The finishing of the facade should not only reliably protect the base from the harmful effects of the environment, but also create the desired decorative effect. Vertical siding is becoming increasingly popular for cladding houses and cottages, being an excellent alternative to the horizontal variety. Naturally, working with such a product has its own characteristics that must be taken into account.

Horizontal or vertical siding, which one to choose?

Pros and benefits of vertical siding

Siding standing vertically has many advantages : 1) It is unique; you won’t see it among your neighbors within 20 km. So everyone will gasp and ask, what is this? Is this corrugated sheet? (by the way, mine really looks like white corrugated board and it’s very funny) 2) It’s beautiful. Despite its unusual aesthetics, 80% of neighbors rated it as beautiful. But I would choose only white or two colors at once. Since white looks more noble 3) It is very quick and convenient to install. It can even be installed from a ladder. One is on top, the other is below. One panel is installed in a couple of minutes. Very easy to insert into the grooves 4) It will make you feel special. Especially when you master the technology of its installation 5) You will have to pray to the dealer to sell you vertical siding. After all, they are so afraid of this, since this is their first time.

Cons of vertical siding

Well, where are the disadvantages or disadvantages of vertical siding: 1) Incomprehensible installation technology: you need to insert a starting and finishing strip in the corners. Below and above J-bars. In general, non-trivial cutouts have to be made around windows to close all the holes. 2) J-bar at the bottom. It needs to be perforated manually, otherwise water will stand there and not only: leaves and other dirt will also settle there very well. Once a year you will have to wash it, and in winter every month you will have to clear out ice and snow from there (who came up with that?) And without the J-ki the bottom will look inferior 3) Dirt and untidiness. Since the product is rarely purchased, it sits in the warehouse for a long time and gets dirty. This, of course, can be washed, but it’s still unpleasant 4) Nobody knows anything about installation! I had to raise experts from the Grandline and even they all didn’t know about the correct installation (well, now I’ll at least tell you) 5) Oh yes, and don’t take the drain strip, just take a metal ebb, otherwise you’ll be doubly tired.

In general, if you are special, are not afraid of problems and like to experiment, choose vertical siding rather than horizontal!

How to install vertical siding correctly? Here are step-by-step instructions for its installation .

(And this is what vertical siding looks like from afar)

Facade design with vertical cladding

Why do you need vertical siding? Yes, simply because a facade with such cladding looks very impressive - especially when it is combined with horizontal or plinth panels.

Note: In addition, vertical stripes visually increase the height of a building or room, so this arrangement of long lengths looks most advantageous on the facades of one-story houses or on the pediment. Vertical mounted panels do not have any more significant advantages over horizontal ones.

Both the façade and the pediment are covered in the same way

A universal option that can be mounted in any direction

Cladding the facade and balcony of a two-story house with vertical panels

A group of vertical siding houses features vibrant colors

Combining vertical panels with brick plinths

Fiber cement panels can be mounted in any position

As you can see in the photos presented as examples, the vertical cladding looks very interesting. If only a few manufacturers offered this option a few years ago, today panels for vertical and universal installation are present in the product lines of all more or less well-known brands.

Parameters and configuration of panels

Since siding is made from materials of different structure and weight, it would not be entirely correct to talk about its installation by generalizing information. They differ slightly in design, and accordingly, are equipped with different fittings. Therefore, we specify the information using the most popular vinyl panels as a basis.

- Products designed specifically for vertical installation are very easy to identify by their form factor configuration. Along one edge it has a characteristic protrusion that stands out volumetrically on the cladding.

- On the contrary, horizontal panels have a depression in this place. That is why they cannot be mounted vertically - so that rainwater does not get into the structure through these depressions. As for the sizes, on average they are approximately the same as in the picture below.

- To install panels on the facade, fittings are required. Its set is similar to that used for horizontal installation - except that the elements are mounted in a slightly different order.

Siding for vertical installation differs due to the form factor

Set of accessories for vertical siding

You can decorate an internal corner in different ways.

The selection of a set of necessary fittings is influenced by the architectural features of the facade. Some of the items may not be needed at all. In addition, the same action (for example, going around an internal corner) can be performed in different ways, which is what we see in the picture above.

We will talk about the purpose of this or that profile when describing the siding installation technology.

Do-it-yourself vertical siding installation. Lathing

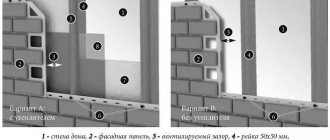

There are four ways to install siding: 1) Directly over the sheathing 2) Over wooden sheathing 3) Over hanging profiles for drywall 4) Points 2 or 3 with insulation

I chose the second option for siding, that is, wooden sheathing without insulation. I didn’t do any insulation, since I already have 200 mm in the wall and another 25 mm won’t help much in any way, and it will delay it a lot in terms of time. Since the siding is vertical, the sheathing must be horizontal. Well, it’s not exactly horizontal, I didn’t even particularly level it, you can bevel it by 2 centimeters and nothing will happen, the main thing is that the pitch of the sheathing is approximately 40 cm.

