When installing new plastic structures, installers often poorly seal the joints where windows meet slopes, window sills meet windows, or do not seal them at all. And most window companies do not install slopes at all, so homeowners make slopes themselves. Then the need arises to seal the cracks with one of the sealing compounds. For this purpose, it is best to use sealant for plastic windows. It is used to seal slopes made of plastic panels, and is also used to fill voids between the frame and the window sill.

For interior and exterior work

According to their physical and chemical properties, all sealants are divided into two categories - those used for outdoor work and those used indoors.

Sealants used for external work are subject to certain requirements that facilitate their effective resistance to aggressive external environments.

Seal the external seam with sealant

Requirements for external sealants:

- Chemical resistance. Expressed in successful resistance to mold, water and chemicals.

- Successful resistance to mechanical stress. That is, such a sealant must be durable and not be destroyed by external forces.

- Elasticity.

- Good thermal insulation properties.

- Have a dye in its composition or have an easily colored structure.

- When applied, have a condition in which all hard-to-reach places are easily filled (have fluidity).

- Easy to adhere to surfaces (high adhesion).

- Wide range of application and use temperatures.

Requirements for internal sealants:

- No toxins. This is the main requirement for sealants used in residential premises, preventing poisoning of people, animals and the development of allergic reactions.

- Resistant to biological agents, mold and bacteria.

- Moisture resistance.

Purpose of putty for windows

Window putty is a thick paste that is applied to the junction of the glass and the frame. Its necessity is to provide a certain level of tightness, as well as greater strength of the connection between the glass and the frame. It is also required to seal the joints of frame parts. Putty for wooden windows is also required to cover small cracks in the frames.

In plastic windows, glass does not often come off the frame, but putty for plastic windows helps solve another problem. It happens that after installing a plastic window, and sometimes a little later, small gaps form between the frame and the wall (window sill). Even if their value is small, this breaks the tightness, therefore, many of the characteristics of a plastic window disappear - heat retention and sound insulation, dampness and ice appear. To eliminate such gaps you will need a special putty.

Important! For wooden frames, the putty needs to be renewed. Failure to promptly replace window putty will result in the window cracking, and excess moisture may cause the wood of the frame to rot.

Kinds

A lot of time has passed since the creation of the first sealing composition and at the moment there are many types of sealants. We will consider those compositions that are most optimally suited for sealing window seams.

Polyurethane sealants

According to their chemical properties, polyurethane sealants can have either a one-component or two-component structure. A characteristic feature of this type is good adhesion (ability to bond) in all its representatives. Thus, polyurethane sealants can be used equally effectively for both sealing and gluing structural elements. If necessary, all seams filled with polyurethane can be easily restored, which means that the sealant has great maintainability.

Advantages of polyurethane sealants:

- Due to their composition, polyurethane sealants are very elastic and, therefore, not subject to the destructive effects of vibrations.

- Rapid hardening in the open air, upon interaction with the moisture contained in it. The sealant becomes solid within half an hour.

- Stability at low temperatures. Cured polyurethane sealant does not lose its properties at temperatures up to - 60 C.

- No shrinkage, eliminating the need for additional sealing of seams.

- It resists ultraviolet rays, therefore polyurethane sealant can be used to fill seams exposed to direct sunlight.

Disadvantages of polyurethane sealants:

- Short shelf life, limited to 9 months, after which the sealant loses its properties.

- Toxicity is caused by isocyanates included in the composition, causing allergic reactions, chemical burns to the skin and irritation of the lungs.

- Strict humidity requirements during installation. An important point when installing polyurethane sealant is humidity, which should not exceed a certain value specified by the manufacturer.

Top 3 polyurethane-based sealants

A reliable one-component option that is suitable for use in many areas. The main feature of the material is its high elastic modulus. The product is designed to seal seams and increase vibration indicators. The quality of the connection is at a high level, allowing you to fix materials made of concrete, metal or polyethylene. The depth of the seam should not be less than 5 mm.

Sold at a price of 345 rubles.

- Durable connection;

- High modulus of elasticity;

- High-quality sealing;

- Vibration resistance.

