When building a house, you were faced with the problem of what finishing material to choose? Then you are at the right place! In fact, the market is flooded with all kinds of materials from ordinary wood to shimmering wallpaper or glowing bamboo. Most often, craftsmen choose drywall and OSB. Let's try to figure out why exactly them.

Drywall

Erection of a plasterboard wall and leveling of structures inside a house is something builders often resort to during renovations. And rightly so! The material has its advantages:

- It is environmentally friendly. Does not emit substances hazardous to humans and is safe for nature.

- It is easy to install, has a small weight and an easy installation mechanism. How to cover walls with plasterboard? You can cope with this even alone. Create a frame, install hangers and profiles, place noise or heat insulation material inside if necessary. Then mount the drywall onto the frame.

- Robust and durable design.

- You can further decorate it with decorative materials, such as paint or wallpaper.

- Low price.

- Flexibility. From it you can create any shape that suits the interior.

Attention! There are two ways to change the shape of drywall. Or moisten the material with water and, having obtained the required shape, fix the sheet until completely dry. Or bend dry drywall. In this case, for better flexibility, cuts should be made with a construction knife or milling cutter.

However, this material also has its disadvantages:

- There is a risk of deformation if you hang a heavy object without first strengthening the frame;

- During installation, fine dust is generated which can cause an allergic reaction. When erecting a structure, use a protective mask and special clothing.

Lifehack: When you make holes in a drywall wall, use a vacuum cleaner to avoid staining the walls and floor.

OSB panels

Builders actively use OSB in the construction and cladding of walls. The material can be used for external and internal decoration of the house. Let's look at the main advantages of OSB panels.

- Reliability and quality. The material received this advantage due to impregnation with artificial resins. It is resistant to various types of damage, fungus and mold;

- OSB panels do not allow moisture to pass through and repel water;

- Rigid construction. OSB walls will not deform;

- Attractive appearance due to its resemblance to natural wood;

- High-quality sound insulation. Noise from the street will not enter the room, which will ensure silence and comfort;

- Low price, since OSB panels are made from inexpensive materials. Buyers note a positive price-quality ratio.

The disadvantages of OSB panels justify the low price of the material:

- At temperatures above +30°, phenol is released that is harmful to humans. For this reason, OSB wall cladding inside the house is not recommended.

- They have low fire resistance.

- With prolonged use, they accumulate moisture and swell due to this.

Walls made of plasterboard or OSB. What to choose?

It is better to choose plasterboard for covering the walls in the house. It can be used to decorate kitchens and bathrooms, as it will not retain moisture. Installing drywall in the children's room and bedroom will provide clean air without harmful substances emitted by OSB. If you are cladding the walls of a residential building with stove heating, preference should be given to fire-resistant plasterboard. OSB panels are used for exterior finishing.

Drywall and OSB are boards made of gypsum and wood, respectively. They have a similar scope of application and are intended for cladding walls, forming floors, leveling floors, creating ceilings and similar construction operations. However, despite their general similarity, OSB and drywall are intended for different purposes.

To compare OSB and drywall, let's take a closer look at these materials.

Advantages and disadvantages of OSB

OSB (generally this material is called “OSB-boards”, from Oriented Strand Board - “oriented strand board”) are multilayer sheets, which are 95% oriented strand boards. The remaining 5% of the composition is occupied by various fixing resins, boric acid for processing and synthetic wax for coating.

Since OSB is made mainly from waste and secondary wood products, as well as synthetic impregnation, this material has a low price. At the same time, the plates are distinguished by high mechanical strength and attractive appearance. As a result, they can be used for both structural and finishing work.

The main advantages of OSB are:

Low price. These slabs are made from inexpensive materials, so they themselves are quite cheap;

High reliability. Impregnation with artificial resins ensures the strength of the material and resistance to both mechanical damage and the action of pests, fungi, mold and aggressive deforming chemicals;

Low weight. Thanks to this, OSB boards can be placed on walls without additional strengthening;

Visual appeal. The slabs look exactly like natural wood, so they can be used for finishing work;

Moisture resistance. It is especially high for materials coated with artificial wax. It has a water-repellent effect;

Good soundproofing qualities. OSB boards absorb noise from both sides, so the room decorated with them is quiet and cozy.

However, OSB boards also have quite an impressive list of disadvantages.

Among them are:

Release of toxic substances. Artificial compounds, including boric acid and glue, produce volatile harmful substances. Under some conditions, slabs can release formaldehyde and toxic resins - especially when heated. However, OSB boards still emit less harmful substances than chipboards;

Low fire resistance. Wood burns, and OSB boards consist of 95% of it;

Low vapor permeability. Moisture can accumulate under installed OSB boards, which negatively affects the building materials of the walls and floors.

Thus, it is recommended to use OSB boards in the following cases:

External wall cladding with simultaneous placement of other facing materials;

Installation of subfloors;

Continuous roof cladding.

