Many owners of apartments and houses choose foam tiles as ceiling finishing. This facing material quickly sticks to the ceiling and does not require special care. In addition, the tiles have a reasonable price and a wide variety of decoration options, which is why they are quite popular. The material is usually glued to the base. Adhesive for foam ceiling tiles should not contain solvents that will melt the foam. When choosing a solution for gluing, take into account the material and characteristics of the base. To understand which glue to use on ceiling tiles in your case, you need to consider the characteristics of different compositions.

The choice of adhesive depending on the characteristics of the base

When listing what is best for gluing ceiling tiles, it is worth mentioning the following adhesive mixtures:

- Solvent-based substances quickly glue surfaces. They are produced on the basis of thermoplastic liquid polymers and special additives.

- Water-based formulations are the most popular. But they take a very long time to dry, which is inconvenient when working on the ceiling (you have to hold the tiles for a long time). These substances are not used in cold rooms. In addition, the water base is a favorable environment for the development of microorganisms, so the base surface needs antiseptic treatment.

- The silicone-based compound dries quickly. The main disadvantage is that after preparation the glue is usable for a short period of time.

- Melt. This is a special glue that is heated to the required temperature before use, so you will need a special heat gun for the job.

- A separate point worth highlighting is liquid nails. These are water-based or solvent-based mixtures that are most often used by professionals. However, water-based solutions are not suitable for use in rooms with wet processes, although they are environmentally friendly and do not harm health.

Attention! Any ceiling adhesive is not suitable for gluing tiles to a ceiling with chalk whitewash, so the base must be cleaned down to the concrete floor.

Each of the above compositions is suitable for working with cement, wood, concrete, plasterboard or gypsum base. As for metal bases, water-based mixtures cannot be used to work with them, since they lead to corrosion processes.

It is recommended to prime the ceiling surface before gluing the finish. When choosing a primer, you should focus on the adhesive used. The primer must be made from the same components as the adhesive mixture to ensure good adhesion of the bonded surfaces.

Classification by composition

| View | Description |

| Rubber compound | The entire Titan Professional line is rubber-based. Such mixtures glue wood, chipboard, tiles, plastic skirting boards, and baguettes well. They tolerate temperature changes and heavy loads well. Their seams are strong and elastic. The series includes “liquid metal nails” on which mirror or glass surfaces are attached. Liquid nails "Titanium 601" are also produced on the basis of rubber. They are used for finishing and insulation work, for gluing cornices, panels and sockets. |

| Polyurethane glue | Styro has a polyurethane based composition. They can be used to glue bitumen, mineral wool, thermal insulation boards, and carry out roofing work. Polyurethane compounds have disinfecting properties. Prevents the development of mold and mildew. |

| Acrylic mixture | Titan Express belongs to this type. They can be used to glue stones, trees, ceramic and glass bases. Hardens quickly. Suitable for urgent work. The product “Stucco Decor” is also produced on an acrylic basis, which attaches cork, glass, and any decorative items to the interior. |

| Polymer glue | More often it is recommended to use it for gluing amalgam, alloys, fiberglass, and other materials, when working with which it is important not to damage the surface being glued. The mixture can be used to glue insulation, ceramic tiles, moldings, and used as sealants. It is waterproof and UV resistant. |

Types of adhesives for ceiling finishing: consumption and characteristics

To glue polystyrene foam boards to the ceiling, use one of the following compositions:

- universal mixtures (these include the Format solution for working with polystyrene foam or Titan adhesive for ceiling tiles);

- hot melt adhesive;

- PVA;

- compound;

- solvent-based mixtures;

- acrylic putty;

- liquid Nails.

When choosing an adhesive mixture, pay attention to the following indicators:

- Quick drying and reliable adhesion to the base. For gluing to the ceiling, solutions that dry in no more than 30 seconds are ideal. The longer the glue takes to dry, the longer you will have to hold the tile with your arms up.

Important! Quick setting is also inconvenient, because after gluing it will not be possible to correct the position of the tile.

- If work is carried out in a residential area, then it is important to choose compounds that do not release harmful substances into the air.

- It is prohibited to use adhesive mixtures based on solvents such as toluene, white spirit and acetone, because they react with the foam and dissolve it.

- Use solutions with good viscosity to ensure reliable fixation of the element to the ceiling.

