Drywall and unheated cottage

We use moisture-resistant plasterboard in the bathroom.

Almost every building material has many different varieties, differing in certain characteristics. Moisture-resistant plasterboard is often used for finishing arches, ceilings, walls and other surfaces.

Drywall is called a building material. consisting of several layers: the plaster itself in the middle and two cardboard sheets. Reinforced material, which is strengthened with metal mesh, fiberglass and other means, has greater strength.

A distinctive property of waterproof plasterboard is that it can be used in rooms with an unstable microclimate. While non-moisture-resistant materials, like a sponge, absorb moisture and gradually collapse.

Before you give preference to a certain material. its performance characteristics should be studied in detail. Properties of moisture-resistant drywall.

As a rule, the color of the product is light green - this feature helps to distinguish moisture-resistant material from ordinary gypsum board. Some companies also produce pink sheets.

The gypsum layer is impregnated with special substances that provide the material with moisture resistance.

Gypsum is treated with substances that protect the material from the effects of mold and mildew, so it can even be used for arranging basements.

The dimensions of gypsum boards are extremely varied. You can choose sheets of literally any size with a constant thickness, the value of which can vary between 7-24 mm.

Moisture-resistant plasterboard, the thickness of which is more than 12 mm, can be used for cladding unheated rooms: for example, a kitchen, a summer house, a bathroom.

Drywall: pros and cons.

A very good solution would be to use plasterboard under the tiles in the bathroom. After all, this material is universal and easy to install. Of course, when decorating wet rooms such as a bathroom, you should use only a moisture-resistant type of material.

Drywall in winter! incredible!

After all, only such products are not damaged due to exposure to liquids and high humidity. When buying drywall for a bathroom, you can easily distinguish it from many other materials: the sheets of the product are painted green and have blue markings with the abbreviation “GKLV” and an indication of the dimensions. The demand for gypsum in the field of rough finishing is also due to many other advantages.

Wide scope of application and versatility. This material can be used for the construction of various partitions, suspended ceilings and wall cladding in any rooms with high humidity.

Excellent water-repellent characteristics.

Sound-absorbing properties, thanks to which it can also be used as sound insulation.

Ease of installation and processing.

Good flexibility, due to which the sheet can be installed on a curved surface.

An excellent basis for all types of finishing: for example, tiles, decorative plaster, wallpaper.

Of course, moisture-resistant drywall, like any other material, also has some disadvantages, so it should not be idealized either. For example, due to prolonged exposure to water, a sheet can absorb it, swell and become significantly deformed. In addition, you need to take into account that drywall cannot withstand strong impacts and heavy loads. That is, it is not recommended to fix such bulky things as a boiler and cabinets on drywall.

It is also important to adhere to the technology of installing moisture-resistant ceiling plasterboard in order to preserve all its characteristics. It is best to entrust the installation of a plasterboard ceiling in a bathroom to professionals. But laying tiles in the bathroom on gypsum plasterboard is not at all difficult and, perhaps, anyone can do it.

Installation of moisture-resistant drywall.

The scope of application of moisture-resistant drywall is truly extensive: it can be glued, cut and mounted on external surfaces, floors, ceiling structures, walls and arched openings. Unlike ordinary plaster, the moisture-resistant product can even be washed.

Direct installation of moisture-resistant gypsum boards is carried out in stages.

preparation of the surface to be finished.

installing the frame or lubricating the surface with glue.

The material can be placed on a frame or in a frameless manner. Each of these options is worth considering separately.

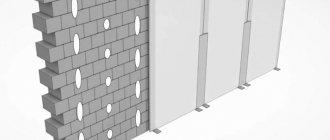

Installation diagram of moisture-resistant drywall without frame.

Frameless method of installing drywall step by step.

First of all, you should prepare the surface on which the sheet will be installed. First you need to remove the old finish from the surface: remnants of paint, plaster or wallpaper. Then the surface must be treated with a primer. It is the primer mixture that will help protect the material from fungus and mold, as well as significantly increase the adhesion of the treated surface and glue. This stage is especially important when processing the ceiling.

Taking into account the condition of the surface, the adhesive mixture can be applied in different ways: with slaps and around the perimeter. If you are covering a smooth wall without defects, glue can be applied around the perimeter. To do this, apply glue along the sides of the drywall and in the center of the sheet. Then place the product against the wall or ceiling and level it using a level. If the surface to be treated has any unevenness or roughness, it is best to apply the glue in splashes. This way you will cover the entire surface with an even layer. In some cases, builders apply glue not only to the drywall itself, but also to the wall. This is necessary to prevent the occurrence of voids between the surface and the material.