An excellent construction option, which is made on a polyurethane basis. Product color is white. The product is immediately ready for use after purchase. When the composition has completely hardened, a reliable and elastic layer is formed that will withstand almost any load and retain its appearance even after 20 years.

The average price is 360 rubles.

- High strength;

- High-quality adhesion;

- Resistance to sunlight;

- Doesn't drain.

A budget-friendly universal sealant that is suitable for home and professional use. Adhesion is at a high level, which allows you to connect different materials. The product meets international ISO requirements and Russian GOST.

Sold at a price of 160 rubles.

- Suitable for waterproofing;

- Good composition;

- Volume 600 ml;

- Durability.

- Not detected.

Rating of high-quality thiokol models

A reliable model that will provide the user with durability. The main feature of the product is good deformability and resistance to chemical attack. The substance is three-component, so it must be mixed and used immediately.

The average price is 6,500 rubles.

- Good performance;

- High service life;

- Resistance to various influences;

- Easy to apply.

- After preparation it must be used immediately.

Which composition to choose?

As a rule, different types of sealants are selected for external and internal work. A simple algorithm will help you avoid making the wrong choice.

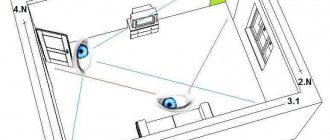

Sealant selection algorithm

- Decide on the location of the seam (indoors or outdoors). Outdoors, it is better to use silicone or acrylic (but at the same time, it will have to be coated with an antifungal compound) sealant. Acrylic sealant is ideal for sealing joints indoors.

- Selecting the color of the sealant or paint for it.

- Selecting weather conditions that correspond to the weather conditions specified by the manufacturer.

Also, useful tips on choosing a sealant for internal sealing of seams - see below:

Why is it needed?

Possessing a polymer moisture-proof composition, sealant for wooden windows is widely used as an insulating material that improves the performance characteristics of a room. Most often used when performing the following types of installation and repair work :

Fixing the glass in the frame structure when it deforms, dries out, or the fixing bead does not fit tightly.- Sealing cracks in the structure of a wooden window profile to reduce the risk of blowing or getting cold in winter.

- Sealing of opening sashes in the narthexes when the profile dries out and a through gap is formed, which facilitates the penetration of air and moisture, which causes frost on the windowsill and the settling of street dust in the room.

Modern sealants, depending on the composition and application technology, reliably close cracks and prevent blowing. After treating the window structure with high-quality material, the owner of the premises forgets about drafts and freezing in the apartment or house.

Sealing technology

To carry out high-quality sealing of window seams, it is necessary to strictly follow the sequence of operations during installation work.

Sealing gaps between slopes

- Along the boundaries of the gap between the window slopes, you should stick masking tape to prevent the sealant from getting on the slopes.

- The seam is filled with sealant so that its excess protrudes above the slope by 1 - 2 cm.

- Then, the sealant is pressed into the seam with a narrow spatula, sponge or simply a moistened finger.

- The masking tape and remaining sealant are removed.

Sealing cracks in window frames

- For better aesthetic perception, the color of the sealant should match the color of the window panels.

- Before carrying out work, you need to prepare the necessary tools and accessories: a gun for applying sealant, 2 small spatulas, a container with water and a sponge.

- The joints are pre-cleaned and degreased.

- The sealant is applied to a spatula and then placed into the window slot using transverse movements.

- After installation, the sealant in the seam is leveled with longitudinal movements of the spatula.

- Upon completion of installation, excess sealant is removed with a damp sponge.

Step-by-step instruction

To properly apply and smooth the sealant, you must follow each step described below in order. The instructions for carrying out the work are compiled based on the recommendations of professionals.

Connection of window frame and glass

If the clamping strip of a wooden window that secures the glass to the profile has lost its operational properties over time, the following steps must be taken :

The old glazing bead is removed and the paint is cleaned with sandpaper. If there is severe physical wear, the clamping bar should be replaced with a new one.- The dispenser cylinder is inserted into the gun, after which the technician carefully squeezes out the substance in a uniform, thin line along the entire contour of the window.

