Tools and materials

So how do you update your coverage? To perform this type of work at home you will need the following:

- putty;

- primer;

- sandpaper of different grain sizes;

- sander;

- roller;

- spatulas of different widths;

- brushes;

- vacuum cleaner;

- solvent;

- masking tape;

- personal protective equipment: respirators, gloves;

- varnish, paint for laminate.

On video: the nuances of laminate processing.

Features of laminate as a floor covering

Laminate is a coating that is quite in demand on the finishing materials market, as it has a lot of advantages, including low price and beauty. It is also valued for a certain level of durability, ease of installation, variety of colors and the ability to choose a coating to suit every taste and color.

Laminate has many advantages

On a note! Thanks to its wide range of colors, laminate can imitate such expensive types of flooring as wood or stone. It can also have a single color or be decorated to match tiles, etc. Thanks to this, it is not difficult to fit it into the overall style of any interior.

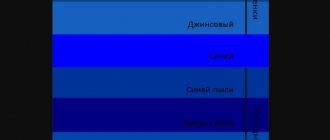

Basic colors and textures of modern laminate

But this material also has a certain range of disadvantages. These include the tendency for scratches to appear on the surface of the lamellas as a result of intense mechanical stress, as well as the fear of high levels of humidity. And if, due to humidity, the question “Can laminate flooring be painted?” does not occur, then scratches, as well as a banal desire to change the color and renew the coating can provoke its appearance.

Laminate flooring

Before we talk directly about the answer to the question, it is worth remembering what this material is. First of all, it is important to know and understand that this coating is multilayer. The table below shows the main layers of laminated boards.

Laminate structure

Table. Laminate structure.

| Coating layer | Characteristic |

| Substrate | Its functions are to protect the board from below from moisture, as well as to give the floor a certain degree of sound and heat insulation. |

| The basis | The thickest and most durable layer, usually made of fiberboard or other material, but most often - from fiberboard. It is this that gives the coating strength and rigidity. But fiberboard is afraid of moisture, and therefore it must be protected from its effects. When liquid gets on the fiberboard, the material swells. Also, it is on this part of the lamella that there are locking locks for connecting individual laminate planks into a single covering in the room. |

| Decorative layer | This is the very layer that gives the laminate a certain color. This is usually the paper on which the image is printed. It is fixed to the fiberboard and covered with an additional protective layer on top. |

| Protective layer | This is a laminated layer, very thin, but durable and capable of protecting the laminated floor from water and a number of mechanical influences. Contains melamine resins. The coating is applied during the production of the material, impregnates the paper layer and, when hardened, becomes durable and transparent. |

GOST 32304-2013. Laminate flooring based on dry-processed fiberboards. Specifications . Downloadable file (click the link to open the PDF in a new window).

GOST 32304-2013

SP 29.13330.2011. Floors (Updated edition of SNiP 2.03.13-88) . Downloadable file (click the link to open the PDF in a new window).

SP 29.13330.2011

Laminate consists of several layers

On a note! The laminated layer of lamellas can be of different quality. Its strength indicators will depend directly on the amount of substance it contains - corundum. The more it is, the more reliable and stronger the top layer of lamellas will be.

What do the images on laminate packaging mean?

What is laminate and why is it not recommended to paint it?

Although laminate imitates wood, in fact it is not wood and does not possess its qualities. The material consists of several layers:

- Upper, protecting the product from mechanical damage. For its production, paper is used - paper impregnated with melamine resin and crystalline mineral. The larger the layer of this protection, the stronger the laminate will be.

- Decorative. It consists of paper on which a design is applied, making the laminate look like wood.

- Carrier. This layer is the hardest and thickest. It is made from fiberboard or PVC. The sides of the product are equipped with a spike, due to which they are tightly connected and form a single surface.

- Lower. This is the name of the laminate backing. Its main task is to protect the room from cold and extraneous sounds. As a rule, it retains its qualities longer than other layers of the product.

