When performing repair and finishing work, special attention is paid to creating interior design. Various materials and coatings are used to decorate walls. The most popular among the known options are decorative plasters.

One of the varieties of such options is decorative plaster, which creates the effect of stone on the wall. When using this material, a coating is created on the wall that imitates decorative stone. To create a stylish and unique design, you should study the features of choosing a material, as well as learn about methods of applying the composition to wall surfaces.

Composition and characteristics of stone-like plaster

Depending on the type of material, the composition of the plaster mixture may differ. However, there are basic components that should always be present in the mixture:

- A cement or gypsum composition is used as a base.

- Granular elements that include sand, quartzite, mica...

- Thickeners are added to give the mixture the desired consistency.

- Dye to give the solution a suitable shade.

In rooms, stone-like plaster is applied in a thinner layer

The use of such a composition makes it possible to impart strength, moisture resistance and increased wear resistance to the coating. Plaster with a stone effect not only gives the walls a beautiful appearance, but also creates a reliable coating.

Imitation methods

Creating stone-like plasters does not require leveling the surface, and maximum freedom is allowed when applying the design. The exception is imitation marble, in which wax is applied. After polishing the surface, irregularities and tool marks appear.

An imitation of a stone surface can be made of relief tiles made of gypsum, cement-sand mortar. Plastic curtain panels, which are often used for façade cladding, are practical and attractive in appearance.

Relief surfaces are created from foam plastic. Stone finishing by applying plaster is a simple and practical way to imitate masonry. To decorate the surface, polymer mixtures containing marble chips and rounded granules are used.

Pros and cons of stone plaster

Decorative material that imitates real stone weighs much less, which reduces the load on the walls. In addition, the plaster composition has the following advantages:

- The decorative effect created by plaster gives the walls a beautiful appearance.

- Walls with this coating allow steam to pass through well and also normalize air humidity.

- The coating has an increased service life.

- The special composition allows you to resist the spread of fungal colonies and mold.

- Facade coating options are resistant to sudden changes in weather conditions.

- Using imitation allows you to save on the purchase of real rocks for surface finishing.

Among the shortcomings that users noticed are the following:

- If a section of the decorative coating is damaged, it will be difficult to restore it, since a large area of the coating will have to be replaced.

- The material can accumulate large amounts of water, which leads to deterioration in the quality of the coating.

- Exposure to elevated temperatures can lead to softening of the plaster on the wall, this is especially true for the facade of buildings.

imitation stonework on the plinth

Required Tools

Before treating walls and applying decorative material, you must prepare a set of tools in advance:

- Trowel, spatula or trowel for application.

- Construction mixer for preparing the mixture.

- Roller, brushes or rags for applying the solution to the walls.

- Level, ruler and rule for distributing the mixture.

- Masking tape to determine the level of distribution of the solution.

- Container for mixing building material.

- Personal protective equipment for ease of work.

Making decorative stone without using a mold

The production of artificial stone material is carried out not only using special matrices. It is also possible to make such decor without the help of molds. This option is very simple. Despite this, it allows you to produce original stones for cladding building structures in a private house.

Before you make an artificial stone without a shape with your own hands, you need to prepare a stencil. It is performed on ordinary oilcloth. Instead, a cardboard sheet of suitable size is often used. The dimensions of future stones are drawn on the selected material.

Although the entire process of making artificial stone decor is simple, it requires time and minimal experience in working with building materials. Therefore, it will be easier for many to purchase ready-made products and hire specialists to install them.

Decorative stone created without using a mold Source samsmogy-remont.ru

The process of manufacturing artificial stone decor is performed as follows:

- Construction plaster is mixed with water in a silicone container. Instead, you can use any container, inside of which a garbage bag is previously placed. Moreover, you can always throw it away after use.

- The stencil is protected with transparent oilcloth.

- The prepared mixture is distributed over the surface of the oilcloth within the boundaries indicated on the stencil.

- The drying gypsum mixture is given the required relief. To do this, use spatulas of different sizes.

- The drying gypsum mixture is divided into separate fragments in accordance with the markings on the stencil.

- The finished hardened tiles are removed from the oilcloth after about 15-20 minutes.

- Tiled decorative material is dried for 1 day.

Preparing the mixture

Usually, when working on wall finishing, ready-made solutions are purchased for application. In this case, to prepare the mixture, you will need to pour the composition into a large container, fill it with water in the ratio indicated on the package, and then stir using a special mixer. It is necessary to stir until the mixture acquires a homogeneous consistency.

It is recommended to use stirring in two stages, this will create a homogeneous mixture without lumps.

A mixer attachment is used for mixing.

Preparation of the solution

If you decide to make a polyurethane mold model, you can purchase a two-component solution, such as Duramould ET 45A. Solutions produced by Mold Star, E-Series, NY 600 Series are also suitable.