Before you begin the gluing procedure, check if there are any drafts in the room. Keep in mind that it is drafts that contribute to premature hardening of the glue. Under normal conditions, the composition hardens within 24 hours.

Then you need to cover the sheet with another layer of primer. The soil mixture dries in approximately 24 hours. After this, the surface can be coated with a universal primer.

Lastly, you can start decorating. However, please note that installation of tiles is only possible on drywall that is mounted using a frame method.

Installation of moisture-resistant gypsum board on the frame.

Of course, frame installation technology differs markedly from the frameless method.

First of all, you need to determine which side to fix the material. Keep in mind that both sides of moisture-resistant drywall are different: one is made of gypsum and the other is made of cardboard. The gypsum side has greater hardness and density - it should be mounted on the frame. And the cardboard side is considered the front side and must be subjected to additional lining, so it remains outside. The tiles are actually laid on the cardboard side.

Considering where the drywall will be installed: on the floor, walls or ceiling, you need to find the lowest corners and mark them with dashes. The guide profile will be mounted along these lines.

Using a level and anchors, secure the drywall to the ceiling, floor or walls. Draw the plane, highlighting the pitch of the main profiles and racks. This characteristic depends entirely on the location of installation of the material.

In order to make the frame more rigid and durable, you need to supplement it with special hangers. The distance between the hangers should vary between 40-50 mm.

Only after this can you begin the direct installation of drywall on the frame. If you plan to create shaped details in the interior, use small-format plasterboard. Sheets of this material can be cut according to patterns and fixed on prepared profiles. Fortunately, waterproof drywall is flexible enough to allow it to be bent and adjusted to fit the desired openings.

As you can see, you don’t need any special skills when working with plaster - everything is quite simple and quick.

However, is it possible to completely rely on a rough finish with moisture-resistant plasterboard and at the same time be completely sure that nothing will happen to the material? In fact, absolutely every material has weak, vulnerable spots, and drywall is no exception! Now we are talking about the cut and unprotected ends of the plaster, as well as the back side adjacent to the existing walls. It is these areas that need additional protection during prolonged exposure to moisture.

Is it possible to protect moisture-resistant plaster from the effects of water? The answer is simple - it’s not easy, but it’s even necessary! Rest assured, absolutely any material, even one that is not resistant to water, can be easily adapted with the help of additional means. How to do it.

Basic recommendations for choosing moisture-resistant drywall.

It is necessary to purchase drywall only from trusted suppliers. You can seek advice from a specialist, or trust the reviews of other consumers. Based on practice, buying a cheap analogue of moisture-resistant drywall leads to additional costs, since this material has a short service life.

Carefully inspect your purchase; this will allow you to notice a low-quality plasterboard board and immediately replace it in the store.

When broken, the core should not crumble too much; to do this, ask the seller for a fragment of moisture-resistant drywall.

The material is thin, not waterproof, and plasterboard, unlike gypsum fiber, has low strength - if you hang something heavy, you can collapse the entire wall.

Inside there is plaster with additives, outside there is a cardboard lining attached with a special glue. Depending on the properties of the drywall, dimensions may differ from standard ones.

Drywall weight and weight . Have you ever wondered - “how much does a sheet of drywall weigh”? The weight of drywall is no more than 1 s (kilograms per square meter). Fire-resistant plasterboard sheets - plasterboard is not so important, in the end it can be cut the way you want, the main thing is the thickness. It comes in different profiles - 6, 9, 12 mm, it does not depend on the place where we buy gypsum boards - on the market or in a specialized store. GKL 6 mm is used for bending sheets using the “wet method” - creating products with curves (designer fantasies, niches, arches). GKL 9 mm is usually used for ceilings, and is also used for bending sheets using the “dry method”. They make beautiful ceilings to reduce the weight of the structure. The thickest ones are used by builders to create partitions and wall cladding. They also create racks and columns, the height of which will indicate the status of the owner. There is little demand for other sizes; non-standard gypsum boards are rarely of interest to buyers.

Is it possible to sheathe an unheated room with plasterboard?

Dear forum users, please advise. Can waterproof plasterboard be used for interior decoration? Given - the veranda is glazed, we don’t go in winter, the house is not heated. I would like to paint the walls with “corrugated paint.”

If drywall is not suitable, what can be replaced? Thank you in advance.Lara, two years ago the second floor was partially covered with plasterboard.

The drywall was secured not with screws, but with a stapler. The joints were closed with slats. They stopped there, didn’t paint, didn’t glue wallpaper.

After the winter, marks and smudges appeared here and there, because a roof leak was discovered in one place. But the drywall did not deform. I don’t know what kind of drywall they used, it’s rough on one side and glossy on the other. The possibility of painting is also of interest. Wood is a warm and clean material. For many years, after construction is completed, it fills the inside of the house with its aroma.

