Tiles are considered popular materials that are used in the decoration of various rooms. Products differ in production technologies, materials, thickness, and length. Further operation and reliability are directly related to properly selected glue, but other nuances should not be cast aside either. One of them is the thickness of the tiles with adhesive on the wall.

Methods for determining the optimal adhesive layer

Experienced craftsmen do not give an unambiguous digital designation for any one universal thickness. Typically, the adhesive layer is determined empirically on site and depends on several components.

To do this, look at:

- size of slabs, their weight (mass), type;

- composition and type of adhesive mixture;

- characteristics of the treated base (wall or floor).

Since the thickness of each element determines its weight, it is used as a guide to apply a layer of tile adhesive. The weight of any product depends on its dimensions. For this reason, tilers do not use scales, but focus specifically on tile dimensions. And they only make adjustments according to the type of product (floor or wall tiles, porcelain stoneware). In this case, with synthetic types of adhesives, the thickness can be increased by a couple of centimeters, but not reduced. Whereas with cement types it is thickened, but not reduced.

So, what is the possible thickness of the glue for different parameters of the elements?

- Elements whose size is 50-100 mm - up to 2-3 mm;

- 100-150 mm - a layer of 3-4 mm;

- 150-200 mm - layer 4-5 mm;

- 250-300 mm - 6-7 mm;

- from 400 mm - from 7 to 10 mm.

Other parameters include, for example, for tiles - surface porosity. Since this porosity is significant, glue consumption therefore increases. Whereas porcelain stoneware in this case is much inferior to ceramics. Therefore, in the process, large-sized elements are laid on glue, distributed over the surface of 1 mm, as well as on the back side of the products.

In addition, the difference exists taking into account the surface on which the cladding is to be glued: the floor or the wall. Thus, by gluing tiles to the floor, the thickness of the adhesive solution can be increased. Whereas when gluing the wall base, this parameter decreases.

Of course, the characteristics of the surface itself to which the cladding will be glued have an increased influence on the size of the layer. The best results are easier to achieve when the base is in perfect condition. This means that the surface is leveled, there are no pits or bumps visible on it (even the smallest ones), it is cleaned of dust and excess mortar, and thoroughly primed with a deep-penetrating composition (you can ask the sellers in any construction supermarket about the suitable composition).

Another factor is the base material. So, for example, brick walls require increased consumption of mortar, while plasterboard and concrete surfaces absorb less, and therefore have a reduced consumption.

In addition, porcelain stoneware slabs, which are intended for floor finishing, often have significant errors in their evenness - both convexities and concavities are noted on them. In such a situation, the thickness under the lowest point of the porcelain stoneware cannot exceed 10 mm.

How to calculate how much glue is needed

I don’t want to buy extra building materials that will have nowhere to be used after the work is completed.

Video recommendations for calculating tile adhesive per 1 m²

To prevent this from happening, carry out the calculations:

- Select the format: as we have seen, the required maximum layer thickness depends on the size and type of future cladding.

- Decide on the choice of glue: there are synthetic adhesives for working with ceramics, and there are cement mixtures. Cement mixtures require more layers, but the low cost allows such consumption. Technical characteristics and consumption depend on the manufacturer and the direct composition. The packaging will contain instructions for use and information about the characteristics.

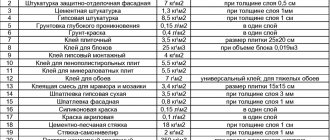

- The pack of tile adhesive indicates the amount of adhesive consumed per 1 m2 if the layer is 1 mm.

- Calculate how much glue you need per 1 m2.

- Then measure Insert shortcode how much area of the floor or wall needs to be tiled and find out how much glue is needed for all the work.

- You should always take materials with a small reserve, taking into account force majeure and possible errors in calculations. Take 10% more than necessary.

Important: the material consumption is indicated based on a perfectly flat surface that has the same water absorption.

The influence of the characteristics of the mixture itself

The key factor when planning the use of tile adhesive is its type, manufacturer, and the presence of components in the composition. The tile composition can be epoxy-based, dispersion type, or it can be a cement-based tile mortar intended for dilution with water.

From different manufacturers, the same type of adhesive may differ significantly in composition, and for calculations, the properties and density characteristics are taken into account. When purchasing a mixture on which you intend to lay tiles, you should study all the related information in the instructions supplied by the manufacturer. And especially - recommendations for volume consumption. It is important to understand here that the manufacturer is guided by the idea that the surface will be treated with the mixture with absolute evenness. Therefore, before finishing, you should bring the base to its proper form (work to eliminate all roughness and irregularities).

Caring for tile joints

Cleaning tiles should be done with acid-free products. Can be washed with plain water or water with soap or powder. Typically, tile manufacturers indicate the cleaning agent that is acceptable for cleaning.

If mold has already appeared, immediate removal is required to prevent further spread. It is cleaned off along with a small layer of putty (depending on the depth of penetration of the fungus). Remove dust. To prevent the reappearance of fungus, an antifungal agent is applied to the space between the tiles. If a small layer is cleaned off, leave it in this form; if you had to remove all the putty, fill the cracks with new one.