In addition, OSB boards can be used in the production of structural SIP panels. They will give these elements increased reliability, strength and excellent heat and sound insulation properties.

However, OSB boards cannot be used for structural and finishing work in the bathroom, kitchen, toilet and attics. This is due to the low vapor permeability of the material, as well as the release of harmful substances when heated or in contact with hot objects.

In which cases is it better to use OSB, and in which plasterboard?

For finishing roofs, for covering floors, for exterior work, for creating frame-panel construction, it is recommended to use oriented strand boards with high technical characteristics.

For interior wall decoration and original designs, choose a material based on building gypsum.

Having found out which is better than OSB or plasterboard, you can begin planning renovations in a specific room. The main thing is to choose a product from a trusted manufacturer and install it reliably and efficiently, following construction technology. If moisture-resistant drywall is mounted on OSB, you can get a surface with a long service life and quite strong.

The modern range of construction and finishing materials is wide and diverse. Here you can find almost any material, or rather, something that meets all your technical needs or personal preferences. For example, OSB, plasterboard (gypsum board) or gypsum particle board (GSP)

. They have a lot in common, which is why they are used for interior decoration. On the other hand, they have many differences and features. Preference should be given based on the specific requirements of the upcoming renovation, finishing or cosmetic repairs and partial redevelopment.

So, the differences are based on the source material and the composition that forms one or another material. Thus, the GSP board consists of 83% gypsum, 15% wood chips and 2% moisture. Drywall is made up of 91.1% gypsum, 5.78% cardboard and the rest water. Externally, the core is made of gypsum and covered with two layers of thick paper or cardboard. OSB is represented by sawdust (95%), the quality and type of which largely determine the properties of the future board, and a certain amount of impregnation, that is, paraffins and glue. In some cases, it is additionally treated with wax, which increases its moisture-resistant qualities. When it comes to drywall, everything is simple: the middle layer is a hardened mixture of gypsum, and the entire sheet is a core glued to the cardboard. OSB, like gypsum particle board, is manufactured in compliance with strictly defined temperature parameters and under a certain pressure. Hence their high strength and wear resistance.

Today you can buy GSP or OSB, gypsum board of any desired size. Especially if you contact the manufacturer. For example, gypsum particle board is produced in the same sizes as plasterboard. And interior finishing with this material is also simple and convenient. OSB is slightly different in size. The main thing here is the uniqueness of some of their properties. Namely:

- OSB is highly moisture resistant. This includes the presence of special impregnations, the use of paraffin in the composition, and rubbing the slab with wax. No plaster;

- The environmental friendliness of GSP is the highest: the complete absence of adhesives and resins, mastics and paraffins in the composition. These substances are not needed during the production process of the material;

- ease of installation and cost-effectiveness. This quality is important, but it is not so easy to track. Thus, GSP is more profitable and economical to use, because it is easier to make corners and bends with its help than drywall. OSB in these qualities is close to gypsum particle board, and these properties completely depend on the type of wood and impregnation from which it is made;

- lightness or density. OSB has a density of 650 kg/m³; GSP – 1100-1200 kg/m³; GKL – 750-800 kg/m³. You can immediately see what is easier and what is harder. Lightness speaks not only about physical weight, but also about the degree of reliability of the structure. It’s easier and more convenient to work with lightweight sheets, but it’s worth remembering that you can just as easily break through a plasterboard wall.

Now a little about the areas of application. Today, interior decoration of both SHG and OSB premises is widespread. Everyone has their own preferences. The most popular material is plasterboard, followed by gypsum particle board, which is convenient to work with. In addition, floors, walls and ceilings made of GSP are highly durable, environmentally friendly and have lower consumption of primer, grout and paint, which are necessarily used for interior finishing work.

What is better suited for interior decoration? Let's take a magnifying glass and take a closer look.

So, drywall. If you type the word drywall on the Internet, you will find a huge number of articles devoted to this material. As you can see, there are plenty of advantages.

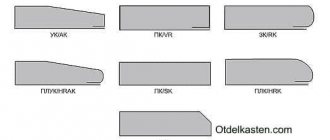

A plasterboard sheet consists of three components: core - includes gypsum and additional additives that determine the strength of the sheet. 2 layers of cardboard - they cover the core from above and below.

Drywall has the following advantages:

This is an environmentally friendly material, light weight, easy to use, strong and durable, low price compared to other building materials makes plasterboard even more popular.

“AVANGARD plus” LLP gives you the opportunity to buy plasterboard wholesale and retail at attractive prices. We deliver to the right place.

This is such a wonderful material that a plasterboard arch can strike your friends in the very heart. Your apartment or office can be transformed beyond recognition and will make them beautiful and original. There are special properties. - moisture resistance. Such slabs are used when renovating bathrooms, kitchens, and toilets. - fire resistance. Incredibly, there are types of stoves that are not afraid of fires. They are used in rooms with a dry microclimate. Due to special additives, such drywall can withstand exposure to open fire. - fire and moisture resistance. A material that includes moisture resistance and fire resistance. They are installed in rooms with wet and dry microclimates.