To finish the walls, it is necessary to take into account the shrinkage of the new structure and the constant expansion of the logs with changes in humidity and temperature. Timber and boards play less. Our neighbors' house is lined with plasterboard inside.

Wallpaper is pasted on top. The house is about twenty years old. Nothing bad happened to the drywall during this time. Only the wallpaper is changed periodically. Yes, a “prefabricated panel” house.

At the dacha you can relax not only from the city noise and bustle. Clean air is an integral part of outdoor recreation. Many are tormented by the question of how to cover the walls of a dacha inside inexpensively and maintain comfort. For this purpose, an environmentally friendly material is used that can easily withstand the winter unheated period.

It is advisable to preserve the natural, country style of finishing.

Budget solution

When deciding what to cover the walls of your dacha with, you should study the possibilities of various materials:

| Material | Characteristic | Application specifics |

| GKL | Weak vapor permeability, low fracture strength, afraid of moisture. | Not suitable for unheated country houses. |

| GVL | Durable, moisture-resistant, flexible, contains reinforcing fibers. | Not afraid of moisture and temperature changes. |

| MDF | Low plasticity, hydroscopicity, environmental friendliness, shape stability. | Not used in areas with a high level of fire hazard. |

| Plywood | Flexible, hydroscopic and durable. | With proper processing it has almost no restrictions. |

When deciding how to decorate the interior walls of a dacha, if the country house is not heated, give preference to moisture-resistant materials: laminate, plasterboard, plastic, penoplex.

The sheets chosen are moisture-resistant GVL; they differ in color from gypsum plasterboard.

Laminate and plastic are installed using a technology similar to installing lining.

Experts do not recommend gluing wallpaper in unheated rooms. If you want to make the interior colorful and bright, it is better to use acrylic paints.

Article rating:

Save to:

Can drywall be used in an unheated room? Link to main publication

Is it possible to sheathe the walls of an unheated cottage with gypsum plasterboard or MDF panels?

Question No. 145: A dacha was built from blocks and facing bricks, the walls are 40 cm thick, unheated. In winter, the usual air temperature is minus 10 degrees, sometimes lower. Is it possible to cover walls with plasterboard? Or is it better to use MDF panels? Thank you. Answer: As for plasterboard, I do not recommend that you use even moisture-resistant plasterboard for cladding walls in your house without heating. In any case, there will be a difference in temperature inside and outside the room, even rare visits to the dacha in winter will change the air humidity inside the room, and the dew point will shift to the inner surface of the walls. This means that the air humidity in the room will increase, the plasterboard sheets will absorb moisture, become covered with frost, freeze, and in the spring they will swell and crumble. Drywall itself does not belong to the family of frost-resistant building materials; its frost resistance is only eight cycles, but should be at least 35. Now about MDF panels. These are very good wall panels and are made from wood dust by pressing; the binder material in MDF boards is lignin, released from wood as a result of heating the wood dust during pressing. So MDF is the familiar fiberboard covered with a textured film. I would not recommend trying MDF panels to decorate the walls of your dacha. This material does not belong to the moisture-resistant class and is not recommended for use in unheated rooms. Over the winter, the panels will become saturated with moisture and begin to deform and swell. Consider panels made of PVC or natural euro lining or simple wooden lining for finishing the walls of your dacha. Good luck. PS If you don’t decide how to decorate the walls before winter, buy one MDF panel and leave it indoors in your dacha for the winter, and see how it behaves in the spring. Calculations show that at -12C your room will be +5C with your wall thickness, so anything can happen and the humidity in the room will be below 70%, and this will allow you to install MDF boards on the walls without fear that they will collapse.

Added: 02/13/2017 11:14

Discussion of the issue on the forum:

Structure of the material and principles of its storage

Drywall consists of two components, which appear in its name. The gypsum base is covered with a layer of paper, which tightens it and prevents it from cracking. This structure makes the gypsum sheet (gypsum board) resistant to serious longitudinal loads. At the same time, its lateral stability remains quite weak. Almost any pressure can lead to the formation of dents or even the appearance of through holes. Due to the large area of the sheet (2400x1200 mm), during the moving process its corners often suffer, breaking off or getting knocked down. According to building codes, the rules for storing drywall are based on the following principles:

- the storage temperature of the material should not fall below +10 degrees (the optimal values are 16–18 degrees);

- humidity in the premises should be 75–80%;

Subject to the above conditions, the shelf life of the material is unlimited. At the same time, failure to comply with at least one point can affect the quality of drywall or even lead to its damage. Particular attention must be paid to the level of humidity and the absence of leaks, since the main enemy of gypsum boards is water.