But such a creative installation of wooden sheathing can be

Note: vertical siding feels normal on the sheathing not only after 40 centimeters, but also after 65 centimeters (but it is better to do 400 mm, so as not to take unnecessary risks).

Differences from horizontal: which is better

Which one to choose, vertical or horizontal siding? Their differences consist not only in installation technology, but also in technical features. Such panels are an independent type of finishing material. Their main feature is that there is no perforation at the bottom, which significantly improves and facilitates the drainage of moisture and condensate. However, the upper part opens, where water from rain and snow can get in. Therefore, the mandatory use of overhead profiles is necessary.

Another difference is the fixation of parts. Vertical panels are attached from a corner or from the center. The fastening scheme should be carefully thought out, which is quite difficult without experience.

Important! Vertical panels have low maintainability. If a certain area is damaged, the entire wall must be dismantled.

OLYMPUS DIGITAL CAMERA

Board for sheathing siding

Which board is suitable for siding? I thought for a long time and finally bought a 100×25 dry board for lathing under the siding. This one costs 9 thousand per cubic meter in season and 8 thousand per cubic meter out of season. I don’t recommend using natural moisture; when drying, it can squeeze out the entire siding.

In fact, the dry board turned out to be between 25 and 29 mm thick, which is a little unpleasant, but not lethal for siding. True, in some critical places I still passed a particularly thick sheathing through a thicknesser (more information about thicknessers in the text which tool is needed for framing).

I first unrolled the board lengthwise so that it became 50x25 in size. This is economical and sufficient for siding, but there is also a minus: often the 4.5 mm self-tapping screw in the corners cracked it. It is convenient to cut a board lengthwise on a homemade machine: we screw a powerful 1-2 kW circular saw upside down to the table from below. Then on top of the table you need to place a stop 50 mm from the blade. Now we simply press the board against this stop and at the end we get two even 50x25 boards.

Window strips for vertical siding. Video

Window strips are made in the same way as for horizontal siding. I filmed a report about this, but the photographs of the process were destroyed, and there was nothing to use again. Here is a video from YouTube of adequate videos (don’t even watch the rest):

Where are they used?

See also

How to build a house with columns: 5 best ideas

Sheathing using siding with a vertical direction is becoming more and more popular and in demand.

In this case, the material is used not only for exterior decoration of the house. Here the material of manufacture and the appearance of the products play a role:

- Vinyl and acrylic panels are suitable for finishing cottages, as well as private homes with large dimensions. They are used to cover facades and pediments;

- Aluminum panels are expensive, and therefore are mainly used for finishing shopping centers and industrial and public buildings;

- Galvanized steel is suitable for residential buildings, industrial buildings, and warehouses. They are good for covering fences and architectural structures;

- Zinc siding is not used almost anywhere in our country because the price is too high.

Making a choice is not difficult, but the main thing is to use high quality material.

How to Install Vertical Siding. Upper J-strap (siding j-strap)

After the corners are in place, we stretch the thread between their upper parts and begin to twist the J-bar along it. In general, I turned the J-bar according to the level, without really bothering with the threads, and everything came together for me, the walls were the same in height.

There is one important reason to lower the J-bar lower (I moved 3-4 cm down from the edge of the rafters) - if you make overhangs from siding, you can not make a receiving jack for these overhangs, but simply throw them on top of this wall jack . Tested, it works. But do not forget that the corners must also be lowered by this amount in advance.

Installation of vertical siding. Bottom J-strap (siding j-strap)

After the upper jack, you need to secure the lower one - and so that a regular siding panel + 1 centimeter fits there. Since our corners are equal in height to conventional vertical siding panels, you can simply lower the lower J-bar a centimeter relative to the corner and then attach it level to the other corner. Everything was complicated for me by the fact that I also bought a plastic drain strip (jakes in the photo below)

And here it is in late autumn (snow and leaves!):

Installation of vertical siding. Drain plate

So drain bar, what kind of fruit is it? This is an analogue of a metal cast, only very small, crooked and useless. Moreover, it needs to be fastened under the J-bar, which means that they won’t let us easily attach the bottom jack so easily, we need to first calculate its place, and then first place the siding drain strip lower, and so that the jack’s fastenings are higher than the drain strip’s fastenings.

In general, it’s better for you not to know. But the result is not as bad as it could be.

Installation technology

Starting bar

- The first panel is pushed into a pre-installed gutter of the corner profile. Having inserted the panel, you need to hook it with the locking hook on the starting bar and pull it up until you hear a characteristic click.

