The cladding for the house has been selected. Now a new task: how to attach siding? The process is simple, but there are many nuances that need to be taken into account in the work. It depends on them how long the cladding will last, how smooth and beautiful it will be. And will mold and mildew appear underneath it? In general, let's figure it out!

What tools will be needed for installation?

The following tools are used to install siding:

- Construction level - to install the sheathing exactly horizontally. This determines how neat the entire façade of the house will be. We don't want rows of panels to float freely along the wall, do we? It’s good if you have 2 levels at once: short (up to 1 m - for small fragments of walls) and longer - from 1.5 m or more - for the main surface of the walls.

- Roulette. The siding panel can be from 3 to 3.6 m long, so choose a tape measure no smaller. A 5-meter one is quite suitable.

- Screwdriver or hammer. As a rule, the first one is used - for fastening siding with self-tapping screws. If you choose wood sheathing, you can use nails to install it. Then you will need a hammer.

- A hacksaw for cutting siding - vinyl, acrylic or metal. You can replace it with a grinder or jigsaw.

- Drill: if the walls of the house are made of brick, foam blocks or concrete. In this case, holes are made in the walls into which dowels are inserted.

- A punch is a special tool for making perforations in siding. Sometimes it is necessary to cut off the perforations on window and finishing strips, and using this tool you can make a new one.

You may also need other tools, depending on the situation and the materials you use. For example, a diamond blade or circular saw may be useful for cutting fiber cement siding.

Installation instructions for metal tiles Monterrey

Material calculation

Since it is possible to calculate metal tiles for a roof only by knowing the exact dimensions of the building and its roof, work begins with taking dimensions. The only tool needed at this stage is a long tape measure. If the roof structure is complex, it is divided into separate planes.

In the case of a gable roof, to calculate the number of sheets of material, the length of the eaves is divided by the working width of the sheet. Incomplete numbers are rounded upward. The dimensions of the roof are taken based on all its elements. The more measurements you take, the more accurate the cutting of the material will be. After taking measurements, the amount of material is calculated and roof patterns are drawn.

Installation of sheathing

If there is concern that ventilation under the roofing sheets will be insufficient, installation of the sheathing is carried out simultaneously with the installation of waterproofing. This helps prevent condensation from forming on the bottom surfaces of the sheets.

Lathing for metal tiles

The instructions prescribe installation of Monterrey metal tiles from the installation of the rafter system. When installing the sheathing, adhere to the following rules:

- The distance between the rafters should be from 600 to 1000 mm. The larger it is, the larger the cross-section of the sheathing boards should be. The lathing for metal tiles is made from boards with a section of 30x100 mm.

- Counter-lattice elements, which are bars with a cross-section of 40x50 mm, are nailed onto the laid waterproofing along the rafters. Sheathing boards are attached to these bars.

- The first transverse step of the metal tile is laid below the first board, so the first board of the sheathing should be thicker than the others by the amount of the step.

- In cases where gutter holders are installed before fastening sheets of metal tiles, the width of the first sheathing board must be at least 150 mm.

Fastening sheets

In the case of a gable roof, installation begins from the end of the building. On hipped roofs, metal tiles are attached starting from the top point of the slope. The sheets are laid so that each subsequent sheet overlaps the wave lock of the previous sheet, located on its left edge. To facilitate the work, installation begins from the left edge. In this case, subsequent sheets are laid under the wave of the previous one.

The edge of the sheet is aligned with the cornice, 40 cm is removed from it and the sheet is attached. It is more convenient to fasten several sheets together, secure them with a screw on the ridge, then align them along the cornice and finally fix them along the entire length.

The order of fastening the sheets

Roofing self-tapping screws are used to fasten sheets of metal tiles. To work with them, use an electric drill with a special attachment. The screw is screwed into the deflection of the wave and placed above the transverse wave in a direction perpendicular to the sheets. To attach 1 sq. m of profile, 8 screws are required - the sheet is attached along the edges in every second wave. In areas where there is overlap, the sheets are mounted in accordance with the transverse pattern.

To cut sheets, use metal scissors or a special tool. Bevels are made using a hand-held electric saw with carbide teeth.

It is advisable to use sealing tape at the joints and under the ridge. It is attached to the profile using small nails. Tape is not needed if the roof has waterproofing at its base. In areas with through holes and overlaps, silicone and other sealants are used.