Drywall on wooden slats

It is best to store drywall in a room where you can organize all the necessary conditions for its safety. Storing material outside is a temporary measure and is carried out exclusively in the warm season. It is better to place it on the roof or attic, where it will be completely protected from precipitation.

It is not recommended to leave plasterboard outdoors for more than 1–2 days. In this case, the material must be hermetically sealed and placed according to all rules.

Other publications in the “Interior decoration of the house” section

As we know from practice, renovating an apartment or house is an interesting, educational, and sometimes even eternal process. Therefore, many homeowners prefer to do repairs on their own. Of course, there are those who do their own repairs simply because they don’t have enough.

What are the risks of using conventional slabs in the bathroom? Let's consider the features of constructing partitions in the bathroom from tongue-and-groove gypsum boards. Each such slab is made of building gypsum and is a rectangular parallelepiped, the joining and supporting surfaces of which are .

The house is made of adobe, walls without lathing, sand-clay plaster, lime whitewash. How to properly approach the issue of leveling walls with putty (finishing) or how to properly prepare such walls for painting with water-based paint. Thanks for the answer Answer: If the house is old enough and there are .

Is it possible to sheathe the walls of an unheated cottage with gypsum plasterboard or MDF panels?

Question No. 145: A dacha was built from blocks and facing bricks, the walls are 40 cm thick, unheated. In winter, the usual air temperature is minus 10 degrees, sometimes lower. Is it possible to cover walls with plasterboard? Or is it better to use MDF panels? Thank you. Answer: As for plasterboard, I do not recommend that you use even moisture-resistant plasterboard for cladding walls in your house without heating. In any case, there will be a difference in temperature inside and outside the room, even rare visits to the dacha in winter will change the air humidity inside the room, and the dew point will shift to the inner surface of the walls. This means that the air humidity in the room will increase, the plasterboard sheets will absorb moisture, become covered with frost, freeze, and in the spring they will swell and crumble. Drywall itself does not belong to the family of frost-resistant building materials; its frost resistance is only eight cycles, but should be at least 35. Now about MDF panels. These are very good wall panels and are made from wood dust by pressing; the binder material in MDF boards is lignin, released from wood as a result of heating the wood dust during pressing. So MDF is the familiar fiberboard covered with a textured film. I would not recommend trying MDF panels to decorate the walls of your dacha. This material does not belong to the moisture-resistant class and is not recommended for use in unheated rooms. Over the winter, the panels will become saturated with moisture and begin to deform and swell. Consider panels made of PVC or natural euro lining or simple wooden lining for finishing the walls of your dacha. Good luck. PS If you don’t decide how to decorate the walls before winter, buy one MDF panel and leave it indoors in your dacha for the winter, and see how it behaves in the spring. Calculations show that at -12C your room will be +5C with your wall thickness, so anything can happen and the humidity in the room will be below 70%, and this will allow you to install MDF boards on the walls without fear that they will collapse.

Added: 02/13/2017 11:14

Discussion of the issue on the forum:

Other publications in the “Interior decoration of the house” section

As we know from practice, renovating an apartment or house is an interesting, educational, and sometimes even eternal process. Therefore, many homeowners prefer to do repairs on their own. Of course, there are those who do their own repairs simply because they don’t have enough.

What are the risks of using conventional slabs in the bathroom? Let's consider the features of constructing partitions in the bathroom from tongue-and-groove gypsum boards. Each such slab is made of building gypsum and is a rectangular parallelepiped, the joining and supporting surfaces of which are .

The house is made of adobe, walls without lathing, sand-clay plaster, lime whitewash. How to properly approach the issue of leveling walls with putty (finishing) or how to properly prepare such walls for painting with water-based paint. Thanks for the answer Answer: If the house is old enough and there are .

Is it worth using drywall for finishing?

Today, the basis for satisfying the information appetite is the Internet. It’s hard to argue with this, because if we need an answer to any question, we turn to Google and Yandex via a PC, tablet or smartphone, rather than going to the library. But here, in the fields of the electronic network, there are many pros and cons, myths and legends. But there are also truthful conclusions. It is with them, against the backdrop of a huge flow of information, that we need to understand if we need to study materials for the architecture and decoration of our own home. Next up is drywall - a popular and sought-after material that is practical and, one might say, somewhat universal. I will tell you in this article whether it is possible and whether it is necessary to use drywall in your own home!

Author: Alexander Kirichenko

Contents of the article:

There have always been disputes on the topic of this material. And their main participants are specialists in our specialized field: designers, builders, decorators, finishing specialists, and directly, the customers themselves. There are not even hundreds of opinions, but thousands and tens of thousands, so you need to sort out the issue, taking into account the recommendations of drywall manufacturers, the features of production and installation technology, building codes, and technical characteristics of gypsum boards!

