Installation of H-profile

H-profile for metal siding is an element that serves as a design for the joints of the main cladding panels.

Installation of the H-profile is not difficult: the main thing is to correctly calculate its location.

Installation is carried out similarly to the corner elements: first, the upper screws are attached, then other screws are screwed in along the entire perforation in 4-cm increments. In this case, it is necessary to indent a few millimeters above the cornice and retreat down from the starting strip - 6 mm.

To lengthen the H-profile, the profiles are joined with an overlap (the upper part overlaps the lower by 2.5 cm). It is recommended to join the profiles at the same level so as not to disturb the decorative design.

Installing the H-connector

How to connect siding together using a connecting strip

Installation of the connecting strip (H-profile). (photo No. 3)

The connecting strip (H-profile) is installed before installing the siding. The process works like this:

- Mark where the soffits will end.

- Fix the profile so that the gap between it and the edge of the soffit is 3 mm, and the bottom edge is 6 mm below the edge of the starting profile.

- Check that the installation is vertical.

- Secure the profile with self-tapping screws. First from below, then from above.

- Insert the siding panels into the connecting strip.

Any connections of the H-profile with other elements must be made in such a way that there is a gap of 6 mm for thermal expansion of the material.

If the height of the house is greater than the length of the planks, use two overlapping planks. In this case, the upper profile must be trimmed so that the gap between the slats is 9 mm, and the overlap is 25 mm.

Preliminary work

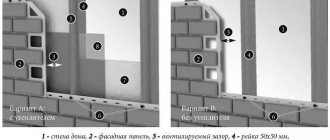

Before buying material, you need to decide not only the color and relief of the finishing panels. It is necessary to take all measurements and decide exactly how the facade will be faced: vertically or horizontally, with a highlight of the plinth or a solid canvas, how the openings, eaves overhangs and other elements of the building will be designed. In addition, the need to insulate walls and install sheathing is taken into account.

Before covering an old house, it is advisable to remove the previous wooden paneling, if any, or make sure that it is in good condition: there are no rotten, fungal or cracked boards, replace them, foam the seams. This is done if it is decided to install metal siding or vinyl panels directly on the wall without insulation and creating sheathing. But the walls must be treated with antiseptic and water-repellent agents.

It would be more correct to first cover them with moisture-resistant plywood or OSB boards, or even better - to mount a frame for fastening the cladding, which will become a reliable load-bearing base and create a ventilated space under the siding.

Metal profile frameSource the-master.ru

The sheathing is attached in a direction perpendicular to the panels: standing up if the siding will be mounted horizontally, and lying down if vertically. The step between elements is at least 40 cm.

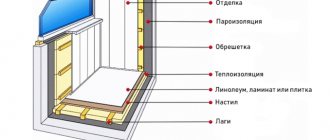

However, insulating the walls will require changes to this scheme. First, a frame is made for the thermal insulation material, taking into account the width of the roll or insulation boards. And after fastening it and installing a wind-hydroprotective membrane on top of it, a load-bearing frame is created in the chosen direction and with the required pitch.

Sheathing diagram with insulationSource files.builderclub.com

All existing openings must be framed around the perimeter, taking into account the angle of the slopes. As a result, the installed sheathing should level the walls and create even vertical planes on which the siding will be laid.

Second step: Setting the starting bar.

This is an important stage by which the quality of all work is determined. Therefore, the installation of the starting strip is carried out exactly horizontally!

- Using a level or water level, find the bottom point on the sheathing, from which it is 5 cm higher. Place a mark and screw in the screw.

- Place screw marks in the corners and along the entire perimeter in a similar way.

- Pull the nylon threads between the marks on the corners.

- Attach the corner profile and mark the boundaries on the sheathing.

- We retreat 6 mm from the corner bar. (thermal expansion gap) and attach the starting rail to the frame. Keep a gap of 1 cm between the slats.

- We check the horizontality of the installed J-profiles. It is important to avoid deviations, otherwise the siding panels will warp!

We install external corner profiles

Attaching the outer corner siding profile

First step. We mark the soffits. We need to see where the edges of these elements will be located in the future.

Second step. We apply the guide to the corner of the frame. We do this with a 3mm gap to the soffit or roof. We fasten the profile with self-tapping screws.