Do-it-yourself siding installation: a set of additional strips

In addition to the tools and the panels themselves, for installing siding you need special fastening strips and profiles:

- starting (also known as starting) bar

- finish bar

- j-trim profile or j-profile

- connecting strip (aka H-profile)

- outside corner

- internal corner

- platbands and slopes

- window trims

- hanging strips

- soffits

- edging strip.

Rice. 4. Planks and profiles that can be useful in installing siding.

As a rule, the entire set is rarely used. The required set and number of planks will vary depending on the architectural features of the building. The supplier's sales department specialists will help you calculate it. Or you can do it yourself on the manufacturer's website.

Don't forget also that you will need a lot of screws (or nails) and dowels. If you decide to insulate the walls of the house under the cladding, you additionally need to select and calculate the insulation.

Perhaps the best option for external insulation today is a cake made of mineral wool and a waterproof membrane that will protect the insulation from getting wet. Waterproofing will also be needed for houses without insulation, but made from materials that absorb moisture - wood, aerated concrete, etc.

Sheathing stuffing

Installation of siding is carried out on a pre-prepared frame.

The frame can be assembled from metal or wooden profiles. The first option is more durable and easier to work with. For installation, hangers are used; with their help, it will be possible to assemble the sheathing strictly according to the level.

Wooden timber is cheaper, but you should check its condition before purchasing. If it is peeling, bent, or has stains on the surface, it is not worth buying. Before installation, the products should be impregnated with substances that will protect the material from rotting.

In any case, the guides must be installed vertically. For fastening to a wooden base you will need self-tapping screws, for block walls - dowel screws. The installation step depends on the size of the panels, which is indicated in the instructions. The process requires regular structural inspection of the structure.

It is advisable to clad all residential buildings with insulation; you can save on thermal insulation material only on outbuildings

Fastening J-profiles

- Using a level, find the bottom point of the frame, move up 5 cm from it and screw in the self-tapping screw. So you need to mark out all the places for the starting parts.

- Install fasteners at the corners of the house and tighten the ropes.

- Attach the profile to the corners of the sheathing, draw lines along the edges with a pencil or marker.

- Move 6 mm from the corner and secure the part to the frame, then check the horizontal installation with a level. If there are deviations, it is better to correct everything at this stage in order to finish the house with siding efficiently and without defects.

The appearance of the entire wall as a whole depends on the quality of installation of the starting strip.

Installation of external and internal corner slats

It is necessary to attach the profile to the corner of the sheathing, retreating 3 mm from the roof, and secure the rail with self-tapping screws, while the product should be 6 mm lower than the J-shaped profiles. Then you need to check the correct installation with a level. If there is no curvature, then you should first secure the lower part, and then all other places.

It is not worth saving on external corner profiles, as they are too noticeable on the facade

If the height of the facade is more than 3 m, then the guides will have to be superimposed on each other. There should be a whole profile at the bottom, and the top one should be trimmed. The slats must be joined at the same level in all places.

The technology for working with internal corner products is no different.

Internal corners are less noticeable, so they can be equipped with a J-profile, but to achieve the ideal result, you will need specialized fittings

Attaching siding sheathing: important nuances

Finally, we have a complete set of materials. You can begin installation. The first step is to install the sheathing - a profile for attaching the siding. It is mounted perpendicular to the panels. If the siding is horizontal, then the sheathing is attached vertically.

Important nuances of lathing installation.

- It is necessary to accurately measure the horizontal and vertical. If the sheathing is installed crookedly, then the entire facade will be uneven.

- If you use wooden sheathing, it must be treated with antiseptics.

- The distance between two adjacent profiles should be 30-40 cm, but not more than 50 cm. The more frequent the step, the stronger the structure. It is best not to take a random value, but to calculate the pitch of the sheathing based on the length of the panels and the wall.

- When you calculate the pitch of the sheathing, make markings on the wall where and how the guides will be located.

- As a guide for installing the starting bar, you need to draw a strictly horizontal line along the entire perimeter of the building.

- First, the sheathing is installed in the corners, then between them, on the walls themselves.

- Do not connect the guide battens together, otherwise you will disrupt the process of natural air circulation.

Lathing pitch: 30-40 cm. Vertical guides cannot be connected to each other so as not to disrupt the air circulation process.