When performing work, you should not interrupt and change the force of pressing the lever, since the thickness of the layer may change. - The clamping bead returns to its place and is fixed to the frame.

- It is necessary to wait until the paste-like substance has completely set, and then carefully remove the excess substance from the glass with a knife.

- When attaching a window to butyl tape, the glass is removed from the profile, after which the material is glued around the perimeter of the seating surface, and the product is returned to its place.

If the work is carried out correctly, problems associated with loose connections, blowing, moisture ingress and rattling will be eliminated.

Seam sealing and protection

To return the old frame to its former performance qualities, it is necessary to carry out repair work to seal cracks, seams and joints by following the following algorithm :

- The window frame is examined for defects. This procedure is best carried out in the cold season.

- The seam or crack is cleaned of dust and dirt with a construction knife and sanded with sandpaper.

- The sealant should be applied from a bottle with a thin outlet on the diffuser.

- After application, the substance is pushed into the seam using a rubber spatula.

- After polymerization, the remaining sealant is cut off with a construction knife and removed with a dry sponge.

Important. Based on the results of the work, it is necessary to re-inspect the defects. If necessary, additional sealing work is carried out.

Reapplication

When performing repair and restoration work, if the old sealant has lost its operational properties, it must be completely removed from the crack or seam :

- First, the material is removed with a knife.

- If the material has retained its elasticity, it can be easily removed by hand.

- If the sealant has hardened during prolonged use, it must be heated.

- After removing the bulk of the sealant, the remaining substance is scraped off with a knife, after which the surface is cleaned with sandpaper or sandpaper.

After cleaning the seam, the sealant is reapplied in accordance with the same algorithm described above.

At what temperature to use

For each type of sealant, the manufacturer determines the application temperature and operating temperature. Silicone and acrylic sealants can be used at temperatures from +5 to +40 C.

Temperature conditions of different types of sealants:

- Acrylic. Its operating temperature range is from -20 to +70 C

- Silicone . Withstands temperatures from -60 to +300 C.

- Polyurethane. Can be used at temperatures from -55 to +80 C.

- Alkyd (STIZ A, STIZ B). Retain their physical and chemical properties at temperatures from -60 to +80 C

- Polymer sealants. They do not collapse in the temperature range from -55 to +130 C.

Subscribe

Useful tips for choosing

In order to correctly select the right sealant, you should use the following tips from professionals:

- You shouldn’t chase a product that’s too cheap; reliability and efficiency are the very parameters that you absolutely shouldn’t skimp on;

- Before purchasing, be sure to read the information provided by the manufacturer (conditions of use, composition of the mixture, instructions for use, etc.);

- If the buyer doubts the choice of the type of sealant (i.e., which base is better to use), then he should choose a silicone base, since in most cases it will be universal.

- If the price is of little significance to the buyer, then it is possible to opt for an expensive polyurethane product;

- You need to choose only those brands that have good recommendations.

Be sure to check the expiration date of the sealant. After long storage, it can deteriorate and lose all its beneficial properties, which, naturally, will ruin all the work done.

Peculiarities

Window sealant is a plastic, self-hardening mixture. The main component of the composition is a special polymer that interacts with air and tightly seals cracks and cracks.

When installing metal-plastic windows, white sealant is most often used. It is not visible at the junction of structural elements, which gives the light opening a finished look.

The use of plastic material allows us to solve the following problems:

- Window noise and waterproofing.

- Protection against temperature changes.

- Aesthetic design of PVC elements.

Sealant for windows of any type has good adhesion to all types of building materials and does not deteriorate under atmospheric influence for a long time.

How to seal seams?

In fact, if the polyurethane foam was applied correctly, then the windows do not require additional sealing. But if there is a need for this, then this event will help to apply the sealant. As a rule, it has good adhesion to most materials, does not allow moisture to pass through, and is able to protect the foam. Sealant for sealing windows can be used for both interior and exterior work. What sealants are suitable?

- Silicone.

- Rubber.

- Acrylic.

- Thiokol.

- Acrylate.

- Polysulfide.

- Polyurethane.

- Acetate.