Designers' opinion

One can agree with the voiced thoughts of most modern designers about the use of material. This is a practical and really good option for interior decoration and the production of decorative elements. But when using drywall, you should start from its direct qualities and purpose, and use it strictly in order to increase practicality, and not install gypsum boards wherever you just want. It is also worth understanding that today there are a lot of other technologies and materials that may better meet the requirements of the process where the customer decided to use drywall. We solve structural problems with gypsum boards and use the material where it is needed. we exclude him as much as possible from projects that bring chaos, thanks to rash and impractical decisions!

Breaking the rules

A negligent attitude towards the process of saving products can be fraught with the following consequences:

- slab deformation;

- the appearance of cracks or chips;

- swelling due to excessive absorption of moisture, which will affect the quality of the material;

- change in color of the outer layer of cardboard.

All these points will lead to a decrease in the service life of the product, a complication of installation work, as well as a deterioration in the quality and properties of the material. All specified storage requirements apply to all types of slabs, even moisture-resistant ones. After all, with prolonged contact with moisture, they will lose their factory performance properties. Storing plasterboard sheets requires the buyer to comply with all conditions specified by the manufacturer. If these conditions are violated, the manufacturer is no longer responsible for his product. Therefore, it will not be possible to exchange it. Be responsible about storage and your repair will be of high quality and durable.

Drywall is a proven material that has earned a large number of positive reviews over many years of use. The scope of its application is huge and does not end with wall cladding or creating partitions. Not only professional builders, but most ordinary people are familiar with it firsthand. At the same time, few people know that drywall storage must be carried out according to certain rules, violation of which leads to deformation and damage to the material.

Full contents of the material

The main purpose of drywall

- There are several main manufacturers on the market - Knauf, Gyproc, Rigips and others;

- Drywall, different types and areas of work: GKL - standard, GKLV - moisture-resistant, GKLO - fire-resistant, GKLVO - moisture-fire-resistant, GVL - gypsum fiber sheet;

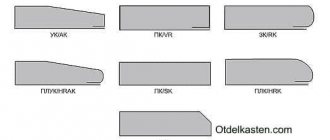

- Material by type of edge - straight, semicircular, rounded, thinned and others, combined;

- Drywall by type of work and purpose - wall, ceiling, arch!

Such a classification is necessary for the purchase of material, as are the dimensions of the sheet, its thickness, and accurate calculations of the area. But, first of all, you should understand the purpose of the material, where it can be used in rough or fine finishing, the production of architecture, and decorative compositions for interior design:

- The main direction is the production of wall structures and partitions. Drywall is used to construct lightweight frame walls for space planning;

- The next task for gypsum boards is leveling surfaces as an alternative to plaster. You can work with walls and ceilings, architectural structures, partitions. Drywall is installed on an adhesive base, wooden or steel frame;

- Drywall is an excellent material for filling niches and producing communication boxes. Under it and behind it you can hide any pipes and wires, highways and channels - water supply, ventilation ducts, etc.;

- And finally, gypsum plasterboard is popular in the production of suspended ceiling systems, classic and multi-level combined. The material can be used for standard ceiling leveling, but also serve as one of the elements of a modern combined ceiling made of gypsum plasterboard and wood, gypsum plasterboard and glass or mirrors, gypsum board and stretch ceiling!

These are the main areas of application where gypsum boards can be used to reduce pressure on the budget and increase the speed of work. Their quality does not depend on the material itself, but on a complex that combines the correct choice of gypsum boards and fastening systems, compliance with technology requirements, and compliance of the material with the assigned tasks!

Despite its main purpose, today drywall is used to solve the following problems:

- Creation of standard and curved arches for zoning rooms, as well as designing doorways;

- Production of storage systems in hallways and pantries, in the kitchen and living room. Difficult operating conditions should be avoided, as well as the production of open thin shelves;

- Production of through partitions and cabinets, special wall niches for placing equipment and equipment;

- Production of significant interior design items - false fireplaces, 3D figures, decorative lighting systems;

- Special overhead decorative items for walls and ceilings, design elements for built-in cornices;

- Bar counters, children's play complexes, special structures for pets, wall panels, screens for wide window sills and bathtubs, etc.!