Traditional wood panels

Traditional wooden siding, when faced with an overlap, requires preliminary marking on the mounted frame to maintain a constant angle of inclination of the panels. Installation is carried out from the bottom up, starting from the base strip, the thickness of which will determine the angle of inclination of the lamellas.

A 25x25 mm block is mounted along the bottom edge of the wall, then the first panel is installed so that it hangs slightly below the block. The lining can be fastened with nails or self-tapping screws; the main thing during installation is to prevent deformation of the lamella: as soon as it begins to bend, the fastening pressure must be loosened.

ATTENTION: To prevent cracking of the wood, the fasteners are made obliquely, that is, nails or screws must pass through the panel at an angle to the annual layers. The next panel is installed with an overlap, the size of which is determined for aesthetic reasons

Then measure the distance on the frame block from the top of the bottom panel to the top of the next one. This value must be constant throughout the entire cladding. The resulting size is marked on each beam of the supporting frame, and all subsequent cladding strips are mounted according to the marks.

The next panel is installed with an overlap, the size of which is determined for aesthetic reasons. Then measure the distance on the frame block from the top of the bottom panel to the top of the next one. This value must be constant throughout the entire cladding. The resulting size is marked on each beam of the supporting frame, and all subsequent cladding strips are mounted according to the marks.

How to attach siding to a wall: installing auxiliary profiles

Before you begin directly installing the siding, you need to install auxiliary profiles. For example, it is worth considering how to connect basement siding with regular siding, and also protect the foundation from erosion. Low tide is used for this. It must be installed before installing the siding. Align everything strictly horizontally. If the length of the wall is greater than the ebb, it is increased by making an overlap of 3-5 cm.

A starting bar is installed above the low tide. This is where the first siding panel will be inserted. If the starting strip is not installed horizontally, the entire façade will be uneven.

If the starting strip is not installed strictly horizontally, the entire facade will be uneven.

Next, the internal and external corners are mounted. If the house is one-story, as a rule, the length of the corner elements (3 m) is sufficient. If the house is higher, you will have to increase the planks. The technology for connecting a siding corner is simple:

- Calculate the missing angle length and add 5 cm to it.

- Cut the corner piece to the appropriate length.

- Install the corner profiles so that the top overlaps the bottom by 5 cm.

Rice. 5. Installation of external corner.

After this, the window strips are installed (they can be replaced with a j-profile). Doorways and arches, if any, are framed in the same way.

Cases where it is necessary to install overlapping siding

Overlapping is necessary in areas where the pipe exits the wall.

The material is produced with imitation of various natural materials, for example, wood, stone, brickwork, fabric, straw. If dividing strips are installed on the facade, the purpose of decoration will not be achieved.

Cases of using overlap when connecting siding panels:

- In areas where pipelines and cables exit the wall, when dismantling and reinstallation are associated with additional costs, difficulties, or are not possible at all.

- Creating an imitation of a solid layer in the form of masonry plinth, walls made of wood, brick.

- Acceleration of cladding work, since the process of installation, alignment and fixation of the joining element is eliminated.

Joining with an overlap is not always justified, for example, in the case of a short length of walls, when standard strips of siding are enough to create the finishing. The length of the ordinary elements is about four meters, and the width is 0.3 m. Strips without joints are used when cladding small verandas, gazebos, garages, sheds, and guest houses.

If the house is located near a highway, there will be a lot of dust around. It will clog into the connecting gaps and show the seams.

How to connect siding along the length?

As a rule, the length of siding is from 3 to 3.6 m. The length of the house can be greater, and in this case the question arises: how to connect the siding strips?

There are 2 ways:

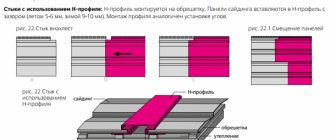

- Using a connecting strip: this is the technologically correct option.

- Without a connecting strip, overlapping: a riskier option.

Let's consider both methods in more detail.

Installing overlapping siding creates the impression of a continuous wall fabric, without dividing strips. It should be noted right away that no matter how hard we try to connect the panels neatly and evenly, at a certain angle the joints will be visible. Over time, dirt will get trapped in them, making them even more noticeable. And yet many people choose this method.

Rice. 6. Installation of overlapping siding.

Important details:

- The panels must be mounted with an overlap (the upper one should overlap the lower one by about 3 cm).

