To perform high-quality repairs, it is necessary to use appropriate materials. For example, when tiling walls and floors with ceramic tiles, porcelain stoneware or other similar means without Knauf Fliesen tile adhesive, it will be difficult.

It will provide a durable layer of fixation that does not lose its holding properties at any temperature and humidity. The use of such construction products will save you from various kinds of defects and unexpected damage to the surface.

Advantages and disadvantages

Trademark tile adhesive has a wide range of advantages. For example, it can be used to work with different types of bases. It is suitable for cladding concrete, cement, brick, stone and other bases (gypsum plasterboard, gypsum board, gypsum plasterboard, SML, TsSP). You can also apply cladding with this glue to cement plaster. In addition, the composition is easy to prepare: if you follow the instructions on the product packaging, preparing it will not be difficult.

This composition is plastic, which allows it to be used when finishing the base with a height difference of up to 2 mm per 1 m2. The diluted mass is convenient, does not flow or slide off vertical planes, and therefore does not increase the degree of inclination of each upper laid row. The solution has a long life cycle, so there is no need to dilute it in small portions.

The company's adhesive is resistant to high dynamic loads. It can be used for laying not only ceramic tiles and porcelain stoneware, but also for tiles, mosaics in the form of individual fragments and on a grid, natural and artificial facing stones. This is a modern adhesive that allows you to finish surfaces at a professional level. Convenience for buyers is the presence of modifications, due to which you can choose a special type of glue for a specific material.

There is no need to pre-soak the tiles. Due to its high plasticity, the solution not only fits well on the base, but also allows you to correct its minor unevenness. It will cover small holes and rid the rough base of microcracks. This is a material with a long service life. If the dilution and installation technology is followed, surface cladding with trademark glue will last for decades without needing repair.

Due to its high resistance to moisture, the mixture can be used for finishing rooms with a high humidity coefficient. The adhesive is a waterproofing agent for hygroscopic and mineral floors. An additional advantage is the fact that this composition is suitable for laying over previously installed tiles. In addition, every buyer is pleased with the price of the material.

However, with a lot of advantages, glue also has disadvantages. For example, it will not hold the cladding well if the base is not properly prepared. In addition, if you do not maintain the temperature conditions during operation, this may affect the quality and durability of the coating. If the air in the room is too dry, the life cycle of the finished solution will be shortened.

Advantages of Fliesen Knauf

Many developers have already appreciated the advantages of Flizen glue. The mixture can be prepared and used by a simple consumer. This does not require any special skills: everything is thoroughly described in the instructions supplied by the manufacturer, starting from the proportions to the process of diluting the solution.

Among the main advantages of Knauf products, we note the following characteristics:

- the high plasticity of the mixture allows the solution to be used when finishing bases with small differences in height, about 2 mm/sq.m;

- the compositions of this brand are mostly frost-resistant and support a sufficient number of “freezing/thawing” cycles (up to 30);

- due to its resistance to increased dynamic loads, the tile cladding material “set” to Flizen Knauf adhesive does not lose strength even in the case of intensive use;

- the adhesive solution of the mixture contains special synthetic components that significantly increase the adhesive characteristics and adhesion of the solution;

- resistance to moisture;

- The popularity of the brand is greatly facilitated by the reasonable price of Knauf tile adhesive and low consumption (on average 2500–2900 g/sq.m.) due to the use of thin-layer application techniques. Accordingly, we can talk about the optimal cost of work.

On a note

Once hardened, Knauf tile adhesive is resistant to significant temperature fluctuations, so it can be used to tile heated floors.

Specifications

Before purchasing a dry composition, you need to pay attention not only to its cost, but also to its technical indicators. The Knauf Fliesen composition has the following technical parameters:

The Knauf Fliesen composition has the following technical parameters:

- high adhesion to concrete bases (more than 0.5 MPa);

- withstand sudden fluctuations in ambient temperatures (from -45 to +80 degrees);

- quick setting and hardening time of the finished solution (dries within 2 days under optimal conditions);

- economical mass consumption (from 2 to 2.5 kg per 1 m2, depending on the quality of base preparation);

- low moisture absorption coefficient (does not exceed 3%).

After laying the material on the mortar, the position of the tiles can be adjusted within 10 minutes. The glue has excellent physical and mechanical properties: it does not “slip” and reliably holds heavy finishing materials, even such as stone.

Glue selection

| Glue | Lifespan | Adjustment | Grouting joints | Full load | Consumption | Frost resistance | Adhesion to concrete | t of operation |

| Fliesen | 3 hours | 10 min | 2 days | 7 days | 2.2-2.9 kg/m2 | > 25 cycles | 0.5 MPa | Up to +80 |

| Flizen Plus | 3 hours | 10 min | 2 days | 7 days | 1.7-3.7 kg/m2 | > 25 cycles | 0.5 MPa | Up to +80 |

| Flex | 3 hours | 10 min | 2 days | 7 days | 2.2-2.9 kg/m2 | > 25 cycles | 1 MPa | Up to +80 |

| Marble | 45 min | 10 min | 2 days | 7 days | 2.3-2.9 kg/m2 | > 25 cycles | 1 MPa | Up to +80 |

Fliesen

Suitable for interior and exterior work.