Glue Titan

Thanks to its high viscosity, the adhesive easily copes with fixing heavy glass and metal products on any surface, so it will securely fasten lightweight foam panels to the ceiling. The solution dries quickly, and the thickened mixture can be diluted for further use. It is important to know how to dilute Titan adhesive for ceiling tiles.

Suitable for these purposes:

- salicylic alcohol;

- denatured alcohol;

- ethanol.

Worth knowing! The minimum price of Titan glue for ceiling tiles is $3.5/l.

The consumption of Titan brand glue is small and amounts to 0.5 liters per square meter of surface. One container is enough to glue the coating over a large area, which is considered the main advantage. Additional advantages of Titan are transparency, moisture resistance, and stability of seams. When applied to tiles, the product does not stretch or deform.

The solution can be used for gluing finishing to a base made of gypsum, concrete, cement and other materials. Since the elasticity of the composition is not affected by external temperatures and humidity, Titan is suitable for use indoors and outdoors.

Glue Moment

The advantages of this expensive and high-quality mixture include the following:

- setting speed;

- good viscosity;

- reliability of the adhesive connection;

- suitable for working with expanded polystyrene;

- speed of work.

Since the glue is sold in a tube, you will need a glue gun to squeeze it out of the container. Another disadvantage of the Moment is its rather high cost. In addition, the consumption of the mixture is quite impressive and amounts to 6 kg/m².

Important! The price of Moment glue for foam ceiling tiles starts from $3.2/0.75 liters.

Liquid Nails

In the production of liquid nails, synthetic polymers and rubber are used as the basis. “Nails” glue homogeneous and foreign materials equally well. They are also suitable for gluing foam tiles.

The advantages of liquid nails are as follows:

- There are no components in the composition that aggressively interact with the foam and melt it.

- High drying speed.

- There are no visible marks left on the surface. The glue does not show through the finish.

- The solution does not change color or turn yellow over time. The adhesive seam is not susceptible to damage by microorganisms and mold. It does not rust and does not react to high humidity and direct contact with water.

- Water-based and solvent-based mixtures are available for sale. For residential premises it is better to use the first one, because it is considered harmless. But solvent-based liquid nails are suitable for use in places with changes in temperature and humidity.

Important! In addition to liquid nails, you will have to buy a construction gun to squeeze the composition out of the tube. The mixture is applied around the perimeter of the tile at a distance of 2-3 cm from the edge and in the center.

PVA glue

Water-based compositions with latex and acrylic particles harden quickly after the water evaporates and bond the bonded surfaces well. Since all water-based adhesives are recommended for contact use, the mixture is applied to the tiles and base.

Due to the contact method of connecting surfaces, the mixture is not suitable for use over a large area, because the time required to complete the work significantly increases, as well as the consumption of the adhesive mixture. But in a small room this glue provides many advantages - it is odorless and does not harm health.

Positive aspects of using PVA:

- ease of application (you can use a spatula or brush);

- good adhesion to any substrate, even plastered;

- thick consistency;

- reliable grip;

- optimal setting times, which allows you to change the position of the product;

- reasonable price (less than $1 per kilogram);

- economical consumption – 0.2 kg/m².

Important! The only disadvantage of PVA is that it takes a long time to dry, so you will have to press the tiles to the ceiling with your hands for a while.

Removing superglue from various surfaces

Superglue can end up everywhere: on your skin, clothes, floor, phone, surface where you glue.

Removing instant glue from human skin

Human skin is a delicate living tissue. Therefore, try to use the most gentle methods for removing superglue from it. And if everything you have tried is unsuccessful, do not despair. The stain will disappear on its own in a maximum of 2 days. When trying to clean superglue from your hands, proceed in the following order:

- Wash the skin area with warm water and soap.

- Apply a paste of salt or soda to the stain.

- Rub for about a minute.

- Add more slurry and repeat, periodically wetting the area with glue in warm water.

- After some time, pick up the edges of the adhesive spot and separate the thin film of glue from the skin.

There are also other effective ways to combat superglue on human skin.

What not to do:

- do not remove the glue from the skin if you feel that it is coming off along with it and you experience pain;

- Do not rub the area with glue with abrasive materials (pumice stone or nail file) too actively: this can damage areas of the skin not affected by the glue.

