Peculiarities

The Tytan company, part of the Polish company Selena, specializes in the production of various building compounds: polyurethane Titan with high moisture resistance, adhesives with a wide range of uses, polyurethane foam and much more.

In this article we will take a closer look at liquid nails from the above-mentioned manufacturer. Most of all adhesives are universal products that are used both for household repairs and for large-scale work. Excellent performance indicators of the products are ensured due to special additives in the composition. All goods are produced abroad and come to Russia through official distributors.

How to apply the composition?

To apply liquid nails, you need to use step-by-step instructions.

- The working surface must be washed, dried and, if necessary, degreased.

- There is no need to apply the composition to the entire base. A stripe or dotted line will be enough.

- For greater convenience, a special pistol is used.

- To protect indoor furniture and other items, use film, thick fabric or newspapers.

- Remember that the setting process takes a second, so the work must be done quickly. Afterwards, you need to securely connect the parts and hold them for about two minutes, pressing them tightly against each other.

- The process of complete hardening occurs in about a day. During this time, it is recommended not to load the connected elements.

How to use Titanium glue when finishing a ceiling

Decorating the surface with different types of decorative tiles will not only give the ceiling an interesting and unique look, but will also allow you to maintain its height. It is important to choose the right adhesive composition, because the speed of execution and the quality of the work depend on it. The main requirements for the technical characteristics of the adhesive are safety, transparency, viscosity, fast setting speed and versatility. The characteristics of Titan glue fully comply with these requirements.

Before you start gluing the facing material, it is necessary to prepare the surface well, because the final result of the work greatly depends on this. It should be borne in mind that if the ceiling has significant differences in height, then the ceiling tiles will not be able to hide such a defect, and it is more advisable to choose another finishing method, for example, a tension or hanging coating option.

Relatively smooth surfaces should be treated as follows: first seal the seams between the slabs, then clean the surface of the old coating. To do this, use a spatula to remove the whitewash, and then apply a primer for better adhesion of the adhesive composition to the surface. Whitewash that is difficult to remove can simply be deeply primed. It is recommended to wipe a ceiling that is not whitewashed with a damp sponge. If the polystyrene tiles are very thin, then there is a chance that defects in the ceiling will show through, so you should apply finishing putty to it, followed by a primer. When the ceiling is dry, you can start gluing.

How to dilute

If the glue has thickened, it should be diluted with medical alcohol. The liquid composition penetrates better into small cracks, but takes longer to dry.

Universal construction adhesive 601 (Liquid nails)

Rubber adhesive Tytan No. 601 is produced in cylinders with a mount for a mounting gun. The main advantage of liquid nails over other formats is the ability to glue surfaces slightly spaced from each other (i.e., it does not require a complete fit). Titanium 601 will easily replace nails and screws.

The composition does not lose its properties in the temperature range from -30 to 60 °C. Apply a thick layer to the entire surface, initial hardening takes 5–10 minutes, complete drying takes 24 hours.

Titanium liquid nails are perfect for gluing metal, glass, ceramics, wood, PVC, polyurethane and thermal insulation materials. They cope with heavy building materials, structures and decorative elements.

For gluing heavy structures, the Tytan line includes heavy-duty adhesive No. 901.

Range

The product catalog of the Tytan brand is varied. Let's take a closer look at the three types of product.

Classic Fix installation product

Classic Fix glue (“Classic Fix”) has versatility. Due to this, the composition can be used indoors and outdoors. To make the transparent composition, the manufacturer used synthetic rubber.

Specifications:

- the complete curing process takes two days;

- product consumption ranges from 150 to 300 grams per square meter;

- resistance to temperatures from – 30 to +60 degrees Celsius;

- Shelf life – 1 year.

Peculiarities:

- increased strength;

- excellent adhesion to most materials;

- resistance to moisture and frost.

Usage:

- working with materials such as wood, metal, PVC, polycarbonate, ABS, glass;

- installation of decorative elements and various items (mirrors, shelves, hooks and much more);

- connection of structures made of light and heavy metals.

Super strong composition No. 901

A rubber compound with excellent strength is used for work indoors and outdoors. During the work, a moisture-resistant, durable and elastic seam is formed.

Technical specifications:

- the glue dries completely within 24 hours;

- composition color – beige;

- material consumption from 200 to 400 grams per m²;

- the glue can withstand temperatures from 30 degrees below zero to 60 degrees;

- The shelf life of the glue is one year.

Peculiarities:

- contains no toluene;

- durable and reliable seams;

- weather resistance.

Usage:

- installation of structures made of materials such as gypsum, plastic, stone, ceramics, glass, wood, plywood;

- connection of elements and panels.

Special glue No. 915

The water-based composition is designed specifically for use in rooms with high humidity. Liquid nails are ideal for adhesion of various building materials to porous surfaces.

Performance characteristics:

- glue color – white;

- the minimum temperature index maintained by the composition is 20 degrees below zero, the maximum is 60 degrees Celsius;

- the material hardens in two days;

- product shelf life – 12 months;

- the flow rate ranges from 200 to 400 grams per square meter.

Peculiarities:

- excellent resistance to steam, humidity and dampness;

- the glue is not susceptible to the formation of mold and mildew;

- fast setting.

Usage: joining elements made of plastic, stone, natural wood, foam and gypsum.

See below for more details.

Glue Titan. Properties, types, application and price of Titan glue

Polymers instead of bones and tendons. These are not new body prosthetics. We're talking about glue. In the Neolithic era, that is, the late Stone Age, it was cooked from bones and veins. Looking at modern jellied meat, it’s easy to believe that they can make glue.

Later, plant resins began to be added to bonding mixtures. Glue based on them and animal fat was found in the tomb of Tutankhamun. The substance was poured into a vessel, apparently suggesting a need for it in the afterlife.