Place the bottom border of the element 0.6 cm below the edge of the starting profile.

Third step. Checking the vertical installation. If there are no deviations, we fix the bottom, and then the remaining places. Experts do not recommend placing fasteners in corner elements too often.

The principle of increasing the length of a corner profile

If the house is higher than 300 cm, the profiles will need to be placed one on top of the other. To do this, we trim the top profile. As a result, there should be a 9 mm gap between the planks of the joining elements. When laying the elements, maintain an overlap of 2.5 cm.

Electric saw for cutting sidingTo cut vinyl siding panels, use tin snips, a hacksaw, a cutter knife, or a hand-held power saw with an abrasive wheel.

If the base has a protruding structure, shorten the profile so that there is a 6 mm gap between it and the base.

Using two starting J-profiles of siding instead of a corner one

Setting the outside corner

- home

- reference Information

- Facade materials

- Installation of “Herringbone” and “Shipboard” siding

- Setting the outside corner

The corner is cut to the required length, 1/3 is left between the top and the cornice (soffit) for a thermal gap.

The lower edge is lowered by 2/3 of the size of the thermal gap so that it is below the level of the lower edge of the starting strip. You can then begin installing the fastener (nail, screw, or staple) into the top of the top punched hole on either side of the corner. It should hang vertically on two nails. To take into account vertical thermal expansion, the following fasteners are installed in the center of the holes 20 - 40 cm from each other, not very tightly.

Before installation begins, the top and bottom nail strips must be trimmed. The cutting distance from above should be equal to the height of the final F- or J-profile plus a third of the thermal gap, and from below the nail strip should be trimmed by 5-6 mm. In this case, the lower part will not protrude from under the siding. If the corner is covered with a lid, the lower nail strip should be trimmed to 2/3 of the width of the thermal gap, plus the height of the J-profile.

If the length of the corner element is less than the height of the corner, you will need to join two panels. Then the joint is made at the same height.

Installation of external corner profile: a - general view; b - overlap joining; c - the same, through the glue pad; g - the same, through a nailed overlay; 1 - external corner profile; 2 — top panel; 3 - bottom panel; n - 1/3 of the temperature gap; t - height of the final profile (F- or J-); c - distance between fasteners (20-40 cm); d - 2/3 of the temperature gap; e - overlap; f—temperature gap.

There are three main docking methods.

The most common of them is overlap. The top element should lie on top of the bottom one. You will need to cut off the nail strip and shaped elements with metal scissors, leaving only two thin strips that will form the corner. The lower one is installed first, and then the upper one. The result is a knot that protects the corner of the wall from rain and snow.

An important condition: the height of the cut part must be greater than or equal to the width of the temperature gap. The overlap width of the panels should be plus 20 mm. In order not to make mistakes in the calculations, it is worth first placing the elements on top of each other with an overlap of 20 mm, measuring the width of the temperature gap at the place where the nail strips overlap on the upper profile and making marks. Then cut according to the marks received.

The second method is docking using an overlay. The top and bottom panels are installed in the same plane, and a vinyl overlay, which can be made from part of the panel, is placed between them. Then the overlay is glued to one panel, preferably to the bottom. A corner designed in this way looks a little more beautiful, but noticeably loses from an engineering point of view - it is somewhat more complicated, and with this method of joining, moisture can get inside the structure.

The third method is a continuation of the second method, with the only difference that the trim does not require completely cutting off the nail strips, and it is attached to the wall like a regular panel.

For all three methods, the rule remains the same: it is necessary to leave a distance for thermal expansion between the nail strips and maintain an overlap of 2-2.5 cm over the overlays.

| Overlapping joining. |

If you need to cover the outer corner at the top or bottom, you will need to make a cover. To do this, you can cut a piece from the remainder of the J-rail that is equal in length to twice the width of the outer corner of the main part. A 90° angle is cut out in the center of the part, the edges of the strip are cut off on both sides, it is bent and nailed to the outer corner of the building. Then the part is inserted into the formed channel and fixed with fasteners.

To install a corner piece into a J-rail if its width is small, you need to cut off the inner curved part of the J-rail. In addition, before starting installation, it is necessary to trim the nail strips, which may rest against the cover fastening during thermal expansion. They need to be trimmed at the bottom by 2/3 and at the top by 1/3 for thermal expansion plus the height of the J-panel nail strip. This distance must be provided inside the covers, between the bottom of the bent J-panel and the end of the corner profile.