Plasterboard on the ceiling after winter

Previously, I wrote about how an unheated house winters. In particular, there was a phrase about the walls and ceilings being covered with frost. Well, cement-sand plaster doesn’t care about frost and humidity, but I was worried about the drywall. So what's the result? Nothing happened to the drywall on the walls, but there were problems with the ceiling. Let me remind you that my ceiling is covered with plasterboard on wooden blocks in increments of 50 cm. In one room I even managed to putty the seams last summer. The rest of the rooms had bare drywall with no putty. Immediately after fixing the sheets to the ceiling, everything looked smooth and I didn’t look too closely at it. In the spring, it became noticeable that the mounted sheets of drywall had bent along the length between the fastening lines. Did you get damp in the winter? The sag was up to 1 cm for each 50 cm gap between the sheathing bars. On the other hand, several sheets were left lying on the floor in the winter - at least they had nothing to do with it, despite the fact that in the spring there was water under the floor and, accordingly, it was very humid. With the onset of summer, I put them into use - strong and smooth, as soon as they came from the store.

Since there is also wood under the guide bars on the ceiling (boards with sawdust insulation on them), I decided to tighten up the sagging sheets with long self-tapping screws. I bought 90 mm self-tapping screws and began to screw them into the bottom of each wave, i.e. in the middle between the guides. I twisted the screws in a line at intervals of 20-30 cm. In this simple way I managed to get rid of large waves. I hope to level out the remaining unevenness with putty. The thing is that when the self-tapping screw is wrapped in a guide bar (or metal profile), it can practically be buried in cardboard. And when there is a void under the sheet at the place where the self-tapping screw is screwed in, and the drywall resists straightening, you squeeze it a little - the cardboard breaks through and the sheet bends again, while the self-tapping screw is recessed far into the depths. Therefore, such waves have to be eliminated in the following way: we attach a line of screws until they touch the sheet and begin to slowly pull them up one at a time. The wave gradually straightens, and the screws remain slightly protruding. If everything is done carefully, then the entire wave line needs to be slightly deepened relative to the plane of the drywall so that the protruding heads of the screws (and they should stick out, otherwise the cardboard will break through and the sheet will bend back) are slightly below the plane of the sheet. As a result, a shallow hollow is formed, which can be easily hidden with putty.

The described technique seemed easier to me than removing drywall, adding sheathing and putting it in place, although ideologically it is probably correct to do just that. Below is a photo illustration of the described

The pencil line is last year’s fastening of the sheet into the sheathing. There was a hollow left on it, which was then hidden with putty.

Source: www.stroyopyt.ru

Benefits of drywall

- Drywall is an inexpensive material for construction and finishing. Its cost is competitive in relation to other construction materials;

- GKL is easy to install - it is installed on a special glue, galvanized steel profile, wooden frame;

- A material with a high level of versatility - it can be cut with a standard construction knife and CNC to create straight sections and any other shapes, bent to produce geometric shapes and 3D elements;

- GCR is lightweight and highly portable. Delivery and lifting to floors is not a problem, as is replacing sheets in case of need for repairs or direct dismantling of the structure;

- It's easy to work with drywall yourself. Also, it will not be difficult to find craftsmen who can use the material in production and finishing work. In the case of complex structural work, the task becomes somewhat more complicated, since not every specialist is thoroughly familiar with the technology and is ready to use all its requirements;

- Wide target area is an additional advantage. You can build partitions from plasterboard, use the material as a base for any type of finishing, use the sheet for the production of boxes and niches, sewing communications, installing sections of multi-level ceilings, finishing slopes, etc.;

- A quick and inexpensive replacement for plaster - leveling the plane, creating levels, bringing corners together, improving the correct geometry of rooms;

- In most works, eliminating dirty and wet processes, as when using standard plaster mixtures;

- Increasing the speed of project implementation due to minimizing waiting periods for materials to dry - putty, primer, paint;

- Elimination of additional costs for special tools and equipment for material processing;

- Rapid production of thermal insulation packages, as well as soundproofing partitions using manufacturer technology, for example, Knauf;

- Reduced costs for the implementation of any of the projects, thanks to the advantages of drywall!

The general list of positive characteristics also includes the vapor permeability of the material, its environmental friendliness and safety, and high-quality geometry!

By ordering the finishing of slopes with plasterboard from Winzord LLC, you can be sure of:

- experience and highly qualified personnel: for more than 10 years of work in the St. Petersburg market, we have established ourselves as a reliable company;

- quality of the materials offered: we work only with trusted suppliers and leading manufacturers in their industry;

- speed and reliability of delivery: we use personal special transport and our own staff of drivers (delivery within St. Petersburg is free).

+7 +7

St. Petersburg, Kollinsky district, st. Dorozhnaya 7a

We offer a convenient and understandable service. Always welcome a call.

Please note that the prices indicated on the website are not a public offer. Please check with our managers by phone or email for detailed information on the cost of goods and services.