This indicates the importance of the glue. Its modern variations are mainly polymer. Such glue is not placed in tombs, but it still means a lot. What are the names alone worth? Today's review will be dedicated to Titan. That was the name of the Greek gods. According to legend, they held the sky on their shoulders. What does Titan glue ?

The basis of Titan glue is polyurethane. Its constituents isocynate and polyol are taken from crude oil. The synthesis was carried out in the 1930s in America. In the 1950s, polymerization of the substance was carried out there. The result was foamed varieties of polyurethane, for example, polystyrene. The abundance of air in it allows you to insulate houses with the material.

Polystyrene is solid. Titan glue contains liquid polyurethane. The product looks like PVA. “Titan” is packaged in different cylinders, bags and bottles, depending on the purpose. We'll talk about it in a separate chapter.

In addition to polyurethane, Titan may contain dimethyl ether, propylene, 4-4-diphenylmethane, their isomers and homologues. This is the name given to substances of a similar composition, but of a different structure. In the case of homologues there are additional CH2 groups.

The exact composition and proportions of the components give variations in the structure and appearance of the Titan. It is not always white like PVA. There are transparent types of glue. There is even a semblance of polyurethane foam. The differences from it are the absence of secondary expansion.

By giving it, the polyurethane foam also gives shrinkage. “Titan”, having expanded once, does not change its volume. In addition, the glue has better adhesion to concrete. Adhesion is the ability to penetrate into the upper layers of other materials and adhere to them.

Types of Titan glue

Titan assembly adhesive is a brand that covers a number of products. It covers various construction and renovation needs. There are 4 main types of glue:

- Liquid nails "Titanium". Liquid nails mean glue with a fine filler. It makes the mixture paste-like and, as it were, concretes it, allowing surfaces that are spaced apart from each other to be held together. There is no longer a need for a tight fit or pressing of the planes. Metal, wood, ceramic, polyurethane and polyvinyl chloride objects can act as planes.

- Adhesive mastic "Titan". In cooking, mastic is a mixture of gelatin, sugar and water. The glue took from it only ductility, density and plasticity. The composition is designed for joining polystyrene, polyurethane, gypsum and plastered surfaces. Cement-lime bases, wood boards and brickwork are also suitable. The use of Titan glue of the mastic category begins with mixing the composition. It sets in 20 seconds and dries completely in 12 hours.

- Powder glue "Titan". Universal composition for wallpapering. Like other adhesives for them, “Titan” is diluted with water. The advantage of the powder is that it is an antiseptic additive. They block the development of fungus. Appearing on wallpaper and plaster surfaces, it penetrates inside the walls in the form of spores. They are invisible and difficult to remove. Priming with Titan glue eliminates the risk of surface contamination.

- Adhesive foam "Titan" . It works on the principle of conventional polyurethane foam, also consisting of polyurethane. When exposed to air, it polymerizes. Contact with atmospheric moisture leads to the release of carbon dioxide. It swells the polymer. This is how foam turns out. Windows, door frames and wall panels fit on it with equal success. However, information on the use of adhesives in the series is collected in a separate chapter.

A narrower classification of “Titanium” is related to application. So, among the wallpaper powders there are those for paper, vinyl, and fabric. Liquid nails include Titan glue for mirrors . But, there are also universal compositions. They are even used as primers. To do this, denatured alcohol is added to the glue - ethyl alcohol mixed with methanol.

The brand's product line also includes Titan ceiling adhesive . It belongs to the category of mastics, good for tiles made of gypsum, polystyrene foam, polystyrene foam. All instructions on the packages are in Russian. The brand, by the way, is also domestic. Entered the market in the 1990s.

Characteristics of Titan glue

The properties of Titan glue depend on its type. In foam form, for example, the composition ignores ultraviolet radiation. It darkens ordinary polyurethane foam and makes it fragile. “Titanium” is used in street work. If the foam is covered with plaster and other “facades,” it is only for the sake of beauty, and not for the safety of the sealant.

In a can of foam, Titan glue is transparent , but when it comes out it becomes cloudier. As the mixture hardens, it becomes light beige. Gas bubbles are enclosed in closed honeycombs. They don't communicate with each other.

Therefore, Titan foam is resistant to moisture. This makes the material suitable for facade work. For internal ones, Titan is also ideal because it does not contain freon. These are gases in which methane is mixed with ethane.

They talk about the dangers of the mixture. However, it is not itself that is harmful, but the tetrafluoroethylene released. It is formed at temperatures above 400 degrees. That is, foams with freons are potentially dangerous only in case of fire.

However, during it the poisons will find something to stand out from. The emphasis on the absence of freons in Titan glue is more of a marketing ploy than a real advantage.

The general characteristics of Titan glue in foam and mastic form are heat resistance. When frozen, the product can withstand at least 140 degrees. The wallpaper series cannot boast of sim.

But Titan powder adhesives have specific advantages. The first of them is slipperiness. It allows you to move the canvas on the wall, adjusting the pattern on the wallpaper. To make them easier to glue, Titan powder dissolves in water without forming lumps. This is the second advantage of mixtures. They dry in 5 minutes.

Application of Titan glue

The question of what glue “Titan” glues has dozens of answers. Even artificial leather is sealed with brand mixtures. Therefore, the use of “Titan” is widespread. If the ancient Greek Gods held the heavens on their shoulders, then the hero of the article bears the responsibility for repairs and the sphere of arts and crafts.

PVC floor tiles and ceiling blocks are attached to the Titan. Under the ceramics, the hero of the article replaces the cement mixture. Titan also works well under moldings and baseboards. Double-glazed windows, slopes for them, and door frames are mounted on adhesive foam.

The low consumption of the mixture encourages replacing competitors with Titan. For example, 1 liter is consumed per square meter of wallpaper. However, on some surfaces all 20 liters are spent per square.

