Regulatory framework for interior and exterior decoration

The interior, as well as the exterior, decoration of residential premises is subject to the jurisdiction of a whole package of documents, among which the Building Norms and Rules (SNiP) stand out. These standards contain the main information regarding the arrangement of a particular finishing option. It is necessary to familiarize yourself with the data before starting repairs, even planned ones.

Designing the interior decoration of houses and apartments will include a large list of documents. For each operation there is a separate legal regulation - GOST, SNiP, instructions.

The construction services market contains offers from various organizations, where craftsmen perform work in full compliance with GOSTs and SNiPs. Each property owner who needs such services is able to independently check the level of qualifications of third-party craftsmen.

For plastering work there is a separate SP and SNiP

Why do you need SP (SNiP)

Existing legal acts provide guidance for different companies, which contains important data and a number of requirements for construction calculations and work. The presence of SNiPs is due to the main need - ensuring the safety of people, as well as the environment. To this end, the documents provide for a number of requirements for the construction of construction projects, as well as readiness for their further operation.

Interior and exterior decoration of residential premises is regulated by a whole list of various documents

SNiP (SP) for plaster

A number of requirements for plaster are specified in SP 71.13330.2017, and specifically in Chapter 7. This standard applies not only to internal and external surfaces, but also affects the plaster of the basement and facade parts of buildings. Here are the requirements for the technology of work, including control of permissible errors in the plastering process.

Several main sections from SNiP for plastering work:

- 7.1.1 – optimal conditions for carrying out work indoors are indicated. The permissible temperature range is 5-30°C with a humidity level of up to 60%. The exception is the indicators prescribed by material manufacturers. This regime must be maintained starting from the first two days before the start of work, directly during the entire period of plastering, as well as for 12 days after completion of laying the mortar.

- 7.1.8 – regulates the mandatory stage of dust removal of surfaces before applying a new coating (if several layers are planned). If necessary, intermediate treatment with a primer is carried out.

- 7.2.6 – mortar on a cement or lime-cement base can be applied not only in one layer; multi-layer coating is allowed in accordance with the instructions of the plaster manufacturers. In the case of a multi-layer surface, each new layer is applied only after the previous coating has set. Based on a number of factors, if necessary, a reinforcing mesh is attached to the walls.

- 7.2.7 – applying gypsum plaster to internal walls is allowed without first attaching the plaster mesh. A single-layer coating is formed from such a solution, unless otherwise specified by the material manufacturer.

The normative document SP 71.13330.2017 corresponds to the German standard DIN V 18550. The European legal act contains recommendations regarding the preparation, as well as assessment of the quality of finished coatings, based on the type of finishing surface - from Q1 (lowest) to Q4 (highest).

A set of rules is a normative document

The main purpose of plastering is to create the correct geometry of the premises. This is, first of all, setting strictly right angles (90°), reducing the width of doorways (including slopes) to optimal values and a number of other operations. In general, you should get a single and even plane.

In this case, there may be permitted tolerances for plaster that fit within the standard limits. These indicators are summarized in the table below depending on the parameters and properties of the plaster.

| Plaster parameters | Simple | Improved | High quality |

| Deviations relative to the vertical | No more than 3 mm | Up to 2 mm | Maximum 0.5 mm |

| Maximum vertical deviations in relation to the entire height of the premises | 15 mm | 10 mm | 5 mm |

| Maximum number of irregularities per 4 m2 | 3 mm | 2 mm | 2 mm |

| Maximum Defect Depth | 5 mm | 3 mm | 2 mm |

| Limit deviations relative to the horizontal at 1 m | 3 mm | 2 mm | 1 mm |

| Maximum substrate moisture level | 8% | 8% | 8% |

| Deviation of slope width from design (for the entire element) | 5 mm | 3 mm | 2 mm |

The document that specifies the finishing quality criteria is SNiP 3.04.01-87. Tolerances in accordance with SNiP should be taken into account as a guide to action.

The document applies to both internal and external work

GOST for plaster

In addition to SNiP, the legislation of the Russian Federation provides for GOST R 57984-2017/EN 13914-1:2005, which affects interior and exterior decoration. It also contains features of the selection, preparation and application of solutions. However, at the moment the document has not entered into force. But there are other GOSTs depending on the binder component of the mixtures:

- GOST R 57957-2017/en 13279-1:2008 – applies to gypsum solutions.