The four layers are bonded together to form a single slab of laminate. Its thickness can reach 1 cm. Such material can last at least 10 years. If the height of the slab is 1.5 cm, the coating can not be changed for a quarter of a century.

However, this service life is only relevant for laminate flooring that has no damage or cracks. The appearance of abrasions on a floor made from this coating indicates that the integrity of the protective layer has been compromised. This means that the waterproof properties of the material are lost, and painting it with a water-based composition will lead to damage to the slab: it will simply swell and lose its shape.

Is it possible to paint laminate flooring a different color if it gets scratched? Yes, but you should know and follow the appropriate technology. Carrying out such work is not always justified.

Paint or change: in what cases does painting laminate flooring make sense?

Despite its strength and wear resistance, laminate sometimes loses its aesthetic function. This can happen if the coating is scratched, faded in the sun, or stained with substances that cannot be washed off. If the appearance of several tiles has changed, it is not practical to replace or completely repair the floor.

You can resort to masking defects, that is, painting. It is also recommended to paint the laminate if cracks or dents appear on it: through them, dirt penetrates into the slab, which leads to its damage. A special coating will help protect the cracked slab.

What is the complexity of the process

A special film is glued on top of each laminated board, which performs certain functions, in particular, it protects the material from moisture. At the same time, it does not allow the paint to reliably “stick” to the surface, i.e. no adhesion.

The very smooth top of the lamellas cannot securely hold regular enamel. As a result, no matter how beautifully you paint the floor, it will peel off within a month. The paint will remain only in the recesses that imitate the texture of wood, and in the gaps between the boards.

What does laminate consist of?

Without an understanding of the structure of the material, it will be difficult to move forward to solve the problem. Therefore, this is what we will do now.

A laminated board consists of several layers, each responsible for a specific function:

- Upper

- protective coating is responsible for the product’s ability to withstand mechanical stress. Due to this layer, the floor remains intact for a long period, despite contact with rough shoes, pet claws and dirt.

It is made from boomoplast - paper that is impregnated with a mixture of corundum and melamine resin. Its strength depends on the content of the first component.

- Decorative

– made of paper onto which the desired image is applied. Thanks to the embossing process, the layer can imitate the texture of natural wood.

- The load-bearing

layer is the thickest and densest layer. It is made from fiberboard or plastic. Equipped with a locking connection - groove or tenon.

- The substrate for the laminate (bottom layer) is responsible for hydro- and sound insulation

. It usually remains intact even when the coating wears out.

Whatever the price of the laminate, the protective and decorative layers begin to deteriorate first. Very rarely, some scratches may reach the supporting base. At the same time, it is the first layer that gives laminated boards their characteristic gloss. And it does not allow the paint to linger on the surface of the product.

That's why:

- To successfully paint laminate flooring, you need to matt the protective layer to increase its adhesion.

- Chips and scratches can be smoothed out by filling them with putty to a depth of 2-3 mm, i.e. the first two layers.

Technology

The instructions for preparing them for painting depend on the degree of wear of the lamellas. The process is complex, so it is better to split it into several stages.

Preparation

- Clean the floor surface from dirt.

- Use coarse sandpaper to remove damaged flooring.

- Remove dust with a vacuum cleaner.

- on wood and wait until it dries. After this, cover the damaged area again with putty until it is level with the surface.

- Take medium-grain sandpaper glued to the foam rubber, and after the putty has dried, level the putty surface.

- Clean the floor with a vacuum cleaner.

- Prepare fine-grit sandpaper for finishing work and carefully matte each lamella.

Advice: the main thing in this process is to make the surface of the laminate matte, and not to level it perfectly.

- Vacuum the floor, soak a soft, lint-free cloth in a solvent such as white spirit, and wipe the surface of the slats.

Choose ordinary enamel for painting, for example, PF 226 or PF 115. Dilute the paint to a liquid state also with white spirit. Keep in mind that you will have to paint in several layers, so the material must not only be liquid, but also thoroughly mixed.