Packaged in 25 kg bags. The composition can only be applied in a thin layer - this is a universal composition, not designed for specialized use. It is recommended to work with porous ceramics that can absorb moisture. Porcelain tiles have a low-porous structure with a water absorption coefficient of less than 0.05%, therefore they are not suitable for working with the Flizen composition. Interior cladding requires working with ceramic tiles with a water absorption of less than 3% by weight. For external installation, tiles are used that have the same indicator of at least 5% for walls and 9% for plinths.

Scope of application in terms of bases: concrete, cement-sand screed and plaster, plasterboard, cement-bonded particle boards. The temperature of the air and the base during installation is from +5 to +25 degrees. Consumption:

| Tile size | ||

| 10-20 cm | More than 20 cm | |

| Height of spatula teeth, mm | 6 | 8 |

| Glue consumption, kg | 2,2 | 2,9 |

Flizen Plus

Reinforced frost-resistant adhesive, used for cladding outside and inside with ceramic and porcelain tiles and natural stone. Resistant to slipping. NOT suitable for heated floors. Substrate suitable for laying on Knauf Flizen Plus: concrete, plasterboard and gypsum fiber sheets, cement-sand plaster and screed, cement boards of the Knauf Aquapanel type. The surface before installation must be smooth and clean, strong and dry, with a temperature of at least +5 degrees.

| Tile size, cm | To 10 | 10—20 | More than 20 |

| Height of spatula teeth, mm | 4 | 6 | 8 |

| Glue consumption, kg/m² | 1,7 | 2,2 | 2,9 |

Compared to the Flizen mixture, Knauf Flizen Plus has the advantage of a wider range of facing materials. With the same adhesion to concrete as the Flizen composition (at least 0.5 MPa), it allows you to work with low-porosity slabs - porcelain stoneware. The consumption of the mixture is reduced due to its elasticity; laying on a thin layer is possible.

Flex

Composition with increased adhesion and elasticity. Designed for cladding with porous tiles and non-moisture-absorbing slabs - porcelain stoneware and natural stone. Used for installation of insulating materials (mineral wool, expanded polystyrene, etc.).

Laying on a non-standard base - waterproofing.

Flex can withstand high thermal and dynamic loads thanks to additives; some of them contribute to elasticity, responsible for the ability to resist deformation. Consumption:

| Tile size, cm | 10—20 | 20—30 | Over 30 |

| Height of spatula teeth, mm | 6 | 8 | 10 |

| Glue consumption, kg/m² | 2,2 | 2,9 | 3,7 |

Marble

Tile adhesive Knauf Marble is a quick-hardening white mixture, which, in addition to cement, contains polymer additives and mineral filler. It is used for cladding a thin layer of marble, granite and other stone slabs. The white shade allows you to work with translucent ceramics, glass tiles and glass mosaics. The color of the adhesive protects porous tiles and natural stone from discolouration.

Laying mosaics with white glue.

The mixture sets quickly, so the time for adjusting the laid tiles is reduced and is a maximum of 10 minutes.

The composition is used for laying tiles on floors with heavy loads. But in this case, it is recommended to treat both the facing material and the base with glue. When laying a large area outside, it is recommended to use expansion joints due to thermal fluctuations. Consumption:

| Tile size | ||

| 10-20 cm | More than 20 cm | |

| Height of spatula teeth, mm | 6 | 8 |

| Glue consumption, kg | 2,3 | 2,9 |

To get high-quality cladding, do not neglect studying the adhesive nuances. Laying tiles with an unsuitable composition will lead to unnecessary financial costs if you use expensive strong glue under standard conditions, or to destruction of the cladding if you do not take into account the specifics of the surface and materials.

comments powered by HyperComments

Features of application

Installation requires compliance with the temperature range. The solution will be applied with a trowel and a notched trowel. Flizen glue has an easy way of working, so you can carry out repairs yourself, saving money on the services of specialists.

The solution will be applied with a trowel and a notched trowel.

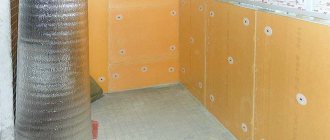

Preparatory work

You can only work at certain temperatures; if the weather is hot, then repairs should be postponed. Also, you cannot work at temperatures below +5 degrees. Surface preparation consists of the following steps:

- Clean the wall from dirt and dust;

- The form lubricant is removed from the concrete surface;

- Degreasing is carried out using the available product;

- Remove old finishes;

- If there is a painted surface, a non-waterproof type of paint is removed; if a moisture-resistant coloring agent was used, then it can be left and sanded;

- The wall must be completely dry;

- If work is carried out with a heated floor, then it is turned off a day in advance.

