Most of those who start renovations are not professional builders. And thanks to the availability of information, it has become easier to carry out repair work with less financial losses. Why renovation begins, of course, with leveling the floors, this is especially true for old buildings, where screeding is required. So what is the cement consumption per 1m2 of screed?

One of the main components required for screeding is cement. The main problem when working with it is the low shelf life after opening the package. Over time, cement cakes and loses its properties. Therefore, it is necessary to purchase this material right before use and preferably the exact quantity.

To do this, you need to carry out preliminary calculations to calculate how much cement will be needed for the entire quadrature where the screed will be carried out. The correct numbers will help save you money and minimize the loss of materials.

Several factors must be taken into account to ensure that the finished surface can withstand future loads. If you use little cement, then after drying the screed will begin to crumble or crack. By increasing the amount of cement in the finished mortar, the floor will be much stronger, but this will hit your pocket.

How to correctly calculate the cement consumption per 1 m2 of screed? It is necessary to take into account many nuances, which we will consider below.

Properties of the screed

When doing all the work on screeding floors yourself, for example, for a home, it is necessary, before starting work, to carry out all possible calculations.

A typical floor screed mortar consists of sand, cement and water; sometimes additional ingredients are added to the mixture to improve strength: enhancers and fillers that help increase the strength of the finished base.

Here are the most important functions of the screed:

- the finished structure allows you to level the surface in order to subsequently lay finishing materials on it: linoleum, laminate, parquet;

- additional protection from extraneous sounds: noise in the process of life, yours or your neighbors; noises from impacts or air;

- improving thermal insulation in the room;

- masking of pipeline communications or engineering manipulations;

- If the house has a built-in heat pipe, the screed ensures uniform heat distribution.

Types of screeds

Thin-layer screeds 20-30 mm thick usually perform the function of leveling the surface. For their arrangement, cement-sand mortars are used. When making a thicker layer - up to 40 mm - fine-grained concrete is used. They include fine-grained crushed stone with a grain size of up to 10 mm, sand, and cement.

Thick-layer screeds are made from concrete of various compositions. They use granite, gravel, and limestone crushed stone as coarse aggregate. The main functions of heavy concrete screeds are raising the floor level or creating the required slope. Additionally, the concrete layer increases the heat and sound insulation characteristics of the floor.

The traditional technology for installing cement-sand and concrete screeds is wet. Concrete can be produced using a semi-dry method.

To determine the consumption of cement screed per 1 m2, you should understand what kind of building material will be used. Binder powder has a dry structure, but it may differ in its component composition. You can learn more about the choice of Portland cement and its modifications from other publications on our website.

Let's consider how to cover a room of 20 square meters, while creating a 5-centimeter surface, if one of the types of composition prepared for use is used.

- The required solution will have a volumetric content of: 20 * 0.05 = 1 cubic meter.

- High-quality distribution will require approximately 100 kg per 1 m2 of such surface. Accordingly, the mass of the composition poured onto the specified area is equal to: 20 * 100 = 2000 kilograms.

- When purchasing standard 50 kg bags, you will need a batch of 40 packages.

When using a pure binder, you will have to add a sand component to it (water is added gradually after mixing to achieve the desired consistency). In the classic recipe, the combination of the binder component and sand scattering is 3 to 1, i.e. 0.25 to 0.75 cubic meters (when processing the site in the house from the instructions above).

Attention! It is advisable to increase the consumption of building compounds in order to eliminate shortages that arise due to the need to fill defective areas (cracks, pores).

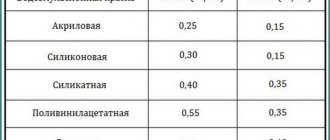

With this approach, it is easier to take the powder mass indicator from the summary table presented below. It is imperative to take into account the brand of powder and, especially, the composition that we get as a result.

| Required mass of binder powder (in kilograms) | ||||||

| Mark of powder | Composition brand | |||||

| 150 | 100 | 75 | 50 | 25 | 10 | |

| 400 | 350 | 255 | 100 | 140 | — | — |

| 400 | 300 | 240 | 175 | — | — | |

| 300 | 470 | 340 | 270 | 185 | 105 | — |

| 510 | 385 | 310 | 225 | 135 | — | |

| 200 | — | — | 405 | 280 | 155 | 25 |

| — | — | 445 | 325 | 190 | 95 | |

| Note: the top line indicates the mass of the binder relative to the sand placer, and the bottom line indicates the mass with a margin (+25%). | ||||||

Types of screeds

The screed is divided into several types.

Structural

- in one continuous layer;

- in several layers (thermal insulation, waterproofing, sound insulation, etc.)

Structural

Composite

- made of concrete;

Made from concrete

- cement-sand;

Cement-sand

- screed mortar using synthetic resins;

- made of plaster;

From plaster

- screed using mosaic , laid on top of concrete.

Mosaic

By type of fastening of screeds with slabs

- screed that is connected directly to the base;

- screed located on the dividing waterproofing layer;

- floating screed laid on top of hydro- and sound-proofing materials

For each type of screed, you must use your own calculations:

- the brand of cement material used,

- its quantitative consumption per 1m2

- individual technology for mixing cement mixture.