- The panels cannot be nailed tightly onto each other. When heated in the sun, they will expand and, if firmly fixed, become deformed.

- The joints must be placed in a checkerboard pattern, at a sufficient distance from each other (at least 50 cm). It is impossible for the joint to be located in the same place in two rows in a row.

If you are installing overlapping siding, do it in a checkerboard pattern. But it is better to connect the panels using an H-profile. It will protect the joint from water and dirt.

Installing siding with a connecting strip allows you to protect the joint. Water and dirt will not get there. The facade will look like new for much longer. If you choose this method of connecting the siding to each other, then the connecting strip will need to be installed simultaneously and similarly to the corner elements.

Rice. 7. Installation of siding using a connecting strip.

- The plank should not reach the foundation (base) from below and the cornice from above by about 0.5 cm - so that deformation does not occur during thermal expansion.

- If the length of the H-profile is not enough, increase it in the same way as the outer corner.

- Check that it is positioned without vertical deviations.

Why use the overlap method

The overlay is economical since an H-profile is not needed

Advantages

There are several reasons to use overlay siding:

- Saving. In order to reduce material costs, an overlap is used - a direct connection. You avoid large-scale trimming, as happens when working with an H-profile.

- Aesthetics. The exterior of the walls forms a single covering without dividing strips. This result is obtained with precise docking, in compliance with the rules.

- Non-standard walls for which the length of the canvas is not enough.

- Easy installation . This method is easier and you can do the house cladding yourself. There is no need to adjust each panel to the required length, and there is no need to install a joining strip. Hired workers take all these nuances into account and significantly increase the payment rate.

- Color spectrum. Using the overlay method, it is easier for you to choose the desired color scheme for the cladding, since components of the desired shade are often not on sale. Therefore, the connection is made without the use of auxiliary decorative strips.

If the correct installation technology is followed, the joint lines are not noticeable

Flaws

There are disadvantages to installing PVC lining with an overlap:

- The work must be done carefully; this is a waste of time.

- The effect of a continuous surface is not observed from all viewing points. The overlay is visible when viewed from the overlay side.

- The cracks become more noticeable with seasonal weather fluctuations.

- If the technological installation rules are not followed, the joints will bulge.

- Violation of tightness. Overlapping areas may be affected by wind. Dirt and dust accumulate in the cracks.

When choosing an overlap method, I recommend weighing the pros and cons, calculating your strengths and only then making a decision.

As the building shrinks and the soil shifts seasonally, the gap may become more noticeable

Installation of siding panels

Now that all the auxiliary strips and profiles are in place, you can begin installing the panels themselves. The technology for attaching siding is simple:

- The panels are mounted from left to right, from top to bottom.

- The first row of panels is inserted into the starting strip.

- Regularly check that the siding is installed horizontally. It is optimal to do this every third row.

- Before the last row of siding, a finishing strip is installed, and the last panel is inserted into it.

However, there are a number of nuances that need to be known and taken into account. How to properly attach siding?

- The panels must be installed using galvanized self-tapping screws (non-galvanized ones are susceptible to corrosion, and you risk that over time the facade will become stained with rusty stains).

- The screws are screwed in all the way, and then half a turn back - to allow the panels to expand and contract freely under the influence of temperature changes.

- Self-tapping screws must be screwed strictly into the center of the perforation of the panel or strip and always at a right angle. It is prohibited to screw self-tapping screws into the body of the panel.

- From the siding panel to the corner elements, near-window strips, H-profiles, adjacent panels and other elements, you need to retreat 3-4 mm in summer and 6-8 mm in winter - so that there is space for thermal expansion of the siding.

Rice. 8. Self-tapping screws are screwed into the center of the perforation and at right angles to the panel.

Self-tapping screws cannot be screwed into the body of the siding panel. But only into the perforation, and in its center and at right angles to the panel.

If all these rules are not followed, the panels may become deformed. And it will be impossible to correct the situation; the facade will have to be completely reinstalled.

Rice. 9. What are the consequences of errors in siding installation?