The easiest way to make a lid from the remainder is to make vertical cuts and bend the planes inward. To prevent the knot from being “loose”, you will need to additionally secure the curved petals.

An effective way to design corners is to make them from four elements (a starting corner profile, two vinyl boards and a decorative strip). This method emphasizes the corners of the building more and involves the use of elements of different colors.

A budget option is to use two cheaper elements - J-rails - instead of a solid, rather expensive corner. The result is a composite element that looks no worse than a solid one, while its cost is almost half the price. Such a replacement is not always advisable. A solid corner is more airtight and aesthetically pleasing, so it is better to leave it on the façade side and not change it to a composite one.

Manufacturing and installation of corner covers: a - manufacturing of a cover from a J-profile; b— installation of covers; 1 - J-profile; 2 - cover; 3 - corner profile

Stacked elements are mounted according to the same rules as conventional corner profiles. A distance of 1/3 of the total temperature gap to the cornice or to the soffit is left at the top, and 2/3 of the width of the starting strip is left at the bottom. The nail strips are also cut to the width of the adjacent elements. The size of the temperature gaps is checked according to the siding installation instructions.

Alternative types of external corners: a - from four elements; b - of two elements; 1 - corner (vertical) two-sided starting strip; 2 - board; 3 - decorative corner element; 4 - J-profile.

- Setting the outside corner

- Setting the inside corner

- Country style corners and impost installation

- Installation of window and door frames made of J-profiles

- Installation of frames for window and door openings from boards

- Processing the corners of frames of openings made of vinyl planks

- Installation of moldings

- Framing openings with slopes

- Installation of H-profiles

- Installation of the finishing profile and J-profile on the gable end of gable roofs

- Installation of horizontal row siding

- Installing horizontal siding

- Installing Vertical Siding

- Transition from horizontal to vertical siding and covering gables with vertical siding

- Installation of spotlights

- Setting the chamfer

- Arched window frames

- Decorative gables and dormer windows

You have questions? We will call you back in 10 minutes

or call +7 (495) 789-96-72

Clicking the "Submit"

, you automatically consent to the processing of your personal data and accept the terms of the User Agreement.

- home

- reference Information

- Facade materials

- Installation of “Herringbone” and “Shipboard” siding

- Setting the outside corner

Metal siding: preparation for work and equipment

To properly install metal siding, you must first prepare the walls: clear debris from them, seal cracks (if any), and cover them with a primer mixture. Inspection of the walls is important: you should check the perpendicularity of the corners, the vertical and horizontal lines of the wall (check by level and plumb line).

At the stage of preparatory work, the markings should be applied correctly: the quality of installation of the metal cladding depends on how correctly it is done.

In addition, it is important to properly prepare the cladding material itself: it is necessary to cut and cut the panels for further work. The metal sheets are covered with protective foam, which must be removed before starting work. If a panel with a protective film is left in the sun, it will be quite difficult to remove it, since under the influence of sunlight the film sticks to the surface even more

If a panel with a protective film is left in the sun, it will be quite difficult to remove it, since under the influence of sunlight the film sticks to the surface even more

The metal sheets are covered with protective foam, which must be removed before starting work. If a panel with a protective film is left in the sun, it will be quite difficult to remove it, since under the influence of sunlight the film sticks to the surface even more.

House with metal siding

Siding cover kit

In addition to the main covering - metal siding panels - it is necessary to purchase component materials for the complete design of the cladding:

- Cornice strips. Necessary for the design of window and door openings, as well as for the design of panel joints;

- window slats. For the design of slopes of openings and windows;

- external corners. For decoration of external corners;

- internal corners. To design internal joining corners of panels;

- starting bar. To create a lower support and guide under the siding panels;

- finishing bar. To design the top (finish) panel;

- soffits. For decoration of the cornice part of the facade and overhangs;

- connecting strips. To design connecting adjacent planks;

- J-bar. For decoration of windows and doorways.

NOTE! When purchasing siding panels, you should immediately purchase components. It is recommended that all materials be selected from the same manufacturer: in this case there will be a complete match of elements in fastenings and a complete match in color.