Video: removing superglue from the skin of your hands

Cleaning textiles from superglue

Often, during work, glue gets on our clothes or furniture upholstery. Such stains spoil the appearance and require cleaning.

You can clean fabric from superglue in different ways - with a rolling pin, acetone, vinegar and other means.

Options:

- Dried glue is beaten off with a rolling pin or wooden masher.

- The item is placed in the freezer and heated with a hairdryer or iron if the fabric does not contain synthetics.

- The upholstery of a leather sofa or eco-leather product is removed from glue stains with a professional Anti-Glue.

- Fabrics stained with glue are often scrubbed in warm water using detergents.

- Natural fabrics are scrubbed with acetone using a toothbrush. After cleaning is completed, the fabric is rinsed and washed. It is necessary to test in advance the reaction of the material to acetone on an inconspicuous area of the fabric. It can discolor some things.

- For thin fabrics, use a vinegar solution.

- If the item is dear to you, and none of the methods work, take it to the dry cleaner.

Video: removing glue stains from clothes

Cleaning superglue from suede products

The following products will help you remove superglue stains from suede:

When cleaning suede from adhesive stains, proceed in the following order:

- Wipe the glue stain on the suede with warm water or hold it over a kettle. Hot steam will soften the dirt.

- Apply the selected product to a clean cloth and treat the stain.

- After cleaning is complete, apply a special impregnation to the suede and lift the pile with a brush.

We clean hard smooth surfaces from superglue: glass, tiles, marble

To remove superglue from hard, smooth surfaces, you can use any of the above products, following safety rules.

- Soften the glue for 20 minutes, applying a damp cloth soaked in the selected product to the problem area.

- We try to pick up the edge of the stain and with a soft tool (silicone or wooden spatula) carefully wipe the glue off the surface.

- Wash the cleaned surface with soap and water.

Glasses require more careful cleaning.

- Soak the glasses in soapy hot water for a while.

- Wipe off the glue stain with a soft cloth.

- Rinse well after finishing work.

Removing superglue from wood

Key points in the process of removing superglue from wooden surfaces:

- if wooden surfaces are finished, then the glue is removed with acetone or nail polish remover, and after cleaning the surface is washed and polished;

- also use citric acid instead of acetone;

- the laminate is cleaned of glue with Dimexide;

- unpainted wood is cleaned with mineral oil;

- If it is not difficult to restore a wooden surface after cleaning the glue, a mechanical method is used: the stain is sanded, having previously covered its edges with construction tape.

Clean wooden surfaces from glue using mineral oil, acetone, Dimexide

Video: removing superglue from laminate flooring

Cleaning your phone screen or laptop monitor

The best way to combat superglue stains on displays and monitors is Dimexide. It carefully and completely removes stubborn stains. However, do not forget about safety precautions: work with Dimexide with gloves.

If superglue gets on your phone screen, you can remove it with Dimexide.

We clean metal and lock cylinders from glue

To clean metal surfaces from glue use:

- acetone, alcohol, solvents such as white spirit and B 646;

- undiluted vinegar;

From the bitter experience of the unfortunate people who had glue poured into the lock, it is clear that the cleaning task will take a lot of time and effort. The glue from the lock can be cleaned using Anti-Glue and available tools.

Why does glue show through the tiles, and what to do?

When gluing very thin stamped tiles, the adhesive with a rich dark color may show through the coating. But in some cases, even white glue can be visible through the surface of the tile if it is glued to a dark base. Some adhesive solutions may change color during use and lead to this defect.

In any case, it is not difficult to correct the situation by painting the ceiling covering. For stamped boards, you can only use water-based emulsion, and extruded panels can be painted with paints that do not contain aggressive solvents.

Now you can decide for yourself which adhesive is best for ceiling tiles. The main thing is to take into account the features of the base, the purpose of the room and the temperature and humidity processes in it. It is also worth remembering the consumption of the adhesive mixture and taking into account the surface area.

Source: build-experts.ru

PVA glue

PVA (polyvinyl acetate) glue is one of the most common, used for gluing materials such as wood, ceramics, linoleum, chipboard, paper, glass, textiles, natural and artificial leather. PVA is widely used due to its excellent adhesive properties, good adhesion to surfaces, resistance to moisture, solubility in water and, last but not least, low cost.