If we compare it with OSB, we can note that drywall is a more fragile material, that is, it requires careful and careful treatment. But due to their characteristics, the slabs are well suited for interior decoration and have a lower cost.

Cons Despite the large number of advantages, drywall has certain disadvantages. Without following the installation rules and preliminary preparation, heavy objects cannot be hung on plasterboard walls. Due to its prefabricated construction, debris is generated when cutting drywall, which is why a face mask should be used. In addition, due to the volumetric frame, drywall reduces the space of the room.

Where is it better to use drywall? The boards are very functional and can be used actively. - a home craftsman can easily level the walls in the kitchen, bathroom, living room and other rooms. - installation of ceiling coverings - furniture can be made from plasterboard. You can easily make a kitchen cabinet from OSB and plasterboard with your own hands. - creation of niches, shelves, arches, both decorative and functional. - production of elegant figured elements. They can be installed on the ceiling or walls.

OSB - universal board

Perhaps no repair is complete without OSB. Builders use slabs together with insulation materials due to their comfortable rough surface, which increases the thermal insulation properties several times. AVANGUARD plus LLP makes it possible to buy OSB wholesale and retail at prices below market prices. The slabs consist of sawdust and special additives. The properties of the slab depend on the quality of sawdust.

Like drywall, OSB boards are inexpensive, they are reliable, perfect for wall decoration, light in weight, durable, have moisture-resistant properties and absorb sound.

Small disadvantages of OSB boards

The ideal building material simply does not exist. And if we analyze OSB in detail, we will highlight the most striking disadvantages. - insufficiently fire-resistant material. - low strength indicators. To increase strength, two plates are needed. - Compared to plasterboard, installation of OSB boards is labor-intensive and more difficult to install on walls. - a lot of construction waste - vapor-permeable properties leave much to be desired.

Where is it better to use OSB?

This building material is best used in the following situations: - for external work with the simultaneous use of facing coatings - roof sheathing using a continuous method. — the slabs are ideal for floor repairs. — for the production of structural SIP panels — for wall insulation.

Conclusion Question - What to choose for repairs - drywall or OSB-3 board - can safely be called insignificant. Like plasterboard, OSB-3 boards have positive properties and applications. Some home craftsmen prefer plasterboard when decorating interior ceilings and walls, but moisture-resistant boards are excellent for frame-panel construction. The price of plasterboard and OSB is approximately the same. In terms of environmental friendliness, drywall wins.

The manufacturer, brand, thickness and dimensions of building materials play a huge role. For example, when purchasing OSB, it is better to give preference to Kronospan boards, which do not contain harmful impurities and are of high quality at a fairly affordable price. There are also quality marks for plasterboard; we recommend buying plasterboard sheets from the manufacturers Decorator and MAGMA.

Read our articles.

There are a lot of finishing materials on the market. And among such abundance, the most popular are plasterboard and OSB boards. Finishing in which plasterboard is mounted on OSB is often used. How justified is this? Each of these materials has positive characteristics and disadvantages that are worth considering in detail in order to understand which of these materials is preferable in construction.

OSB in the attic OSB on the walls

Finishing gypsum plasterboard Room finished with plasterboard

It is impossible to understand which is better than plasterboard or OSB without examining these materials in detail. Each material is unique. It has positive and negative properties, as well as its own installation nuances.

Drywall

GCR is by far the most in demand and popular among builders. And this is not surprising; the structure of this material gives it a lot of advantages. comprises:

- cores – a compressed gypsum mixture, the special properties of which are achieved by adding special additives to the gypsum;

- thick cardboard - 2 layers, which is located on both sides of the core.

Plasterboard sheet

This device gives plasterboard a lot of advantages:

- it is an absolutely harmless environmentally friendly material;

- small specific gravity. It will not be difficult for even one person to carry out the installation;

- simplicity in arrangement of structures;

- lasting;

- durable;

- plasterboard slabs are an excellent basis for further finishing with any materials; in addition, you can create any;

- possibility of using insulated walls, arches, and niches;

- price - if you are making repairs in a house or apartment, then it is easier and cheaper to use plasterboard than any other building material.

Using plasterboard slabs you can transform the interior of your apartment, making it exclusive and unusual.

Interior arch Ceiling made of gypsum plasterboard Niche for a TV made from gypsum

plasterboard Drywall has features due to the additives that are present in the core of a certain brand of material:

Knauf sheet size Comparison table of Knauf size and weight

To summarize: GCR can be used in almost any room, be it a bathroom, attic or loggia.