- Make sure the fastening is secure by pulling it from side to side, check whether the panel can slide in the lock, move it so that a temperature gap is formed between the receiving groove and the edge of the siding.

- Install the fasteners strictly in the center of the hole.

Rules for installing fasteners

- When installing the panels, make sure that they do not sag and maintain uniform tension on all edges. A misalignment in the installation of even one panel will affect the result of the entire work.

Installation of framing profiles

Note! If there are any obstacles on the working wall (power line traverse, watering tap), recesses must be cut in the panels to be laid so that they fit exactly along the contour of the place.

Installation of vertical siding. Row siding panels

So, ordinary panels. Well, everything is simple with them. I put a spike in the corner to help it hold better, then one end into the upper jake, bend the other and stick it into the lower one. All this must be under tension, otherwise, most likely, your siding panel is too short (that is, the lower and upper jacks are too far apart).

Then we set the first siding panel according to the level, and then you don’t have to look at the level, everything will go as it should. The panels snap into place PERFECTLY, unlike horizontal siding (according to stories), I have not encountered any problems.

Advantages of vinyl siding

Combination of horizontal and vertical views

Among the many positive qualities of this material, the following advantages can be highlighted:

- vertical panels are fastened using an edging profile - a new fastening element;

- the material is equipped with an anti-hurricane lock, which is not equipped with horizontal siding;

- ease of installation and ease of operation;

- the service life of the material is more than 50 years;

- resistant to fading under exposure to sunlight;

- vertical siding is resistant to extreme temperatures;

- vinyl panels are durable and elastic;

- high resistance to fire and moisture.

The metallic look has its own number of positive qualities:

- wide variety of colors and shapes;

- provide natural ventilation of facades;

- Possibility of installation in any season;

- equipping with special locks greatly facilitates installation;

- service life of at least 30 years;

- not subject to fading, at least for 10 years of operation;

- resistant to very high temperatures – from -600 to +800°C;

- resistant to weather conditions;

- durable and resistant to mechanical stress.

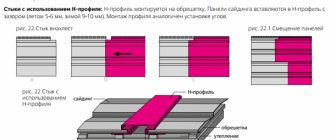

Installation of vertical siding. H-plank (H siding plank)

H-plank is the heavy cavalry for vertical siding, the need for which does not arise very often. I placed an h-plank in the middle of the gable so I could start with two tenons on either side of the gable.

It turned out interesting:

I also used an H-bar at the meeting point of the gable and eaves overhangs. Oh, and in one more place above the porch roof, although a jack could have been used there, the h-plank just seemed more beautiful to me (but I cut off the lower part of it, otherwise it would have been visible).

Also in the photo you see a ventilation grille for the pediment from Tekhosnastka, here it is larger:

Tips for choosing

In order to beautifully and efficiently sheathe a structure, it is necessary to pay attention to the fact that the siding panels have the same level of coloring on both sides (painting in the mass), which guarantees the protection of the material from rapid paint shedding and fading.

Also, one cannot ignore the thickness of the metal panels and the cut, which ideally should be the same on all elements.

It is best to choose siding from trusted manufacturers, which will reduce the risk if you need to re-order a batch of material.

Installation of vertical siding. Gable

On a gable with vertical siding it is more difficult, since its panel is 16 centimeters thick, and the horizontal siding is about 23 centimeters, which means it will have to be cut more often. But I didn’t experience any particular problems with this. The main thing is to make a template for the slope of your jake and then everything will go like clockwork.

Unusual design solutions

As a rule, such material is not often used to finish the entire facade. The main area of its use is the cladding of individual parts of cottages. The combination of two differently oriented types of siding for exterior decoration allows you to correctly place accents, resulting in truly elegant design solutions.

Vertical siding looks great on its own. Currently, panels in four color schemes have gained the most popularity on the market:

Most popular colors

- cream;

- cappuccino;

- banana;

- kiwi.

Metal vertically oriented siding is also found in other color options - it’s just that this material is still much less widespread than its vinyl counterpart. If vinyl siding is more suitable for residential buildings, then vertical metal siding is more often used for cladding industrial and commercial buildings.

Installation of vertical siding. Pediment and cornice overhangs

I decided to make the gable and eaves overhangs also from vertical siding. It turns out to be a very budget solution. All overhangs (42 linear meters) cost about 10 thousand rubles. And special overhangs cost about 25 thousand. Moreover, vertical siding does not need perforation; it is well ventilated due to the tenon. The only thing is that stubborn wasps can fly inside through the thorn, but this is a minus, you have to accept it.