Advice: do not use a roller and do not forget to wear gloves and a respirator.

Coloring

- Start painting the laminate from the board furthest to the door.

- Paint using long strokes along the strip. In this case, the paint should be spread over the surface.

- Try to paint the gaps between the boards.

- After applying the first layer, it must sit for at least 24 hours with the windows and doors closed.

- Apply a second coat using the previous principle.

Tip: while painting, do not forget to periodically stir the paint in the jar. Otherwise, it will sit on the bottom, causing the floor to become stained. If this happens, apply another coat of paint to the laminate surface.

Useful tips

How to paint laminate flooring? The flooring experiences significant loads when walking and from furniture. In addition, it is regularly subjected to wet cleaning. Therefore, it is recommended to choose paint in accordance with these conditions. For these purposes, it is best to use polyurethane or alkyd paints that have good performance characteristics.

Can laminate flooring be painted with wood varnish? The use of such material is completely acceptable. But when choosing, you must take into account that varnishes usually create a translucent coating. To create a glossy surface, a special polyurethane or epoxy tinted varnish is used.

For painting, it is better to use polymers combined with melamine resin. The fact is that the laminate undergoes a special factory finishing during the manufacturing process, as a result of which a moisture-resistant coating is formed. In order to create a more durable coating, it is necessary to make the thickness of the coating as large as possible. Also, using a thick layer of coating will eliminate the problem of floor squeaking.

Preparing laminate flooring for painting

When the paint and brushes have already been purchased and are waiting in the wings, you need to start preparing the working surface. It is clear that you will not apply paint to crumbs, twigs, putty residues and other “delights” of the repair that remain on the floor. Otherwise, you don’t have to ask how and what to paint the laminate with.

The second step will be sanding the floor. This is done in order to remove the smallest debris from the surface of the laminate that could not be captured with a rag or a washing vacuum cleaner. In addition, sanding provides the best adhesion of the surface to the paint. If you think this step is a waste of time, after a few months you will see your paint starting to peel off your newly painted floor.

This is what a cleaned laminate surface looks like

After the floor has been completely cleaned with coarse sandpaper, it is necessary to once again do a general cleaning of dirt and dust that arose during the cleaning process.

Elimination of cracks and deep scratches

Old laminate flooring is more susceptible to damage because the protective coating layer becomes thinner as a result of use. Then quite deep scratches appear on the floor surface. However, even in this situation, it is possible to restore the laminate using the following means:

- Putty for laminate;

- Spatula for filling cracks.

Special putties for restoration are sold in the form of powders and diluted with water according to the instructions. Apply the product exclusively to the scratch and only with a spatula. The putty should not be allowed to “crawl out” beyond the damage, since cleaning it is quite problematic.

Conclusion

Many compatriots are of the opinion that as soon as the first deep scratches appear, the laminate must be replaced. This is actually not true, and if you are interested in saving money, the tips in this article will be useful to you.

By the way, in order for a freshly painted floor to retain its appearance for as long as possible, wash it before using it. To make laminate restoration simple and of guaranteed quality, watch the video presented in this article.

Rules for using laminate flooring that will prolong its service life

- Wash the floor with plenty of water.

- Use abrasive detergents.

- Use sharp objects to remove dirt.

- Use moisture-retaining mats on the surface of the laminate.

- Lay carpets on the surface of the laminate, under which the heated floor system is installed.

Text: Natalia Stepanova

The article was published in the magazine “Professional Advice” No. 9 (2019). You can subscribe to the print version of the publication.

Technology of applying varnish to laminate

The composition is applied to exclusively dry lamellas with a paint roller or a wide soft brush

. Preliminarily cover the lower perimeter of walls and other vertical structures with protective tape. It is also important to ensure high-quality ventilation of the room and to work using personal protective equipment.