The gypsum screed and part of the area where contact with water is expected is covered with waterproofing materials. The plaster layer should not exceed a centimeter; application in one layer is used. If installation will be carried out on surfaces that are well saturated with moisture, then priming is required. It is better to choose a primer from the same manufacturer; a combination of materials will give the best result; Knauf has two types of suitable primer solutions, which are selected according to the type of base.

If installation will be carried out on surfaces that are well saturated with moisture, then priming is required.

Dilution and application of glue

The composition must be diluted strictly according to the instructions in the manufacturer's instructions. Per kilogram of mixture from the bag you will need to use 250-300 milliliters of water. Cold water is poured into the prepared container in the required quantity, then the mixture is poured in, and the components are mixed. For this purpose, use a construction mixer or a drill with an attachment. You need to get a homogeneous mass, without lumps. Then leave the solution in a closed container for five minutes, after this time the composition is mixed again and begin to work.

You need to get a homogeneous mass, without lumps.

The glue is taken with a trowel, transferred to a spatula, applied to the material, then leveled with a notched trowel. It is necessary that 80% of the area is covered with glue; to check, the freshly laid tile is removed and they look to see how much glue remains on it. If the quantity is insufficient, you can use a larger spatula, or apply the composition to the base as well.

Ten minutes are given to correct the position of the tiles; they should be pressed firmly against the surface. When a crust appears on the glue, it is removed manually. If the composition gets on the front side of the tile material, then it must be wiped immediately using a damp cloth.

Ten minutes are given to correct the position of the tiles; they should be pressed firmly against the surface.

Application

Preparatory work

- To ensure the maximum level of adhesion of the base under the cladding, the surface to be finished should be carefully prepared. To begin with, it is cleaned of dirt, dust and grease, grease stains, peeling and other defects are removed. Old waterproof paint, varnish and any glossy areas are sanded, non-waterproof paint is washed off.

- The cleaned surface is thoroughly dried.

- If the base is made of highly absorbent materials, for example, cement or gypsum plaster, it is pre-primed using Tifengrund Knauf and left to dry for three hours. The temperature of the base should not be less than 5 °.

- When finishing a heated floor, it must be turned off for a day before starting finishing work.

On a note

During the cold season, you can limit yourself to reducing the floor temperature to 15˚.

Preparation of the solution

Dry Flizen mixture and clean water are mixed in a ratio of 5 kg per 1.4 liters. A construction mixer is used for mixing. The ready-to-use composition must have a homogeneous structure. It is recommended to prepare the solution in two stages:

- mix until smooth;

- let the mixture sit for 5–10 minutes;

- mix again. If necessary, the consistency can be adjusted by adding water or dry mixture.

On a note

The finished composition can be used on average within three hours. If the facing work requires more time, and the mixture has already thickened, it can be mixed again without adding more water.

Applying Knauf glue

The mixed dry mixture is not applied immediately - it is necessary to soak the solution for 10-15 minutes. To apply the binder mixture, use a notched trowel, which is selected taking into account the caliber of the tile. The size of the teeth should be such that the back side of the tile is in contact with the adhesive layer on at least 80% of its area. In the case of external cladding, the back side must be in full contact with the adhesive.

| Glue brand | Tile caliber, mm | |||

| up to 100 | 100–200 | 200–300 | from 300 | |

| Fliesen | 6 | 8 | 8 | |

| Fliesen Plus | 4 | 6 | 8 | 8 |

| Flex | 6 | 8 | 10 | |

| Marble | 6 | 8 | 8 |

Selection of spatula by tooth height (in mm)

It is recommended to first evaluate the choice of spatula. This is done simply:

- remove freshly laid tiles;

- examine it from the back;

- if the glue does not cover the tile enough, the spatula is replaced with another, larger one;

- You can choose another option: apply the adhesive mixture to the tiles as well.

- The adhesive composition is evenly distributed over the surface of the base, using a spatula on the smooth side. Then the smooth surface of the adhesive layer is “combed” with its serrated side, holding the tool at an angle of 60 degrees. In the area of the upper level of the cladding, a horizontal broach is performed approximately to the height of the tile.

- For external cladding and tiles that have a grooved texture on the side, the composition is also applied to the back side of the tile.

- After fixing the tiles, it takes 10 minutes for full adhesion. During this time, if necessary, it can be adjusted.