There are several types of PVA glue:

- Stationery - used for gluing paper and cardboard;

- Household (wallpaper) – used for gluing paper products and wall surfaces (plaster or wood);

- Construction - used for gluing materials with a base made of fiberglass, vinyl or paper, added to primers in order to increase manufacturability and adhesion of subsequent materials (putties, plasters or dry mixes);

- Super M - used for vapor-permeable materials, ceramics, porcelain, fabrics, glass, leather, as well as for fixing floor coverings;

- Extra - used for gluing wood, plywood, construction mesh, wallpaper, sickle sheets or as an additive to increase strength characteristics;

- Universal - for gluing paper or decorative elements made of paper or plastic to wood, glass or metal.

Let's try to answer the question, how to dilute PVA glue? It is recommended to dilute household and office PVA glues with warm water with vigorous stirring. The use of other solvents may affect the properties of the adhesive. In case of severe thickening - the formation of a crust on the surface or dry flakes, these crusts and flakes are removed. When diluting PVA, it must be remembered that a large amount of water will reduce the adhesive strength and ductility will also decrease.

To dilute universal and office glues, when they thicken, use acetic acid or organic solvents such as acetone, methanol, ethyl acetate, benzene.

Glue 88

There are three types of glue 88: 88-CA; 88-NP; 88-N, each of which has its own area of application:

- Glue 88-CA is moisture resistant, used for products in contact with aquatic environments, both fresh and salty, and withstands significant temperature changes. Finds application in construction, footwear, aviation and automotive industries. Used for linoleum flooring. Contact of the adhesive with steel and aluminum surfaces does not cause corrosion, and there is no release of toxic compounds.

- Glue 88-NP - used for gluing rubber made on the basis of rubber to metal, wood, glass, leather, concrete and various surfaces, and for gluing rubber products. The advantages of the glue include moisture resistance, resistance to temperature and the absence of corrosion of steel and aluminum.

- Glue 88-N is used for gluing vulcanizing rubber to products made of metal, wood, plastic, glass and concrete. Recommended for gluing polyisobutylene to metal and concrete.

When it dries or thickens, the question arises - how to dilute glue 88. For dilution, it is recommended to use benzene, the amount of solvent is determined visually - to the state of liquid sour cream and so that the glue does not flow off the brush and does not drag on it (video).

How to dilute the product?

When working with glue, during repairs or when making various crafts, many are faced with its thickening, which occurs due to improper or long-term storage. The glue may get on clothes or other objects and then it must be removed. You can get rid of these problems by knowing what you can use to dilute the glue or dissolve it. Let's look at the most popular types of glue and what solvents are used to dilute them.

If necessary, the product can be diluted with denatured alcohol or ethyl alcohol. If the glue has thickened, a small amount of alcohol will bring its consistency in order; it will penetrate into the cracks better, but it will take longer to dry completely.

If the glue is stored for a long time or improperly, it may thicken. Let's look at how you can dilute the most popular adhesives.

PVA or polyvinyl acetate is probably the most common. It is used for gluing wood, linoleum, fiberboards, paper products, glass, textiles, leather (natural or artificial). PVA is versatile due to its good adhesive properties, resistance to wet environments, low price and can be dissolved with water.

The following types of this glue are produced by industry:

- stationery – used for paper and cardboard;

- wallpaper - used in the process of gluing wallpaper on walls, both wooden and plastered;

- construction – used for joining products consisting of fiberglass, vinyl or paper, and also as an additive to primers to improve the adhesion of putty, plasters and dry mixes;

- super M – suitable for joining vapor-permeable rolled materials, textiles, ceramics, glass and porcelain products and for applying floor coverings;

- extra - used for gluing wood and plywood, gluing wallpaper, mesh, serpyanka and as an additive that increases strength;

- universal – applicable for gluing paper and decorative items made from it or plastic on surfaces made of wood, glass or metal.

Glue 88

The following brands of this glue are used: 88-CA; 88-NP; 88-N:

- 88-CA – has increased moisture resistance, is used for gluing parts in contact with water (both fresh and sea), and is resistant to temperature changes. It is used in construction and in the manufacture of footwear and in the automotive industry. Indispensable for laying linoleum. When in contact with metals, including aluminum, it does not cause corrosion and does not emit harmful fumes.

