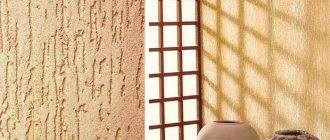

Structural plasters emerged from the desire to diversify the texture of the resulting surfaces. A smooth finish is very different from a grainy finish. In structural finishes, namely roller plaster, the texture formed due to the peculiarities of the laying technique is supplemented by the texture formed due to the protrusion of filler grains.

Roller plaster, which appeared not so long ago, quickly became popular due to its ease of application, as well as other advantages. From a distance it looks like a smooth monolithic coating without seams. But as you approach, patterns formed by numerous grooves begin to appear. Most often, this type of finishing is used for facades and large premises. It is rarely used in small rooms, as it visually hides the space in them.

However, designers have found an “outlet”; they use it in interiors to create small plaster panels.

Roller mixture and its features

How is this plaster different from other types? First of all, the peculiarities of the composition of the mixture, namely, the filler. It is not for nothing that it is labeled as decorative with a bark beetle effect. Its filler is quartz sand and rounded marble chips.

They produce three types, differing in the size of marble chips:

- coarse – grain size 2-2.5 mm;

- medium – grain size 1.5-2 mm;

- fine-grained – grain size 1-1.5 mm.

Coarse-grained mixtures are used for finishing facades, walls of halls, offices, and hallways. Fine-grained ones are used to decorate the walls of medium-sized and small-sized rooms.

Only two types of bases are used for it: acrylic and gypsum.

The acrylic resin base has great elasticity. Thanks to special additives, it can be used both inside and outside the house. Acrylic resins are flammable substances, therefore it is advisable not to place compositions, even with fire retardants, near places where fire is used. Vapor permeability is not very good, so it is not suitable for bedrooms and living rooms. Easy to clean. Tolerates temperature changes and heavy precipitation well. Frost-resistant. Mixtures can be produced in buckets of various capacities. It is possible to purchase a ready-made composition already tinted. However, its color selection is still small.

Gypsum roller decorative plaster contains gypsum as a binder. Sold only as a dry mixture. The gypsum-based composition is more sensitive to various types of vibrations, therefore it is not recommended to use it in areas with troubled seismic activity or near railway lines, as well as in new buildings until the house settles. Gypsum plaster is best suited for interior spaces. It goes well with walls made of aerated blocks, “breathes” better, and this contributes to an optimal microclimate. Lightweight, non-flammable. Not recommended for unheated and damp rooms, as well as for facades.

One of the features of this type of coating is its low weight, good noise and heat insulation. The guaranteed service life is the same as other latex and mineral finishes - 10 years. A significant disadvantage is the impossibility of local repair or restoration. All trim will have to be cleaned off.

Tools needed for roller application.

To work you need to prepare in advance:

- Painting spatulas in sizes 100 and 300 mm.

- A plastic trowel that will be used to create the design. A Venetian trowel is also suitable for this work; with its help, a better and more beautiful coating is created.

- A bucket in which you will collect warm water, and a rag for cleaning the spatula while working. The mixture dries quickly, so to avoid unnecessary scratches, the spatula must be cleaned of dirt.

- Electric drill for stirring plaster solution.

- Container for preparing the mixture. To avoid differences between the shades of material from different cans, part of the plaster from one container is mixed with a solution from another.

Required Tool

Roller plaster does not require a large number of tools or any special equipment for its application.

To apply it use:

- trowel,

- wide spatula,

- To form patterns you need a plastic grater.

Painting tools are also common:

- brush,

- roller,

- sponge.

You will need containers, masking tape, and clean rags. To prepare and tint the solution, you need a mixer.

Plastering process

Speaking in general terms, applying roller plaster to a surface is not that difficult. The method is standard - use a small spoon or a stainless spatula. These tools are also used when you simply need to putty the surface.

You need to act like this:

- In the bucket, the mixture is thoroughly mixed;

- Then, using a small spatula, it is placed on a large tool - it is with its help that the composition will be finally applied to the wall.

Preparing the walls

Although roller plaster can hide some minor imperfections in the base, wall preparation includes both repairing cracks and smoothing out the wall surface. If the previous wall coating is oil paint, the paint coating must be removed to ensure proper adhesion.

Sequence of base preparation:

- the wall surface is inspected,

- is cleared of the remains of the old coating,

- oil stains are removed,

- moldy areas or areas of fungal infection are disinfected,

- checking the evenness of the wall and its verticality,

- if necessary, cracks and large gouges are repaired, and the wall is leveled with sand-cement mortar,

- primed in two layers - a primer suitable for deep penetration wall material (first layer) and a primer with quartz sand (second layer).

After complete drying, the wall is ready. Roller plaster, like decorative plaster with a particularly thin layer in the grooves, may require adding color to the primer to achieve the desired color effect.

Roller plaster is the main method of application.

Work begins on the right side, from the bottom corner. Use a small spatula to pick up the material and transfer it to a large one, with which an even layer of plaster is applied to the prepared surface. At the same time, they try not to make omissions.