Layer Thresholds

Despite the fact that the thickness of the tile adhesive layer can vary within a certain range of numbers, this interval has boundaries. To ensure that ceramic or porcelain stoneware elements are securely fixed to the base, these extreme values must be taken into account.

The minimum layer of mortar applied when finishing with tiles is calculated individually, taking into account the format of the elements. In general, for small-sized products it is not recommended to make a layer greater than 2 mm. For heavy tile samples (for example, for porcelain stoneware floor slabs), the lower limit can be increased to 4-5 mm.

There is another indicator - the maximum thickness of the solution. An increase in the thickness of the mortar is usually due to attempts to level the base being finished without the use of auxiliary building materials and screed devices. In such a situation, mark all the depressions on the base and bring out the minimum layer of solution under the highest mark. The holes and cracks are filled with the mixture. And again, they adhere to the maximum thickness values - 10 mm for standard tiles on the wall, 15 mm for ceramics on the floor and 20-22 mm for porcelain stoneware products. Otherwise, a further increase in the mortar layer may result in poor adhesion performance and unreasonable costs.

Characteristics of ceramic tiles

Ceramic is a popular and very practical material for wall decoration.

The optimal solution for laying on a wall in a bathroom or kitchen is ceramic tiles. It has an attractive appearance and good strength and quality. The coating is not afraid of moisture and has good protection from mechanical stress. The cladding is made from environmentally friendly components, so it will not cause harm to health.

Finishing walls with tiles is a simple procedure, so even a novice builder can handle it. At the same time, the service life of the coating is quite long; if the installation technology is followed, the material can last more than 10 years.

The cost of the material is also at an acceptable level, due to which the finishing is quite popular.

Calculation of required volume

The adhesive solution, that is, its weight, is measured in kilograms (kg). To calculate the maximum volume of mixture required for the entire repair, first determine the amount of glue that will be required to lay tiles on 1 square meter of base area. After which the found figure is multiplied by the total number of meters of area.

To clarify the thickness of the tile mortar and its required mass for the entire volume of the tile, it is necessary, based on the initial data, to perform calculations in several steps.

- Determine the dimensions of the elements and select the optimal thickness of the mortar for them, taking into account the characteristics of the base being coated;

- The packaging of the mixture for injecting the solution must contain information about how many kg of the mixture is consumed to cover one square meter with a minimum thickness of 1 mm;

- Next, these two found values are multiplied, the intermediate result becomes known - the volume of the mixture to finish a meter of square area;

- After which they are determined with the total area of the base to be finished;

- Multiply the first total value by the number - square footage;

- In case of force majeure, you must always have a certain amount of the mixture in stock. Why is the final value in the last paragraph multiplied by a factor of 1.1. This will allow you to add 10 percent to the estimated volume for the reserve.

Spatula teeth size

The amount of mortar on the tiles and wall will directly depend on the height of the trowel-comb teeth. The thickness of the final adhesive layer will be approximately half the height of the teeth - that is, to get a layer 4 mm thick, you need to choose a spatula with 8 mm teeth.

When working with tiles that have a grooved pattern on the back, you should also take into account its depth, since the teeth will fit into the grooves. The greater their depth, the greater the height of the teeth the tool should have.

The composition of the glue also determines the height of the teeth. Since cement mortars are applied in a thicker layer, it makes no sense to use low tines. And vice versa - for synthetic mixtures, low teeth that create a thin layer are just right.

Experienced builders emphasize the importance of preliminary preparation of walls and floors before facing work. A smooth surface impregnated with a primer will take less glue, the coating will be even, with minimal risk of cracking and distortion.

Determination by other parameters

When deciding how much mortar to spread, it is based on characteristics such as the moisture absorption of the base and the moisture content of the finished mortar. When laying ceramics on a wall surface, the solution should be of normal humidity, but not semi-dry. In addition, the wall material must be treated with primer.

The greater absorbency of the base entails the need to increase the thickness of the solution, on which the tiles cannot fall off. At the same time, it is not recommended to pour water over the surface, especially surfaces plastered with a cement-sand composition with a low cement content. Floor cladding allows the use of a drier mortar than for the wall. But subject to low moisture absorption by the material.

The thickness of the solution is also greatly influenced by the height of the spatula tooth for distributing the mixture. So, with a tooth height of 8 mm, the layer of solution will be 4 mm thick. That is, it is equal to approximately half the height of the spatula teeth.

Beginners often find themselves at a dead end when determining the size of the mortar layer when laying out facing elements. Taking into account all the nuances described above, the correct answer will be found without problems.

Porcelain tiles for flooring

The minimum permissible thickness for ceramic tiles laid on the floor is eight millimeters; these tiles can only be laid in rooms with minimal mechanical loads. Therefore, for greater reliability, it is possible and necessary to lay tiles with a greater thickness, but here you should also not get carried away, since tiles thicker than twelve millimeters in domestic premises have no meaningful use. This will simply be a waste of your budget, since 12 mm tiles will withstand any type of household load.