What is the result? First, the window is installed (it is advisable that the distance from the wall to the frame does not exceed 2 centimeters). Next, the seams are filled with polyurethane foam (if work takes place in winter, it is necessary to use a special one-component polyurethane for work at subzero temperatures). When the foam dries, you need to cut off the excess. Next, the joints are sealed with sealant, plastered, puttied, and painted. Then the ebb, window sill, external and internal slopes can be installed.

Is it possible to seal a PVC window if the frame is cracked? If the structure itself is damaged, it must be replaced. Otherwise, it will not be possible to achieve high-quality sealing.

Is it possible to seal windows from the outside if the glass unit is cracked? Damaged glass unit needs to be replaced. It is impossible to achieve its sealing at home.

Types of sealing agents

Sealing products are divided according to various parameters. They can be used for specialized treatments or at home.

- Specialized ones are distinguished by the fact that they are suitable for individual processing of an object - for example, when gluing glass to a window frame. The main task is to solve the problem of moisture penetration into the glass unit. They are used primarily in production for sealing double-glazed windows.

- Sealing agents for household use are freely available in hardware stores. They have a different chemical composition and are more versatile.

Among the main sealing mixtures, there are several suitable for working with plastic windows:

- polyurethane;

- silicone sealants;

- acrylic compounds;

- polymer;

- alkyd.

Let's take a closer look at each review.

Polyurethane

Mixtures are used both on the outside and inside of the window. Thanks to excellent adhesion, the product is able to combine materials with each other. After a short time it sets. The paint adheres perfectly to the treated surface.

Polyurethane

Characteristics of the polyurethane sample:

- Resistant to the harmful effects of moisture, ultraviolet rays, and temperature changes.

- High levels of strength and elasticity make it resistant to mechanical damage.

- After drying it gives minimal shrinkage.

- Good grip.

- The polyurethane mixture creates a good seal of the windows.

It is produced in cylinders, which are a container filled with a creamy substance and a tip that delivers the component. The tip is a removable part.

Silicone

Silicone products are made from rubber. They are divided into three varieties.

Silicone

Let's look at the ingredients:

- Antiseptic specimens. Used in high humidity, where there is a high risk of mold and fungal growths. Thanks to its special composition, the silicone mixture copes with this task perfectly. When working with this type, special care should be taken, since the sample is toxic.

- Neutral. Suitable for working with any type of surface, but after drying it emits fumes of butyl alcohol, which does not have the best effect on the well-being of those living in the apartment. This is a reason not to use the composition inside the apartment. Another option is to create a draft by opening windows and doors for normal circulation of clean air.

- Acidic. Contraindicated for metal surfaces. Cause oxidation, corrosion with subsequent destruction of the metal. The vinegar smell that spreads through the air makes working with it unpleasant.

Acrylic

They are among the cheapest, most accessible sealing agents. The acrylic sample is capable of bonding surfaces of any type.

Acrylic

Let's look at the advantages:

- Good adhesion. An excellent tool for working with various materials - from wood to metal. When covering walls with plasterboard, it acts as an adhesive.

- Can be painted. The main color of the substance is white, and therefore after completion of the repair it needs to be decorated.

- Without smell. Unlike its silicone counterpart, it does not contain a strong odor and does not emit harmful substances.

Among the disadvantages, lower ductility should be highlighted. After drying, the mixture quickly hardens. With small displacements of the structure being treated, cracks appear on the surface of the sealant. Does not tolerate frost well.

Compositions made from polymers

The base consists of glue with the addition of transparent polymers. It acquires its usual white color after adding dye to it. Unlike other types, the polymer composition has a better penetrating effect. As a result, after processing is completed, a strong connection is created.

Polyurethane

Advantages:

- The white color makes the seam joints almost invisible.

- The shade does not change during use.

- Bonds surfaces well.

- Thanks to the penetrating action, the seam joint has high strength.

Flaws:

- It is necessary to use personal protective equipment - rubber gloves, overalls, goggles, and a respirator. This is due to the toxicity of the mixture.

- After application it starts working in less than a minute.

Alkyd

Advantages of these compositions:

- Surface staining of the sealant is possible.

- Used for external or internal work.

- Low price.

STEEZ A and STEEZ B