Before attaching the gypsum board, it is necessary to determine the accuracy of the location of the part. This is not difficult to do, because the differences are very noticeable, and the chance of making a mistake is minimal.

On a note! To properly attach small fragments or remnants, it is recommended to mark them on the reverse side.

The importance of the exact location of the plasterboard

When carrying out work on the construction of plasterboard foundations (especially with your own hands), attention is not always paid to which side the slab is screwed to the profiles or the base. If you incorrectly place a few minor fragments, then dismantling will not be required, but when covering the ceiling or walls with the wrong side out, a lot of problems can arise.

Correct placement allows you to:

- Preserve product properties. The front part of the gypsum board has a more stable treatment, which affects the reliability of the resulting coating. Therefore, if you screw moisture-resistant drywall to the wall in the bathroom or shower room with the wrong side, you may not fully achieve the desired effect. Of course, the surface will withstand high humidity, but the service life will be significantly reduced.

- Ensure better adhesion of tiles or wallpaper. If you sew the sheets on the wrong side, then the desired adhesion can only be achieved through complex preparation.

Save finishing materials. The outer coating of the sheet, subject to production technology, has a more dense structure, which reduces the consumption of compounds used for surface treatment during finishing work.

For large volumes of finishing work, an error in the location of the sides of the drywall, due to different levels of adhesion, can lead to significant consumption of primer and putty.

Thus, it is not difficult to correctly determine the front side. But this allows you to lay drywall in such a way as to eliminate problems in the future.

Why fastening technology recommends vertical fastening of sheets

Modern technologies in finishing work indicate the use of the method of horizontal and vertical fastening of plasterboard boards with the same frequency. This is due to the geometry of the room and the versatility of the material itself. However, for each of these methods there are a number of nuances that should be taken into account so that there are no problems with the final finishing with wallpaper or paint.

When attaching drywall vertically:

- It is much easier to calculate the location of the profiles in the sheathing, since they must be located exactly at the junction of adjacent slabs and 1-2 pieces are made between them.

- Factory-finished drywall edges ensure a tight fit and require no additional sanding or adjustment.

- As a result of puttying the joints of drywall sheets, defects are smoothed out much more easily, so cracks are less likely to form.

- Puttying of the entire surface is required only if it is subsequently wallpapered. This is done so that after their removal the top paper layer of drywall remains intact.

Thus, even for a person without much experience in finishing work, installing plasterboard sheets will be a simple task.

Have you tried the horizontal method of attaching drywall?

Yes

No

Correct installation, which side is the drywall attached to?

An ignorant person may naturally ask, which side should I attach the drywall to the wall? There should be no mistakes in this, since in the future this will lead to defects in the entire finish.

To understand this issue, you need to know the structure and features of the sheet of material with which we will work. They determine the technology and rules for the installation process.

Full contents of the material

How to choose

It is very important to choose the right drywall. The store offers a wide variety of products from different manufacturers. Of course, the determining criterion is cost. It is necessary to pay attention to the ratio of price and quality. Sometimes, overall wear resistance and durability make a more expensive material much more attractive in terms of cost.

When choosing a specific material, you must take into account that drywall can be very different. In particular, these are degrees of protection. Simple light cardboard is standard. You can see green sheets in the store. This is moisture resistance. This material can be safely used even for the bathroom. In addition, fire-resistant options are offered, they are characterized by increased safety and during a fire they can slow down the spread of fire.

Sometimes you can find a combination panel. It is a good quality drywall to which a special heat-insulating layer will be attached.

Differences between different types of drywall

At the moment, there are several types of products with different characteristics. The required option is selected based on the specific situation:

- Standard drywall. These are simple white and gray products. Placed in rooms with constant humidity and temperature. The resulting coating provides additional sound and heat insulation. The material has different thicknesses, which are selected depending on the mounting location. It is taken into account that the products cannot withstand loads and strong mechanical influences.

- Moisture resistant. This material differs from the previous one by special additives, which not only provide protection from moisture, but also prevent the appearance of mold and mildew. The products are green in color and are intended for installation in rooms with unstable or high humidity. Also suitable for cladding internal slopes.