If you take additional elements from other manufacturers, the color and dimensions may not match

If you take additional elements from other manufacturers, the color and dimensions may not match.

Metal siding is divided into the following types:

- Under the tree;

- Under the beam;

- Ship plank;

- Under a stone;

- Under the brick;

- Under a log.

Equipment

Advantages

The main advantages of metal siding are:

- Long service life. Most manufacturers guarantee the service life of their products for 20-25 years without burnout and up to 50 years before through corrosion;

- Light weight structure. Since thin sheets of metal (about 0.5 mm) are used in production, and protective coatings are applied in a layer calculated in micrometers, then 1 m2 is only about 4 kg;

- Economical. By using domestic metal, creating an extensive logistics network and distributing production facilities throughout Russia, manufacturing companies can offer metal siding cheaper than foreign manufacturers;

- Environmental Safety. Metal panels, unlike PVC, are not only non-flammable, but also do not emit harmful substances during operation;

- Ease of installation. Due to the fact that metal is not so susceptible to thermal deformation and is not afraid of low temperatures, the installation process is not complicated by the need to control the tightening force of fasteners, there is no need to leave special temperature gaps, etc.

We mount the pediment

We sheathe the pediment around the perimeter. All fasteners, except the top one, are installed in the center of the holes. We install the upper fastening element at the top of the hole. It can be sheathed either with profiles for arranging internal corners or with a starting profile.

The installation procedure is similar to fastening wall panels. We trim the edges of the elements and connect them to the locks of the receiving profiles. We remember the 6 mm indentation when installing in warm weather and 9 mm when doing work in winter.

We fasten the last element of the gable cladding directly through the panel material - this can only be done here.

The cladding is complete.

In order for finishing a house with panels to be as successful as possible, you need to know certain subtleties of performing such work. There is a list of general recommendations for any siding, as well as specific tips for panels made from a specific material.

Now you can perform it yourself at the highest level.

| Name (model) | Benefits | Length x width x thickness, mm | Quantity per package, pcs. |

| Vinyl Siding "Canada Plus" | 1. Coloring in dark colors is performed using the “Cool Color” method (heat absorption), which involves the use of masterbatches. 2. Excellent appearance remains unchanged even when exposed to high and low temperatures, the range of which ranges from -50°C to +60°C. 3. Retains shock resistance, even if the ambient temperature drops to -20 to 60°C. 4. Not susceptible to microbiological corrosion (fungi, mold). | 3660 x 230 x 1.1 | 20 |

| Acrylic Siding "Canada Plus" | Among other useful qualities of acrylic siding “Kanada Plus” it is worth highlighting: Increased resistance to direct ultraviolet rays; Excellent tolerance to acidic and alkaline solutions, as well as to various fats; Good tolerance to washing with chemical detergents; High degree of deformation resistance (perfectly tolerates temperatures up to 75°-80° C). | 3660 x 230 x 1.1 | 20 |

| "Alta-Siding" - Vinyl Siding | "Alta-siding" is: one of the safest finishing materials on the Russian market; frost resistance and the ability to maintain strength even at very low temperatures (from -20 to -60°C); resistance to significant temperature changes and environmental influences; durability: the service life of Alta-siding is up to 30 years; resistance to aggressive substances (detergents can be used to clean siding); non-susceptibility to infection by mold fungi. | 3660 x 230 x 1.1 | 20 |

| Facade metal siding INSI | INSI siding is made of galvanized steel coated with a layer of polymer composition, which means it inherits all the advantages of this material: resistance to temperature changes (-50°C – +80°C) and mechanical damage; long service life with preservation of original properties (about 50 years); environmental friendliness; non-flammability; Possibility of installation both horizontally and vertically; protection of the building from overheating (in a ventilated facade system); and when choosing one of two new colors (alder or rosewood) - a complete imitation of the appearance. | Length up to 6000, width up to 200, thickness 0.5 | – |

Good luck!

Video - Do-it-yourself siding installation

From old wood you can make a garden path, steps, country furniture, and a firewood shed. See how to use scrap boards for gardening tools.

Many people are familiar with this picture: when you go into a country shed, the shovel tries to fall, and the rake, if you step on it, hits you on the head. Sometimes it’s so difficult to find the right tool, so you need to make an organizer for your garden tools. Here is another problem regarding where to put the old tree, or rather, boards, that will be resolved.