How to avoid mistakes: 7 rules

Direct connection of panels, without a connecting strip, has its own characteristics. A guarantee of a good result is provided by following certain rules:

| Photo | Description |

| Rule 1 Installation is carried out only at positive air temperatures, not lower than 10 °C. Otherwise, large gaps will be difficult to set correctly. | |

| Rule 2 The overlap of panels must be strictly observed in the interval of 20–30 mm. | |

| Rule 3 The top panel must be clearly aligned with the horizon, achieving a single continuation of the bottom part. | |

| Rule 4 Trimming of nail strips/panel locks is mandatory. As a result, the required distance is formed, allowing for an even overlay and compensation for expansion moments. | |

| Rule 5 A staggered arrangement helps level out overlap areas. | |

| Rule 6 A stop is placed under the end of the interior siding panel. A timber or board is stuffed, eliminating the possibility of deflection. | |

| Rule 7 To reduce the visibility of the seam, no physical effort should be made. Bending the end, pressing, or pulling on the lock will damage the material. |

Try to remove joints from doors and corners. Start laying from these areas, so the overlay will be placed at a certain distance. This is especially important in areas of doorways, where the wall vibrates when slammed shut.

Fastening metal siding: features

Above we described the technology for installing vinyl and acrylic siding. In general, metal panels are installed in the same way. But if PVC siding has a fairly large thermal expansion, then the linear coefficient of thermal expansion of the metal is 10 times less. Therefore, when installing them, there is no need to leave such gaps. A small space is enough to make the installation process comfortable.

One more nuance. The siding is attached to a metal profile. Use only metals that do not corrode.

Metal siding is tougher than plastic siding. Therefore, installing it is somewhat more difficult and longer. You won’t be able to do the work yourself – you will need at least 1 or 2 assistants.

What to consider

You have decided to buy yourself vinyl siding, the texture of which is made to resemble wood, stone or other material. And you are interested in seamless siding, installed with an overlap.

The following instructions are not for dummies, but rather for people with some experience. First, I advise you to try the classic fastening technology. After this, practice editing in the American way.

Before we talk about how the panel is joined, a few more words. This technology allows you to do without an H profile, that is, without a connecting strip. Siding is mounted on a wooden frame and metal sheathing. Suitable for vertical siding as well. You can make mistakes here if you don't follow the rules. Therefore, before doing the work, practice.

Attaching siding: summary

The siding installation process is simple. You can handle it yourself, especially if you have one or two assistants. The main thing is to know how to properly attach siding and not deviate from the manufacturer’s instructions. All the nuances are not accidental. They are justified by technology:

- Gaps are needed for thermal expansion of PVC siding.

- Lathing is necessary to prevent the walls of the house from being destroyed by mold and fungi.

- Self-tapping screws must be galvanized, and they must be screwed into the center of the perforation strictly at a right angle, not all the way, but with a small gap. So that you can insert a coin between the screw head and the panel.

Still, if you are not sure that you can handle the installation yourself, delegate the work to professionals. Remember: the price of a mistake is decades of service not only for the finishing, but often also for the walls of the house. Professional installers know all the features of fastening different panels. And they will clad your house quickly, efficiently, without increasing the price and timing, as well as sudden troubles.

You can find such installers.

If you still haven’t chosen panels for cladding your home, take a look at the siding catalog. A huge selection of options to suit every taste and pocket. Return to list

Lathing device.

In a house with frame walls, you can do without lathing, but only if the corners and surfaces of the walls are perfectly smooth, which does not happen often. On uneven frame wooden, as well as stone and block walls, sheathing must be installed

Please note: “flat surface” does not mean “vertical”. It's not the same thing

Siding can be installed on either a vertical or an inclined wall. It’s just more convenient to cover vertical surfaces. However, the main thing is that the walls are without bulges and depressions. They must be even throughout their entire plane. For lathing under vinyl siding, take dry wood with a moisture content in the range of 12 - 14%. A tree that is too wet will dry out over time, the sheathing will warp, and the covering will slide off along with it.

Typically, the sheathing is made from bars with a cross-section of 25 (30, 40, 50) × 60 mm. A galvanized plasterboard profile of the same width is also suitable for these purposes. Wood must be treated with antiseptics and fire retardants. Drywall does not require impregnation.

60 mm is the optimal width of the lath, at which the fastening falls exactly into the middle of the beam. With narrower slats, problems may arise.