- If a crust has formed on the surface of the laid binder mixture, this layer is removed and replaced with a fresh solution.

| Glue brand | Tile caliber, mm | |||

| up to 100 | 100–200 | 200–300 | from 300 | |

| Fliesen | 2,2 | 2,9 | 2,9 | |

| Fliesen Plus | 1,7 | 2,2 | 2,9 | 2,9 |

| Flex | 2,2 | 2,9 | 3,7 | |

| Marble | 2,3 | 2,9 | 2,9 |

Glue consumption, kg/m²

Important

The glue contains cement, so when working with it,

- put on gloves

- protect your eyes from contact with the solution. If this does happen, you should immediately rinse your eye and seek medical help.

- After finishing installation, the tools are immediately washed with water.

- Adhesive stains are removed without delay, without allowing them to dry.

Consumers who have personally used the composition leave extremely positive reviews about Knauf Flizen tile adhesive. They note excellent characteristics: low consumption, ease of preparation and application of the composition, convenient price.

Application and consumption

Knauf Fliesen tile adhesive is universal. It can be used both indoors and for outdoor decoration. The composition is able to withstand the harsh climatic conditions typical of Russia.

The following materials are fixed using the solution:

- porcelain stoneware;

- ceramic tile;

- various types of opaque stones, tongue-and-groove slabs and other materials.

The dry mixture is suitable for almost every foundation. It can be made of concrete, cement, limestone, plasterboard and other materials. The solution can also be laid on previously installed matte tiles. Due to the fact that the glue can withstand temperature fluctuations, it can be used for arranging floors with a heating system.

With a maximum permissible thickness of the mixture layer of 5 mm, the consumption per 1 m2 will be approximately the following:

- for tiles with dimensions of 10x10 cm, no more than 1.8 kg of material will be needed (when using a spatula with a tooth length of 4 mm);

- for cladding 20x20 cm you will need at least 2.3 kg of mortar (trowel with 6 mm teeth);

- for 30x30 cm tiles it can take up to 3 kg of finished mass.

Breeding

Before work, the dry mixture should be prepared. To do this, you need to take 1.4 liters of water and 5 kg of material (to dilute 1 bag you will need approximately 7 liters of water). To prepare the solution, you need to pour the mixture into a prepared container with a measured amount of liquid. After this, you should mix the components using a construction mixer or a drill with a special attachment. The mixture must be mixed for 2 minutes. The finished mass is characterized by plasticity and homogeneity.

After mixing, let the mixture sit for 10 minutes, then mix again. The finished solution must be used within 3 hours (then it will begin to lose its elasticity). Working time with the material may be reduced if the air temperature is too high or if there are drafts. If the mixture thickens, you need to mix it again with a mixer without adding liquid. An additional amount of water will deteriorate the technical characteristics of the solution.

Preparatory work

Knauf Fliesen solution cannot be applied to unprepared substrates. Before starting finishing work, it is necessary to clean the base from various contaminants, grease stains, and old peeling layers. You also need to wash off the water-based paint. After all manipulations, the base should dry well. Application of the composition to wet structures is not allowed.

When working with the solution, it is important to ensure that the room temperature is between +5 and +15 degrees. If the composition is planned to be used for arranging heated floors, the heating system must be turned off one day before

If the material is intended to be applied to poorly absorbent substrates (for example, concrete), they must be pre-treated with a primer. The primer composition is applied to the cleaned surface using a brush, roller or spray. If the base has increased moisture absorption (cellular concrete, porous brick), it must be coated with a primer at least twice.

Application of the solution

The finished adhesive composition must be distributed in an even layer over the surface of the base, using the smooth side of a spatula. Then you should “comb” the applied solution with the jagged side. The solution should only cover the area that can be treated within 20 minutes. For street work and installation of tiles with a corrugated texture, the solution is applied to both the base and the finishing material.

After laying the first tile, you need to lightly press it onto the base. Within 10 minutes it is possible to adjust its position, since after this time the cladding reliably adheres to the material.

Ceramic tiles are installed using the “open joint” method. In this case, the plane must be leveled using special construction equipment (level, level). If a dried crust forms on the surface of the applied mortar, the layer must be removed and the composition reapplied. If glue accidentally gets on the cladding, it must be immediately removed with a damp sponge or rag before it hardens.

It is important not to forget that the composition contains cement, which is why you need to follow some safety rules: you should work with protective gloves and avoid getting the solution in your eyes. After installation is completed, you must immediately rinse all used tools with water.

Composition and properties

When choosing any building mixture for high-quality repairs, the consumer usually pays attention to its properties and chemical composition. The quality and durability of the finish will directly depend on this. The fact is that not all substances can contact each other and provide strong adhesion.

The presented tile adhesive is well suited for finishing both outside and inside a building, but it should not be used when tiling a floor with an integrated heating system. Otherwise, it is ideal, but requires certain conditions to be met for the repair to be durable. Able to withstand moderate physical stress and has high adhesion.

The tile adhesive in question is made on the basis of cement, mineral additives and water-repellent components that prevent water from penetrating into the thickness of the installation layer, protecting it from destruction.