The exact indicator depends on the porosity of the base. Titan Wild glue fills voids. This is extra volume. On a flat and dense surface, the consumption of mixtures is several times less.

The use of the hero of the article, like other adhesive compositions, risks getting the mixture on clothes, floors, and furniture. The outfits are sorted out after waiting for the “Titan” to harden.

In its solid form, it is covered with gauze and tapped. It breaks like glass. All that remains is to shake off the fragments and wash off small particles stuck in the fibers of the fabric with warm water and soap.

When removing mixtures from home surfaces and facades, the question arises of how to dilute the Titan glue . Suitable: alcohol, disinfectant liquids with it and denatured alcohol. On packages of solvents you should look for “butyl acetate” and “isoprapanol”. They are even in nail polish remover. So, it will also help get rid of glue stains.

Some recommendations indicate acetone as a Titan solvent. However, the practice of adding it to glue leads to curdling of the latter. It can be avoided by observing exact proportions.

For 4 parts of “Titanium” take 1 part of the solvent. Therefore, acetone is suitable for cleaning surfaces, but it is risky to use it to dilute a thickened mixture.

Price of Titan glue and reviews about it

The price of Titan glue depends on the type and volume of the mixture. Half a liter of universal, for example, costs from 100 to 220 rubles. They charge from 210 to 370 per liter. Is it worth paying? Customer reviews will tell you about this:

- “This glue is outdated. I took it for the ceiling tiles, since the nearby store only had Titan. It turned out that it needs to be applied to the ceiling, wait 5 minutes, then glue the block and press for another 5 minutes. Masachism straight up. I felt like a titan holding the sky. The glue doesn’t live up to its name.”

Kric2507

- “I appreciate Titan for its resistance to water. When the glue has dried, at least give it a bath. It is easy to clean from hands and grips surfaces tightly. The main thing is to hold it for 1-3 minutes. I use it for minor repairs, I’m happy.”

Angelica EL

- “Titan’s stranglehold is both its main plus and minus. You don't always measure accurately. Sometimes you need to tear off and re-glue a part. In the case of the Titan, the thing is damaged. It only comes off with meat. But if you measure 7 times and glue only once, there is no price for Titan.”

Greuman

These reviews are published on I Recomens.ru. Most of the site visitors gave Titan 4 stars out of 5. Three-star reviews are about 30%. Fives are rare.

This characterizes domestic glue as a solid average. It is accessible, reliable, although not cutting-edge. But the quality of the brand’s products is constant, and the instructions for them are clear.

Liquid nails Tytan Professional: features and application

When renovating, interior finishing or decorating premises, there is often a need for reliable gluing of materials. A specialized glue – liquid nails – can be an indispensable assistant in this matter. Such compositions appeared on the market relatively recently, but have already gained popularity among builders due to their numerous advantages.

The products of this brand are of high quality and affordable prices.

Types and scope of use

Tytan Professional liquid nails come in several types. Based on their purpose, they are divided into two types.

- Universal. Such compositions are suitable for gluing any materials.

- Special purpose products. Such adhesives can be used for certain types of materials. On the packaging of special-purpose adhesives, the manufacturer indicates information about the purposes for which they are intended. These can be compositions for fastening heavy structures or metal parts, for exterior work, for mirrors, glass, for installing foam panels.

Liquid nails also vary in their composition. Adhesives can be made from rubber or acrylic. The first are polyurethane materials with an unpleasant odor caused by synthetic components. Such products are suitable for gluing heavy materials.

To work with such nails, a respirator and protective gloves are required. It is recommended to use rubber adhesives in well-ventilated areas.

Acrylic (water-based) compositions do not contain toxic substances, due to which they are odorless. Such nails cost less than rubber nails, but they do not have increased strength.

Depending on the composition, liquid nails are used for the installation of window sills, cornices, brick structures, various panels, plasterboard products, glass, aluminum, and solid wood. Glue is not recommended for working with damp wood and for creating aquariums.

Advantages and disadvantages

Tytan Professional liquid nails, like other assembly adhesives, have both advantages and disadvantages. Therefore, before purchasing, you should carefully read all the characteristics. The composition has more advantages.

- High adhesive strength. Nails can withstand loads from 20 to 80 kg/cm2.

- Resistant to rust formation.

- Ease of use. For convenience, you can use special pistols.

- A “clean” process of joining parts, in which there is no dirt or dust.

- Quick adhesion of glued materials (within 30 seconds).

- Can be used on uneven surfaces.

- Fire resistance.

- Affordable price and economical consumption.

The only disadvantages of liquid nails include their unpleasant odor and possible difficulties when working with the material for the first time.

Range

The construction market offers many varieties of liquid nails from the manufacturer Tytan Professional. The company produces a wide range of products for construction and finishing works.

There are several types of the brand's most popular liquid nails.

- Classic Fix. This is a clear rubber mounting adhesive that can be used both indoors and outdoors. It is characterized by high adhesion, moisture and frost resistance. When hardened, the product forms a transparent seam.

- Heavy-duty adhesive No. 901. The rubber-based material is suitable for exterior and interior use. Thanks to the improved composition, the product can withstand increased loads. The composition is recommended for gluing heavy structures; it forms a waterproof seam.

- Liquid nails for bathrooms No. 915. This is a water-based composition characterized by increased resistance to high humidity, high temperatures and steam exposure.

- Mirror adhesive No. 930. It is recommended for attaching mirrors to various bases (concrete, wood, ceramic). The product has a high initial adhesion force.

- Adhesive for moldings and panels No. 910. This is a water-based composition designed for gluing elements made of wood or plastic. It is highly resistant to mold and other biological damage. The product has a high initial setting and resistance to adverse climatic conditions. The composition can withstand temperatures from -20°C to +60°C.