- GOST R 57336-2016/en 998-1:2010 – for lime-based solutions.

- GOST 31357-2007 – regulates dry cement mixtures.

As a rule, these GOSTs are used for the production of building mixtures on an industrial scale. But a number of companies for the manufacture of their products, in addition to the basic documents, are supported by the requirements of the Technical Specifications.

The standard applies to dry construction plaster mixtures

Improved plaster: layer thickness

All requirements for the performance of work and the quality of the resulting coating are specified in the document SNiP 3.04.01-87 “Insulating and finishing coatings”.

According to the technology, improved plastering is performed in 3 layers. The thickness of each of them depends on the base and mortar material and is prescribed in the SNiP rules.

- Spraying is necessary to increase the adhesion of materials. It uses a solution with the consistency of liquid sour cream. The thickness of the continuous layer applied to brick or concrete bases should be within 5 mm. For wooden bases, the maximum layer thickness increases to 9 mm, taking into account shingles or mesh.

- The soil is used to level the walls. If the walls are significantly uneven, it is possible to apply primer in several stages. The thickness of each individual layer of soil should be within 5 mm for cement-based mortars and 7 mm for light lime and gypsum-based mortars.

- The covering layer is the final stage of the plaster finish, which is rubbed down using a trowel and serves to obtain a smooth and even coating. Its thickness can be no more than 2 mm. When using decorative plaster, the covering can be up to 7 mm thick.

Advice: the technology for performing improved plastering does not necessarily require the use of beacons, but to facilitate the work of leveling the surface and control the thickness of the layers, beginners are still recommended to work with beacons.

Each layer is applied only after the previous one has set. The total thickness of the material varies within 2 cm. When this figure needs to be exceeded, a metal mesh is placed on the base. Experts also recommend using it when plastering foam concrete walls and when working on wood and metal. The reinforcing mesh in all cases helps prevent the occurrence of cracks.

The current SNiP does not contain regulations for attaching plaster mesh, and its mention in documents is advisory in nature.

Classification of plaster according to SP

According to Russian SNiP 3.04.01-87, which is devoted to finishing and insulating coatings, the classification of surface plaster includes three main classes:

- simple;

- improved;

- high quality

All requirements, as well as the list of construction standards for plastering work, specified in the relevant documentation, apply not only to the manual technique of applying mortars, but also to the use of machinery. The same applies to the classes mentioned above. They have a number of differences and requirements, depending on the specific situation.

According to the accuracy and quality of execution, plaster is divided into three types

Simple plaster

Unlike the next two classes, a simple finishing technique is used in rare cases, since it is suitable for situations where there are no high requirements for the quality of finishing. In particular, this applies to these places:

- utility rooms;

- basements;

- ground floors;

- outbuildings.

If deviations are acceptable after painting the walls or wallpapering, all irregularities are clearly visible. For this reason, this is not the best solution for decorating the rooms of an apartment or country house.

Use simple plaster when finishing utility rooms, basements, warehouses

Gypsum or cement-sand mortars are suitable for work. The thickness of the laid coating varies within different limits, based on the degree of curvature of the base. As a rule - 20 mm. But you should also take into account the recommendations of plaster manufacturers. However, in this case there are some mandatory requirements:

- The brickwork is moistened before work.

- Porous surfaces, including highly absorbent substrates, are primed before plastering.

- It is not recommended to carry out work if the room temperature is below + 5-10 C.

Since installing beacons is optional, the process does not take much time. When applying the solution manually, a trowel or trowel is used. In the case of the mechanical method, the station is responsible for supplying the mixture, from where the composition reaches the walls through a gun. To control an even surface, a rule 2-3 m long or a rule with a level is sufficient.

Simple plaster does not require the use of reinforcing mesh. A 3 or 4 cm coating holds well without reinforcement. But when the thickness of the plaster exceeds 5 cm, it is no longer possible to do without reinforcement.

By smoothing and grouting a relatively flat and smooth surface is obtained.