The package includes two containers with two types of liquid - white and red. It is necessary to take 0.5 liters of each solution and mix it in a bucket with a mixer.

How to make your own mixture

If you want to save money on purchasing expensive building materials, you can make the mixture yourself. Decorative plaster to look like stone with your own hands is quite easy to do; you can use one of the following options:

- Mix putty with sand. For one bucket of putty you need to add 1.5-2 liters of regular sand. If necessary, water is added to the resulting mixture, and then everything is stirred with a construction mixer.

- Lime, cement and sand are mixed in a ratio of 1:1:2, then water is added in the required proportion and liquid glass (5% of the total mass of the mixture).

The prepared mixture can be used to decorate any surface. At the same time, a properly prepared solution will not differ in quality from mixtures purchased in a store.

Cost of decorative plaster per square meter.

Ordering the service of a construction team is the most expensive finishing option. The total price is determined taking into account the cost of the plasterers' work (charged per m2). A separate expense item is the cost of purchasing plaster mixture and consumables.

The advantage is the speed of finishing: with your own hands, the work is done much slower, which is associated with a low level of organization and insufficient plastering skills.

On average, professional services cost between 1000-1500 rubles per sq.m. decorative plaster. When contacting a construction company, you should expect an additional increase in price by 15-20%. And this does not take into account the costs of building materials.

If you have the desire (skill, knowledge, time, health), then with this money you can buy a high-quality mixture and do the work yourself.

A budget option is do-it-yourself plastering with inexpensive mixtures and solutions prepared with your own hands.

Preparing the base

To ensure quality work, care should be taken to prepare the walls. To prepare the base, follow these steps:

- Initially, it is necessary to remove all elements from the old coating (wallpaper, remnants of paint or whitewash, decorative inserts).

- After removing large parts, the surface should be treated to give it a smooth shape.

- Large defects, chips, cracks and other imperfections must be repaired with cement mortar.

- After the mixture has dried, you can treat the wall with antiseptics and chlorine-containing substances, and then rinse it.

- To improve adhesion to the solution that will be applied to the wall, it is recommended to coat the surface with a primer.

Decorative stone effect plaster will adhere firmly only to the wall that has been pre-treated. If preparation is not completed, the composition will not adhere well to the surface, which will lead to deterioration in the quality of the coating.

Techniques for creating imitation stone from plaster

There are various techniques for creating a wild stone coating on the facade and indoors. The choice of method of applying the material depends on the characteristics of the base, the quality of the plaster composition, as well as the experience of the master. To decide on the choice of technique for creating decorative stone from plaster with your own hands, it is worth considering the features of existing options for performing the work.

Smooth stone surface

The decorative coating on a smooth surface in the form of stone is similar to decorative plaster Travertine. Usually, to create a pattern that imitates stone, solutions with different colors are used. In this case, the prepared composition is applied to the prepared surface in several stages. Then a multi-layer coating with different patterns of stones is formed. At the final stage, the wall is processed with a grinding machine or a trowel to create an even coating.

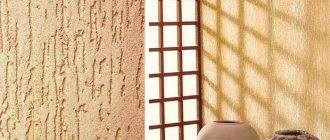

Textured stone surface

Plaster can be used to create textured coatings. In this case, one of the following methods of performing the work can be used:

- Applying plaster in a continuous layer with further scratching of recesses to form a textured coating.

- Layer-by-layer application of the solution. In the first layer, the mixture is applied evenly, the second layer forms a textured surface on the wall.

Masonry

One of the most common design options is to create brick or stone masonry. In this case, seams are formed on the wall, resembling recesses between individual elements:

- The building mixture is applied to the wall.

- After the solution has partially dried, a seam is formed using a trowel or chisel.

- You can create a pattern in another way, for this you will need a stencil. It must be applied before applying the solution. When the mixture completely covers the wall, all that remains is to remove the stencil.

- In the final stage, it is necessary to process the coating with a sanding disc.

Imitation with impressions

You can imitate natural or artificial stone using impressions or matrices. The process consists of several stages:

- The prepared solution is applied to the pre-treated wall.

- A matrix, previously moistened with water, is applied to the wall.

- The matrix is pressed tightly against the wall to form a pattern, after which it is removed. This must be repeated until a uniform pattern is formed on the wall.

- If a section of the material comes off the coating, it must be reapplied and then the procedure repeated.

- Uneven surfaces on the wall should be sanded using a sander.

Using an impression to imitate masonry

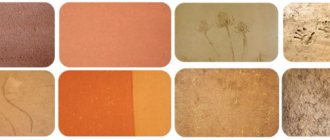

Imitation of texture.

Plaster is used to create both solid stone (a full-wall slab) and masonry.

The block wall imitates expensive finishing materials (marble, granite, lapis lazuli, etc.) or ordinary building materials (sandstone, limestone).

Marble wall decoration.