Thanks to the wide range of products, everyone can choose the composition suitable for specific types of work.

Home use cases

Titan glue is an indispensable assistant in everyday life. In construction and repair, it helps to hold together wood, metal, drywall, plywood, and glass. For household purposes, a combination of paper, plastic and even fabric is often required.

Check out several examples of using all-purpose glue at home and you will learn how to solve your problem. With Titan you will get:

- PVC tiles, ceiling blocks, fiberboard, chipboard, MDF;

- tile;

- natural and decorative stones;

- ceramics;

- carpet;

- moldings, baseboards;

- door frames, double-glazed windows;

- natural and artificial leather;

- polystyrene and polyurethane;

- vinyl, non-woven fabric, wallpaper (paper);

- baguettes;

- mirrors;

- furniture;

- Kids toys;

- shoes;

- mineral wool, bitumen;

- roofing, wall and other coverings;

- decorating interior items, etc.

Any surface (concrete, cement, sand-lime or ceramic brick) is not a problem for Titan

There are dozens of answers to the question of what glues Titan. In addition to its fastening properties, it has proven itself as a filler for voids in walls, in sealing cracks and other defects, and in leveling non-uniform surfaces. Insulation of cornices, rosettes, and panels is achieved using rubber in Titan liquid nails.

Do not apply the mixture to whitewash, polyethylene and polypropylene - gluing will not occur. Wet areas are also contraindicated for treatment (moisture resistance is ensured only after the composition applied to a dry and pre-prepared surface has dried).

Material on topic! Where is phosphoric acid used in everyday life?

Tytan Professional sealants

Titan Professional offers high-quality sealants for any task: silicone and silicate sealants, acrylic, polymer, polyurethane (PU), bitumen and rubber sealants. In addition to universal and multi-purpose compounds, the brand offers specialized sealants (roofing, for example).

Silicone sealant

Titanium silicone sealants have proven themselves well in professional circles. They have a high level of adhesion to most materials and are resistant to various weather conditions. The universal sealant is used not only to seal seams and seal joints, but also to seal wires and protect polyurethane foam from ultraviolet radiation. Withstands 1 freezing cycle.

In addition to the universal range of Tytan silicone sealants, it includes sanitary sealant, glass sealant, kitchen and bathroom sealant, marble sealant, window, door and siding sealant, acrylic bathtub sealant, high temperature sealant, etc.

Multi-purpose sealant

Tytan Multi-Purpose Sealant (Hybrid) can be used to bond and seal even on wet surfaces. The composition is odorless and does not contain solvents, so after drying it can be painted.

This sealant practically does not age and retains its elasticity.

Like the entire Titan line, the multi-purpose sealant is suitable for most building materials: ceramics, glass, concrete, cement, stone, metal, wood, polycarbonate, PVC, etc. The sealant is excellent for roofing work.

Acrylic sealant

The brand’s acrylic sealant has a high level of adhesion to porous materials; it can be applied to wet surfaces and can also be painted after drying. The sealant quickly forms a film that can be removed before complete hardening; then only a mechanical method will help.

Composition and purpose of glue

Before using Titan glue, you need to understand the main areas of its application.

See also

How to properly glue a rear view mirror and choosing the best product

Rubber

This is a universal adhesive made from synthetic rubber. In the construction industry it is used for gluing cornices, slats, wooden panels and boards. It is also used when working with metal, plaster and plastic surfaces. The distinctive features of rubber compounds include their high level of elasticity and good adhesion to most surfaces.

The product is completely transparent and therefore does not spoil the appearance of the materials being glued.

Polyurethane

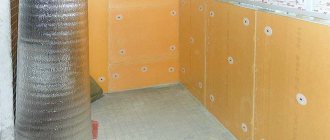

Polyurethane adhesive mixtures are used for laying slabs made from compressed polystyrene foam. Most often, this material is used for thermal insulation of internal or external walls, foundations, floors and roofs.

The main advantages of polyurethane products include ease of use and heat resistance, due to which the glue does not lose its properties at temperatures above 40-50 degrees.

Acrylic

Acrylic sealing adhesive is a popular product used for sealing joints and filling cracks in surfaces. Among the advantages of acrylic mixtures are the following:

- possibility of coloring;

- resistance to ultraviolet exposure and high humidity;

- elasticity, allowing the glue to be used on surfaces with deformations;

- adhesion to porous coatings;

- Easy to clean dried glue.

Polymer

In the manufacture of polymer compositions, boron nitride and antimony oxide are added, which improve their thermal conductivity. Polymer products are used when gluing fabric products, cardboard, genuine leather, wood, ceramic and parquet tiles. The properties of polymer adhesive liquids include:

- moisture resistance;

- resistance to mechanical stress;

- heat resistance;

- resistance to low temperatures.

Liquid Nails

Liquid nails are produced in small tubes with a volume of 200-300 milliliters. This thick paste is used as a replacement for fastening screws or nails. In the construction industry, liquid nails are used to secure decorative stones, cement products, bricks, wood, iron and plywood. However, they are not suitable for working with wet and polyethylene surfaces.

Sealant

Titan sealants are popular among professional builders. Such compositions easily tolerate high humidity and frost. They also have a high degree of adhesion to most materials used in construction.

Many people believe that sealant is used only to seal joints, but this is not true. Such products are often used to protect polyurethane products from ultraviolet radiation and to seal wiring.

Foam

Sometimes in the construction industry such means as adhesive foam are used. Their main area of application is laying thermal insulation made from foam boards or expanded polystyrene. The advantages of adhesive foam include:

- no unpleasant odor;

- strength of fixation of thermal insulation materials;

- high level of thermal insulation;

- the possibility of using foam both inside and outside;

- protection from moss and fungi;

- ease of use.

