Characteristics of drywall

Belongs to the group of composite materials, made from gypsum and cardboard and available in the form of slabs of different sizes. They produce moisture-resistant drywall, which can be used in rooms with high humidity. GKL sheets are an environmentally friendly material that retains its shape due to thick cardboard; It contains gypsum and additives that improve the properties of the material.

There is wall and ceiling plasterboard. They have different properties, so there is no need to use the plates for other purposes. If you plan to make a ceiling from plasterboard, you need to take into account that such sheets are thinner than wall sheets. This is the main difference. The thickness of the ceiling tiles is 9.5 mm. A separate category includes fire-resistant, moisture- and fire-resistant, arched (flexible) material.

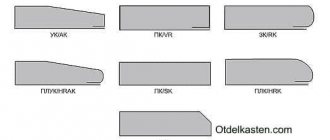

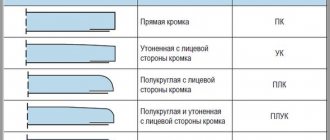

When choosing, the shape of the sheet edges is also taken into account.

Material characteristics:

- bending strength: from 10 kg for gypsum plasterboard with a thickness of 10 mm;

- fire resistance: even standard sheets of material can withstand the effects of fire, and a special type retains its shape much longer when in contact with environments with extreme temperatures;

- the tendency to absorb moisture is high - the absorption rate is up to 10%, but upon contact with water the material loses strength;

- low thermal conductivity (up to 0.35 W/(M*K)) - savings on insulation, since gypsum board retains heat well;

- tensile strength - 30 kg/1 m²; if the intensity of the load increases, the plasterboard slab cannot withstand it.

Advantages and disadvantages

Positive traits:

- low price;

- ease of installation: when assembling plasterboard ceilings, complex equipment or special skills are not required, as, for example, in the case of tension structures;

- flat surface – costs for finishing the rough coating are reduced;

- versatility, gypsum board sheets are used for various tasks: delimiting space (multi-level ceilings), leveling the ceiling, etc.;

- it becomes possible to install lighting systems with any lamps (chandeliers, spotlights, spotlights, etc.);

- the material reduces heat loss through the ceiling, and the effect is enhanced by the air gap between the sub-ceiling and the gypsum board slabs;

- hiding wires behind a profile structure;

- after installation there is no chemical smell; the material is environmentally friendly, does not pose a health hazard even in difficult conditions (during combustion);

- moderate plasticity.

Flaws:

- the more complex the configuration, the more it will hide the space;

- the need for strict control of the work to ensure the alignment of the frame and slabs in order to avoid destruction of the ceiling in the future;

- hygroscopicity: if the humidity level is high, the structure will absorb excess water from the air, which will lead to deformation.

Criterias of choice

Stolen space!

This is an important parameter. If a stretch ceiling in the absence of built-in lighting may need up to 5 cm, then when choosing gypsum boards, especially multi-level ones, you can lay the entire 30 cm. If the room is small, it is better to give preference to stretch ceilings.

Built-in lighting

Since both options provide air space between the ceiling and the structure, in both cases it is possible to design built-in lighting, including multi-level lighting. The main difference is that in suspended ceilings all wires are packaged in special corrugations, but in the case of plasterboard this is a recommendation. Also, in the case of suspended ceilings, when installing lamps, it is necessary to install thermal rings that do not allow heat to spread from light sources.

Expenses

Prices for both options vary depending on the complexity of the project. The cost of suspended ceilings increases the application of complex patterns on the canvas. While the price of suspended ceilings increases with each subsequent level in the project. The standard price of the first option varies between 400–2000 rubles. per sq. m plus the work of a specialist, the price for the second option starts from 1000 rubles. per sq. m.

Exploitation

Stretch ceilings will be much easier to use - it is enough to wipe them from dust from time to time with a dry soft cloth; it is permissible to remove dust with a vacuum cleaner. The warranty for such a ceiling starts from 15 years.