- 88-NP - used for gluing rubber on a rubber base, with various materials, including metals, wood, glass, leather, concrete, as well as for its gluing. 88-NP is resistant to moisture and temperature changes. There is no corrosion to metals.

- 88-N - applicable for gluing vulcanized rubber to surfaces of metal, wood, plastic, glass and concrete. When thickening, this glue is diluted with benzene to a state close to 5% sour cream.

Titanium is a universal composition used when joining parts made of foam plastic, wood, PVC, leather substitutes and others. Used for gluing finishing elements, including ceiling tiles, to concrete, wood and plaster bases. Suitable for both outdoor and indoor work; the resulting compounds are elastic, resistant to moisture and negative temperatures. There are no harmful secretions.

Alcohols, including salicylic acid and denatured alcohol, can be used for dilution. If there is an excess of solvent, the glue can be used as a primer. It is not recommended to dilute nail polish remover based on isopropanol, as this leads to curdling of the glue.

Glue Moment

Common in construction and repair work. When Moment thickens, it is diluted with acetone, as well as by adding dimethyl sulfoxide, which can be purchased in pharmacies.

Tile adhesive

The following types of adhesives are used for gluing tiles:

- cement-based;

- ready-made one- and two-component material.

These adhesives can be diluted with warm water. To dilute, you will need to add 5 liters of water per 20 kg of dry mixture.

The technical characteristics of the glue determine its wide range of applications. The Titan Wild composition glues parquet, glass, ceramics, paper, wood, linoleum, as well as natural and artificial leather. Ideal for attaching foam and polystyrene foam. The universal composition allows you to glue dissimilar materials.

If the glue has become too thick, it can be diluted with medical alcohol. The liquid consistency allows for better penetration into small cracks, but this glue takes longer to dry.

We suggest you familiarize yourself with How to wash the inside of a bottle of greens: simple and quick methods

Glue Titan

Titanium glue is a universal glue, which is explained by its high technological properties. Titanium can be used for gluing products made of foam plastic, wood, PVC, leatherette and others. It has proven itself well for installing finishing elements on surfaces made of concrete, wood, plaster, including ceiling tiles. The adhesive can be used for external and internal work; the connection is characterized by elasticity, moisture resistance and frost resistance. Eco-friendly because does not contain solvents hazardous to health.

If Titanium has thickened, you can use alcohol, including salicylic acid or denatured alcohol, to dilute it. In its liquid state, Titanium does not bond well, but can be used as a primer. Craftsmen, when advising how to dilute Titan glue, can point to nail remover. It should be borne in mind that the use of isopropanol-based nail remover may cause the glue to curdle (photo).

Varieties

A universal composition is used everywhere. Besides it, there are other modifications, for example:

- sealant Titan;

- glue-mastic;

- Tytan Professional PVA D3 for wood and other analogues.

Universal glue

Titan SM universal glue is used to connect PVC, ceramics, leather, wood, carpet, parquet, and other floor surfaces. It adheres well to polystyrene foam, so it is often used as a ceiling adhesive for attaching ceiling tiles. The mixture should be applied in a thin dotted line to the back of the tile, then wait a few minutes and gently press it to the ceiling. It is available in tubes with a thin spout, so it is convenient to apply even a very thin layer.

The universal composition is colorless, so the seam becomes barely noticeable after drying. It does not allow moisture to pass through and does not lose elasticity either at low temperatures up to -30°C or at high temperatures up to +60°C. The crystallized seam is not susceptible to direct sunlight.

- It is necessary to first clean and level the surface.

- Apply the product to both surfaces in a thin layer.

- Then you need to wait until the composition dries and connect both parts.

- The glued surfaces must be pressed tightly against each other for 5-10 seconds.

Complete hardening of the seam occurs after 40 minutes, its maximum strength is achieved after 24 hours.

The universal epoxy adhesive Epoxy Titan is popular. This is a two-component adhesive that consists of a resin base and an amine type hardener. Bonds metal surfaces, plastic, wood, porcelain, concrete, ceramics, and other materials. Used as a sealant, as a leveling mastic, to seal cracks, pores, and holes. After crystallization, the seam retains its properties at temperatures from -40 to +100°C, it does not conduct electricity, is not susceptible to aggressive environments, and is resistant to vibrations and loads.