Polyurethane

When carrying out thermal insulation work, polyurethane mixtures are often used, which will help securely attach thermal insulation boards. Such compositions will help not only to insulate the walls of the room, but also the roofs and facades of buildings. The advantages of polyurethane glue include its cost-effectiveness. One cylinder is enough to treat ten square meters of surface.

Polymeric

Polymer adhesive solutions are actively used in the construction industry during repair work. Many builders use them to finish ceilings and floor coverings.

They are able to reliably glue glass products, wood, paper, linoleum, parquet boards and plastic. Polymer products interact well with gypsum, concrete and cement coatings. Some people use them for gluing polystyrene foam.

Mastic

Adhesive mastic is one of the most heat-resistant compounds that can withstand temperatures of more than 100 degrees. This heat resistance allows it to be used for cladding and laying fireplaces and stoves. Mastic reliably glues surfaces made of brick, cardboard, wood, paper, plywood and concrete. This glue has poor moisture resistance and therefore cannot be used on wet surfaces.

See also

Characteristics of adhesive for MDF panels, review of the best manufacturers and instructions for use

Waterproof

For outdoor use, waterproof products that are resistant to moisture are often chosen. They are designed to work with parquet boards, ceramic products, carpets, leather, wood, fabric and paper.

Advantages and disadvantages

First, let's look at the advantages of liquid nail compositions.

- Spacious and easy to use.

- Excellent adhesion to a variety of materials.

- Connection reliability. The layer can easily carry loads of up to 80 kilograms per square centimeter.

- The product is not susceptible to rust formation.

- When working with construction adhesive, dust and dirt do not form. There is also no noise.

- The composition sets quickly, literally in seconds.

- Liquid nails can be used on surfaces that have defects. The product greatly simplifies the process of laying material on curved bases.

- Unlike standard fasteners, glue maintains the integrity of the surface without destroying it.

- The compositions offered by modern manufacturers are safe for health due to the non-toxicity of the elements.

- A high-quality product is not afraid of increased moisture. Some compounds can withstand low temperatures.

- Excellent fire resistance.

- Favorable expense.

Experts assure that the product has no significant shortcomings. Except that some compounds have a sharp and unpleasant odor.

Description and features of Titan glue

Adhesives of the Russian brand “Titan” have been produced since 1992 and have a wide spectrum of action and are considered universal. With their help, you can connect homogeneous and dissimilar materials - the adhesion force will be high in any case. Adhesive compositions "Titan" are used to connect:

- wood;

- linoleum;

- laminate and parquet;

- wallpaper;

- paper and cardboard;

- polystyrene foam;

- plastic;

- metal;

- concrete;

- ceramics;

- gypsum;

- skin;

- fabrics;

- aerated concrete;

- ceiling tiles.

“Titan” will be able to replace a whole set of adhesives for construction purposes: tile adhesive, compositions for laying porcelain stoneware, tile blocks. Polyurethane foam of this brand is used for installing PVC windows, liquid nails and universal glue are used for fixing mirrors, cabinets, and for repairing any household products. Titanium sealants help seal seams and joints in the bathroom and kitchen.

The composition of “Titan” does not spoil materials, is suitable even for different types of plastics, is environmentally friendly and does not harm humans. Adhesives are suitable for interior and exterior use; they are waterproof and do not deteriorate from temperature changes or ultraviolet radiation. After drying, the adhesive joint becomes plastic, elastic, resistant to frost, and has a heat resistance of more than +100 degrees.

What glues Titan

Titan Wild cyanoacrylate adhesive first went on sale in 1992. It is used in repair and construction for gluing different surfaces, which is why it received the title of universal. You can combine materials with the same or different textures.

Titanium glue will reliably connect the following materials:

- plastic;

- ceramic tiles;

- suitable for ceiling tiles;

- PVC;

- aerated concrete blocks, pieces of foam blocks;

- tree;

- in everyday life it is used for crafts and needlework;

- in liquid form it is used as glue for mirrors;

- used for gluing wallpaper, paper, cardboard, foam, linoleum, parquet or carpet.

In addition to wood, polystyrene, concrete, floor coverings, the product glues plaster, leather, polystyrene foam, and porcelain stoneware.

- To lay tile blocks and porcelain stoneware, you need to choose tile adhesive.

- Assembly adhesive is used when installing plastic windows.

- Liquid nails or a universal product can be used to secure mirrors, cabinets, and repair any other household items.

- Waterproof Titanium is used for sealing joints in the bathroom, kitchen, and when processing seams.

The universal composition of the adhesive makes it suitable for use both inside and outside the building.

Liquid nails Tytan Professional: features and application

When renovating, interior finishing or decorating premises, there is often a need for reliable gluing of materials. A specialized glue – liquid nails – can be an indispensable assistant in this matter. Such compositions appeared on the market relatively recently, but have already gained popularity among builders due to their numerous advantages.

The products of this brand are of high quality and affordable prices.

Types and scope of use

Tytan Professional liquid nails come in several types. Based on their purpose, they are divided into two types.

- Universal. Such compositions are suitable for gluing any materials.

- Special purpose products. Such adhesives can be used for certain types of materials. On the packaging of special-purpose adhesives, the manufacturer indicates information about the purposes for which they are intended. These can be compositions for fastening heavy structures or metal parts, for exterior work, for mirrors, glass, for installing foam panels.

Liquid nails also vary in their composition. Adhesives can be made from rubber or acrylic. The first are polyurethane materials with an unpleasant odor caused by synthetic components. Such products are suitable for gluing heavy materials.

To work with such nails, a respirator and protective gloves are required. It is recommended to use rubber adhesives in well-ventilated areas.

Acrylic (water-based) compositions do not contain toxic substances, due to which they are odorless. Such nails cost less than rubber nails, but they do not have increased strength.