GCR ceilings can be cared for in the same way, only the color will need to be refreshed as needed. With proper care, they will last at least ten years.

Purpose of the premises

This is a very important point, since suspended ceilings cannot be installed in cold rooms such as a balcony or veranda. At sub-zero temperatures the material will crack. But stretch ceilings have a good relationship with water: not only will they not deteriorate themselves, but they will also help retain moisture in the event of flooding - they can store a volume of water of up to 70 liters for several days. The main thing is to call a specialist who will help you get rid of the water and bring the surface into proper shape! Thus, they can be safely used in case there are “unscrupulous neighbors” living upstairs, or just in case you live on the top floor. But gypsum plasterboard ceilings do not really like moisture. Even moisture-resistant plasterboard sheets become deformed in close contact with water, and the ceiling requires repair. It is also worth holding off on gypsum boards in newly built buildings. During shrinkage, the ceiling may not only become slightly deformed, but also require rework.

Vinyl stretch ceilings

When installing this structure, a material of increased elasticity is used. This property becomes more pronounced when heated. This is the basis for the installation principle of vinyl stretch ceilings. The material that is used is chosen taking into account the dimensions of the room. Thus, options from 1.5 to 5.2 m are available for sale. The standard size is 3.3 m. This fabric can be used to make a seamless ceiling (a seam can ruin the look and complicate the design).

To fasten the elastic material, a frame made of metal profiles is used. Considering that the film is characterized by relatively low strength, structural elements and lighting fixtures should be fixed on the rough floor, because vinyl will not withstand significant loads.

The coating is two-layer: vinyl is provided on top (thickness no more than 0.18 mm), the base is polyvinyl chloride. During production, additives are added to improve the properties of the film. The material belongs to the finishing group. It can be purchased in different colors. In addition, there are matte, glossy, satin varieties of coating.

Advantages and disadvantages of film

Positive traits:

- moisture resistance: the film does not lose its properties even in direct contact with water;

- resistance to fungi and mold;

- versatility: thanks to its properties, the coating can be used in premises for various purposes;

- high degree of elasticity;

- tensile strength: vinyl is not damaged if you pull it hard, it easily restores its shape;

- variety of colors and textures and sizes;

- installation does not take much time;

- you can create structures from several levels, combine different types of vinyl;

- easy care;

- long service life - several decades.

If you compare which is better: plasterboard or suspended ceiling, you need to take into account that the latter option lasts several times longer (the service life of gypsum plasterboard sheets is 10 years).

Disadvantages of vinyl structures:

- the upper maximum temperature limit is +50°C;

- It is not recommended to cool the film to +5°C, because under such conditions it cracks and begins to lose its properties;

- despite the material’s resistance to tensile loads, low strength under point loads (impact, puncture, etc.) is noted; it is impossible to restore the coating in case of such damage;

- Given exposure to high temperatures, do not use lighting sources that become very hot, such as incandescent or halogen lamps; the possibility of installing fluorescent or LED lamps should be considered;

- after installation, a specific smell of the film appears, which disappears during the first 2 weeks of operation;

- if you plan to install a suspended ceiling in a large room, you need to eliminate the risk of sagging of the elastic material.

Fabric stretch ceilings do not have many of the listed disadvantages.

Practicality of suspended and suspended ceilings

For many, good aesthetic properties are not the main qualities of a good ceiling design. Stretch and suspended ceilings, as in the previous section, can be compared according to the main practicality criteria in the table.