Characteristics and conditions of use

Vertical aluminum siding

The type of finishing we are considering is decorative panels made of aluminum or galvanized sheet steel, protected from external influences by a special multilayer coating made of polymers of various colors. As for the vertical design we are considering, it is represented by special plates that have a smooth or structured surface and imitate the covering of boards.

In addition to the main blanks, the set of panels includes a number of decorative elements that facilitate their installation and give the building façade a neat, finished look. Vertical siding plates have the following remarkable properties that completely cover the cost of their purchase:

- durability (service life – up to 50 years);

- decorative appeal;

- resistance to climatic influences while maintaining the brightness of the color palette;

- environmental friendliness, eliminating the possibility of the material emitting harmful substances;

- ease of installation of panels (due to their special shape, which significantly simplifies the finishing of building openings).

Before installing siding panels, you will definitely need to consider the issue of placing insulating material that reduces the thermal conductivity of the outer covering. We especially note that finishing with siding will not require you to prepare a perfectly flat surface, since minor irregularities are hidden under a special sheathing (frame) used to fasten the panels.

FAQ on vertical siding:

Vertical siding price per m2

The price of vertical siding is almost the same as the price of horizontal siding. The price of vertical siding is quite a bit more expensive due to the fact that each of its panels measures 0.45 square meters and, in fact, it is a non-perforated soffit, which has grown to 3.05 meters. The price per m2 of vertical siding is approximately 250-300 rubles.

Get yourself a discount, since the vertical one often sits in warehouses. Then the price will match the horizontal one. By the way, the price in Moscow for vertical siding is no different from the prices in Nizhny Novgorod and other cities.

Vertical siding photo

What does vertical siding look like? I had the same question before purchasing. Now I can show you my façade!

Buy vertical siding

You can buy vertical siding from any Grandline dealer, and if you are from the Nizhny Novgorod region, then through me you can buy vertical siding cheaper. Contact us! In Nizhny Novgorod you can buy vertical siding through me with a 20% discount.

Vertical siding installation instructions (siding literature)

There are several instructions for installing vertical siding. I’m posting everything I have: Grand Line installation instructions for vert. siding American installation instructions vert. siding A whole book on installing all siding

Vertical siding. Calculation

Many people are interested in how to calculate the amount of siding to decorate your home? Vertical siding as finishing occupies 0.45 sq.m. like a panel. Accordingly, you can divide your facade area by 0.45 and get an approximate result, and then add another 15% for cutting.

Reviews for vertical siding

1. Since no one uses it except me, please accept my review:

Vertical siding is amazing and unusual. And easy to install (except for some ill-conceived moments).

2. There was also a review about a neighbor’s siding:

The material is original, at first it seemed quite thin to me, but during the installation process I was unable to rip out its connection (without breaking it) and realized that if a powerful hail does not occur (hail can damage the siding, as I understand it), then it should stand for 20 years without changes.

What is the length of vertical siding?

The length of vertical siding is 3 meters 5 centimeters. Or 3.05 meters

Soffit vertical siding

Indeed, vertical siding can be used as a soffit, since it is ventilated even without perforation. Here's a life hack, just don't tell anyone). Otherwise, the price of vertical siding will be raised and cheap soffits will be destroyed. Well, by the way, not everyone likes such spotlights visually.

Vertical siding: panel width and length

I already spoke about the length of the siding above, but the width of the panels is interesting - 16 centimeters or 160 mm - this is the visible part of the siding, in fact, in the rough part it is another 3-4 centimeters longer.

Vertical siding deck

Don't buy Deke siding, better buy Grandline because I already tested it. And with the deck again you will have to fill the bumps (in fact, this is a joke). Deke siding is very decent, but more expensive than Grand Line vertical siding.

Specifications

Manufacturers offer vertical siding made from different materials. Panels can be made of plastic, metal, fiber cement. The most widespread are PVC panels made of vinyl and its more modern analogue - acrylic.

Both types of siding have similar production technology and are produced in the same sizes. Both vinyl and acrylic panels are made of two layers. The inner layer ensures the strength of the product, and in addition to modifiers and stabilizers, high-quality dyes are added to the outer layer.

Dimensions of vertical plastic panels: length - 3100 mm, width - 200 mm, thickness - 1.1 or 1.2 mm. Acrylic siding differs from vinyl siding in its glossy surface and richer range of colors. If vinyl panels are produced in lightened colors, then acrylic panels have bright shades.

Metal siding is made from sheets of galvanized steel and aluminum. There is vertical siding made of zinc. Metal sheets are produced with a thickness of 0.5 mm, a width from 120 to 550 mm, and a length from 2 to 6 m. The outer side of metal siding is painted, often given the texture and color of various types of wood.

Fiber cement or cement fiber siding has gained little popularity. There are several reasons for this:

- significant weight;

- complexity of installation;

- use of special tools;

- high price;

- poor color range.