Due to the fact that the material hardens quickly, it is better to do this work together. In this case, one master applies a layer of plaster to the wall, and the second levels it using a Venetian trowel.

Decorative finishing can begin after a few minutes, when the coating layer begins to dry.

When the coating loses its shine, it means that it has begun to harden and you can begin decorating it.

Application technology

Everyone notes that this finish is easy to apply. Even someone who has never done plastering work, not to mention decorative plastering delights, can handle it.

As with any new task, it is advisable to practice on drywall.

The work is carried out in two stages:

- applying the composition in an even layer,

- applying a pattern.

Since both types of compositions - gypsum and acrylic - set quite quickly, with a large coverage area it is better to do the work together: one person applies the plaster layer, the second follows and applies the design.

It must be remembered that correcting the flaws of this type of coating is not easy. The damaged surface will have to be cleaned of the entire layer. Therefore, it is especially important to carry out all work (preparation, dilution of the solution, application of coating) in accordance with the technology.

Work outside can only be done in dry weather at a temperature not lower than 5°C and not higher than 35. The wall being treated must be protected from direct rays of the sun, and after application, also protected from possible rain.

To prepare a gypsum-based solution, pour water into a clean container in the amount specified in the instructions. The water should be warmer than 12°C. The dry mixture is poured into a container, color is added and stirred. If the mixture is thick, add a little water and mix again. After stirring with a mixer, the solution is left to stand for 10 minutes, after which it is stirred again. The finished acrylic solution is also colored, if necessary, and stirred before use.

First, an even layer of decorative mortar is applied. This is done with a trowel. The layer is made equal to the diameter of the grains. The layer is allowed to set a little.

Roller plaster is familiar to many with the method of applying a pattern such as bark beetle. It is obtained by rolling large round grains, moving a plastic grater along the base. Rolling grains leave marks-grooves in the stuck mortar, which are no longer completely covered by the mortar mass. To apply a pattern, a plastic trowel is placed with the working surface on the layer and moved in the desired direction. There is no need to press the trowel, otherwise the coating may be damaged.

Strictly speaking, the bark beetle pattern is part of the patterns that can be obtained by rolling grains into a roller structure. The popularity of the effect has led to the fact that roller plaster is popularly called bark beetle plaster rather than roller plaster. In fact, these are chaotic arcing or winding grooves, reminiscent of passages gnawed by beetle larvae. The remaining patterns - rug, rain, concentric circles are not related to this type. They are applied in a similar way - by rolling a trowel, but the direction of movement has an order.

- The rain is obtained by parallel straight trowel wires vertically or at an angle.

- Rug - with alternating short cross-shaped movements.

- To apply concentric circles ( lamb ) the trowel is rotated around the center of its working surface. Strictly speaking, these are not exactly circles, but their semblance.

After applying the pattern, the solution is allowed to stand for half an hour and a stainless steel trowel moistened with a clean surface smoothes the pattern. The dried coating is processed with sandpaper to remove sharp protrusions. Dust is then removed from the surface.

Details

First, we should talk about the composition of roller plaster, because this aspect is very important for any finishing material, especially for a plaster mixture.

Compound

What does roller plaster contain? Here you can note:

- Acrylic putty. It also contains rounded marble screening of some fraction;

- When choosing, the buyer can choose exactly what he needs (the size of the fraction, as a rule, is very important for designers so that they can implement certain ideas);

- There is a small fraction of screenings, it can also be large or medium. Small is a screening from one to one and a half millimeters in diameter;

- The average screening fraction is from one and a half to two millimeters;

- The largest option has a diameter from two mm to two and a half.

However, anyone can cope with applying such a composition on their own.

Since the composition contains astringent acrylic components, the adhesion of the solution is quite high. But, at the same time, it should not be placed on a surface where there is dust.

- It is because of this that it is customary to pre-treat the rough base with a primer - only with this approach the result will be of high quality;

- At the same time, it is the requirement described above that can be called the only technical one in this case;

- That is, careful leveling of the base before applying roller plaster is not required (the same can be said about other types of putties);

- A variety of bases are ideal for applying this plaster. Stone surfaces, concrete, fiber cement, brick. The material is even laid on drywall - this is quite normal;

- If we talk about the disadvantages of finishing, it is only appropriate to mention the high cost. But these are the realities of our life - if you want quality, you have to pay for it. There are no other options.

You can purchase the composition of roller plaster in almost any store that sells construction products and finishing materials

Today you can buy roller plaster at almost any hardware store. The material is packaged in buckets, and there are offers with different capacities. The most popular options are 9 kilograms, 18 kilograms, and you can also find 50 kg ones at once.

- Work related to the application of roller plaster can be carried out when the room temperature is not lower than 10 degrees Celsius;

- The substance is stored from the date of release for no more than 18 months - these are the recommendations given by the manufacturer himself. Any experienced master finisher will also confirm this. For storage you should choose a cool, dark place.