There is also a special plasticizer that makes the finished solution elastic and pliable. Easily applied to the surface using a comb, grater or spatula.

Strengthened composition

The presented product for tiling walls and floors with tiles or porcelain stoneware is highly durable, so it is recommended by specialists when installing finishing with a total weight of 1 square meter. m up to 45 kg. Moreover, the material can withstand up to 50 cycles of complete freezing, which indicates relative durability.

The reinforcing properties are ensured due to the presence of special polymerizing components in the composition, so it is ideal for laying floor coverings in rooms with high traffic.

Types and forms of release

The Knauf line of tile adhesives is presented in various types. The mass is produced in dry form in bags of 5.25 kilograms. The bag is made of durable material that protects the contents from moisture and solar radiation.

Clay Flizen

Knauf Flizen glue is a high-quality, consumer-grade mixture on the market. It does not require special skills in preparing the solution; it is enough to study the instructions and follow the proportions and instructions. Designed for gluing various types of tiles.

Advantages:

- Flexibility. Used to level planes with differences of up to 2 mm per square meter.

- Strength and reliability are ensured by special synthetic-based components. They significantly increase the adhesion of materials, which withstands maximum loads.

- Availability. Along with similar compositions, fleece is low cost and economical in consumption.

Flizen Plus

This adhesive composition is similar to the previous one. But an additional quality is the ability to work with stone.

Application requires preliminary cleaning and leveling of the working surface. You should also follow the instructions strictly.

Knauf Marble

Adhesive mixture for Marble tiles - white composition. The composition includes polymers and additional components. The mixture is used for finishing marble, granite, etc. Since the white consistency does not change the color of materials, it is applicable for translucent products: ceramic tiles, glass mosaics.

When covering floor slabs, the mixture must be applied to both surfaces to be glued.

Advantages:

- Fast hardening.

- Suitable for indoor and outdoor work.

- Heat resistance. Used with a heated floor system.

- Low consumption level.

One of the disadvantages is the need for careful preparation of the working plane. The principle of working with this composition:

- Remove dirt, dust, grease stains, and loose materials.

- Prime and let dry completely.

- The diluted mixture is infused for 10 minutes, then mixed, applied with a notched trowel to 80% of the surface.

Knauf Perlfix

Perlfix glue is a gypsum mixture containing polymer components. Used for interior finishing of hygroscopic surfaces (brick, concrete, etc.).

When preparing the solution, no lumps are formed, fast adhesion, adhesive strength. Complete drying occurs after half a day. The period depends on the room temperature and humidity. The shades of the mass may differ, depending on the ratio of additives in different batches. Knauf Perlfix is produced in packages of 15 and 30 kilograms.

Clay Knauf Flex

Knauf Flex is a tile material used for indoor and outdoor gluing of ceramics, all types of stone, and porcelain stoneware. Materials are glued to horizontal (floor) and vertical (walls) planes. Applicable for underfloor heating systems.

Advantages:

- Water resistance.

- For fastening heavy materials that are under constant mechanical and physical stress.

- Base: concrete, brick, stone, old tiles.

The negative side is the long drying period. To achieve maximum performance properties, you must wait at least a week. Before application, it is necessary to level the surface and ensure its strength.

Varieties

Knauf is available in several types, each of which has its own technical characteristics that distinguish it from the rest. To obtain high-quality cladding, before choosing a composition, it is necessary to study the features of each adhesive variety.

Universal fleece

Recommended for work inside and outside the building. Shelf life after preparation is about 3 hours. For 1 m2 you need from 2.2 to 2.9 kg of Fliesen. Apply a thin layer. Adhesion – 0.5 MPa. Recommended for porous ceramics that absorb moisture. Not suitable for porcelain stoneware slabs, since they have low water absorption and have a low-porous structure.

Flizen Plus with enhanced formula

This composition has increased frost resistance. Indispensable for interior and exterior decoration using porcelain stoneware, ceramic tiles, and natural stone. Not suitable for heated floors. For 1 sq.m. consumption is from 1.7 to 2.2 kg (reduced consumption) depending on the type of surface, which must be leveled, dried and cleaned before installation. It differs from the universal Flizen in its wide range of facing materials, since it allows you to work with low-porosity ones.

Flizen Flex

It differs from the universal Fliesen in its increased adhesion to concrete (1 MPa) and elasticity, since it contains certain additives. Used for natural stone, porcelain stoneware, suitable for porous tiles. Used for fastening polystyrene foam, mineral wool, and other insulating materials.

Fliesen Flex is recommended for surfaces with heavy loads or temperature fluctuations. Suitable for industrial plants, as well as balconies, terraces, and heated floors. Has proven itself well when used on wood and chipboard. Thanks to increased adhesion, it is possible to lay tiles on top of other tiles.