The nuances of creating a varnish coating on a laminate:

- Since the composition dries quickly, you need to work carefully and at a fast pace. It is worth considering that there will not be time to correct errors;

- work with a roller in a cross-shaped motion. Apply the composition across the line of laying the flooring, level it in the direction of the boards;

- when painting, M-shaped movements with a roller are excluded, this is fraught with shadow-like phenomena on the plane and a decrease in the decorative and operational potential of the varnish finish;

- process the surface, creating a thin layer of varnish, achieving uniform distribution of the substance;

- paint the laminate with 3-5 layers of varnish, maintaining a pause between applications for drying.

Important! Finally, the surface is finished using a special polish, taking into account that the varnish surface of the laminate is subject to minor damage.

Source: https://gidpokraske.ru/sovety-ot-gida/kak-pokryt-laminat-lakom-kakoj-vybrat-lak-podgotovka-i-tehnologiya.html

How to put it yourself?

All work on laying laminate on walls can be done independently. You don't need to be a super master to do this. You can sheathe any one with high quality with your own hands, be it straight or crooked.

Very often people ask us - how to nail it vertically? So - there is no need to nail it anywhere; even if you imagine that the heads of the nails will be driven into the grooves of the lamellas, then the next board will not fit tightly.

Remember the main thing: before you start fixing it yourself, let it rest after purchase, it must be saturated with the atmosphere of the room and accept the ambient temperature.

Do-it-yourself fastening can be divided into two main options - horizontally and vertically.

Application technology

The work is performed as follows:

- the floor is thoroughly cleaned with a vacuum cleaner;

- if there are defects on the coating, they are masked using special colored pastes or wax;

- apply the varnish with a roller or brush, evenly distributing the composition over the surface;

- You need to apply it in three or four layers, waiting for the previous layer to dry.

Some home craftsmen believe that before applying the first coat of varnish, it is necessary to sand the laminate in order to improve adhesion. Experts categorically do not recommend doing this, since sanding will render the coating unusable and will need to be replaced.

Laminate varnish can be used for restoration or protection purposes. Practical experience shows that the latter option is more profitable, especially if there is a high risk of damage to the laminate in the house. For example, if there are pets in the house that can damage the laminate.

Technique for applying coloring solution

To paint laminate flooring in a different color, you need to follow certain rules:

- As with varnishing, the floor must be clean. The only peculiarity is that when painting you need to clean the floor with hard sandpaper. Paint adheres better to rough surfaces. To remove large scratches, you can use wood putty. When dry, it is smoothed away from the tubercles with softer sandpaper.

- The prepared matte surface is cleaned again and treated with a special emulsion composition (primer). It acts as an adhesive link between the floor and the paint, and also levels the surface. The primer must dry well. Only after this can you start working with paints. The color and number of layers are determined independently.

- When renewing a laminate with polyurethane coloring mixtures, an important point is constant stirring, since due to the different densities of the solvent and the paint diluted with it, the coloring pigment will settle to the bottom.

- After application, you must wait until the enamel is completely dry, then you can apply the varnish.

How to care for painted laminate flooring

Having dealt with the question of what can be used to paint laminate flooring, it is worth mentioning the subsequent care of the coating. Floors will last longer if you care for them properly. Regular cleaning of homemade surfaces is a top priority. If we are talking about wet cleaning, then the floors need to be wiped dry. The humidity in the room must be maintained adequate to the performance characteristics of the laminate strips. The paint layer can be easily damaged by sharp or heavy objects (when moving them). Therefore, when planning reshuffles, you need to prepare in advance for updating the coverage. Carpets with dust and sand particles, heavy furniture, high-heeled shoes - all this can damage the painted surface.

Cleaning laminate floors

Summarizing

Carrying out measures to change the appearance of a laminated floor using varnish is possible, but subject to special rules. It is worth noting that this is not the most highly effective method, as it requires considerable labor and expense. You will have to breathe the paint and wait a long time for each layer to dry. In any sense, it is more profitable to completely change the laminate rather than fix it. The price of such a finishing resource is not so high, and even a beginner can assemble it.