Flaws

The material has many advantages, which is why it is popular among developers, but despite this, it is worth talking about the disadvantages:

- Before hanging it on a heavy object, you need to install the mortgages while installing the frame;

- if a heavy object is incorrectly fastened to the wall, the slab may become deformed from the weight;

- when processing and cutting the material, fine dust is formed, which can cause allergic reactions if inhaled, so you need to use protective clothing;

- the frame that is assembled for takes up useful space.

Frame on the wall for plasterboard Frame installation on the ceiling Frame for a gypsum plasterboard partition with a door

These are non-critical indicators. By adhering to strict assembly rules, they can be minimized; the only negative that remains is the reduction in space.

Purpose of the material

Drywall can be used in the following cases:

- Leveling the walls is even used when finishing the attic.

- of any complexity.

- Installation of furniture of various configurations.

- , shelves, and decorative elements.

- Construction of stands.

Design of a room with a decorative partition made of gypsum plasterboard Plasterboard construction on the wall

This material has many more advantages than disadvantages, which is why it is so popular.

Important. Before you start installing this material, you need to determine what you want to get in the end; this is the only way to complete high-quality interior design.

OSB panels

Increasingly, OSB boards are used in construction, which are usually used in conjunction with insulation for the construction of frame buildings. The material has proven itself so well that it is often used for cladding indoor and outdoor surfaces. What are the slabs made from?

- wood shavings;

- resin;

- boric acid;

- synthetic wax.

This material consists of 95% chips, 5% resins and adhesive. The quality of the slabs depends on the type of wood from which it is made. For moisture resistance, the slab is coated with a wax composition.

Properties of OSB board

Due to its texture, the material has many advantages:

- reliability;

- affordability;

- resemblance to a tree;

- low specific gravity;

- high quality;

- durable when used correctly.

Characteristics of OSB OSB boards

have certain properties:

- High strength indicators.

- Moisture resistance when properly processed.

- Easy to use.

- Rigidity.

- Sound absorption.

OSB is an excellent material that can be used for interior decoration, and it is used without.

Flaws

In addition to all the listed advantages, OSB boards have a number of disadvantages:

- Boards from manufacturers from Canada and Poland are moisture-absorbing. As a result, they swell and are subsequently unsuitable for installation work.

- The slabs are divided into environmental classes. The safest markings are E0, E1. The rest, starting with E2, emit phenol, which is dangerous to human health. This component is released especially strongly at temperatures from +30 and above.

- Before purchasing OSB boards, you should carefully study the quality certificates and the compliance of the boards with these certificates.

- Particular attention should be paid to manufacturers from China.

When checking the reliability and safety of OSB boards, they are used in installation work indoors.

Installation of OSB board

The process of producing boards is quite simple: large wood chips are pressed using glue, which causes the release of toxins into the air.

Important! If you have doubts about the safety of OSB, then you should know that the same glue is used for the production of chipboard, only in larger quantities. OSB is less toxic.

In addition, there are the most significant disadvantages:

- low fire resistance;

- if you need a durable surface, you have to lay the material in several layers;

- installation is much more difficult than that of drywall;

- generates a lot of debris and sawdust during processing;

- the material is practically vapor-tight.

The best option for finishing premises with this material is an attic, a bath or a kitchen, or the interior decoration of a frame house.

OSB on the floor

What is OSB used for?

In construction, slabs are used:

The material appeared on the market not so long ago, but thanks to its positive characteristics it has become widely used in construction. Of course, its low cost also plays an important role. These materials are often used in tandem, since OSB boards are very difficult to decorate with decorative coatings, which are often much easier to cover. This makes the structure durable. This is the answer to the question: is it possible to attach drywall to OSB for interior decoration? The video describes the use of OSB boards.

Repairs always involve a certain waste of time and money. Everyone is well aware of this and strives to save both. That is why the question of what to choose: plaster or drywall will never lose its relevance. Both materials have already gained trust (one earlier, the other later, but with equal success). But people have not yet decided who they can trust more. Let's try to sort out the doubts.

Advantages and disadvantages of drywall

Drywall is a slab that is made, as the name implies, from gypsum covered with cardboard on both sides. The material usually contains about 91% gypsum and 6% cardboard, and the rest is additional impregnation. Or just water.

Drywall is used in structural and finishing works. So, it can be used for the construction of partitions, wall cladding, and so on. In addition, it is widely used as a material for creating suspended ceilings in houses, apartments and offices.

The following advantages of drywall can be highlighted:

Ecological cleanliness. The material is safe for nature, the environment, and people. Unlike its predecessor, it does not emit harmful substances either when heated or simply during operation;

Light weight and easy installation. In principle, even one person can handle the task of “carrying a sheet of drywall, sawing it and installing it on a wall or ceiling”;

Durability and mechanical strength. Plasterboard sheets last a long time, do not degrade on their own over time, and are also resistant to accidental mechanical impacts;

Possibility of further finishing. On top of the plasterboard sheets, you can place other finishing materials - paint, wallpaper, tiles, artificial stone and much, much more;

Low price. Plasterboard sheets are cheaper than most other finishing materials.