Sheathing materials and installation tools

The sheathing can be made of wooden blocks or metal profiles.

The timber is easier to fit, it is easier to attach siding to it, it does not serve as a cold bridge between the cladding and the wall, and does not change geometry when temperature changes occur. But the tree does not tolerate high humidity. Therefore, the timber must be seasoned (dry) and treated with an antiseptic.

Installation of siding on a wooden sheathing can be seen:

It is more difficult to work with a metal profile; it has high strength and durability (if it is galvanized). The only operational drawback is high thermal conductivity. Therefore, the supporting brackets must be mounted to the wall through heat-insulating gaskets.

To install sheathing and siding you need:

- a set of tools for marking and level control;

- a hacksaw for metal or wood (depending on the material of the siding and sheathing);

- metal scissors for fitting panels (for metal siding);

- hammer drill or drill (depending on the material of the walls and base);

- hammer, pliers, screwdrivers or screwdriver with attachments for the hardware head;

- fasteners;

- twine, chalk for marking;

- stepladder, ladder, scaffolding.

The video shows how to install a metal frame for siding:

How to determine the required size of a corner profile

To determine how long the corner siding should be, you need to measure the value from the bottom edge of the starting strip (it is the one that is first attached to the sheathing) to the place where the cornice will be installed. Subtract 6 mm from the resulting value. This is necessary in order to take into account linear changes under temperature influence.

It happens that the length of one standard profile is not enough to frame a corner or you need to finish it in several pieces, what to do then? In this case, you will have to install the elements overlapping. Add 2 cm to the size of the additional part for joining.

Such an area will be enough to completely protect the structure from moisture, dirt and cold.

General principles of vinyl or metal siding

To have an idea of how to properly cover a house with siding, it is enough to know the general principles of installation:

- Cladding occurs on the principle of filling the contour panels from additional profiles.

- Install the sheathing with a spacing of vertical purlins of 250-300 mm.

- They make markings for the starting strip, the correct installation of which largely determines the quality of the cladding.

- First, beat off the low tide fastening line. If the entire façade is sheathed around the perimeter, then it should converge “to a point.”

- The starting bar attachment line is above the low tide plus a gap to compensate for thermal expansion.

Installation of the ebb, starting strip and all cladding parts to the sheathing occurs according to the general rules:

- the fasteners must be positioned strictly vertically relative to the sheathing;

- the fastener head must be in the middle of the perforated hole (except for the upper fastening of corner profiles);

- tighten the screws or drive the nails in not completely, but leave a gap between the head and the surface of the part of about 1 mm.

Installation of the first, load-bearing strip of sidingSource otoplenie-gid.ru

After the starting strip, corner profiles are attached, hanging them vertically at the top attachment point. Install window strips or J profiles around the openings. Finish the “framing” of the contour with a finishing strip or J profile.

The siding is increased in length either by overlapping by 20-25 mm (by trimming the perforations of the bottom panel), or through a connecting profile with an internal gap at each end, as in a corner profile.

Every 5-6 rows control the level.

Example of installation of metal sidingSource thestroyker.ru

The traditional method of installing siding

Horizontal siding is installed from bottom to top and from left to right. For simplicity, additional strips and elements are used. The traditional siding installation scheme looks like this:

Preparing the wall surface

It is necessary to remove all decorative volumetric elements from the walls (platbands, shutters, lamps, gutters, etc.). If there are traces of mold on the walls, treat them with appropriate compounds. Apply protective compounds to wooden surfaces.

Installation of sheathing, insulation

A sheathing - wooden, metal or plastic - is mounted on the prepared walls. For vinyl and acrylic siding, the latter is preferable - it is closest in its performance properties, so the facade will not suffer from sudden temperature changes.

Installing the starting bar

Siding installation begins with the installation of a special starting strip.

!

Important! It must be mounted strictly horizontally. Check and double check. The appearance of the entire facade depends on this.

Framing openings and corners

Along the perimeter of the opening, special profiles are installed into which siding panels are inserted. This could be a j-trim or finishing strip. Also at this stage, corner elements are installed.

Installing the connection strip (if equipped)

If the length of the wall is greater than the length of the siding, the panels will be connected horizontally using a connecting strip. Design where it needs to be installed (in the center of the wall or on the side). The connecting strip is installed before installing the panels.

