately highlight the German company Knauf, as well as the domestic manufacturer Volma.

They differ somewhat in cost (Knauf is more expensive), but in terms of quality they are almost equal. It’s safe to say that using plasterboard sheets in a wooden house will greatly facilitate your renovation. Today on the construction market you can find several types of plasterboard sheets, which first of all differ in purpose, and then in the properties they have. Drywall is presented in the following three main varieties: The main advantage of frameless technology over frame technology is its lower cost. The second technology is more common, as it allows not only to hide any unevenness, but also to lay utility lines. The sheathing can be made of either wood or galvanized steel.

Galvanized steel is preferable - it is stronger and it is impossible to damage it during installation. Drywall for walls is one of the most common ways to level surfaces, regardless of their type. The main thing that is necessary for it to hold well is to buy high-quality material that is suitable in thickness and follow all the rules during installation.

How to avoid mistakes when choosing drywall and how to choose the thickness has already been discussed earlier. Now let's move on to its installation.

Areas of application. The necessary conditions

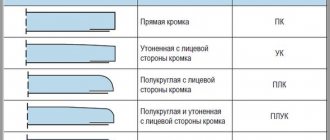

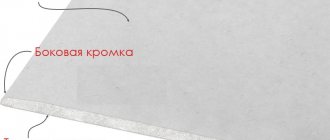

During finishing work, the question may arise about which side should be used to mount moisture-resistant drywall. Each sheet has special edges that can have different profiles. This design solution is designed to make it possible to seal the joints between the sheets using various materials.

The edges can be rectangular in shape (no sealing required), have a so-called stepped contour (a thin profile made of reinforced tape and gypsum for putty), and also rounded in shape (putty without using tape).

When laying sheets of drywall, there must be a chamfered part on the outside. When using regular drywall sheets, the side that is lighter should remain on the outside. The same rule applies to moisture-resistant drywall.

Moisture-resistant drywall can be used instead of regular drywall, but regular drywall should not be used instead of moisture-resistant one. True, the price of moisture-resistant drywall is somewhat higher and it is better to use it only for special use, and it is not practical to use it instead of regular drywall. When using moisture-resistant drywall, the manufacturer recommends ensuring that there is good ventilation so that the drywall sheets can release the moisture they have accumulated.

As can be seen from what is written above, the dimensions of moisture-resistant plasterboard do not differ from ordinary sheets, but moisture-resistant plasterboard has many useful characteristics, which allows it to be used for any finishing work indoors: for finishing walls, for making ceilings and various internal partitions.