It is worth noting that there are special types of drywall. For example, moisture-resistant ones that can be placed in the kitchen, attic or bathroom. Or fireproof, capable of withstanding up to 40 minutes of exposure to open fire. Fire and moisture resistant sheets also exist.

However, drywall also has disadvantages:

Lack of load-bearing properties. Before hanging a heavy object - a TV, mirror or shelf - on a wall or plasterboard partition, it must be prepared by installing a supporting frame;

Deformation. Sheets can bend, bend and break when trying to place massive objects on them;

Gypsum dust. When you try to cut a sheet of drywall, a huge amount of fine gypsum dust rises into the air. Therefore, such procedures can only be carried out using respirators.

It is worth noting that in some cases, the cut edges of the plasterboard sheet continue to emit dust even after installation. It is advisable to process the edges before placing their material on the frame to protect the room from dust.

Thus, drywall can be used in the following situations:

Alignment of walls in rooms. Suitable even for installation in the kitchen;

Installation of suspended ceilings of any complexity;

Design of furniture, stands, shelves, decorative and practical elements.

Drywall is an almost universal material for finishing and construction. However, it is worth considering that it does not have load-bearing properties. And therefore, for some purposes - installation on a sub-roof and sub-floors, for example - it is simply not suitable.

Let's talk about the shortcomings

Despite the huge number of advantages, plasterboard as a material used for interior decoration also has some disadvantages:

- It is impossible to hang heavy objects on walls made of plasterboard sheets without prior preparation and compliance with installation rules - paintings, wall cabinets, TV, mirror, shelves;

Sheet cutting

Note! Each individual situation has its own step-by-step instructions that will help you cope with the task of hanging heavy objects on plasterboard walls without any problems.

- deformation of the slabs when trying to fasten heavy objects to the walls;

- When cutting sheets into pieces, small construction debris appears. Therefore, all work on cutting plasterboard should be carried out with special safety glasses, and also cover your mouth with a mask;

- reducing room space by assembling the frame.

If desired, all these negative aspects of working with the material, in addition to reducing space, can be leveled out. To do this, you must strictly follow the appropriate step-by-step instructions.

What to choose - OSB or plasterboard?

When choosing a suitable material, you should be guided by the following principles:

If load-bearing properties of any kind are required (from further laminate coating to future placement of the TV), drywall will not work. Or you should prepare to further strengthen it in various ways;

If moisture resistance and vapor permeability are required for finishing walls, floors or ceilings in the kitchen, bathroom or veranda, it is better to choose plasterboard, since OSB is not suitable for work in such rooms;

It is better to place drywall in a children's room, since it is environmentally friendly and safe.

In other cases, you should choose based on your situation, budget and plans for further finishing.

Oriented strand boards and gypsum boards are widely used in construction. Both materials are used to form partitions, walls, and external cladding. Due to the similar scope of application, it is difficult to choose a material - OSB or plasterboard, which is better to use in repairs. To understand this, you need to study the pros and cons of building materials.

Plywood. Features and Applications

Plywood is the last sheet building material of this review. Plywood can be used for any construction of prefabricated screeds, and also as an underlying layer for poured screeds.

The widespread use of plywood is limited by its high cost, which is not reasonable for installing a cheap floor, say, from linoleum. However, for parquet floors, plywood is indispensable. It creates a smooth, durable base with performance characteristics as close as possible to parquet.

Laying plywood

Plywood is laid in two layers, pre-cut into sheets measuring about 50 by 50 cm. The rows of plywood are shifted, the layers of plywood are shifted to avoid the seams matching along the horizon and layers. A gap is left between the sheets.

Plywood is laid on a 1 mm layer of mastic applied to concrete or cement bases. Additionally, the plywood is secured with screws on dowels. Plywood is laid on the joists without the use of mastics, only with the use of self-tapping screws.

Today, debates among finishers continue to debate whether plywood or plasterboard is most suitable for finishing, since these materials are considered the main competitors in finishing.

Plywood is also a sheet composite, which is made by gluing several layers of peeled birch, pear, maple, hornbeam or coniferous veneer with formaldehyde resins under significant temperature and pressure. It is often confused with chipboard, however, the difference between them is significant, both in the field of manufacturing technology and technical characteristics.

There are 5 main types of plywood:

- FBA - ordinary general purpose sheets;

- FC - moisture resistant;

- FSF - increased moisture resistance;

- FOF - laminated, non-hydrophobic;

- FBS - resistant to moisture, fire and frost.

Depending on the type of plywood, it is widely used:

- In the cladding of walls, ceilings, floor coverings, building facades, as a rough or finishing coating;

- To create some types of furniture;

- When designing multi-level structures;

- For box masking of communications.

Advantages of plywood

The advantages of using this material include:

- More economical to purchase than chipboard;

- High strength, unlike gypsum plasterboard;

- Durability;

- Biostability.