Siding installation

Siding panels are mounted from bottom to top. The first row is inserted into the starting bar. On the sides - in corner elements, profiles that frame openings, or a connecting strip.

Installation of finishing strip

The finishing strip is installed on top.

Installing the last top panel

The last siding panel is attached to the finishing strip.

Features of cladding a wooden house

When covering a wooden house with siding, it is necessary to take into account the characteristics of the materials:

- finishing of the facade, as well as interior work, must begin after the house has settled;

- for the lathing, it is advisable to use a wooden beam (seasoned and treated with an antiseptic);

- It is mandatory to treat the surface of the walls with an antiseptic, since after installing the sheathing it is impossible to control the condition of the wood and promptly carry out preventative measures for areas affected by fungus;

- for additional protection, you can lay a waterproofing membrane;

- Even if the walls are smooth and the siding is installed without insulation, the panels cannot be attached to the wall - for proper use of the wood, a gap is required that the sheathing creates.

Cladding a wooden houseSource elka-palka.ru

The ease of installation of siding does not exclude care and accuracy when carrying out work. An error when installing the starting profile, fasteners that are “tightened” or incorrectly installed in the hole, non-compliance with recommendations for the size of the temperature gap - all this can lead to serious consequences for the skin, which will not be so easy to eliminate.

Eighth step: Sheathing the gables.

- Finish the gables around the entire perimeter in the same sequence as the installation of the main panels, using an internal corner or starting rail.

- Trim the edges of the connecting elements and attach the receiving strips with locks. Maintain an interval of 6/9 mm.

- Fix the last panel to the sheathing directly through the material.

Key points in siding finishing work.

- Perform horizontal cladding in the direction from bottom to top from left to right.

- When connecting two panels into a lock, effortlessly slide the top siding into the bottom until it clicks.

- Take into account the thermal expansion of the material. Fix metal and PVC siding with a slight gap.

- Only stainless steel (for example, galvanized) screws or nails with a length of 35 mm or more, with a head of at least 8 mm, are suitable for fastening.

- Fasten the self-tapping screw exactly in the center of the factory holes specially designed for this purpose, do not press the panel tightly. The exception is the last plank on the pediment.

- The panel fixation step is no more than 45 cm, components – 25 cm or less.

- Assembly on the façade of a log house can begin only after the building has settled, otherwise the siding will “lead.”

At Vasha Roofing, you can always order siding installation. Our installers will professionally complete the work within the agreed time frame. With us you will receive a written guarantee for installation and keep the manufacturer's warranty card for the material.

Metal siding: preparation for work and equipment

To properly install metal siding, you must first prepare the walls: clear debris from them, seal cracks (if any), and cover them with a primer mixture. Inspection of the walls is important: you should check the perpendicularity of the corners, the vertical and horizontal lines of the wall (check by level and plumb line).

At the stage of preparatory work, the markings should be applied correctly: the quality of installation of the metal cladding depends on how correctly it is done.

In addition, it is important to properly prepare the cladding material itself: it is necessary to cut and cut the panels for further work. The metal sheets are covered with protective foam, which must be removed before starting work.

If a panel with a protective film is left in the sun, it will be quite difficult to remove it, since under the influence of sunlight the film sticks to the surface even more

The metal sheets are covered with protective foam, which must be removed before starting work. If a panel with a protective film is left in the sun, it will be quite difficult to remove it, since under the influence of sunlight the film sticks to the surface even more.

House with metal siding

Siding cover kit

In addition to the main covering - metal siding panels - it is necessary to purchase component materials for the complete design of the cladding:

- Cornice strips. Necessary for the design of window and door openings, as well as for the design of panel joints;

- window slats. For the design of slopes of openings and windows;

- external corners. For decoration of external corners;

- internal corners. To design internal joining corners of panels;

- starting bar. To create a lower support and guide under the siding panels;

- finishing bar. To design the top (finish) panel;

- soffits. For decoration of the cornice part of the facade and overhangs;

- connecting strips. To design connecting adjacent planks;

- J-bar. For decoration of windows and doorways.