Improved plaster

Among all classes, the most popular finish is considered to be improved

its variation. The surface after processing the base is strong and smooth. Suitable for both walls and ceilings. Here the work is carried out according to beacons. Unlike simple plaster, the improved version gives a better result.

The coating is created with a different number of layers, depending on the type of construction mixture. In most cases, gypsum solutions are applied in one layer. When using cement-sand mixtures, a three-layer “pie” is formed:

- splash;

- priming;

- cover.

For the first layer, a liquid consistency of the composition is prepared in order to increase the adhesion of the material during subsequent processing. The primer layer requires a thick composition to level the surface and smooth out unevenness. The cover acts as a finishing coating.

The total thickness of improved plaster is up to 15 mm

High quality plaster

High-quality finishing allows you to get the most even surface. This option is suitable for painting or wallpaper. However, proper preparation of surfaces is necessary before work. The walls are cleaned of dirt and all types of stains (because of which the level of adhesion of the base deteriorates), deep defects are repaired. For high-quality plaster this is extremely important.

At the next mandatory stage, the surface is treated with a primer. You can use a roller or spray.

Next comes an important responsible process - fastening the beacons and setting up the corner profiles. Without such preparation, the wall cannot be made sufficiently even. The joints of surfaces made of dissimilar materials, as well as the tops of door and window openings, are reinforced with fiberglass or metal mesh to prevent cracking. With further use of putty for painting, the mesh can be attached to the entire surface depending on the type of base.

After completing the preparatory stage, the main part of the work is carried out - applying the plaster mixture. When the coating has set a little, the beacons are removed and the remaining furrows are sealed. Finally, the surface is leveled.

High-quality plaster must be carried out on beacons

Permissible deviations for improved plaster

In accordance with SNiP 3.04.01-87, plastered surfaces may have deviations that are not a violation of the standard:

- the coating may have a deviation from the vertical and horizontal of no more than 2 mm per 1 m of length;

- over the entire height of the wall, the surface can be deflected by no more than 10 mm;

- slopes of windows and doors, pillars, pilasters, husks can be deviated no more than 2 mm from the vertical and horizontal per 1 m of length;

- the radius of curved surfaces can be deviated by 7 mm from the value specified in the project (control is carried out using a pattern);

- The width of the slope may differ from the design by 3 mm.

Important! SNiP for improved plaster does not allow the presence of peeling, cracks, sinkholes, efflorescence, or visible traces of the tool used for grouting on the surface.

Plaster thickness

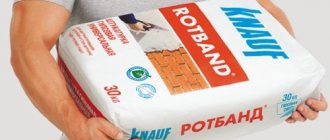

The finishing technology requires observance of the thickness of the plaster layer, adhering to the framework. This depends on the specific type of mixture used and in each case the indicators vary. For example, the thickness of the layer of Knauf MP-75 gypsum composition varies from 8 to 50 mm when applied by machine in one pass. If a thick surface is needed (more than 5 cm), the plaster is applied in two layers with intermediate drying of each. In this case, after drying, the first layer must be primed before laying the next one.

Specific values are selected depending on the degree of curvature of the surfaces. Relevant information is contained in the descriptions of the materials. To familiarize yourself with them, it is better to visit the manufacturers’ electronic resources.

The thickness of the plaster cannot be arbitrary

Plastering works in St. Petersburg.

Since 2008, the StenFor - mechanized finishing company has been developing in the field of plastering, floor screeding and facade insulation. During this period, we have accumulated vast experience in this area and are ready to share it with our customers. We carry out plastering work on any volume, from apartments, offices and cottages to industrial and residential areas. The main criterion that we use in our work is the high quality of finishing work. The main region of presence of our organization is St. Petersburg and the Leningrad region.

In our work, we do not skimp on the equipment we use and therefore use only the most modern equipment from European manufacturers. All employees of our company undergo a rigorous competitive selection process and are professionals in their field. In the staff of our company you will not find “master” generalists. Each employee is a highly specialized specialist, and thanks to this, the high quality of our work is achieved. By contacting the Mechanized Finishing company, you get a professional partner when carrying out plastering work.

The key activity of the StenFor company is machine plastering work.