- Fire-resistant gypsum board. The leaves have a pink tint, which makes them stand out from other varieties. The material contains reinforcing fiber, which increases resistance to flame. Due to this, the coatings do not deteriorate for a long time, which makes it possible to leave the premises in the event of a fire.

- Combined. Waterproof and fireproof variety. GKLVO is recommended to be installed in difficult areas and used to create boxes for unified communications.

High-quality drywall from trusted manufacturers can be easily recognized by the color of the shirt; each type of material has its own shade.

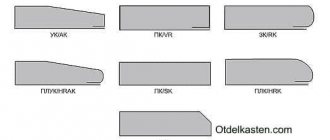

Ceiling and wall products are also distinguished. Their main difference is dimensions: for horizontal surfaces, parts are usually smaller in thickness and in edges. The edges of the slabs for vertical bases may not have a factory bevel (chamfer), which provides more convenient application and high-quality adhesion of putty compounds during leveling.

To obtain an excellent result, it is necessary to take into account the characteristics of each option.

The thickness of the plasterboard sheet directly affects the weight, otherwise the characteristics of the different types of material are similar

Features of the material

This material is actively used in a variety of rooms. Now there are even options for balconies and kitchens, they have special protection against water. This is an opportunity to level the walls relatively inexpensively and prepare them for further finishing. In addition, plasterboard has thermal insulation and sound insulation properties. This is a great way to transform any room. Now it is possible to create multi-level structures to make the layout to your own taste.

Some complain about the negative aspects. In most cases, they appear if you don’t figure out which side to mount the moisture-resistant drywall. If you make mistakes with the installation of a regular one, troubles can also arise.

First of all, it is important to understand the structure of the material. There are not just 2 sides:

- Facial layer

- Back layer

- Gypsum filler

Most manufacturers can help you figure it out. Which side should you attach the drywall using various markings? They must be applied to the back. The front is made perfectly white, light, so that you can do absolutely any decoration and nothing will show through, even if we are talking about thin wallpaper or a small layer of paint. The front side itself also has a nice smooth texture. It is usually multi-layered itself. This is the basis that allows you to perfectly level the surface, and only then the surface is positioned so that you can directly stick wallpaper on it or apply paint, decorative plaster and other materials.

The back side is usually uneven. Here manufacturers can save on the quality of the material. If you mix up the sides, the finish may lie unevenly. It is very important to install moisture-resistant drywall correctly, because in this case only one, the outer side, has additional impregnation and protection from water.

In general, you need to pay attention to several details. These are markings indicating which side is lighter, as well as the fact that the wrong side is slightly tapered at the edges.

How to screw drywall to a profile: instructions for beginners

Once you have decided on the correct side to work with the plasterboard, you can begin installation.

Read about what you need to prepare for work here:.

How to screw drywall sheets (step by step instructions):

- First you need to build a structure from profiles. Make markings for this.

- Attach the guides to the base surfaces.

- Screw the profiles onto the guides.

- Lay insulation, communication or anything else that is provided for by your project on the frame.

- Secure the drywall using extra long self-tapping screws. The standard step is 30 cm between screws.

The correct arrangement of sheets will facilitate further work with gypsum boards. Our article will help you make walls from gypsum plasterboard with your own hands: https://homeli.ru/remont-i-otdelka/steny/steny-iz-gipsokartona-svoimi-rukami.

Difficulties

Some of the work may be carried out with minor difficulties. In particular, if a waterproof material is used, care must be taken to insulate the fasteners themselves. Without special gaskets, moisture can easily penetrate through the screws.

If you need to attach a multi-level structure, then similarly we place drywall on a special frame and try to screw it well. Difficulties may arise not when they are fixed, but directly during the creation of the base.

It is important to note that the fastening must be special elongated screws. Otherwise, even if the drywall is screwed, it is not very reliable. This is especially true for gypsum boards; in this case, accuracy is important, because it is necessary to try to neutralize all holes and prevent moisture from getting inside the structure, because the back side will not be protected from such influence in any way.