The plaster is carefully leveled and brought to perfection. It is better to use gypsum compounds with a deep, white internal “glow”. When the wall dries, it is leveled with a sanding mesh and covered with a layer of acrylic primer to “nourish” the pores. This will allow the finish to adhere as firmly as possible to the surface.

Then stone imitation is performed for interior decoration:

- Materials. Prepare 2-4 buckets of plaster of different colors: use ready-made mixtures of various shades or a white solution to which liquid pigment with an acrylic binder is added.

- Main color. The surface is covered with a general tone. The luminosity of the entire plaster depends on its saturation.

- A marble pattern can be created in two ways:

- Step by step creation. Using a spatula, apply stains first of one shade, then of another.

- Simultaneous installation. Using a small spatula, solutions of different shades are applied to the edge of the main working tool. Then they are “smeared” on the wall in such a way as to achieve an uneven mixture of shades directly on the surface of the wall. This imitation of natural stone is simpler.

- Smoothing. Irregularities are leveled with a trowel or spatula. Make sure that the pattern is as flat as possible, but not completely cleaned off. In case of excessive thinning of the coating, the operation is repeated.

- Waxing. The plaster is covered with a layer of wax - it gives the wall water-repellent properties and saturates it with a natural shine.

- Polishing. The wax coating is carefully polished with a soft sander attachment.

This is how you create an imitation of natural stone with your own hands. When “recreating” marble, natural tones for this stone are used.

To learn how to make beautiful plasters and introduce new, interesting ideas, you need to train. It is better to use a piece of drywall for this, and only after testing, move on to the wall.

Imitation of building stone slab.

A simple inexpensive stone does not have a smooth shiny surface. It is uneven, rough, covered with tool marks, natural grooves, and tubercles. This complication of the texture only makes plastering work easier - there is no need for careful leveling.

This do-it-yourself stone imitation is done in stages:

- Preparation. The wall is leveled, dried, and saturated with penetrating primer.

Primer – preparing the surface for any type of plaster. An unprimed wall does not hold plaster well.

- First layer. The plaster is applied with a convenient tool (trowel, trowel) and leveled. Without allowing it to dry, the layer is roughened by jabbing blows with a brush or square bristle brush.

Cover the entire surface. Imitation of natural stone looks more believable if it is not done smoothly.

- Second layer. Apply after the first coat has completely dried.

Only part of the surface is covered with plaster (small shapeless spots).

These inserts are leveled over time (you need to wait until the bottom layer of the new plaster has already “set” and the top layer is still wet). This is how they achieve a kind of “ragged” relief.

- First coloring. Use “breathable” acrylic paint.

Dried plaster is painted with a roller and brush (in poorly accessible recesses).

- The second painting should be a different color. A short-haired roller is used so that the color is applied only to the raised parts.

- Coating. The plaster is protected with wax (which must subsequently be sanded) or acrylic varnish.

The pattern depends on the nature of the surface, the area and direction of the spots of the second layer, and their thickness.

The difference in colors should emphasize the volume. To do this, the first painting of the plaster is done with a darker paint, the second - with a light one. Or vice versa.

A metallic paint will add elegance and sophistication to the wall (a metallic dye, for example, aluminum powder, is added to the pigment of the second layer of paint).

Features of plastering work on the facade

When decorating the facade of a building with decorative plaster, the following features of the work should be taken into account:

- For the facade, you should choose stronger and more wear-resistant materials, since the plaster will be in contact with the external environment.

- It is worth taking into account sudden temperature changes, so before purchasing the mixture you need to pay attention to the main characteristics of the plaster.

- For external walls, it is recommended to use decoration in the form of stones and cobblestones. This coating will create an imitation of real rocks.

- If overheated for a long time, the composition may dry out, which will lead to a deterioration in its properties. In this regard, it is recommended to periodically moisten the composition while performing work.

What mistakes to avoid

Before you start decorating, you should pay attention to the most common mistakes that beginners encounter. When performing finishing work, the following mistakes should be avoided:

- It is necessary to remove all small granules, eliminate unevenness and roughness on the coating. These small details not only spoil the appearance, but also spoil the quality of the coating.

- When creating artificial masonry from stones, the depressions between them should be made of different widths and shapes. This will create maximum resemblance to natural rocks.

- If you want to create brickwork or block design, you must use a grid. Without a special mesh, the pattern of lines will be uneven, which will ruin the appearance of the wall.

The tips and recommendations presented will help you avoid the most common mistakes when creating decorative wall coverings.

Stone-like plaster photo on the facade and inside the house

If you want to evaluate the possible options for decorating walls using decorative stone-like plaster, you should look at photos of the finished works. In the photographs you can see how the interior of the room will look depending on the chosen decoration method. Also, thanks to the photographs, you can pre-select a design option that will suit a specific type of room.

Tyutyunnikov Dmitry

Article verified by a decorative finishing specialist