Find out from our article: what to use when constructing a façade: wind protection or vapor barrier

The lathing is installed around the perimeter of the walls, on the gables of the roofs, as well as along the perimeter of all existing holes and openings (windows, doors, niches, etc.). However, it is not recommended to nail the lower horizontal boards in the “frame” of the sheathing, as these bars will impede air exchange. Thus, along the perimeter, the lathing should have the shape not of a quadrangle, but of the letter P. Between the “frame” bars, intermediate laths are stuffed at a distance of 20 - 40 cm from each other. The standard step width is 40 cm, but in areas with strong winds it is reduced to 20 cm. If the siding panels are supposed to be placed vertically, then the battens are installed horizontally, and vice versa: if the siding panels are placed horizontally, the battens are placed vertically. Options for the location of laths: a) horizontal laths for vertical installation of siding; b) vertical slats for horizontal installation of siding; c) cords for installing the sheathing between the corners; d) perimeter lathing around the windows First, the corner laths are attached. Cords are pulled between them, which serve as guides for attaching the remaining lathing. Usually the distance between the lath and the wall is set using direct hangers. Other fastening methods can also be used, such as wooden leveling pads

It is important that the slats do not deviate from the vertical position. To check, use building levels or plumb lines and cords.

Installation of starting strips. After installing the installation, this is the second important step that affects the appearance of the skin.

If the starting strip is not installed strictly horizontally, the entire casing turns out to be skewed. Trying to fix the situation is useless. Sometimes the ends of the row panels are trimmed and the siding is stretched. However, this is not a solution: after some time, the casing will still warp.

The key point in installation is determining the size of the temperature gap. This applies primarily to vinyl siding, since such panels have an extremely high coefficient of thermal expansion. Vinyl siding panels must be installed so that nothing prevents their size from changing under the influence of temperature. In hot weather, the panels should have room to extend and not rest against anything. Otherwise, the casing will rise. In the cold, the vinyl should shrink freely, nothing should hold the panels, otherwise they will burst.

First, the cornice soffits are installed, or at least the location for their installation is marked. If the length of the corner profile is greater than the height of the wall, a length equal to the height of the wall corner plus 3 mm is measured on the profile. The marked profile is applied to the corner, set back 3 m from the soffits or roof eaves and secured to the top of the upper nail hole on both sides of the corner.

The profile will hang on two nails in a vertical position. There will be 3mm between its top end and the roof eaves. The lower end of the corner profile will be located 6 mm below the starting strip.

A special case is the cladding of houses with protruding plinths or structures that do not allow the installation of the corner profile described above to be used. This happens, for example, when tiling verandas. In these circumstances, the corner profile is trimmed so that it becomes less than the length of the corner itself. A gap of 3 mm is left between the upper edge of the profile and the cornice. The lower end of the profile is cut so that 6 mm remains between it and the base (floor or other obstacle).

Related Posts

- Which siding to choose and what types of siding are there for cladding a house?

- Step-by-step instructions for covering a gable with siding

- Step-by-step instructions for installing all siding elements yourself

- How to finish and install basement siding with your own hands + installation of sheathing and cladding procedure

- Which siding is better: vinyl or metal?

- Installation instructions for basement siding deke-r

- Facade cladding panels

- Are MDF panels suitable for ceilings?

- Bathroom ceiling made of plastic panels: installation of frame, panels and lamps

- Metal sheathing

- Construction and application of sandwich panels

- Do-it-yourself house cladding with metal siding

- Interesting ideas for decorating a toilet with plastic panels

- Adhesive for plastic: review of waterproof and heat-resistant products

- Stone siding: advantages, tips for selection and installation

- Decorative 3D panels for walls in the interior of the house

- How to make a plastic ceiling: we install the ceiling according to the instructions from plastic panels

- Dimensions and cost of PVC plastic ceiling panels

- How to beautifully cover a house with two-color siding

- Ceiling in the kitchen: functions and beauty components. which ceiling is better?

- Installation of metal siding: instructions for cladding and finishing the facade of a house with your own hands + photos

- Sip

- Construction of buildings from sandwich panels

- Facade finishing

- How to independently select and apply profile 27 60

Read with this

- Which siding to choose and what types of siding are there for cladding a house?

- Step-by-step instructions for covering a gable with siding

- Step-by-step instructions for installing all siding elements yourself

- How to finish and install basement siding with your own hands + installation of sheathing and cladding procedure

- Which siding is better: vinyl or metal?

- Installation instructions for basement siding deke-r

- Facade cladding panels

- Are MDF panels suitable for ceilings?