Disadvantages of plywood

• Flammability; • Poor resistance to moisture (when using non-moisture-resistant general-purpose material); • Low environmental friendliness due to the use of phenolic resins in manufacturing; • High cost; • Low ductility; • Low sound absorption; • Complexity of cladding.

Advantages and disadvantages of drywall

Drywall consists of a layer of building gypsum laid between two cardboard sheets with a density of 0.17 - 0.22 kg/m². This structure allows you to make various arches, partitions, niches, and columns from it.

Advantages of plasterboard boards:

- safety. There are no toxic components in the composition, so the material is completely safe for humans;

- moisture resistance. Moisture-resistant gypsum board grade can be used in rooms with high humidity;

- ease of processing. The sheets can be given any shape without deforming the structure. This allows you to create arches and other non-standard designs;

- versatility. It is convenient to use plasterboard for leveling walls, and lay sound or heat insulation in the resulting voids between the wall and the sheet;

- fire resistance. GCR is resistant to high temperatures; smooth surface. The sheets are suitable for any finishing: wallpaper, paint, plaster, tiles.

- Even the moisture-resistant class of gypsum plasterboard eventually ceases to withstand moisture. The sheets are not recommended for installation in bathrooms without additional moisture-proof finishing. Otherwise, the drywall will become moldy and begin to deteriorate;

- plasterboard is a fragile material that requires additional reinforcement with fastening guides during installation;

- sheets require mandatory finishing: grouting joints and recesses.

Decorative interior elements made of plasterboard

Drywall on the walls of an apartment without a frame

If you want to make columns from plasterboard, then you will need a profile. Installation of the structure is done using crabs and self-tapping screws. It is necessary to make a reliable fastening to the floor. Place vertical strips at the seams. Crabs are placed from the inside.

After this, begin installing the plasterboard column with slabs. Seam tape is not suitable. A perforated L-profile is required. It aligns vertically and provides strength. Fiberglass is used to strengthen the surface. Place it correctly vertically. If you use a standing beam under the column, then a frame is not needed.

If desired, niches are made in the wall from plasterboard. For this purpose, slabs of medium thickness are selected. When making a plasterboard shelf inside the recess, cover its end with decorative tape. Dimensions cannot exceed the distance from the wall to the frame.

Fasteners using crabs. After finishing the seams with tape, you can glue them to plasterboard shelves. To create niches and columns, a wooden frame under plasterboard is used.

Advantages and disadvantages of OSB

OSB boards consist of several perpendicularly arranged sheets of compressed wood chips with connecting resins. This structure gives the material high strength. This allows the use of oriented strand boards for external and internal cladding, construction of houses, baths, and formwork.

- high bending strength without cracking;

- the presence of moisture-resistant OSB classes, which are used for finishing baths, bathrooms, and kitchens;

- strong fastening with self-tapping screws, simple processing of slabs;

- suitable for any finishing;

- durability with the correct installation technology;

- suitable for installation of different types of floors;

- not subject to shrinkage.

Cons of sheets:

When heated, OSB can release harmful formaldehydes that are hazardous to health. Therefore, OSB cannot be used for finishing in baths.

Fiberboard boards

Fibrolite is a board material made by pressing special wood fiber (wood wool) and an inorganic binder (magnesium binder). The fiber is obtained from waste from the wood processing industry, as a result of processing on wood planing machines. One of the advantages of fiberboard boards is their low volumetric weight.

Fiberboards are a fire-resistant, bioresistant material that is used as thermal insulation, structural, thermal insulation and acoustic materials in building structures of buildings and structures with a relative air humidity of no higher than 75%.

Conventional fiberboard boards are produced with a thickness of 3-5 mm using gray cement as a binder. These boards are used for various types of thermal insulation, when constructing roofing and plastered partitions. Acoustic slabs are usually made from fine wood wool (0.75-2 mm), which improves their appearance, are not covered with anything, and are also tinted in colors that harmonize with the interior or are made using magnesite or white cement instead of gray.

A composite fiberboard panel is a two- or three-layer panel with a middle layer of thermal insulation material, such as rigid foam or mineral fiber (mineral silicate wool). The thickness of the middle layer usually ranges from 15 to 140 mm, although the outer layers of fiberboard range from 5 to 20 mm in thickness. In this case, the level of thermal insulation increases significantly.

Fiberboard boards

Advantages of fiberboard boards:

- Ease of installation;

- Good insulation;

- Mechanically strong;

- Extensive decorative possibilities;

- Good moisture resistance and fire resistance;

- Soundproofing;

- Hygiene, harmless to human health and the environment;

- Do not spoil rodents and insects, does not rot.

Disadvantages of fiberboard boards:

- Low bending strength;

- Considerable weight.

Feel free to comment on the article if you have anything to add to this material. If you find errors or inconsistencies. Perhaps you know some other similar material not presented in this article?