Preparatory work - what needs to be done

It is most convenient to apply roller plaster using special tools.

As in any other case, if roller plaster is purchased and you need to use it, you cannot do without certain preparatory manipulations.

The rough foundation must be clean - you can’t do without it.

What does pure black base mean? Everything is simple here: there should be no finishing materials on the base, as well as their possible residues, which is found everywhere.

What absolutely needs to be cleaned? Usually removed:

- Varnishes, any paints;

- Grease stains;

- Lime;

- Wallpaper and elements of paintings;

- Old plaster that is already falling off;

- If the base is lime-cement mortar, it must be removed. This is done even when it is quite strong and does not fall off.

Another interesting point that the master should be prepared for:

- Sometimes the following picture occurs: oil paint is applied to a cement-sand mortar (

Coloring

If the mixture was not painted before work, the coating must be painted (read more about painting decorative plaster). Roller plaster is often used as decorative with a bark beetle effect. It looks especially advantageous when two contrasting colors are used for painting. This can be a contrasting pattern in which the grooves are painted lighter than the main background, or they are darker.

It is best if the paint and plaster were from the same manufacturer. If this does not work, then water-dispersion paint (precipitation-resistant) or acrylic-based paint is used for outdoor surfaces. For interiors, acrylic and water-based paints are used. Facades are usually painted one color.

For painting work with a large coverage area, as a rule, spray guns (and similar mechanization) are used. Indoors, brushes, rollers, and a sponge are used for painting in two colors. The painting method is similar to painting plaster with a bark beetle effect. When painting with a roller, use a long-nap roller for the first layer. Painting is carried out by rolling the paint vertically and horizontally. The main thing is that all grooves are painted over. For the second layer, a roller is taken with velor (short pile), and painting is carried out only in one direction (either vertically or horizontally).

After the paint has dried, the surface can be varnished.

conclusions

Dexterity and design thinking are all that is required to achieve excellent texture when using roller plaster.

The design of roller plaster does not end there at all. The relief on the surface can be made more varied even simply by hand.

Masters use a spatula for this and other tricks. Artificial irregularities on the surface look organic.

You can learn more about how roller plaster is applied in the thematic video. It is definitely recommended for viewing by anyone interested in this topic.

Sometimes they do more than just tint. On the wall, for example, you can print stencil drawings of various colors and themes - the result is more than worthy, and also very interesting. The interior becomes as diverse as possible (the same can be chosen for the design of the building’s exterior). In a word, the design will only gain in attractiveness and individuality - there is no doubt about it.

Rating: 4.5 / 5, total ratings: 2

Roller plaster is a material that allows you to create relief surfaces. Builders call it “bark beetle” for its pattern with numerous furrows. The coating looks unusual and impressive. Such a relief texture does not tire the eyesight. It resembles a wooden plane with many thin grooves.

To prepare the mixture, you need to add water to the container with the powder. The amount of water is indicated in the instructions for each type of plaster. The finished solution must be used the same day; after 48 hours it hardens to form a stone-like material. This coating can be sanded and sanded to achieve decorative effects or smooth out sharp corners of patterns.

How to calculate material consumption.

There are many types of such coatings on the market.

For example, VGT acrylic roller plaster is available in all varieties. You can purchase both coarse-grained and fine- and medium-grained mixtures. It has an affordable price. Buyers liked it for its excellent quality. With its help, you can create a particularly beautiful coating on the walls, which will be durable and durable. You can purchase roller mixture at all construction stores. It is sold in packages of 9, 18 and 50 kg. You can calculate the required weight as follows: per 1 sq. m of wall you will need about 2-3 kg of bark beetle.

One of the most interesting finishing materials is VGT roller plaster. A wall covered with such plaster has an unusual texture, shaped like a cut of wood in which the bark beetle has left passages. Therefore, this finishing material is popularly called “bark beetle” plaster.

The use of this composition allows you to create several texture options, as well as finish in almost any color. Such possibilities of the material open up many combinations of building design, which skillfully used by skilled designers.

What mistakes should you not make when applying?

Pay attention to the temperature and humidity when performing this work. Plaster cannot be applied at low air temperatures, less than 5 degrees Celsius. If the room is more than +30, then the technological process will also not be of high quality. Roller compound is poorly affected by direct sunlight. It is not advisable to apply it in rainy weather. The wall prepared for work must be dry.

Monitor the thickness of the plaster in the jar; it must be the correct consistency; if the mixture turns out to be too thick, you can add more water than prescribed in the instructions. This does not apply to acrylic compounds. For example, there is no need to add water to VTG roller plasters.

Material that falls off the trowel is not suitable for reapplication. The wall cannot be covered in several stages with breaks, because the joints of individual sections will be noticeable. It is better to do all the work at once, inviting several craftsmen.

If it is not possible to complete the work without joints, then the edge of the plaster cannot be made smooth so that its continuation is less noticeable.

If you did not have time to smooth out the sharp edges of the drawing before it hardened, you can sand them.