The use of mechanisms allows you to achieve undeniable advantages:

- the solution has a uniform consistency since the mixing process occurs automatically

- speed of applying the mixture to the surface

- the cost of mixtures for machine application is significantly lower by 30-40% compared to mixtures for manual application

- Due to the elasticity of the mixture for machine application, it is possible to obtain a smooth surface ready for wallpapering

- The Mechanized Finishing company provides a 12-month guarantee on work.

Necessary conditions for plastering

In many public buildings, as well as residential buildings, perfectly flat surfaces are extremely rare. This is especially true for buildings erected during the USSR. For this reason, it is necessary to level the walls before starting work. If the work is carried out independently, then take into account a number of nuances in order to avoid gross mistakes. All standards for plastering surfaces can be found in SNiP. In addition, it is desirable that the preparedness of the territory complies with the norms and regulations.

During the winter season, the operating temperature of the room should not fall below +10 degrees above zero. Humidity level – strictly up to 70%. To prevent cold from penetrating into buildings, all openings are insulated, including the vestibule and all openings.

Base moisture indicators also play a role. For brick and stone walls, these values should not exceed 8%.

The temperature in the working room should not be lower than +10°

Depending on location

Since the operating conditions of the plaster coating outdoors and indoors are radically different, this also affects the thickness of the plaster layer.

What characteristics of the coating are affected by the size of the laid layer:

- coating strength;

- base strength;

- leveling efficiency;

- financial and labor costs.

The maximum thickness of wall plaster, depending on the number of layers (according to the quality of finishing), can be represented as:

a) 1.2 cm – simple (total thickness of spray and soil);

b) 1.5 cm – improved (total spray, soil and covering layers);

c) 2.0 cm – high-quality (spray + 2 ground layers + covering layer).

The maximum value is set to reduce the likelihood of cracks forming, shrinkage of the plaster coating when drying, and slipping of the freshly laid mortar.

Read more about plaster defects and the reasons for its cracking in the materials on our website.

Plastering indoors

The thickness of the plaster on the interior walls may depend on the design features of the room. For example, if electrical wiring is laid along the surface of the walls, the thickness of the coating is increased to hide the location of the wire. In this case, it is necessary to ensure a minimum height above the wiring itself.

In interior spaces, increased demands are usually placed on the quality of plaster finishing. This concerns the geometry of surfaces. If the walls collapse or the angles between them are less than or more than 90 degrees, then leveling is performed, which may require a layer of more than 8 cm.

An increased layer may be necessary in the case of dense reinforced concrete walls for operational reasons. For example, to install fasteners on which paintings are hung, dense, strong concrete walls have to be drilled.

For walls made of cellular concrete, it is especially important to ensure vapor conductivity of the interior and exterior finishes. Moisture from such walls must be removed continuously. Therefore, in order not to resort to complex calculations, we are guided by the rule: the internal plaster coating should be twice as thick as the external one.

So, if the permissible minimum thickness of the street layer is 10 mm, then the internal plaster is made no thinner than 20 mm. This method will prevent condensation from entering the room to the base of the wall. In this case, the right choice would be to use a silicone or silicate mixture for facades.

Facade plaster

For facades, the strength of the coating is the primary condition, since this side of the building is exposed to hail, strong wind, temperature and rain loads, and the base is subject to strong mechanical stress. And the protective function is more important than the decorative one. The composition of the mixture that will be applied to the outside of the house depends on this. Therefore, cement compositions are more often used for facade work, which determines the minimum layer of simple plaster - from 10 mm.

The minimum standard is also due to the need to ensure the integrity of the plaster coating during operation. An excessively thin plaster layer has low strength. A small mechanical load is enough, and the finish will begin to crack and peel.

When plastering facades, insulation is often installed under the coating. Here the plaster shell must be especially durable, monolithic, and not cause problems during operation. This is achieved by reinforcing and maintaining thickness.

Application of plaster mesh according to SNiP

There is not yet a valid regulatory act that describes in detail the installation of the reinforcing component. There is also no legal information regarding the need for such a measure. In this regard, the process should be regarded as a recommendation.