Fliesen Marble

A quick-hardening adhesive containing cement, mineral filler, and polymer additives. The lifespan of the prepared mixture is 45 minutes. It has a white tint, which allows it to be used for glass tiles, translucent ceramics, and glass mosaics. The color of the glue protects the facing material from changing color. Also suitable for cladding granite, marble and other stone slabs.

Flizen Marble is suitable for both external and internal finishing of all standard flat substrates. Used for balconies, terraces, heated floors, and other surfaces subject to temperature fluctuations. It is used for laying tiles on floors with heavy loads, in this case it is also applied to the tiles.

Fliesen Max

A thick-layer mortar used in cases where increased strength of the masonry is important. Applied in a layer of up to 3 cm, it allows you to achieve the effect of leveling the floor and walls in parallel with the cladding. Not suitable for heated floors.

Main advantages

Knauf glue has several undeniable advantages.

Plastic

Due to its plasticity, the composition can be used on surfaces with minor defects, since it will evenly fill problem areas. There is no need to pre-soak the tiles in water. The elastic structure of Knauf allows it not to collapse for a long time.

Frost resistance

High frost resistance allows Knauf to be used for outdoor work. When temperatures change, the seam retains its characteristics and remains intact.

Strength

The glue does not slide off the surface, making it possible to hold even heavy facing materials

In this case, it is important during work and further operation to observe the temperature specified in the characteristics of the mixture

Good adhesion of the solution

Knauf glue has good adhesion to substrates. However, since Knauf hardens quickly, it cannot be applied to large areas at a time, since when laying facing materials on glue that begins to dry, the quality of the bond will be reduced.

Ease of use

Working with Knauf glue does not require special training. It is enough just to strictly follow the instructions written on the packaging. Due to the fluidity of the composition and its inherent self-leveling effect, gluing tiles to walls and floors is not difficult.

Kinds

The Knauf company is one of the most popular among consumers. Currently, it produces several types of adhesive mixtures. Each of them has its own characteristics and properties. The common features of all samples are high frost resistance, moisture resistance, strength and low consumption.

Knauf Fliesen

This adhesive can be used for a wide variety of construction work. It is often used for interior and exterior decoration. It is worth noting that such a solution is capable of gluing together even heavy, massive structures made of ceramics or porcelain stoneware.

Knauf Fliesen glue is an excellent basis for fixing various insulating materials:

- polyurethane;

- polystyrene;

- polystyrene foam;

- glass wool;

- mineral insulation;

- decorative objects made of foam plastic.

Apply this glue in a thin layer using a notched trowel. Experts classify this adhesive solution as a universal type. After all, it can be used on almost any type of surface.

Most often, this glue sample is used for the following types of substrates:

- silicate;

- brick;

- cement;

- gypsum and plasterboard;

- limestone;

- concrete.

Knauf Flex

This adhesive mixture is also very popular among consumers. It is distinguished by special hermetic properties and high elasticity, and boasts special moisture resistance and frost resistance. This composition is ideal for gluing porous surfaces, stone, and moisture-absorbing porcelain stoneware.

This glue is usually used for gluing large, heavy slabs and for installing insulating materials (expanded polystyrene, mineral wool). It is often used when decorating balconies, verandas, and terraces. During production, special substances are added to this solution, which determine the high strength and reliability of the mixture.

Knauf Fliesen Plus

This adhesive mixture has the same enhanced frost resistance, moisture resistance, and hermetic properties as the Knauf Fliesen sample. But at the same time, this solution can boast that its consumption is much lower compared to other samples of this brand (1.7-2.9 kg/m2).

The time for adjusting a tile structure with this glue is only 10-15 minutes. The solution hardens within several hours. This mixture is one of the most durable and reliable. It is often used for heavy and large porcelain stoneware and ceramic slabs.

Most often, this adhesive mixture is used for finishing the following materials:

- fake diamond;

- marble;

- mosaic and glass tiles;

- ceramics;

- porcelain stoneware;

- decorative brick;

- granite.

Knauf Marble

This sample of Knauf assembly adhesive is the fastest-hardening among its analogues. Therefore, slabs and other parts should be fixed within the first few minutes. The mixture contains not only the usual cement mass, but also various mineral fillers and polymer additives. This adhesive solution is used, as a rule, for tiling granite and marble tiles.

This adhesive is suitable for both exterior and interior decoration. It can be applied to almost any type of surface: concrete, gypsum and plasterboard structures, screed, cement-sand plaster, cement-bonded particle board products. It can glue dissimilar types of materials.

Such a sample, as already mentioned, sets very quickly; the time for adjusting the tile is no more than 10 minutes. The composition is perfect for structures that are subject to heavy loads. At the same time, most experts recommend treating both the base and the facing material with glue at once.