It is worth noting that during installation there will definitely remain a small gap between the two sheets. This groove will be well sealed with mortar in the future; you don’t have to worry about its existence.

Finishing

It is worth noting that after selecting and installing a specific drywall, you can proceed to absolutely any finishing. Be it a multi-level structure or just a flat surface. The front side has a certain adhesiveness. Thanks to this property, it manages to adhere to any materials. You should definitely pay attention to this point.

Often, drywall is used simply for wallpapering. It does not need any additional processing; you can immediately apply glue and glue any wallpaper. The only point is the neat, clear finishing of the joints; they should not be visible. That is why the resulting groove is first sealed with putty. Drywall can absorb materials; to prevent this, you can prime the entire surface; this task will not take much time and effort.

Don't stop at just the wallpaper. In fact, drywall allows you to realize any fantasy. This can be decorative plaster, paint, some kind of panels and almost any materials. It is also worth noting that these sheets are very easy to work with in the future. In addition, they can create built-in lighting if we are talking about the ceiling. When you need to attach a picture, lamp or any other interior element, you just need to make a hole using a self-tapping screw.

Many people choose drywall as a starting point for repairs. This is insulation, sound insulation, and also a way to quickly and inexpensively level all walls. Afterwards, you can make any cosmetic repairs you wish. This material is easy to handle. The single most important mistake may be that a beginner confuses the front side of the sheet with the back, or thinks that in this case there is no difference. It is worth remembering simple signs and it will be possible to neutralize the likelihood of this mistake.

Perpendicular and parallel application

Drywall can be applied perpendicular (long edges of the board at right angles to the framing members) or parallel (long edges parallel to the framing).

Fire-resistant partitions may require parallel application. (See Chapter 10 for specific information on fire-rated systems.) Perpendicular application is generally preferred because it offers the following advantages:

- Reduces linear footage of joints to be treated by up to 25%.

- The strongest dimension of the board is through the framing members.

- Irregularities of bridges in the alignment and arrangement of frame elements.

- Better fastening strength - each board connects more frame elements than parallel applications.

- The horizontal seams on the wall are at a convenient height for finishing.

For wall mounting, if the ceiling height is 8″-1″ or less, perpendicular application of standard 4″ wide panels results in fewer joints, easier handling and less cutting. If the ceiling height is greater than 8"-1", or the wall is 4" or less, parallel application is more practical.

Walls ranging from 8″-1″ to 9″-1″ in height can be lined with 54″ wide perpendicular panels to eliminate the need to add more joints. (See Sheetrock Brand Gypsum Panels – 54” in Chapter 1.)

For ceiling applications, use a parallel or perpendicular method that results in fewer joints or is required due to frame spacing restrictions

When applying a two-layer ceiling, apply the base layer slabs perpendicular to the frame members; Apply the face coat parallel to the frame with the joints offset. On the walls, apply the base coat parallel to the long edges in the center of the frame; Apply the face coat perpendicularly.

From an aesthetic point of view, a vertical installation can look very good since there are no butt joints between the two non-beveled edges. These un-beveled edges create 4" long humps that can be seen with careful observation (and especially with poor handling of dirt).

However, for structural shear strength, drywall is typically installed horizontally. This bonds most of the studs together on one sheet of drywall to resist shear forces on the wall. You also maximize this force by moving your joints. The effect of two offset sheets of drywall is similar to placing a long diagonal brace from the top corner of the top sheet to the opposite corner of the bottom sheet.

As an added benefit, horizontal settings make it easy to tape at waist level, reduce the effect of any bending of the tenons, and are much easier to correct for a slightly misplaced tenon (you're only trimming a short unbeveled edge as opposed to the full length of the finished beveled edge).

However, for non-load-bearing walls, especially in office environments where metal studs are used, vertical installation can be done for speed. It's also more practical for high ceilings where you'll need 3 or more sheets of drywall to hang it horizontally. I will also do a vertical installation on any wall that is 4 feet wide or less, as this results in a single sheet without any mud bonding.