Depending on the composition, liquid nails are used for the installation of window sills, cornices, brick structures, various panels, plasterboard products, glass, aluminum, and solid wood. Glue is not recommended for working with damp wood and for creating aquariums.

How can you dilute dried glue, how can you remove it from clothes, ceilings and other surfaces?

Thickened glue does not glue materials well, so to restore its performance properties, you can dilute it with medical or industrial alcohol, but in no case with acetone or isopropyl, since the glue completely deteriorates when combined with these substances. Diluted glue takes longer to dry, so it is better not to let it thicken: you need to close the lid tightly or buy the smallest container.

To clean clothes from fresh stains of universal glue, you need to remove it with a napkin and quickly wash the item. To remove old glue, substances such as vinegar, acetone, white spirit, Dimexide, etc. are used, but you need to first test them in an inconspicuous area so as not to completely ruin the clothes. Apply the solution to the stain, leave for 30 minutes and wash as usual. You can try to cut off a thick layer of glue with a thin sharp knife or blade.

To remove traces of glue from the ceiling, use grinders, grinders with special attachments, spatulas and chisels to clean hard-to-reach places.

To protect the respiratory tract and eyes from dust, use goggles and a respirator. For the same purpose, spray the ceiling with warm water from a spray bottle. To make cleaning easier, before work you need to cover the furniture and floor with oilcloth.

The hardest thing to get rid of is dried “liquid nails.” Rubber-based assembly adhesive can be removed using solvents. You can try to clean leather items with petroleum jelly or vegetable oil by wiping the stained area with a cotton pad until the stain disappears or becomes less noticeable. The tiles are cleaned using solvents and rubber spatulas. It is easier to prevent the formation of stains, so before working with glue you need to cover the furniture with polyethylene and change into old clothes that you don’t mind getting dirty.

Types of Titan glue

The most popular types of glue are found on sale everywhere in construction and hardware stores and supermarkets. There are also a number of specialized compounds that are much more difficult to find, for example:

- Titan Professional EV W (chemical professional winter anchor) – a two-component composition for use at sub-zero temperatures (down to -18 degrees);

- “Titan PVA D3” – PVA construction adhesive with increased moisture resistance;

- Titan Thermospray – polyurethane sprayed thermal insulation;

- Power Flex adhesive sealant is a silicone sealant with enhanced strength.

Universal glue

Polymer universal Titan SM (“Titan SM”) and “Titan Wild Premium” are adhesives that have a wide range of applications. They are sold in translucent plastic bottles and are conveniently applied through a dispenser. After drying, the seam becomes completely transparent, therefore the scope of use of adhesives is not limited to the color of the surface. Most often, products are purchased for gluing the following materials:

- wood;

- PVC;

- polystyrene;

- wood-based materials;

- carpet;

- glaze and ceramics;

- leather.

How long does it take for universal glue to dry? 1 hour is enough for the composition to dry completely and the product can be used (without serious mechanical stress). The seam remains flexible and does not deteriorate from vibration, it is moisture-resistant, heat-resistant, but gains full properties after 24 hours.

Adhesive foam "Titan"

Several types of adhesive foam are produced under the Titan brand - “Titan Professional 65 Uni”, Titan Professional Euro for block masonry, “Titan 60 seconds”, etc. Such products are characterized by high adhesion to mineral substrates, economical in consumption, perfectly fills cracks and holes. The maximum level of adhesion to surfaces is observed after 2 hours. You can work with the compositions at temperatures from -10 degrees. They are used for installation:

- thermal insulation;

- foam silicate blocks;

- ceramic tiles;

- sand-lime brick;

- gas silicate blocks.

Adhesive mastic

Mastic "Titan" is intended for working with tiles, natural and artificial stone, glass, plywood, brick, and plaster. It can also be used to glue ceiling tiles, baseboards and decorative elements, plasterboard sheets, chipboard and fiberboard. Mastic can be used to level bases and seal any defects.

The composition is frost-resistant, heat-resistant, lasts a long time, and does not collapse. You can work with it at temperatures from +8 degrees. Despite the fact that the mastic sets in 20 seconds, it will not be possible to quickly dry the entire adhesive seam; this requires 12 hours. The glue consists only of safe components; there are no solvents in it.

Liquid Nails

Among analogues (such as “Moment”, “Epoxy-Titan 6 BL” and others), liquid nails of the “Titan” brand stand out for their high degree of adhesion, economical consumption, and moderate cost. They are available in tubes of 200-310 ml, and the larger package is additionally equipped with a glue gun. The most popular adhesives in this series are:

- “Titanium rubber adhesive for roofing” is a roofing composition that reliably fastens metal sheets, tiles, tiles, PVC gutters;

- mounting Classic Fix (“Classic Fix”) - a rubber-based product for any interior and exterior work;

- installation Hydro Fix - a water-based general construction adhesive used in interior work and for gluing porous materials;

- assembly Heavy Duty is a universal tool for finishing work in construction.

The adhesion to surfaces of liquid nails is so powerful that they can become an excellent alternative to metal nails and screws. They are used for fastening tiles and stone, polystyrene and polyurethane, gypsum, cement, brick, cork and other materials. The compositions cannot be applied only to products made of polyethylene, polypropylene and to wet substrates, although after drying the adhesive joint will be moisture resistant.

Powder

Dry powder refers to Titan wallpaper adhesives, which include three varieties - for paper, non-woven fabric, and vinyl. The instructions for use contain all the necessary data on the dilution of the products. They can be easily dissolved in water according to the specified proportions, mixed and after 5 minutes used for their intended purpose. The composition contains additives against fungus and mold, as well as special components that make it easier to adjust the position of the paintings on the wall.