Types of Knauf brand adhesive for tiles, technical characteristics

There are four types of Knauf tile adhesives; they differ somewhat in their properties and operating rules. Mixtures are produced in paper bags, in which protective layers are made to prevent moisture and other substances from getting inside. Packaging is carried out in 10 and 25 kilograms. It is advisable to store on wooden pallets in dry conditions.

Mixtures are produced in paper bags, in which protective layers are made to prevent moisture and other substances from getting inside.

Fliesen

Knauf Fliesen is a universal composition suitable for tile material that will be laid indoors with a moisture absorption level of up to 3%. When working outside, the level should reach 5%. The best quality is shown when gluing to plasterboard, concrete, cement-sand base, and also to plaster. It is unacceptable to use low-porosity tiles for connecting to walls; their moisture absorption rate is low.

A universal composition suitable for tile material that will be laid indoors with a moisture absorption level of up to 3%.

Fliesen Plus

Knauf Fliesen Plus strength characteristics are better than the previous type. To obtain this quality, polymers and mineral fillers are added to the composition. They stand out for their better adhesion to different surfaces. Can be used when laying tiles with low moisture absorption and stones. It has the property of frost resistance, so it is often used for cladding work, also for cladding plinths.

Can be used when laying tiles with low moisture absorption and stones.

Flex

“Flex”, when compared with Knauf Flizen universal tile adhesive, is more plastic and elastic. Can be used for porous and medium-porous tile products, porcelain stoneware. Can be used for working with insulating products. Stable under dynamic loads. Suitable for working with wood, chipboard, heated floors.

Can be used for porous and medium-porous tile products, porcelain stoneware.

Marble

It is white in color and contains a white cement mixture, polymers and minerals. It has excellent reliability and adhesion, which is why it is used when working with different types of stones, both artificial and natural. Knauf adhesive for porcelain tiles is also suitable for glass and ceramic tile materials, mosaics. To enhance the effect of the connection, it is recommended to apply the solution to both the base and the tile.

It has excellent reliability and adhesion, which is why it is used when working with different types of stones.

Peculiarities

Since Knauf Fliesen tile adhesive is a product of a Russian manufacturer, its cost is acceptable for most domestic consumers. The facing mixture is suitable for laying wall ceramics, porcelain floor tiles indoors and outdoors on various types of surfaces, including tongue-and-groove slabs. The prepared mixture has a grayish tint, the consistency of the glue is thick, with minimal fluidity. The main feature of the adhesive material is the strong fixation of heavy tile dies, and not all foreign-made adhesives can cope with this task.

Knauf Flizen tile adhesive contains high-quality cement and fine sand. Auxiliary components of the glue are special additives and fillers, which give the finished mixture moisture-repellent and frost-resistant characteristics. Antiseptics provide reliable protection against the formation of mold and mildew. Knauf Flizen adhesives have quality certificates and comply with the required standards and norms.

Key features of the adhesive mixture:

- One hundred percent contact with dimensional tiles.

- Good interaction with primer mixtures.

- Minimum layer thickness and uniform application.

- High adhesive properties, good adhesion.

- Universal applicability for finishing, insulation.

The main purpose of Knauf Fliesen products is the installation of moisture-absorbing tiles on flat surfaces. Applying the composition to a base with defects, differences, or deformations leads to greater consumption of glue. Plaster and surfaces in contact with water must be pre-treated with a waterproofing material.

On a note! Flizen Kleber Knauf tile adhesive is suitable for installing finishing and insulating materials. The glue firmly adheres polystyrene foam, polystyrene, polyurethane, glass wool, mineral wool, and decorative items.

Usage

Before laying tiles or other facing materials, it is necessary to properly prepare the base. This involves not only removing the crumbling old coating. It is necessary to remove any dirt and oil stains, and get rid of lime if there is any on the floor surfaces.

Next, a deep penetration primer is applied to the ceiling. It will strengthen the base, level its structure, and bind remaining dust particles and microcracks. After applying the primer, the surface is leveled with a cement-based rough plaster mixture, then trimmed and treated again with a primer. And only after this can cladding be carried out.

The glue is diluted with clean water at room temperature according to the instructions indicated on the bag label. In this case, a construction mixer is used so that the working solution has a uniform consistency. After the initial stirring, it is left for a few minutes, then mixed again and used. During the work, use a regular spatula to apply glue to the work surface, as well as a serrated tool to normalize the amount of glue.

Apply glue to part of the surface, distribute it evenly, then remove the excess using a notched trowel. Take a die, spread glue on it, and then pass through the solution with a notched trowel in a direction perpendicular to that on the plane. This way you will be able to distribute the glue correctly and also carry out the work as carefully as possible. Afterwards the element is slightly pressed to the base.

This is how all the dies are laid. To identify the gaps between the tiles, plastic crosses or special clamps are used. Excess composition is removed with a rag. You cannot scratch it from tiles or other materials, as this will affect the aesthetics of the cladding.