Only vertically , that’s the proof and the truth!

Why and how the horizontal is wrong (and why the vertical is right). don't spoil the new one from the very beginning:

1 – Defective seam. Horizontal courses requiring more than one drywall panel create (rather than avoid) butt joint ends that are not flat and present a double (minimum) defect . Socket and switch covers, window and door trim, baseboards, paintings, mirrors and cabinets do not stand still. The use of any “butt joint product” erases all “the stated advantages of horizontal!

2 – Unsupported seam – the conical edge of the horizontal is not supported by 90% , only 10% (instead of 100%) of the contacts are framed, the seam will crack. Light switch and electrical panels inside the seam equal more slack and double the butt joint, minimum effort.

3 – Structural Defect – Horizontal reinforces only a wall that is 4 feet high or less, the top slab of a full height wall is never connected to the bottom slab. As per #2 above, frictional contact is minimized (instead of maximized vertically).

4 – Seam breakage. 4x8" Panels - Example 1: 48" tall by 102 " long wall, horizontal = 48" (technically) and that's a 24" wide butt joint or at least double the 48" (Vertical = same, generous, 96" but they simple 6" wide joints. Example 2: 96" high by 102" long wall, horizontal = 222" with 50% being 24" wide butts (vertical = 192" Easy joints 6" wide, yes less). in kitchen horizontal plane = 100% 24" wide stock (vertical = 0%) Yes, horizontally the cone area is halved (at least) to hide her stocks, so very minimally another 24" was added, and #5 below was not counted in Horizon's monumental fraud.

5 – Self-breaking corners – Horizontal uses only one of the tapered edges of the panel and places the other cone at the corner of the ceiling and baseboard, creating (instead of being avoided as with vertical) a crooked corner that must be rolled up or further caulked. It also instantly erases all the “claimed benefits of horizontal, doubling the amount of seam, correcting itself to equal vertical!

6 – Unfriendly seams. The chest-high horizontal seam makes it seem like a 24-inch wide floor-to-ceiling joint doesn't exist, and there's always a baseboard bevel for work-in-progress . (The vertical has easy joints and the top is screwed, glued and rubbed in later along with the ceiling corner, and the baseboard stains can also be done separately).

7 - Fire Hazard Liability - Horizontal fill only fills the face of the thinnest joint and does not block the back, causing smoke and fire to spread, inviting fuel air for fire growth (The vertical is full and airtight if simply screwed on).

8 – Unsafe Installation – Horizontal position requires 2 people to install safely and the panel is in the air, literally creating the potential for injury (vertical position is easily lifted by one person). Using a panel lift is not even as easy or safe as tilting the Vertical.

9 – Extra Waste – When properly covering a knee wall, half wall, tub front, column or ceiling by first removing both tapered edges, Horizontal cannot use tapers elsewhere (Vertical can and does). In addition , Horizontals waste 4 times more dirt on their completely unnecessary butt joints and baseboard bevels. if it was ever done.

10 – Destructive Ignorance – The Foundation and Framing crews work hard to make everything smooth, level, plumb and square. The horizontal destroys these efforts with their defective humps and baseboard bevels (the vertical retains perfection).

11 - Grasping at Straws with Outright Fraud - Horizons falsely and unknowingly brandishes the absurdly invalid (FPL439) 1983 test, “The Contribution of Drywall to the Durability of Light Frames ,” by self-convicted fraudster Ronald W. Wolfe. FPL439 found that all tapered wrapped edges of the paper must be completely intact in order for the horizontal to hit the vertical, period. In the real world, the bottom edge of the paper, wrapped horizontally in paper, is legally removed to remove it from all floors and thereby completely nullifies Wolfe's unforgivably deceitful and useless “research ( ridiculous ) and summation.

12 - Seam or Joint Treatment - According to ASTM C840 8.2, horizontal seams should be caulked to provide any resistance to fire, smoke and air movement (vertical is so good that it does not need to be treated at all).