At the same time, when the planned coating thickness exceeds 50 mm, it is better not to refuse to attach the mesh. The same applies to structures made of foam concrete, as there is a high risk of cracks.

Existing SNiPs do not contain regulations for the installation of plaster mesh

Thickness for different bases

When finishing, it is necessary to take into account the type of wall material. For example, the thickness of plaster for walls made of wood, OSB or concrete, provided the walls are the same evenness, will be different.

Brick

The relief of the brick surface affects the cross-sectional size of the plaster coating. Applying less than 5 mm means not ensuring good distribution and high-quality performance of the composition; such a layer turns out to be ribbed with a difference in thickness. Recommended sizes: optimal – 2.0-2.5 cm, largest – 5.0 cm.

Concrete base

Concrete walls in panel houses have a smooth surface with a small number of large pores. Plastering work is carried out not so much for leveling, but for sealing joints, for heat and sound insulation. Here, in the absence of differences, you can get by with a layer of 2 mm. In case of unevenness, rotation or collapse of the wall, the upper limit (with mesh reinforcement) is 70 mm.

Aerated concrete blocks

The material is not as strong as brick or concrete, so the heavy weight of the plaster coating can become an intolerable burden for the cellular base. With proper preparation for plastering using a plane, you can achieve a smooth wall. In this case, it is possible to plaster aerated concrete blocks with a minimum of 2 mm. If the walls are uneven, then you can correct the situation by achieving a layer 0.8-1.5 cm thick. Anything above these values will easily crack and fall off. Sometimes the surface of aerated concrete blocks is destroyed.

Wooden surfaces

Quite a complex material for plastering. Wood tends to dry out and get wet from excessive humidity - “play”. In such conditions, it is not possible to achieve reliable adhesion with all plaster compositions. To ensure a strong connection with the base, before plastering the wood, mesh or shingles are attached to the wall. The first layer of plaster is applied so as to cover the slats/mesh, the second - 15-20 mm.

Drywall

The surface of plasterboard sheets is initially flat. The joints and dents from installing self-tapping screws are plastered. Drywall plaster is used in cases of unevenness not exceeding 1.5 cm. Therefore, we can consider this 1.5 cm to be the greatest thickness of the plaster layer for plasterboard bases, and the minimum thickness of plaster is 1.5 mm.

Insulation materials

Penoplex, as well as other insulation materials installed on the walls of a house, require enhanced mechanical protection, since they, especially polystyrene foam, do not resist mechanical influences well, such as impacts or abrasion. Such loads are especially high in the area of the base. Therefore, the plaster finish of the insulation must be reinforced for strengthening. The first layer (1.5 cm) is applied to solidify the reinforcing mesh, the second (1.0-2.0 cm) is applied for leveling and protection.

Requirements for the quality of plaster compositions

To control the quality of mixtures, there is a separate current standard - GOST 28013-98, which affects the general technical conditions for the use of mortars. According to this document, the mixture must meet the list of requirements:

- So that the composition for spraying the soil passes freely through a mesh with cells measuring 3 mm.

- The plaster for covering must pass through a mesh with 1.5 mm mesh.

- The size of sand granules is no more than 2.5 mm (soil, spray), and up to 1.25 mm (finishing layer).

Among the technical parameters regulated by GOST are mobility, strength, moisture retention and delamination. An additional requirement is that the building mixture must have a document with data. These are cooking time, brand, quantity, mobility, binder, standard.

To understand which plaster for walls is better, you need to familiarize yourself with the requirements for the material

High quality plaster

This type of plaster is used for finishing rooms in theaters, in some residential apartments, and other public places. With high-quality plaster, a spray is applied to the surface, one or more layers of primer and a finishing layer - a covering. In this case, plastering of the walls is carried out with hanging and the mandatory use of beacons. The thickness of such plaster can be approximately 20 millimeters.

According to the rules, the requirements for high-quality wall plaster are the most stringent. Deviations of up to 1 millimeter are allowed per 1 meter vertically, and 5 millimeters along the entire height. Permissible errors for waves – 2 irregularities per 4 sq.m. Each unevenness can be up to 2 mm deep. On the horizontal plane, permissible deviations are allowed less than 1 millimeter.