Comparison of gypsum board and OSB

To understand which is better, plasterboard or OSB for interior decoration and exterior cladding of a building, you need to compare both materials according to different parameters:

- Scope of application. GCR and OSB can be used for any construction purposes: interior and exterior decoration, installation of arches and partitions. For rooms with high humidity, moisture-resistant classes of slabs can be used.

- Safety. In the absence of violations during production, both materials are safe for humans.

- Moisture resistant. Although both materials can be used in damp rooms, they are more resistant to damage, as well as the appearance of mold, OSB class 3 and especially 4.

- Strength. Due to their multi-layer structure, oriented strand boards are much stronger than plasterboard.

- Treatment. Both materials are easy to process and install.

- Sound and heat insulation. OSB and gypsum board (acoustic class) have an equally good effect.

What's better

The different technological thicknesses of plasterboard sheets and OSB boards allow them to be used on almost all surfaces , but there are options when a certain type of material is more practical and reliable in construction.

Practical application, as well as safety precautions, show that plasterboard sheets with appropriate impregnation can be used in any room with a wide range of temperatures and humidity. OSB board does not have such properties.

In damp rooms, for example, a bath or kitchen, it is better to use a moisture-resistant plasterboard sheet. When installed correctly, it operates well and for a long time, withstanding high changes in humidity.

For roof insulation or when building new houses, it is better to use OSB boards. They are good sound insulators and excellent heat retention when coated with special insulating materials that are less vapor permeable. And also they do not carry a strong load on the structure of the roof beams.

Sandwich panels of stationary or portable type are best made from OSB boards. They retain heat better and are more resistant to damage and shock when moving and during operation.

In children's rooms and bedrooms it is better to use plasterboard sheets. They are fire-resistant (do not support combustion and shut off fire), and also do not emit toxic substances, for example, formaldehyde, used for gluing OSB boards.

For ceiling structures, it is better to use plasterboard sheets with a thickness of 9 mm, and for the manufacture of designer and shaped protrusions, arches, shelves and other decorative elements, sheets with a thickness of 6 mm.

Both types of materials are practical and budget-friendly . With proper use and proper installation, the service life is quite long. When installing it yourself, you should take into account the purchase of fastening materials and it is better to first consult with specialists.

Material selection

Both materials have many advantages and are widely used in construction. For different purposes, you need to choose the appropriate material: OSB or plasterboard. For walls, a durable, moisture-resistant OSB board is better suited. It is also mainly used in the construction of buildings and leveling floors. GCR is used for interior decoration and the formation of non-standard structures. The main thing is to choose safe materials of high strength class. This will allow for durable repairs and high-quality finishing.

How to make a partition from OSB inside a house and what screws to use?

OSB is a completely suitable material for the construction of internal room partitions. The strength and light weight of the sheets are clear evidence in favor of this product. OSB boards can be mounted on a metal profile (like gypsum plasterboard) or on a wooden frame.

If the second option is used, the wood should be treated with protective materials against mold and mildew, as well as fire retardants.

Now regarding the partition installation diagram , which will be discussed using the example of a wooden frame:

- Markings are made at the installation site of the structure. Lines are drawn along the floor and ceiling, which will serve as guidelines for installing horizontal guides.

- Beams with a cross section of 4x6 cm are attached along the marking lines. If the wall will be subjected to serious loads (for example, you plan to hang furniture on it), it is better to use thicker bars - 5-8 cm. The guides are attached using dowels.

- Vertical posts are installed, which are fixed to horizontal beams using metal corners and self-tapping screws.

The pitch between the racks depends on the width of the slab, which varies. So, if the transverse size of the OSB sheet is 125 cm (the value characteristic of European brands), then the optimal distance between the axes of the vertical beams is 62.5 cm. In this case, it will be possible to screw the edges and the middle of the slab to the frame.

- After installing the racks, OSB panels are installed.

They are attached using self-tapping screws, the length of which depends on the thickness of the sheets and should be 45-50 mm greater than this value. For example, when using material with a thickness of 12 mm, the recommended length of screws will be 60-65 mm.

In the middle of the slab, self-tapping screws are screwed in increments of 30 cm , along the edges - every 15 cm. The distance from the edge is 1 cm. A gap of 1 cm is left between the slabs and the floor. The same gap should remain between the OSB and the ceiling.

Also, the panels should not be installed closely, but at a distance of 3 mm from each other. This will protect the sheets from deformation due to changes in humidity.

Making a partition from bars and OSB - watch the video:

Another alternative: Cement particle board (CSP)

DSP is the golden mean between wood and stone in its properties. Made from cement, wood fibers and liquid glass (stationery glue). There are slabs for interior decoration and for facade (FCSP). Size of one slab: 2700 x 1250 mm or 3200 x 1250 mm, and thickness to choose from 8/10/12/16/20/24/36 mm. For interior partitions, widths of 10 and 12 mm are most often used; the weight of slabs of this width is 46 and 54 kg, respectively. It is better to choose the widest frame - metal or wood. The final width of the wall will be about 12 cm.