Disadvantages of drywall

- The first of the disadvantages is the increased fragility of the material. It does not tolerate dynamic loads and mechanical stress;

- The second disadvantage is based on the first - instability of structures. When they are overloaded, cracks and chips appear, seams fall out at the junction points, and unprotected corners crumble;

- Lack of moisture resistance. Direct contact with high humidity and water quickly leads the material to a visually unusable state, which is complemented by a loss of strength. Therefore, for wet rooms it is better to use gypsum boards with additional protection with facing materials, or even other special materials that have a neutral reaction to moisture and direct contact with water. The recommendation applies more to bathrooms;

- Reducing the area and volume of rooms that are covered with plasterboard. The value is minimal and depends on the initial geometry of the premises, the type of structure and the method of its fastening, but it is still worth paying attention to this fact when performing calculations for the project;

- Hollow economical walls and partitions are structures with minimal sound insulation. Mineral wool and basalt fillers should be used, taking into account the technology of double cladding of the frame;

- GCR walls can hardly be called durable. They can be punctured, broken, damaged during the removal and installation of furniture, subsequent repairs, or during children’s games;

- GCR surfaces have minimal load-bearing capacity. Therefore, even decorative objects should be installed on them carefully!

Important: Having experience working with drywall, I recommend using special fasteners for gypsum boards - butterfly dowels, driva, Hartmut, umbrellas. Be sure to pay attention to possible loads when purchasing fasteners. In the case of installing or hanging heavy objects and equipment on the wall, it is better to mount directly into a galvanized steel profile, a profile reinforced with wooden beams, or special embeds, thought out at the start of work. Another fastening method is used when installing gypsum boards with glue to the wall. This is the installation of anchors through gypsum boards directly into a wall made of concrete or brick!

Considering the volume of areas where plasterboard is used today, one can cite many more advantages and disadvantages of the material in relation to each individual structure or process. But is it worth doing this if the main qualities and characteristics have already been announced?

Whether you use drywall in your own home or work with another material is up to you. The decision can be based on a body of knowledge obtained from various sources, strictly on the characteristics and features of drywall, but also on design requirements that are important to consider in repairs and decoration!

Dimensions and types of profiles for drywall

The profile for plasterboard is made of cold-rolled metal sheet with galvanized coating. To assemble the structure, guides and rack profiles are used. All cladding profiles are designed for:

- Ceiling.

- Walls and partitions.

- Arch.

- Angle

For the ceiling, guide profiles PN or UD are used, which are mounted along the entire perimeter of the ceiling. They are often produced with perforations so that rack profiles (PP or CD) can easily fit into them. Rack-mounts add strength to the structure.

For walls and partitions, PN or UW (guides) and PS or CW (rack-mount) are intended. If doorways are mounted in partitions, then a reinforced UA profile is used, which is made from higher quality steel. External wall corners require a PU protective profile, which prevents damage during operation. For arches, arched PA is used, which is easily bent into an arc. The dimensions of various profiles for drywall can be found in the table.

Table. Comparative characteristics of the sizes of metal profiles.

| Purpose | Name | Length, mm | Height, mm | Width, mm |

| For the ceiling | Guide PN or UD | 3000 | 27 (side) | 28 (base) |

| Rack PP or CD | 3000 | 27 (side) | 60 (base) | |

| For walls, partitions | Guide PN or UW | 3000 | 40 (side) | 50 - 100 (base) |

| Rack PS or CW | 3000 | 50 | 50 — 100 | |

| For outside corners | Reinforced PU | 3000 — 6000 | 40 | 50 — 100 |

| For doorways | Enhanced UA | 3000 | section 25x25x0.4 | |

| Arched | PA | 3000 (concave part), 6000 (convex part) | The bending radius of the concave part is 500, the convex part is 1000 | |

For high-quality and durable assembly, additional elements are required: anchor and straight hangers, crab connectors, one- and two-level connectors. To fasten the elements you will need anchor dowels and screws.

Do-it-yourself interior wall decoration at the dacha

In creating a cozy atmosphere in a country house, the decoration of the walls in the country house plays a significant role. Materials of varying costs can be used as final decorative finishing.

In the case where the work will be carried out in a seasonal house in which there is no constant heating, preference is given to budget options.

When purchasing a finishing material, it is important to understand whether it can be used in conditions of high humidity, which are inevitable in unheated rooms.

Material selection criteria

In addition to the presence or absence of a heating system, when choosing decorative finishes, it is necessary to take into account the base material of the walls. The most suitable solutions for finishing a country house for seasonal use are recommended:

For enthusiastic and dynamic people, it is better to choose a finishing method that allows you to easily change the finish layer. For such owners, it would be more correct to choose plaster or gypsum plasterboard sheets as the interior decoration of the walls at the dacha. For a perennial option, it is better to choose a finish with a soft texture and color.