Adhesive foam Titan

Adhesive foam “Titanium 60 seconds” works on the principle of polyurethane foam. When exposed to air, its composition polymerizes in no more than 60 seconds. Upon contact with moisture contained in the atmosphere, CO2 is released, which swells the polymer. This is how foaming occurs.

It can be used for installing windows, doors, wall panels, sand-lime bricks, gas silicate blocks, and ceramic tiles.

Adhesive foam increases the adhesive properties of porous substrates. It is used sparingly and seals cracks and potholes in surfaces. Maximum adhesion to the surface after 2 hours. Operating temperature should not be lower than -10°C.

Glue mastic

Titanium mastic is used for gluing ceiling skirting boards, slabs, decorative elements, foam plastic, polyurethane, and expanded polystyrene. The mixture adheres well to concrete, cement, gypsum, wood, and plywood substrates. Mastic can be used to glue fiberboard. Styrofoam mastic can be used to level bases, seal cracks and defects before installing polyurethane objects.

The hardened mastic is resistant to low temperatures and UV light. It contains no solvents or toxins, which means it is safe.

Before applying the composition, the surface must be cleaned and degreased. The mastic is applied with a spatula at an operating temperature of at least +8°C. The initial setting of the mixture occurs after 15-20 s. During the first 10 seconds, the position of the bonded surfaces can still be adjusted. The seam dries completely in 12 hours.

Liquid nails Titan

Tytan Classic Fix assembly adhesive is available in tubes of 0.2 and 0.31 liters, equipped with a mounting gun. The mixture has a white color and a thick paste-like consistency, which, when hardened, replaces nails or screws.

Classic Fix is suitable for gluing metal, PVC, wood, cork, and plaster surfaces. They are used to glue tiles, bricks, polystyrene foam, polyurethane, and cement. Polyethylene, polypropylene, wet surfaces cannot be glued. It must be applied in a thick layer to the surface to be treated. If excess appears, remove it with a sponge. The initial contraction will occur a quarter of an hour after application. The seam will be super strong, resistant even to very low temperatures.

Powder

The product in powder form is suitable for wallpapering. The composition has disinfecting properties. It prevents the development of mold and mildew. The initial setting of the adhesive seam occurs after 5-10 minutes, which allows you to adjust the location of the wallpaper directly on the wall. You can use vinyl, non-woven and paper wallpapers on powder Titanium.

Before use, the powder must be diluted with water until a homogeneous mass is formed.

Afterwards, the composition can be applied to the wall if non-woven wallpaper is being glued, or to the back side of the wallpaper when gluing other types of wallpaper. The paste should be applied from the center of the canvas to its edges. After application, it needs to be given 5-10 minutes to set on the surface. When diluted, the composition can be stored for a maximum of 1 month.

Glue Moment

The moment is also extremely popular when carrying out construction and renovation work.

The range of its application is large. To dilute Moment, acetone and dimethyl sulfoxide, freely available in pharmacies, can be used.

Tile adhesive

Anyone who is busy renovating an apartment needs to know how to choose tiles and adhesive for them, and how to glue the tiles efficiently and quickly.

There are three types of tile adhesive:

- based on cement, for its preparation it is necessary to carefully observe the proportions and follow the instructions;

- ready-made one-component glue, sold in the form of a ready-made paste, does not dry out for a long time;

- two-component glue. Prepared immediately before use. Its advantages include elasticity and manufacturability.

To properly prepare tile adhesive, you should know a few rules:

- the temperature of the components should be approximately equal, i.e. You cannot bring the mixture from the cold and fill it with hot water;

- add water to the mixture in small portions with thorough mixing;

- During operation, it is necessary to periodically stir the finished glue to prevent delamination.

Tile adhesive must be diluted with warm, clean water. Number of mixture components: 5 liters of water account for 20 kg of dry mixture.

Source: kleigid.ru

Description and properties of Titan glue

Titanium adhesive is in demand on the market due to the quality of surface bonding and excellent technical characteristics:

- Effective for gluing most building materials.

- Suitable for both indoor and outdoor use.

- Resistant to mechanical stress, ultraviolet radiation, and temperature changes.

- It is water resistant.

- Elastic after drying.

- Eco-friendly (does not contain toxic components).

- Use sparingly.

The composition is suitable for gluing wood (including parquet), glass, leather, linoleum, ceramic tiles, polystyrene foam, expanded polystyrene, brick, gas silicate blocks, and also provides reliable adhesion to plaster and concrete.