NOTE! When purchasing siding panels, you should immediately purchase components. It is recommended that all materials be selected from the same manufacturer: in this case there will be a complete match of elements in fastenings and a complete match in color. If you take additional elements from other manufacturers, the color and dimensions may not match

If you take additional elements from other manufacturers, the color and dimensions may not match.

Metal siding is divided into the following types:

- Under the tree;

- Under the beam;

- Ship plank;

- Under a stone;

- Under the brick;

- Under a log.

Equipment

Innovative material

The word "siding" means a material intended for covering various surfaces. At the same time, its main functions are aesthetic and protective. Once upon a time, an ordinary board was used for this, which was processed accordingly. And only much later panels appeared on the construction market, which we call siding. They began to be produced from a variety of materials.

Siding has gained immense popularity due to its strength and lightness, durability and attractive appearance. But that's not all. Such panels are a very convenient material for fastening. And this sometimes acts as a determining factor for those who study the question of how to install siding in order to do the work themselves.

The profile of siding panels can be made in two versions. This is a “ship plank” or “herringbone”. They provide, respectively, a double or single fracture. But for installation this does not matter.

All siding panels are covered with a protective layer, made either by painting or by applying a polymer film.

A huge advantage of this material is its excellent performance qualities, as well as maintainability. After the owner finishes the house with these panels, he can forever forget about impregnating the wood with special compounds, tinting the facade and other similar work. And to eliminate damage in the shortest possible time, it is enough to simply replace 1-2 products, which does not require any preparatory measures.

Description of components

- starting profile - a load-bearing element, the first siding panel is attached to it;

- the finishing strip is the last one in the row, hiding the top edge of the last panel;

- corner elements - they are used to form corners, the profiles have grooves in which the siding panel is placed;

- platbands for doors and windows - perform a decorative function, decorating door and window openings;

- window and door profiles - if the window or door is not located flush with the wall, but in a recess, then these profiles will help close the slopes during finishing;

- J-profile is needed for fastening panels, sometimes used instead of corner profiles;

- The J-chamfer is necessary to decorate the edge of the roof, otherwise it is called a wind board;

- ebb tides are designed to drain water from the walls;

- ceiling soffits can be perforated or solid; they cover the overhanging part of the roof from below; perforated ones provide ventilation between the siding and the wall;

- moldings connect panels located in different planes;

- H-profile is required for joining panels.

Siding design

Finishing panels are divided into several types according to their shape and purpose. The sellers' catalog contains the following options:

- Private. This type is made in the form of a sheet, intended for covering the main part of the wall. You need to place it groove in groove, which determines the absence of gaps.

- Starting. This panel is attached along the lower perimeter; the peculiarity lies in the lower end, which is in contact with the foundation. The curved shape of the lower part eliminates the possibility of sediment getting under the finishing material.

- Inner corner. This type is attached at the point of contact between two walls. This siding must be installed where the internal corner is formed.

- Low tide. It is fixed under the window and removes accumulated precipitation.

- Near-window profile. This option is designed to protect window slopes.

- External corner. The finishing element is represented by a panel with planes located relative to each other at right angles.

- The J-shaped chamfer is used as a wind deflector. It has a special key that acts as a lock for adjacent panels.

- The H-profile is attached at the transition point of the house wall. Its purpose is to connect the end surfaces of adjacent ordinary sidings.

- The soffit is represented by a siding panel for horizontal installation. The main difference from ordinary panels is the presence of perforated holes through which air enters the under-roof space.

- The finishing profile is used as a universal element when cladding a house. Most often it is used under the eaves overhang or along the perimeter of the window opening.

- J-profile is a universal product that is suitable for covering rows of siding or decorating openings. It is attached along the edge, adjacent panels are inserted into special grooves. Due to this, the rows are guided with their additional fixation.

- Molding acts as a decorative element, which is fixed when installing soffits. In its functionality and appearance it resembles a plinth. The main part is bent at different angles; in the upper part there are holes for self-tapping screws.

- The platbands are made in the form of small panels with holes for self-tapping screws. The purpose is for the outer covering of windows or doors.

Types and device for fastening siding

The technology of their installation depends on the shape of the product and the location of the holes for fasteners, as well as on the type of grooves. To save money, the special profile is replaced with scraps of ordinary panels. However, it is possible to aesthetically sew up all the resulting gaps and corners of the structure only by using special panels, the price of which is slightly higher.