Product types and application technology

There are several varieties of Titan adhesive mixtures, which you need to familiarize yourself with in advance. Also, before using them, the instructions for using adhesive compositions should be studied.

Assembly adhesive

The most common installation tool is the universal Titan Wild, which is used for gluing mirrors, linoleum, carpet and much more.

Before using the adhesive mixture, the surface is cleaned of dirt, leveled, degreased and dried. Then glue is applied in a thin layer, after which it is not touched for 1-2 minutes until it dries. In order for the glued products to be securely fastened, they must be pressed against each other. The connecting seam will harden within 30-35 minutes.

Transparent assembly adhesive

People who prefer to use crystal clear and transparent adhesives often purchase Titan Classic Fix and Titan Hydro Fix. Some people use Power Flex, which also remains transparent after drying.

Before applying “Classic Fix”, the surface to be treated must first be wiped of dust and cleaned of stubborn dirt. To ensure that the composition adheres more reliably to the coating, it is disinfected with an alcohol solution.

Glue for decoration

For gluing wallpaper or ceiling tiles, use a special two-component composition “Titan Decor”. First you need to dilute the glue with water to prepare an adhesive solution. First, prepare a container in which you need to dissolve Titan Decor and mix it with the liquid. For mixing, it is better to use a drill with a mixing attachment. The composition is mixed for about 60 seconds, after which it will be ready for use.

If there are lumps in the liquid after stirring, the mixture will have to be stirred for a few more minutes.

PVA glue for wood D2-D3

When gluing wood, special PVA glue is often used. Its main features include environmental friendliness, safety, moisture resistance, elasticity and low cost.

Many people are interested in how to dilute the composition before gluing wood. To prepare the adhesive solution, PVA is poured into a pan and heated to 40-45 degrees. Then it is mixed with water and left to infuse for 10-15 minutes. The prepared composition is applied to the surface in one layer.

Roofing adhesive

Tytan Professional is used for roofing, which is resistant to ultraviolet radiation and does not deteriorate in conditions of high humidity.

Before applying the adhesive solution, prepare the surface. It is cleaned of paint residues, rust, dirt and other substances that may be on it. Then everything is degreased with ethanol and dried. The glue is applied to the coating in thin strips, after which the surfaces are firmly pressed against each other.

Number glue

Titan numbered adhesives are also used in construction.

601

This product is made on a rubber base. Many people are interested in what glues this composition. It is used for external or internal work when gluing brick, concrete or wooden products. The advantages of the composition include its frost resistance, high strength and level of adhesion to the surface.

604

A universal mixture made on a water basis. "Titan" No. 604 is used for indoor and outdoor work. It reliably bonds bricks, cement surfaces, wood and paper. Among the advantages of the glue are non-flammability, environmental friendliness, lack of solvents in the composition and strength.

901

This numbered adhesive is highly durable, which allows you to glue structures with considerable weight. It is used to secure materials made of wood, paper, brick, concrete and glass. Some people are interested in how long Titan No. 901 takes to dry. It completely hardens 15-20 hours after application.

See also

Which adhesive sealant is better to choose for car glass and gluing rules

910

To work with plastic and wooden products, numbered glue 910 is often used. This composition is resistant to mold, mildew, dampness and low temperatures. Among the disadvantages is the long-term hardening of the composition, since it dries for 2-3 days.

915

When gluing building materials to porous substrates, use “Titan” No. 915. The product is resistant to temperature changes and tolerates temperatures above 50-60 degrees. Hardening of the applied adhesive solution lasts 30-40 hours.

930

This is a high quality adhesive made from resins and rubber. Experts advise using it when gluing polystyrene, ceramic tiles, wood and concrete.

Classification by composition

Titan brand adhesives are also divided depending on the main composition. Each adhesive has advantages and disadvantages, and also differs from others in the specifics of application, although the difference in the area of use is small. Here are the main types of adhesives:

- Rubber. This includes the Titan Professional line of products, which are convenient to use for wood, particle boards, gluing tiles, baseboards, and baguettes. The adhesives are resistant to changes in pressure and temperature and have excellent elasticity. This same line includes the so-called “liquid metal nails”, which are used to glue mirrors and glass only indoors. The rubber also contains universal liquid nails “Titan 601”, intended for finishing and insulating materials, cornices, sockets, and panels.

- Polyurethane. Adhesive Styro 753, which contains polyurethane, is a representative of this group of adhesives. It can glue almost any material, even bitumen, mineral wool, and is often used for fastening thermal insulation boards and roofing coverings. Polyurethane glue has antiseptic properties and does not allow fungus and mold to multiply.

- Acrylic. Titan Express glue is an excellent product for gluing stone, wood, ceramics, and glass; it hardens very quickly, so it is used for urgent work. Lepnina Decor adhesive is also an acrylic adhesive, has excellent quality characteristics, is suitable for cork, glass, and can glue any decor in the interior.

- Polymeric. The scope of application of such a product is wide, but more often it is used for unusual materials that it does not harm - amalgam, alloys, fiberglass, etc. This product attaches equally well to various types of insulation, ceramic tiles, and moldings. The glue has powerful sealing properties and is not affected by sunlight.

Funds are also divided according to the form of release. They can be packaged in metal buckets, plastic buckets, tubes with a nozzle or dispenser, which are used with a glue gun. Titan is also sold in plastic bottles and small tubes with a screw cap.

What's included

Recognized as safe. The manufacturing method provides for the rational blocking of isocyanates - harmful fumes generated when working with many chemicals.

The manufacturer indicates on the glue packaging the composition, which includes styrene-acrylic dispersion and modifying additives. In general, these are copolymers of vinyl acetate in an organic solvent (denatured alcohol).

Does not contain toxic impurities that are harmful to health and well-being

Styrene-acrylic dispersion is an aqueous binder material, a product of radical emulsion polymerization, it provides high resistance to temperature changes, exposure to sunlight, and mechanical stress.