Cost: 800-900 rub. per slab 2700 x 1250 x 10 mm.

Pros:

- The assortment includes DSP with a three-dimensional decorative pattern imitating brick, stone, wood, etc. Such DSPs are more expensive, but do not require finishing.

- Moisture-resistant material, can be used in bathrooms even with direct contact with water.

- Non-flammable - can be used in saunas, baths and around fireplaces and stoves.

- Does not rot, very durable.

- You can make many other elements from DSP, besides walls: use it as a top layer to level subfloors, make window sills, steps.

- On a butterfly dowel it can withstand up to 50 kg.

- The partitions are strong, but easily chipped.

- They are easy to install, except that due to the weight it is more convenient to do it with two people.

- Good sound insulation.

Minuses:

- There are 1-2 mm joints between the plates, which cannot be avoided. So, either use this material in rooms whose length does not exceed the width of the slab (in bathrooms, storerooms), or cover the joints with wood or metal overlays.

- Not the lightest weight, complicates installation and puts an average load on the floors.

Why is plaster still relevant?

It would seem that this finishing material should have long ago and hopelessly lost its position as morally obsolete. However, it continues to be used, and in the age-old rivalry of which is more reliable and better: plaster or drywall, it confidently holds its own on a par with its competitor. And all because he has some qualities that are inaccessible to him.

- If the plastering work is carried out at the proper level, you won’t have to return to it again for about 30 years. Yes, you will change the wallpaper, re-paint or re-tile the tiles, but there will be no need to restore the base.

- The high cost of plastering work is the main argument when choosing between plaster and plasterboard sheets. However, this is a myth, blown out of proportion. The work of a professional, naturally, is not cheap. However, drywall experts will also cost you a pretty penny. But in terms of consumables, plaster is simply incomparable to gypsum board. If we consider impartially, it will cost 2-2.5 times cheaper than the famous designs.

- When choosing between plaster or gypsum board, first of all you should think about the reliability of the resulting surfaces. The first one is shock resistant and absolutely indifferent to water. The second one can be broken by hitting it well with your elbow, but moisture causes it to swell and become deformed.

- The main advantage of plaster is that you can safely attach any heavy objects to it, from air conditioners and water heaters to heavy bookshelves and cupboards.

Disadvantages of plaster mixture

However, nothing is perfect in the world. Drywall strengthens its position due to the inherent disadvantages of plaster.

- Plastering is a dirty process that requires cleaning, and not only in the room where the work is being done: traces of it somehow spread unnoticed throughout the apartment.

- An important argument against plastering is the delay in time. Before you begin the final finishing, you need to wait until it dries.

- With large defects in the walls, it is extremely difficult to achieve their smoothness with a layer of plaster.

- And the main thing: without being a professional builder, you are unlikely to be able to accurately determine how well the plasterer did his job. All the troubles will appear when painting or wallpapering, when it will be too late to make a claim.

Why putty drywall?

After installing the plasterboard ceiling and walls, it’s time to putty them. Here you can also hear that why do this if the walls are already smooth. Don't rush to a conclusion, let's figure it out better .

Indeed, in terms of smoothness, only a suspended ceiling can compete with the material. And it may seem that the puttying process is simply a waste of resources and money, but there is one “but” if you do not subsequently change, for example, the wallpaper. If this happens, then you will remove the cardboard layer along with them, i.e. You will also have to throw away the stove and install a new one, which will take a lot of time and money.

The photo shows the consistency of the finishing mixture

Then you will understand that previous expenses compared to these are just pennies. Therefore, it is better to do the initial finishing putty on the gypsum board surface than not to do it, since it will be more expensive for yourself.

Before applying the finishing layer to the surface of the drywall, it is necessary to cover it, not all of it, but only the joints, corners and places where screws are installed with the starting mixture. It is more grainy and can hold a greater thickness of application, so it will be easier for it to work with large areas. The finishing putty has significantly smaller grains, so it allows you to make the layer perfectly smooth.

What is the difference

There are some differences and features of using plasterboard sheets and OSB boards:

- All types of OSB boards are not recommended for use near an open fire, as this is dangerous according to safety regulations.

- To fasten heavy objects to plasterboard sheets, special fastening is required.

- The resins used to produce OSB boards can emit formaldehyde compounds that are harmful to health.

- When cutting plasterboard sheets, a lot of dust is generated, penetrating into the human lungs.

- OSB boards are more difficult to install in some rooms.

- If damaged during transportation, plasterboard sheets are more susceptible to breakage.

- Various decorative elements with small inserts are best made from plasterboard sheets (they are easier to trim and form the desired bend).

- For certain types of shelves and partitions, OSB board is better suited in terms of strength.

- If the plasterboard sheets are stored incorrectly and have sagging, it is easier to correct the unevenness while maintaining the properties.