Table No. 2. Comparison of suspended and suspended ceilings according to functional indicators.

| Criterion | Peculiarities |

| Durability | Both types of ceiling last the same amount of time on average. But the suspended ceiling will have to be periodically “refreshed” by re-painting |

| Resistance to damage | Here the suspended ceiling is inferior to the plasterboard one. PVC and fabric coverings are much easier to damage than sheets of drywall. |

| Tolerance to temperature changes | Stretch ceilings will be able to retain their shape in the cold, but only if they are made of fabric. PVC film is deformed at low temperatures. Gypsocraton tolerates both frost and heat well. |

| Water resistance | Stretch ceilings can withstand large amounts of water, after which the liquid can be drained and the coating restored. But this only applies to canvases made of PVC film. Suspended ceilings made of moisture-resistant plasterboard retain water, but in the event of a flood in the neighbors above or if the roof is damaged, water will likely flow down the walls. |

| Fire resistance | Suspended and suspended ceilings do not burn, but in the event of a serious fire they are deformed. |

| Care | It is enough to periodically wipe tension coverings with a damp cloth, but removing dirt from plasterboard is more difficult. After stubborn stains appear, the suspended ceiling will have to be painted again to hide the defect. |

Loss of altitude

When deciding which is better: suspended ceilings or plasterboard, the structures are compared by size. If you plan to use vinyl sheeting, then in this case the ceiling will be reduced by 35 mm. However, this result is obtained when the ceiling is level. If there are differences in levels around the perimeter of the room, you will need to additionally lower the structure to a height corresponding to the difference in levels.

Drywall hides more free space. For example, when using standard materials (profile - 27 mm high, sheet thickness - gypsum board 9.5 mm), there is a decrease in height by 40 mm (+/- several millimeters). In most cases, the value of this parameter increases to 10 cm, because thermal insulation is placed inside the structure or a multi-level ceiling is installed.

Stretch ceilings

This technology arose relatively recently and became widespread about 15 years ago. Today she is very popular. There are reasons for this:

- speed of installation;

- Possibility of installation in any room;

- creating a very smooth coating;

- no need to remove furniture, you just need to provide access to the ceiling around the entire perimeter of the room;

- Possibility of installation in low rooms;

- ease of installation of lighting fixtures;

- water resistance - in the event of a leak, the suspended ceiling retains water, protecting the room.

Stretch ceilings also have disadvantages. The main one is the mechanical instability of the film. The film of such a ceiling breaks easily. Therefore, it is much less durable than a plasterboard ceiling. The fire safety of drywall is also higher. To create a stretch ceiling, you need a film that is non-flammable, but when exposed to fire it melts and releases toxic substances.

Installing a stretch ceiling requires appropriate skills and special equipment that imparts elasticity.

The stretch ceiling is fastened quite quickly. At the same time, a fastening system is installed around the perimeter of the room. The heated film is pulled into it. This structure is attached around the perimeter 8-10 cm below the ceiling level. This gives a certain advantage if the room has low ceilings.

In case of flooding by neighbors living above, the film protects the room. It can withstand a lot of water and rarely breaks. After this, the craftsmen remove the water and dry the film, restoring its shape.

Which one is faster to install?

In terms of installation speed, the tension option wins. To install it, prepare a frame, which is fixed under the ceiling. At the last stage, it is heated, the vinyl becomes more elastic, then it is tucked into a baguette. The total work time is up to 4 hours.

The plasterboard structure is assembled at different speeds, which is influenced by the degree of complexity of the ceiling. In most cases, the work takes 2 to 4 days to complete.

It is necessary to compare these options taking into account the installation method. For example, it is difficult to make tensile structures yourself if you do not have experience in performing such work. In this case, you will need assistants, as well as a heat gun, with which the vinyl is heated to give the desired shape.

Drywall is easier to install; standard tools are used; If the room is large, you will need help.

What takes longer, stretch or plasterboard ceilings?

The complexity of installation is not the only factor influencing the choice of ceiling for your home. The duration of installation also plays an important role.

Each ceiling has its own nuances that affect installation time:

- Due to the many steps involved in its installation, a plasterboard ceiling can be installed in a period of 5 days to 1 week;

- A regular stretch ceiling without decorative elements can be installed in 3-5 hours, a ceiling with intricate decorative elements can be installed in 2-3 days;

- Although a plasterboard ceiling requires a lot of time to install, it is quite possible to do it yourself without spending money on specialists;

- It will not be possible to install a suspended ceiling on your own due to the complex system of tension and preparation; you will need the help of specialists.