If, nevertheless, such a step has been taken: the floor covering has been painted, varnished, then caring for it is important. The enemy of any laminate, including those treated with various chemicals, is water. Therefore, you should wipe the floor dry after cleaning and avoid high humidity in the house. You should avoid interaction of the floor covering with sharp, rough objects, and also clean the laminate under the rugs from particles of sand and dust.

The arguments presented regarding whether laminate flooring can be varnished or painted a different color clearly provide answers to these questions for anyone who wants to change the look of their floor.

Laminate flooring is more popular today than ever before. But, despite the external attractiveness of the coating, some compatriots are interested in whether it is possible to paint laminate flooring?

And why paint a laminated board if it already looks very good?

Economic justification for painting work

When choosing this method of updating the floor covering, it is worth considering the cost of the work. As mentioned above, to carry out this type of work it is necessary to purchase a considerable amount of building materials and have a lot of free time. By the way, according to most experts, purchasing a new laminate will be much cheaper. It also takes less time to install new flooring.

Expert advice (2 videos)

Materials for processing laminate (18 photos)

Choosing the right varnish solution

If the decision to strengthen the finishing coating with varnish is unchanged, then it is better to do it correctly. The result is influenced by the principle of competent selection of materials.

The choice of varnish depends on the type of coating applied to the laminate:

- if the laminating protection is made on an acrylic base, a special acrylic varnish is required;

- if the top layer of the laminate is a polyurethane film, then polyurethane varnish is used.

The color of the solution must match the color of the laminate. In most cases, a transparent varnish is used, suitable for any colorful shade of the finishing material.

There is a special varnish designed for laminated floor surfaces. It contains elements that ensure strong adhesion of the mortar to the panels, strengthening and protecting the floor covering from adverse influences.

Laminate restoration

Despite the resistance of this material to mechanical loads, during operation scratches and abrasions appear on it, which are difficult to remove. The most effective option for restoring an old surface in this case is painting.

As for how to update laminate flooring using stain and finishing varnish, this is impossible. This is due to the fact that before painting the coating should be restored with putties, which will remain visible under the varnish layer. Read whether laminate flooring can be varnished, and draw your own conclusions.

The main problem that arises in the process of painting such a surface is the lack of adhesion. On the smooth surface of panels, ordinary enamel does not adhere well. Because of this, the paint on the floor may peel off within a couple of months. It will remain only in the recesses and joints between adjacent panels.

Laminate varnishing: main advantages

Over time, any floor covering (even the most durable) is subject to wear and tear. Scratches from animal claws, the wheels of a computer chair, massive furniture constantly standing on the floor, the fall of sharp and cutting objects - all this can leave their mark on the laminate. As a result, roughness, chips, and abrasions appear on it, requiring masking. To remove them and return the flooring to its former freshness, you can apply varnish to the floor surface. Using an additional coating will cost much less than refinishing a worn-out floor.

For the purpose of additional strengthening and protection, the application of varnish enamel is also possible when laying a new, fresh laminate. This will allow the primary characteristics of the flooring to be preserved for a long time.

A pleasant appearance of the floor is an important point in home decoration. Laminate covered with a shiny film will give the interior a special appeal. But if enamel is needed only to decorate the home, then it is recommended to buy a ready-made finishing resource already varnished.

Safety precautions: how to protect yourself and indoor surfaces?

Carrying out repair work with coloring compounds at home requires compliance with safety measures. Vapors from varnishes, paints, stains, primers and other materials are poisonous and can cause poisoning of the body. To protect yourself from them, you need to wear a mask over your mouth and nose, and glasses over your eyes.

For minor repairs to small areas of laminate flooring, furniture may remain in place or may need to be moved. Masking tape will help protect its legs or lower part from paint, varnish or stain.