A day after installation, the crosses or clamps are removed, and the voids between the fragments are filled with a special grouting compound. After it has dried and hardened, the remaining grout is removed with a dry sponge, rubbing it over the entire facing area. You can treat the surface with a special spray. Do not grout if the tile adhesive has not yet dried.

Glue characteristics

Compound

Knauf Fliesen is based on construction sand, which is necessary to create the final mixture, and cement, which plays the role of a binding component. In addition, tile adhesive contains a number of components that improve its characteristics. It contains special additives that allow it to maintain its original state in all weather conditions and improve its reliability when fastening materials.

Laying tiles

Properties

The key advantage of Knauf glue is its minimal consumption per area, which is achieved using the thin-layer application technique. Despite this, it does an excellent job of installing even the heaviest coatings. Tile adhesive of this brand is resistant to moisture and low temperatures, which is very important in Russia. Among other things, it can be stored for one year, provided the original packaging is preserved.

Application area

Knauf Flizen can be classified as a universal adhesive solution, since it fits almost any base. It goes well with ceramic, marble and mosaic tiles, and is also suitable for exterior cladding. Knauf glue copes well with hanging slabs, as well as on open-air surfaces.

Application

To obtain the maximum level of adhesion, you first need to prepare the surface for cladding. It is necessary to clean it from grease, dust and old coatings such as varnish or paint. After this, the base must be thoroughly dried. If Knauf Fliesen is used for a glossy surface, it is advisable to give it a little roughness. Any defects in the facing surface must be removed, otherwise the glue may not cope with the intended task.

The consumption of one kilogram of the adhesive mixture is per 200 ml of water at room temperature. When mixing, you need to achieve a homogeneous mass by stirring it for 5 minutes. It is best to use professional construction equipment, such as an electric drill. To achieve the best quality solution of the adhesive mixture, you need to let it sit for another 5 minutes, then mix again. On average, Knauf retains its properties for 3 hours, however, if it took longer to coat, you can mix the composition again without adding water. The tile adhesive is applied to the base using a special spatula. Within 10 minutes after fixation, the tile can still be adjusted, but after this period, the glue will completely adhere to the surface.

Types and forms of release

produces several types of glue: “Flizen Universal”, “Flizen Plus with enhanced formula”, “Flizen Flex”, “Flizen Marble”. They have a lot in common, but there are also differences: in the thickness of the adhesive layer, the ability to lay different-sized tiles.

Also in stores there is Knauf Fliesen Max adhesive - a thick-layer material that can be applied in layers up to 3 cm when increased strength of the masonry is required. In addition, “Flizen Max” makes it possible to level the floor and walls, but this adhesive is not suitable for underfloor heating systems.

All products come in durable paper bags of 10 and 25 kg, which have several levels of protection. The glue should be stored on wooden pallets in dry rooms.

Universal glue

This composition is a classic Knauf Fliesen adhesive, which is used indoors for tiles with water absorption up to 3%. For outdoor work, this figure should be higher - from 5%. The glue contacts best with concrete, drywall, cement-sand bases, and plastered surfaces. It cannot be used on low-porosity tiles because their water absorption coefficient is too low.

"Flizen Flex"

This glue is more elastic and ductile than the previous version. It is also used for porous, medium-porous tiles, stone tiles and porcelain tiles. "Flizen Flex" is suitable for any substrate, including insulating materials. The adhesive is especially effective where significant dynamic loads are expected. It is also widely used for cladding wooden bases, chipboard surfaces, and for installing heated floors.

Glue "Flizen Plus"

Knauf Fliesen Plus is another tile adhesive that has improved strength characteristics. This is achieved by adding mineral fillers and special polymers. The product has the highest level of adhesion to concrete, cement screed, and drywall. It is well suited even for tiles with low water absorption and various types of stone, is frost-resistant, and is used for finishing building facades and plinths. Total load per 1 sq. m of cladding made with Flizen Flex can be 50 kg.

Comparison with other analogues of the line

If you compare the products in the Knauf line, you will notice certain differences in the adhesive products. Flizen Flex is suitable for working with heated floors. It withstands significant temperature changes well. Porcelain tiles can be laid on any of the four compounds, except for the universal Fliesen Knauf.

There are other features:

- Flizen Marble is white in color and does not interfere with the artistic characteristics of the masonry.

- Flex is more suitable for industrial floors or substrates subject to intense loads.

- Universal Flizen cannot be used for porcelain tiles and heated floors.

- Heavy dies laid on a vertical plane are glued with Knauf Marble.

- Flex can be used on unstable surfaces - chipboard, wood, PGP.

For the bathroom, reinforced tile adhesive Knauf Flizen Plus or Flizen Universal is suitable. It is rational to glue large-format and large-sized tiles, stone, granite onto Marble, and Flex is best used indoors.