If we talk about disadvantages, consumers mainly pay attention to the “death grip”, which in some cases turns from a plus into a minus.

Specifications

It is resistant to mechanical loads. The glue is elastic and does not become brittle after hardening. Technical characteristics allow it to be used at high humidity or temperature changes. It is used very economically and dries quickly. Titan glue does not have harmful components, therefore it is considered safe and is widely used in residential repairs.

Technical characteristics of the glue

Types of glue

Titan glue is available in several forms: in addition to universal Titan, the manufacturer offers liquid nails, wallpaper glue, styrofoam glue, sealants, acrylic glue and much more.

Universal glue

Universal mounting adhesive Titan is suitable for gluing PVC, polystyrene foam, linoleum, carpet, glaze, ceramics, leather, as well as wood and parquet. Very often this glue is used for installing ceiling tiles.

It is convenient to apply the composition in a thin layer directly from the tube; it sets quickly, plus when it dries it remains transparent and therefore invisible. Does not lose elasticity from -30 to +60 °C, is not afraid of either moisture or sunlight, confirming its versatility.

Mode of application.

Before application, the surface must be cleaned, leveled and dried. Next, apply the composition to both surfaces in a thin layer, wait a few minutes until it dries a little, and connect the parts to be glued (press for 5-10 seconds). The glue hardens in 40 minutes and reaches maximum strength in 24 hours.

Liquid Nails

Titanium liquid nails are available in tubes of 200 and 310 ml (the latter are equipped with a mounting gun) and are a white paste. They are a replacement for nails and screws.

Titan Wild liquid nails are perfect for gluing metal, PVC, wood, cork, tiles, plaster, brick, cement, decorative stone, polyurethane and polystyrene foam, etc.

Important: the composition is not suitable for polypropylene, polyethylene and wet surfaces.

The composition is applied in a thick layer to the entire surface, the excess is removed with a sponge, initial setting occurs after 15 minutes. The glue does not lose its properties even after freezing.

Powder glue (for wallpaper)

Titan wild powder adhesive is a universal composition for wallpapering. The glue has antiseptic properties, which prevents the appearance of mold and mildew. In addition, due to the special composition, the wallpaper can be adjusted directly on the wall.

The product line includes three adhesives for different types of wallpaper: “universal” for paper, “non-woven” and “vinyl”.

The powder is diluted with water until homogeneous, and then applied to the canvas (or to the wall, in the case of non-woven fabric) from the middle to the edges. Before gluing, you need to let the composition set a little for 5-10 minutes. Diluted glue can be stored for no more than 1 month.

Styrofoam glue (Titan mastic)

Titan Wild adhesive mastic is used primarily for gluing ceiling tiles, baseboards, decorative elements, as well as products made of polystyrene foam, polystyrene foam and polyurethane. The composition has a high level of adhesion to concrete, cement, gypsum, plaster, wood, plywood and fiberboards.

Styrofoam adhesive can also be used to level the substrate and fill cracks and other surface imperfections before installing polyurethane products.

The composition is resistant to external influences, including sub-zero temperatures and ultraviolet radiation. It contains no solvents or toxic substances, so it is safe for humans.

Important! The glue must be mixed before use.

The composition is applied with a spatula to a cleaned and degreased surface. It is better to work at a temperature of at least +8°C. The glue sets in 15–20 seconds, but during the first 10 seconds the position of the object can be adjusted. It should take about 12 hours for it to dry completely.

Sealants

Titan Wild sealant (universal silicone) has reliable adhesion to concrete and foam concrete, stone and brick, PVC, wood, plaster and metals. It also effectively glues gypsum boards, and also fills gaps, cracks, seals seams, etc.

Like other compounds in the Titan Wild line, the sealant is resistant to various weather conditions and temperature changes from -40 to +80 °C. It can also be painted after drying.

The sealant is applied in a single layer using a construction gun.

Instructions for use

The options for using Titan Wild glue are varied, and therefore can significantly save money. One package of such material can replace many other means required for repair and construction.