Eliminating cracks

It is also possible to restore laminate flooring when gaps form between the lamellas, but only if they are insignificant. After repair, they are usually not visible, but to eliminate the defect you need to use a special repair kit, or a composition made in a “handicraft” way.

Homemade composition includes:

- Crushed chalk;

- Construction paint matching the color of the coating;

- Liquid glass;

- Wood sawdust.

To ensure a high-quality putty, before connecting all the components, dilute liquid glass with a small amount of water. The finished composition should be quite thick. Only after this are all the cracks covered with a spatula, and then carefully cleaned with sandpaper. Then the restored floor must be polished using a special solution for caring for wood flooring.

Surface preparation

First of all, as already mentioned, the surface of the laminate will have to be carefully prepared before painting. This procedure will take a lot of time.

Step 1.

First you just need to clear the coating of debris, if any. It is not necessary to wash it with all sorts of means, but you still need to put it in order.

Step 3.

After this, all significant and deep scratches and chips must be puttied. This will level the surface to be treated. It is important to apply the putty with a spatula and not in an excessively thick layer, the upper part of which should be flush with the floor surface.

Step 4.

Now you can sand the floor with finer sandpaper. It is important not to miss a single laminated area.

Step 5.

Then the floor needs to be cleaned of any accumulated dust - rinsed and dried. It is also recommended to treat the surface with a degreaser.

This treatment will help achieve the desired degree of adhesion. As a putty, it is better to use one that is designed for working with wood.

How to care for painted surfaces?

Home painting makes the coating more susceptible to any mechanical stress, so you need to treat it more carefully. It is prohibited to walk on painted laminate flooring in stiletto heels. It is not advisable to place heavy furniture on it.

Many experts assure that a floor renewed by painting must be washed extremely carefully, wiping with a slightly damp cloth and then wiping dry. However, housewives note that after proper repairs, laminate flooring becomes not as capricious as before. They wash it more boldly using liquid household chemicals.

I note that a varnished floor will last another 3-4 years. Then it will have to be updated. However, this will still be a simpler and cheaper repair than completely replacing the laminate. For completeness, I suggest you watch the following video.

Preparatory work

The complexity of preparation depends on the wear of the laminate. Sometimes just sanding is enough, in other cases serious repairs are needed before painting.

Stages of preparation:

- cleaning the floor from dirt with a damp cloth;

- puttying potholes, cracks, gaps between boards;

- waiting for areas to dry, removing excess material;

- giving a dull finish to the laminated coating with sandpaper;

- cleaning up garbage with a vacuum cleaner;

- wiping the surface with a soft, lint-free cloth soaked in solvent.

Each lamella is sanded separately, and the degree of pressure is adjusted so that after matting, an even area remains. White spirit or an acetone-based product is used as a solvent.

Installation

According to the technology for performing the work, installing a plastic (PVC) laminate is no different from laying a regular one. Interlocking connections allow you to create a durable monolithic canvas without cracks. Before starting work, we recommend that you read the coating instructions in full and strictly follow the manufacturer’s recommendations. This will ensure the guaranteed service life of the floor.

Preparing the base

The base is leveled so that the difference does not exceed 2 mm per 1 linear meter. Depending on its condition, leveling is carried out by pouring a cement-sand screed; small defects are eliminated by sealing them with a leveling mixture. After this, remove debris and dust with an industrial or household vacuum cleaner.

Wooden floors are leveled with chipboard or OSB slabs, the joints of the slabs are puttied and cleaned.

Tools

Installing plastic is no different from installing conventional laminate. The work will require the same tools:

- level 2 m long;

- measuring tape or metal ruler 1 m long;

- pencil or marker;

- mallet;

- metal clamp;

- a flat wooden block measuring 2x4x50–100 cm for padding the laminate;

- limiter wedges 1.0–1.5 cm thick to fix the gap between the walls and the covering (you can

- purchase ready-made ones or use pieces of wooden planks of this thickness);

- jigsaw with metal file;

- masking tape.