Preparation

Finishing is the final stage in the repair, therefore it is carried out after all the work on laying engineering and plumbing communications has been carried out. When deciding to purchase material, you should remember the specifics of unheated rooms.

If you plan to visit the house in winter, then raw materials should be selected that are resistant to possible sudden temperature changes. It is also worth considering how to insulate the walls from the inside.

Any finishing begins from the back room of the upper floor and is carried out towards the exit. If work is carried out with a high degree of soiling: plastering, painting, whitewashing, then the already treated surfaces should be protected with plastic film.

The necessary materials should be calculated and purchased in advance, and the working tools should be prepared.

Finishing with natural materials

There are many options for finishing brick or foam block walls and the inside of a wooden house. Modern technological finishing materials offer various cladding options, for example, wood wallpaper, which is made from natural wood. They are applied to the walls of the cottage indoors using a special adhesive solution. The main and very significant disadvantage is their cost.

A less expensive method would be to decorate the interior walls of a house with block-house material. Before installing the slabs, allow them to rest indoors at room temperature for 48 hours. The material is mounted on flat walls, on pre-stuffed wooden frame beams.

Fiberboard will be an inexpensive finishing material

The elements are screwed to the guides with self-tapping screws through the base of the tenon, which all boards are equipped with. The elements are connected to each other using a groove-tenon system. To give additional external gloss, upon completion of the work, the surface can be coated with varnish, wax or stain.

Lining is one of the easiest materials to work with, a way to inexpensively cover the walls of a country house with your own hands. This results in a completely environmentally friendly and clean finish. The lining is mounted by stuffing slats onto horizontal guides, fixed at a distance of 0.5 - 0.7 m from each other. For more information about how and how to decorate a country house, watch this video:

The wood must first be treated with antiseptic and fire-retardant compounds.

Preferred Materials

Thus, there remains a very small selection of materials that will last a long time in an unheated country house without any problems. The best way to decorate the walls of a country house is with plaster, putty and painting. For panel materials, you can use wooden or plastic lining, and for flooring it is better to use a tongue-and-groove floorboard.

Moreover, preferences in the use of these materials are divided according to the type of house frame: for stone houses they use plaster and plastic, and wooden lining has firmly established itself as the main material for finishing wooden houses.

Plaster

This is the most reliable and cheapest way to level the surface of the walls. Plaster tolerates changes in humidity and temperature well, and if you finish it with putty and moisture-resistant paint, you will get a beautiful and smooth surface. The wall surface finished with plaster will remain intact for decades; the wall can be washed without fear of damaging the surface.

Plastering is carried out according to the beacons. They are glued to cement or gypsum mortar. To level the applied solution, use a long rule. A cord is stretched along the wall, along which all the beacons are positioned and aligned vertically.

The most economical option is to mix a solution of sand, water and cement yourself in a ratio of 3:1:1. But you can buy ready-made dry plaster mixtures, the composition of which is balanced by the addition of various additives and plasticizers. This will make the process of leveling the surface easier.

After the plaster has been grouted and dried, further finishing can be done with regular or decorative putty.

PVC panels

Another material that is not afraid of moisture and temperature changes is plastic lining. Many different types of panel coverings are made from plastic, including siding, which can be used to cover the outside of any building.

It is convenient to lay mineral wool insulation under the PVC panels between the lathing slats. PVC lining has a variety of designs, sizes, and surface types, so it will not be difficult to choose a material to suit every taste.

The lining is convenient because you can easily install it yourself. Externally, all joints and transitions are masked with corners and connecting strips, so the coating will turn out neat even if the installation is not the most skillful.

Cladding with insulation

In an unheated room, only a galvanized metal profile is used for the frame under the lining, since the bar can become deformed due to changes in humidity, which will affect the quality of the cladding. When covering large areas, it is necessary to provide expansion gaps around the perimeter.

Ceramic tile

Tiles are also a universal material, with the help of which you can tile not only the floor indoors in your dacha, but also finish the basement and porch.

Before tiling the floor or walls, it is necessary to perform a leveling screed or plaster.

Wood flooring

The tongue and groove board is an ideal material for arranging floors in the country. It can be laid on a screed, or it can be laid on joists with rough padding. With this option, the logs are laid on timber, which is the load-bearing elements of the basement or interfloor floors. This timber is laid during the construction of the box.

A solid wood board can be used to decorate the inside of a country house, while for decking on a veranda or garden paths you can safely use a board made of composite materials or heat-treated wood.

If a construction board was used for laying, then it can be covered with thick linoleum on top. Such a board can also be painted, having previously puttyed and sanded all surface defects.

Wood flooring of wood quality can be sanded and covered with stain or parquet varnish.