The second ingredient is auxiliary. Additives are responsible for regulating the processes of setting and hardening, acquiring a homogeneous structure, and rheological properties. A separate group of additional substances represents multifunctional additives (organosilanes, polyesters, coalescents, thickeners). Also contains:

- polyurethane, consisting of polyol and isocyanate (petroleum products);

- liquid polystyrene;

- dimethyl ether;

- diphenylmethane;

- propellant.

This is interesting ! The name fully reveals the main advantage - the strength of bonding heterogeneous surfaces. It takes its origins from ancient Greek mythology, where this was the name given to the strongest gods who hold the sky on their mighty shoulders.

Polyurethane foam STD

Tytan STD one-component polyurethane foam is used to fill and seal joints, cracks and other gaps. Most often used when installing windows and doors. Ideal for wood, stone, concrete and metal.

Advantages of STD foam:

- does not require additional equipment (the bottle is equipped with a special applicator);

- noise insulation up to 62 dB;

- thermal insulation;

- ergonomic packaging;

- can be used for 2 months;

- rapid hardening;

- prevents the appearance of fungus and mold.

Mode of application:

Before use, shake the container thoroughly and then keep it upside down. Apply foam to a clean, degreased and damp surface using an applicator. When hardened, the composition doubles in size.

Characteristics of Titan glue

For each type, the technical characteristics are individual; they depend on the substances included in the composition. The most popular is transparent universal glue, the parameters of which look like this:

- thickness of the adhesive layer – up to 4 mm;

- weight of 1 m2 of glue – 4.5 kg;

- breaking force in the transverse/longitudinal direction – 600/400 N;

- heat resistance – up to +140 degrees.

The properties of the glue allow the finished seam to withstand significant mechanical loads and, after drying, not to become brittle or deteriorate over time. Titan brand products can be used in rooms with any humidity; they can withstand even intermittent direct contact with water.

Operating rules

Manufacturers of adhesive compositions provide instructions for use located on the back of the jar or bottle with the mixtures. The categories for which this composition is intended for gluing are also listed there. Despite their species diversity, we can highlight the main recommendations for the correct execution of work:

- The result depends on the quality of surface preparation: they must be dry, smooth, and free of grease (alcohol, solvent, white spirit). Sand or plaster surfaces if there are serious uneven areas. Use primer or putty.

- After 4 hours of the primer drying, start gluing. The fastening composition dries in 30–40 minutes.

- More doesn't mean better. Do not overdo it with application - stick to an average layer thickness (up to 4 mm).

- Allow the product to “set” by waiting from 2 to 10 minutes (the exact time will be indicated on the package, which varies depending on the materials). Only then connect the disparate parts.

- If you are dealing with porous structures, you will have to apply Titanium in 2 layers: the first to level the base, the second to bond. The principle of operation is the same: apply it the first time, wait a few minutes until a film forms. Treat the area again, tightly fixing the elements together.

- Apply liquid nails in a thick layer, diluted wallpaper powder in a thin layer, first diluting it with water.

- Certain types of gluing (for example, foam tiles to a concrete ceiling) require short holding of the parts by hand: hold the tile for a minute so that it better adheres to the surface. Then release and wait for it to dry completely naturally.

Advice . Thick composition is not suitable for filling small cracks and gaps. If you don't have liquid glue on hand, dilute the existing one with denatured alcohol.

Instructions for use

First you need to choose the right glue so that it perfectly matches the materials used. The easiest way to use polyurethane glue is that it dries faster and is easy to apply. When working with glue, you need to ensure good ventilation, but without drafts - the latter interfere with the quality of gluing and change the drying speed of the composition.

You need to work with glue like this:

- Carry out high-quality preparation of the base. All dirt and dust must be removed from the wall, ceiling, and other surfaces. Remove any pieces of old coating that are falling off, apply plaster, and cover up all holes and defects. Sand and degrease metal and plastic products. If possible, use a primer. Immediately before applying the glue, the base must be completely dry.

- Apply Titan glue to one side (for complex or large surfaces, you need to treat all the substrates to be glued; for tiles, apply the glue with a snake). Firmly press the materials together, do not lift your hands or the fixing device for at least a minute (if we are talking about ceiling tiles, you need to hold them with your hand for 60 seconds, then you can release them). Leave the products alone until the glue dries completely.

Adhesive-mastic is applied using a spatula, either pointwise or in a continuous manner if the product has significant weight. “Liquid nails” are applied with a glue gun in stripes or waves in a thick layer; they can be used to finish surfaces with differences and defects.

Dried smudges of glue are visible in bright light, so it is recommended to remove them immediately. Expanded polystyrene and other soft substrates can be cleaned with a damp cloth if the glue has not yet hardened. Remove the glue from solid bases after it has dried by picking it up with a sharp spatula and tearing it off with your hands. You can also use organic solvents – acetone, white spirit – to clean surfaces.

How to dilute glue

It happens that the glue dries out and becomes more viscous. If it has thickened, you can dilute the composition using simple steps. You need to take regular medical alcohol, add it to the glue in a small volume, and shake well. The diluted product dries a little longer, but penetrates better into the smallest cracks and pits. How to dilute the glue in tubes when it thickens? It will not be possible to restore the normal consistency of such a product due to the tightness of the packaging, but it can become too viscous only after the expiration date.

How to dilute

During use, Titan glue may thicken, which will adversely affect its properties. This problem can be solved by diluting the composition, returning it to its previous characteristics.

You can dilute the glue using the following means:

- Medical ethyl alcohol.

- Technical alcohol.

- An alcohol solution of salicylic acid.

Reference! Do not use acetone, isopropyl alcohol or nail polish remover as a solvent, as these products can cause the glue to curdle.