13 – Expensive, slow complication. Horizontal depends on expensive special muds and even dirty tape or tools that waste mud. The strapping tools still require a 2nd step of cutting the tape, and the mud requires a mixing step. That means more cost, more time, more tools and equipment, and more water. for bad work! Vertical outperforms the cheapest ready-mixed solutions and dry adhesive tape. Again, the Vertical seam treatment is just for looks.

14 – Poor Fire Resistance Rating Vertical installation of single-ply or single-ply commercial drywall is required to ensure actual drywall strength This is well known to most horizontals, but you and your children are not important to the horizontal. And why, to respect the fraudsters who taught them wrong? Now you've seen that Vertical is faster and better in every way.

Just advertise Horizontal as wrong and confidently quote the above-mentioned irrefutable facts.

Installation technology and rules for fastening drywall

Published on September 30, 2017 in the category Building materials // 0 comments // Author: Admin

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Drywall is a popular material and a good choice for DIY repairs. Ideal for leveling, thanks to which the wall acquires an aesthetic appearance, it is also used to create partitions in the room. The material is low-cost and easy to use, and following all installation rules will allow you to create a beautiful and unique interior. To achieve the desired result, it is important to know which side to attach the drywall and how to screw the drywall to the profile, which will allow you to quickly and easily transform any room.

How to properly screw drywall using the frameless method: necessary materials

To make the work of attaching plasterboard sheets easy, you need to stock up on all the necessary materials.

What materials and tools will be needed when installing drywall using a frameless method:

- Drywall;

- Dry mixture;

- Container for dry gypsum mixture;

- Painter's knife;

- Rule;

- Rubber hammer;

- Roulette;

- Level;

- Putty knife;

- Fishing line;

- Jigsaw.

The frameless method is suitable if the base wall is almost perfectly flat.

At what distance should I fix drywall?

Experts offer several recommendations on how to properly screw the material:

- Fix the wall sheet correctly onto the support strips, the distance of which is at least 40 cm from each other

- Moisture-resistant plasterboard - 60 cm

- A mesh is assembled onto the ceiling from the profile, the cell size of which is no more than 40x40 cm

The desired result also depends on the correct spacing of the screw holes. Screwing in too often will lead to crumbling of the slab, the same will happen if there are not enough fasteners. It is optimal to place the parts at a distance of 20 cm.

Necessary materials and work plan

Before proceeding with installation, it is important to level the surface of the walls in the room and prepare the necessary materials for work:

Scheme for installing a plasterboard ceiling.

- building level;

- pencil;

- drill;

- perforator;

- dowels;

- screwdriver;

- self-tapping screws;

- metal scissors;

- roulette;

- pendants;

- profile;

- moisture-resistant drywall;

- knife for cutting drywall;

- putty knife;

- putty.

We will carry out the work in the following sequence:

- Marking.

- Frame installation.

- Drywall fasteners.

- Finishing.

Having prepared everything necessary, we proceed to the first stage of work.

Differences between the front and back sides

There are signs that will indicate the correct location of the gypsum board:

- The markings are located on the reverse side, there are no inscriptions or signs on the front side

- The front side of drywall is the same color with edges

- The front part has a different chemical composition, it has a higher cellulose content, which ensures minimal costs of finishing materials

The front side of ordinary drywall is white, moisture-resistant is characterized by a green tint, fire-resistant - pink.

It is important to carefully inspect the sheet before starting work and know exactly which side to screw the drywall on. Correct screwing guarantees convenience and ease of operation, as well as a long service life.

Correct side for mounting

The sheet of this material is similar to a sandwich; between the layers of back and front paper there is a layer of gypsum.

On the back side (cardboard color) there are all the marking data of the manufacturer. Its front part is white if it is a regular type of material, or, for example, green if it is moisture resistant.

Also, its texture is of higher quality and pleasant to the touch. This is done to reduce the consumption of primer and other finishing materials.

Important! When installing, ensure correct fastening, focusing on the face and back of the plasterboard sheet.