Features of plaster according to SP

Plastering work is carried out in accordance with a set of rules in order to avoid unwanted nuances. In particular, it is worth highlighting the following features:

- When the temperature ranges from 22 °C to 24 °C and when working on brick and stone, the surfaces are sprayed with water.

- Improved, like high-quality plaster requires the installation of beacons. The height of the slats depends on the thickness of the coating, with the exception of the covering layer.

- The single-layer surface is immediately leveled. But when using a trowel, wait until the plaster sets.

- In the case of multi-layer application of the mixture, each subsequent stage begins only after the previous layer has completely dried. However, leveling the soil is carried out without waiting for the solution to completely set.

- Sheets of gypsum plaster are glued to brick bases using special compounds. The material is attached to the wooden surface with nails.

To install gypsum products on walls, it is necessary to create a reinforcing frame from reinforcement in advance. Thanks to this, the structure lasts for a long time. The fittings should be selected from stainless steel to avoid rust and stains throughout its life.

After each stage of applying the mixture, you must allow the layer to dry completely.

Key excerpts from SNiP for plastering work

3.15. When plastering brick walls at an ambient temperature of 23 °C and above, the surface must be moistened before applying the solution.

3.16. Improved and high-quality plaster should be performed along beacons, the thickness of which should be equal to the thickness of the plaster coating without a covering layer.

3.17. When installing single-layer coatings, their surface should be leveled immediately after applying the solution; in the case of using trowels, after it has set.

3.18. When installing a multi-layer plaster coating, each layer must be applied after the previous one has set (the covering layer - after the mortar has set). Leveling the soil should be done before the mortar begins to set.

3.19. Sheets of gypsum plaster must be glued to the surface of brick walls with compositions corresponding to the design, placed in the form of marks, measuring 80x80 mm over an area of at least 10% along the ceiling, floor, corners of the vertical plane every 120–150 mm, in the spaces between them at a distance of no more 400 mm, along the vertical edges - in a continuous strip. Sheets should be fastened to wooden bases with nails with wide heads.

3.20. Installation of gypsum moldings should be done after the base of plaster mortars has set and dried. Architectural details on the facade must be secured to the reinforcement embedded in the wall structure, which is previously protected from corrosion.

We also suggest that you familiarize yourself with useful and very important information on plastering work (installation of mesh, mixture consumption, removal of beacons, special primers, plastering on beacons, etc.).

These works are used on various building materials: monolith, brick, foam concrete using special primers for each type of material. Before applying plaster on metal and wooden surfaces, it is necessary to make special preparations (fill a metallized plaster mesh, prime the surface with a special primer), we do not recommend performing plastering work on such surfaces, it is better to resort to using the dry leveling method - installing gypsum board sheets. You cannot plaster over the plasterboard sheets themselves, since gypsum board sheets can become deformed under the influence of moisture; if your plasterboard partitions are assembled crookedly, it is better to redo them than to level them with plaster.

None of the current SNiPs contain regulations for the installation of plaster mesh, so this process is purely advisory in nature.

We recommend using plaster mesh with a plaster layer thickness of 50 mm or more, as well as on walls made of foam concrete, since there is a high possibility of cracks appearing there.

Performs plastering work in strict accordance with current SNiPs. Our prices for plastering work are affordable, since we carry out this work by machine.

You can order this service by phone; a specialist will visit you and prepare an estimate for free.

Rules for acceptance and control of plastering work

After finishing is completed, the stage of acceptance of plastering work begins. In this case, a number of rules and requirements are taken into account:

- The presence of bubbles, cracks, waves, and obvious roughness is not allowed.

- Angle indicators are 90°. There must be smooth surfaces with clear edges.

- A blow with an open palm does not cause a booming sound or the feeling of the plaster crumbling.

- Tolerances for plastering walls relative to horizontal and vertical are within acceptable limits.

- Special types of plaster must meet special requirements.

- An error relative to the vertical and horizontal planes of up to 20 mm is visible to the naked eye. Anything that exceeds these indicators is regarded as a defect that needs correction.

The final result of the finished coating depends on the quality of work.