- Bathroom ceiling made of plastic panels: installation of frame, panels and lamps

- Metal sheathing

Laying technology

Installation of siding begins with the creation of sheathing, laying insulation, and vapor barrier. The pitch between the vertical bars is maintained at 50–65 cm. The horizontal bars are calculated based on the size of the material.

If the rules are followed, the seams are difficult to notice

Stage 1. Sequence of actions

- The starting bar is placed above the ebb/foundation. Fixation is done with self-tapping screws in the center of the fasteners. The screws do not tighten flush, leaving free play for the material to expand.

- If there are complex/internal corners, start working from these places, installing the corner profile, corner elements to hold the panels. A special overlay will be used for external corners.

- The issue with the direction of the lining is being resolved, that is, move towards the seam: first, the lower bar covering it.

- The alternation of joints is determined. Calculate so that the offset is made through two panels.

- To perform proper alternation, some elements will be trimmed to length.

- Checkerboard docking must be performed symmetrically.

- The fastening lock is cut to the depth of the joint. The front part is not affected.

The principle of installing overlapping siding

Stage 2. Installation of the first panel

The process of attaching siding begins with installing the starting profile. Next, the lower part of the first panel is inserted into the profile, and the upper edge is fixed to the sheathing with screws/nails. Start fastening from the middle, gradually moving towards the edges.

In the place of fastening with fittings, leave 6 mm for “walking/expansion” of the material. If work is carried out during the cold period, the gap should be larger (10–12 mm).

Temperature clearances are calculated when installing fasteners/starter molding

Stage 3. Installation of the attachment part

The overlay panel is aligned horizontally, adjusted to match the cutouts and attached over the first plank with an overlap.

Reinforce under long sections to eliminate sagging. Nail a piece of block/board in the right place directly to the wall.

Carry out the fastening slowly, carefully adjusting each part, then the joints will be less noticeable. The finishing strip is installed before installing the last row

Stage 4. After installation

A sealant will help prevent the penetration of dust/moisture in the areas of the linings. Choose a special type of siding; it is elastic and absorbs the “walking” of the planks by 50%, for example Tytan, Weather Master.

Seal the panel seams with sealant.

The locks on the panels are not latched

The ordinary siding strip has a locking connection, which consists of a lower hook and an upper lock. Installation of planks is carried out from bottom to top. The first bar clings to the starting profile using the bottom hook. In this case, the fastening element of the upper panel must overlap the lower one. The hook is inserted into the groove until it clicks slightly. Particular attention must be paid to this, because a poorly secured strip may fall off due to temperature changes. As a result, the entire wall will have to be dismantled to correct the flaw.

The locking fasteners of the plank came loose, causing the panels to fall out of the wall.

Incorrect start profile installation

The starting profile is an additional element that is installed at the bottom of the wall, from which the laying of row siding panels begins. The evenness of the installation of the entire casing depends on its installation. Installation can be done horizontally or vertically. The most common installation method is horizontal. It is important that the starting profile is set exactly to the level. To do this, use a laser, hydraulic or bubble level. Self-tapping screws are screwed into the corners, between which a rope is pulled, indicating the horizon line.

Installing the starting profile on the sheathing.

For vertical installation, the starting profile is attached to the corner of the building.

If the starting profile was installed incorrectly, then all subsequent planks will be inclined. The slope may not be so noticeable to the eye on the first panels, but closer to the top of the wall the distortion will increase.

Rules for joining materials without a connecting strip

To achieve the integrity of the facade, when installing with an overlap, connecting strips are excluded. When docking, strict adherence to certain rules is necessary. Failure to comply with any of them can lead to a violation of the tightness and disruption of the effect of a monolithic facade.

Installation of overlapping panels must be done at a warm outside temperature. The temperature gaps for each siding manufacturer are different. But the general rule when installing siding is: the lower the outside temperature, the larger the gap needed. The recommended installation temperature is not lower than –10 °C.

It is also necessary to trim the lock joints. This is necessary to absorb expansion of the panels due to temperature changes throughout the year. The fastening strips at the top and bottom of the lock are cut in the same plane. The overlap size should be 25-30 mm to prevent snow from getting into the seams.

Installation of overlapping panels is done in a checkerboard pattern. This is necessary to “spread” the appearance of overlaps across the façade. Overlaps in one row should not be repeated more than twice in a row.