Recommendations for use:

- apply Titan glue only to a previously degreased, flat surface, and the layer should not be too thick, otherwise the gluing will be of poor quality;

- allow the composition to dry after application for two to five minutes, then connect the surfaces to be fastened;

- the glue will dry completely in 60 minutes, the maximum strength of the seam is achieved after 24 hours;

- Apply the composition in two layers to the porous surface;

- installation of ceiling tiles involves applying glue in small intervals;

- It is strictly forbidden to apply glue to whitewash; it must first be removed and the surface thoroughly treated with a primer - a mixture of glue and denatured alcohol.

In some cases, when the repair is already completed, you can see minor defects in the form of a loose corner of a tile, linoleum or wallpaper. All these shortcomings will be eliminated by Tytan glue, as it is highly effective.

Types of glue

Titan glue is available in various forms: universal glue, mastic glue and liquid nails. Instructions for use must be printed on its packaging.

Universal adhesive is usually used for gluing polystyrene foam, PVC, parquet, wood, and linoleum. It is squeezed out of the sealed package in a thin layer through a dispenser. After drying, the seam becomes invisible. Apply to a dry, pre-cleaned surface. The glue is transparent, water- and heat-resistant, sets quickly and remains flexible. Drying time less than 1 hour. These characteristics make it especially popular when installing ceiling tiles.

Adhesive mastic "Titan". Glues concrete and cement, gypsum and brick, wood and plasterboard, fiberboard and chipboard, polystyrene foam and polystyrene foam, and all materials together, in any variations. Suitable for leveling surfaces and gluing decorative tiles. Requires stirring before use.

Liquid nails "Titanium". Available in cylinders with fastenings for a mounting gun. This type of adhesive composition can be used in a very wide temperature range, so it is successfully used both indoors and outdoors. Perfectly glues metal, ceramics, polyurethane, PVC, wood.

How to apply

- Universal adhesive is applied to the ceiling tiles in a thin broken line. They let it dry for a couple of minutes and press the tile against the ceiling. The adhesive dries in 1 hour, and the seam becomes strong within a day.

- Adhesive mastic should be applied to the tiles with a spatula, pointwise: in the center and 3 points on each side. After application, place the tile on the ceiling and adjust its position within 3 seconds. The glue sets in 20 seconds and dries completely in 12 hours.

- Liquid nails can be applied over the entire surface of the tile in a thick layer. Thanks to this feature, this glue is chosen for working with ceilings that have severe defects.

How to use Titanium glue when finishing a ceiling

Decorating the surface with different types of decorative tiles will not only give the ceiling an interesting and unique look, but will also allow you to maintain its height. It is important to choose the right adhesive composition, because the speed of execution and the quality of the work depend on it. The main requirements for the technical characteristics of the adhesive are safety, transparency, viscosity, fast setting speed and versatility. The characteristics of Titan glue fully comply with these requirements.

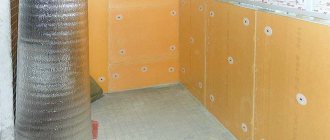

Before you start gluing the facing material, it is necessary to prepare the surface well, because the final result of the work greatly depends on this. It should be borne in mind that if the ceiling has significant differences in height, then the ceiling tiles will not be able to hide such a defect, and it is more advisable to choose another finishing method, for example, a tension or hanging coating option.

Relatively smooth surfaces should be treated as follows: first seal the seams between the slabs, then clean the surface of the old coating. To do this, use a spatula to remove the whitewash, and then apply a primer for better adhesion of the adhesive composition to the surface. Whitewash that is difficult to remove can simply be deeply primed. It is recommended to wipe a ceiling that is not whitewashed with a damp sponge. If the polystyrene tiles are very thin, then there is a chance that defects in the ceiling will show through, so you should apply finishing putty to it, followed by a primer. When the ceiling is dry, you can start gluing.

How to dilute

If the glue has thickened, it should be diluted with medical alcohol. The liquid composition penetrates better into small cracks, but takes longer to dry.

Source: opotolkax.com

How to dilute titanium glue if it has thickened

Modern products and concentrates

To clean unnecessary glue stains from various surfaces, we will need assistants, which are modern chemicals. As a rule, such products can deal with adhesive stains in a few minutes.

So how to dissolve Superglue? Some housewives use products such as alcohol, acetone, soap, vinegar, and water to combat the adhesive base. All of these remedies are effective, especially if they are combined with each other. But this depends on the nature of the pollution.

Let's take a closer look at each method for removing adhesive stains.