Acceptance of plastering work must be accompanied by verification of compliance with requirements

Compliance with the requirements of SNiPs and GOSTs is the key to a successful finishing result. The durability of the finished coating, including aesthetics, depends on this.

Was this information useful to you? Share in the comments!

General information about plaster

For work, various types of mixtures are used, which are used depending on their purpose. It is also necessary to take into account the climatic conditions of the region, room temperature, humidity, etc. The plaster mixture is designed to protect walls and other structures of the house from the influence of the external environment.

When choosing plaster, all conditions should be taken into account. In addition, the composition must have waterproofing and acoustic properties. Ready-made mixtures are used for decorative finishing. However, you can prepare the composition with your own hands, and you need to select the right ingredients and dye, according to a special recipe.

To apply plaster to a stone base, complex solutions are used. Cement mortar is applied to the concrete wall. In this case, the concrete must first be scored. A lime-gypsum mixture with additional elements is suitable for a wooden surface.

If it is necessary to cover the surface with a layer of plaster 20 mm thick or more, a reinforcing mesh is used. It is also used for plastering architectural elements made of concrete and brick. Mesh is often used at the junction of walls, especially if they are made of different materials. This procedure will prevent future cracks from appearing on the coating.

SNiP and tolerances for high-quality, improved and simple plaster.

Before starting repairs, many people think whether they need to carry out plastering work; this is due to only one fact - ignorance of the technologies for performing repair work and the consequences of not complying with them. Plastering work is the process of leveling any surfaces vertically and horizontally using special dry mixtures (gypsum, cement-lime plasters). The main task of applying plaster is to obtain the correct geometry of the premises: setting 90-degree angles, leveling the width of doorways and slopes, making walls parallel, obtaining a single and even plane.

Based on the quality of execution, plaster is divided into three categories: simple, improved, high-quality.

Document regulating the quality and technology of these works -

All these requirements apply both to manual application of plaster and to machine application.

Tolerances for plastering work

| Parameters and properties of plaster | Simple | Improved | High quality |

| Deviations from the vertical by 1 m, no more | 3mm | 2mm | 1mm |

| Maximum deviation from the vertical for the entire height of the room | 15mm | 10mm | 5mm |

| Number of irregularities per 4m2, no more | 3 | 2 | 2 |

| Depth of irregularities, no more | 5mm | 3mm | 2mm |

| Deviation from horizontal by 1 m, no more | 3mm | 2mm | 1mm |

| Base moisture content, no more | 8% | 8% | 8% |

Thickness of the plaster layer (plaster)

When following the technology of plastering work, it is worth paying special attention to the thickness of the plaster, both the minimum and the maximum permissible!

These values depend on the plaster mixture and are different for each. For example, for machine-applied gypsum plaster Knauf MP-75, the thickness of the plaster layer should be in the range: from 8 mm to 50 mm (for one sweep). If it is necessary to apply plaster with a thickness of more than 50 mm, then this should be done 2 times with drying and re-priming the first layer. See this information in the descriptions of plaster mixtures and, better yet, on the manufacturers’ websites!

Permissible thickness of the plaster layer

| Parameter | Knauf MP-75 (gypsum) | Knauf Rotband (plaster) | Knauf Unterputz (cement) | Knauf MN Start (gypsum) |

| Permissible value of plaster thickness | Wall: 8-50 mm Ceiling: 8-15 mm | Wall: 5-50 mm Ceiling: 5-15 mm | Wall: 10-35mm | Wall: 10-30mm |

Based on these parameters and the curvature of your walls, you should select the appropriate mixture.

This is a very important parameter, the observance of which determines the quality and durability of the plaster! If this requirement is not met, cracks may appear on the surface and even detachment from the base.

Minimum layer of plaster on the wall

The thickness of the plaster layer on a brick determines the level of quality of protection of walls from moisture, variable temperatures, and mechanical damage, and for a room, the thickness of the plaster layer is an indicator of protection from extraneous noise and freezing. This type of finishing work to create a protective coating is associated with the technical and operational characteristics of the structure. Plastering is carried out both outside and inside the building. Each type of finishing has its own distinctive features and nuances, but what is especially important is the thickness of the plaster layer, which can become a complete protection of the structure.