A stretch ceiling can be installed fairly quickly, but for this you will need the help of specialists

Those who like to experiment with the color and design of the ceiling will like the suspended ceiling, because PVC has a little more possibilities. A plasterboard ceiling can look unusual due to the paint color and patterns on it, while a stretch ceiling can be absolutely anything, matte, glossy, or glass. Everything depends on the will of the customer.

Plasterboard ceilings and suspended ceilings have different shelf life with the same care. A plasterboard ceiling will last about 11 years.

Its restoration will be necessary if the putty cracks in the seams or flooding occurs. In the first case, the putty can be updated with new paint; in the second case, the slabs will have to be dismantled and replaced with new ones. Stretch ceilings have an official shelf life of 16 years, but some experts claim that the service life can be 30 or 50 years. They are very easy to care for: it is enough not to heat them from above, but this rarely depends on the owners of suspended ceilings. The consequences of the “flood” can be eliminated with the help of a special team.

Which to choose

A number of factors are taken into account:

- own capabilities: in the absence of experience, it is better to choose drywall if the structure will be installed independently;

- intended purpose of the room: vinyl is used in areas of high humidity;

- height of the room: the lower the draft ceiling is located, the more suitable a tension structure becomes in this case;

- operating conditions: take into account the type of lighting fixtures that are built into the ceiling, the average air temperature in the room (you must remember that vinyl does not tolerate strong cooling, and also loses its properties when overheated).

Environmental indicator

Many consumers are interested in the question of which ceiling is more environmentally friendly—stretch or plasterboard. As for gypsum board sheets, they have the following positive qualities:

- are made from natural and environmentally friendly material, for which they have gained their popularity;

- are absolutely safe, therefore they are often used in the design of apartments where small children or people prone to allergic reactions live;

- do not emit unpleasant odors, harmful or toxic substances.

Tensile structures have also proven themselves to be excellent. The film has moisture-resistant properties, so it can be washed, which means dust and dirt will not accumulate on it, which is extremely important for people with asthma.

Taking into account all the factors, it is extremely difficult to say exactly what is more environmentally friendly - plasterboard or suspended ceiling. Each person makes their own decisions, since both types of material are safe.

Combined ceilings

In this case, during installation, a frame made of a metal profile is used, onto which drywall is attached. The slabs are used to create a box for the purpose of further laying the vinyl sheet in the center.

The configuration of the plasterboard structure and elastic coating can be different; the choice is made taking into account preferences and operating characteristics. The combination of a glossy finish and gypsum boards allows you to create a complete composition. The design is attractive.

How to attach a suspended ceiling to plasterboard

Decorative film can be attached to the surface of a plasterboard sheet using three types of locks:

- Using a harpoon glued to the edge of a PVC film;

- A glazing bead placed into the lock of the load-bearing baguette after the canvas has been stretched and inserted into the mounting groove;

- Clip or cam lock. In this case, the edge of the film is pressed with a spatula inside the double-edged mounting profile.

The tension fabric can be mounted on vertical walls, no matter whether the surface is finished with plasterboard or just a concrete slab. In this case, a special type of baguette is used, designed for ceilings.

Three types of fastening

Important! To install polyvinyl chloride ceiling films on straight and flat surfaces, aluminum baguettes are used; for rounded and curved structures, split or elastic profiles are used, usually models with an additional stiffening rib.

In all cases, metal screws are used to fasten the baguette under the suspended ceiling; no other types of fasteners, including butterfly dowels and self-tapping plugs, are used for these structures.

The butterfly dowel has a high load-bearing capacity, but the profile is not pressed firmly enough to the wall; there may be a gap, which sooner or later will lead to the destruction of the drywall or breakage of the film.