If the technology is violated, the screed can peel off, become covered with cracks and even fall out in large pieces, not to mention the formation of voids.

Types of cement mortars for plaster

Plaster mixtures used for wall finishing differ in the presence of certain components and their ratio. Divided into types:

Type of mixture Characteristics Proportions Cement-sand Used for rough interior and exterior finishing, resulting in a durable, moisture-resistant coating. Suitable for finishing walls, ceilings in unheated, damp rooms and for cladding facades.

The constituent components are cement and various fillers: sand, plasticizers, etc. The standard solution is prepared in a 1:3 proportion of sand and cement. Cement grade M 400 can be diluted 1 part to 8 parts sand. M 100 is mixed in a ratio of 1:2.

The composition is selected depending on the type of surface, layer thickness, and operating conditions. To increase plasticity, add PVA glue to the finished mixture in a ratio of 50-100 ml per 10 liters of the finished solution. Cement-lime have good adhesion to all types of surfaces.

Used for finishing plinths, cornices made of stone and wood. Lime has bactericidal properties, protects the surface from mold and fungal infections. 1 part cement and lime to 5 parts sand. For a 25 kg bag of cement we take 21 kg of lime, 280 kg of sand, 50 liters of water.

The cement composition is most often used for rough finishing of walls. A thin layer cracks during operation, so it is recommended to apply cement-sand mortars with a thickness of 3 to 6 cm, depending on the material from which the walls are made and the plaster application technology used.

What materials are required for floor screed?

To begin preliminary calculations, it is worth deciding in which room the screed will be carried out. Because cement has different properties due to its composition.

If you plan to lay porcelain tiles in the room or this is an office space, you will need to use cement with high-strength properties. The reason for this is the pressure exerted on the floor.

To screed floors in a residential building, you can use GOST 31108 cement of medium strength; only in recent years, the demand for material with a coefficient below M300 has practically fallen. Therefore, its production has decreased. Because of this, the M400 cement grade is most often used. But what does this mark mean on the product?

- M 400 - indicates the ability to withstand pressure of 40 tons per 1 m3;

M-400

- if the designation “D” , then it means the presence in percentages of various additives that increase the resistance of the finished screed to cold and moisture;

With additives

- the designation “GF” indicates how much the material is afraid of moisture, hence the place of its storage is taken into account.

But not only cement is used for screed; sand is another important component. It must be calculated in the ratio of 1 kg of cement 3 kilograms of sand.

What affects material consumption

The amount of solution depends on the level of the walls. The more defects, the more mixture required

You can easily calculate the cement consumption for plastering walls yourself. Consumption is determined based on the following components:

- the type of mortar and its components; how smooth the walls are, and what material they are built from.

In multi-storey buildings, the level deviation of the plane is 2-2.5 cm. The greater the unevenness of the surface, the thicker the layer will have to be applied.

To reduce the consumption of the plaster mixture, the surface is treated with a primer in several layers. It helps remove dust from the surface, reduce absorbency and better adhesion of materials.

At the junction of two surfaces made of different materials, we install a construction mesh. Because of this, a thicker layer of plaster is required. Calculation of the consumption of decorative plaster is carried out using a special method.

In old houses you can find perfectly straight walls, but more often they have crooked walls.

Preliminary measurements of room floors before starting cement and sand calculations

- To determine the exact consumption of sand and cement per 1 m2 of screed, you must accurately measure the area of the room in which you plan to screed the floor.

- The room must first be cleared of all foreign objects, including debris and dust, so that nothing affects the measurement results. After this we move on to measuring the floor.

- Initially, the zero level of the mark is determined; it can be located in any part of the room. To do this, you will need a laser tool or spirit level, then mark each wall of the room from the found point.

- The next step is to connect all the marks with one straight line . This is how the level of height difference is determined; it should not exceed five centimeters. The thickness of the screed at the highest point of the room must be at least 8 mm. If the differences are too critical, you should first level the most uneven areas.

Otherwise, after completing the screed with sharp changes in the level of layer thickness, the surface will become covered with cracks and will crumble.

Tips for calculating cement consumption

Helpful tips and recommendations from experts will help you more accurately determine material costs:

- For calculations use a tape measure and a calculator. First, determine the zero point. Starting from it, find the minimum and maximum difference. If local bulges are too large, they are cut off with a grinder. It is recommended that the layer be as uniform as possible over the entire surface.

- When choosing a mixture, take into account the number of layers, type of base, type of finishing coating.

- The composition should be purchased in the required quantity. The stock is made no more than 10% of the volume.

- When calculating, the values for doors and windows are subtracted from the total area.

- When purchasing, pay attention to expiration dates and storage conditions. The longer the solution is stored, the worse its performance characteristics.

- When using stale goods, they make a larger stock in quantity.

Leveling the walls and creating a screed are mandatory stages in the rough renovation of apartments and houses. Theoretical knowledge and practical experience in calculating the required materials allows you to significantly save costs on materials and avoid making mistakes when choosing the appropriate composition.

How do you calculate the ratio of the components of the cement-sand mixture? Share your experience in the comments.

Screed mortar - how to calculate the consumption and amount of cement on a calculator

There is no standard formula that would calculate the exact volume of cement material required for a screed.

Each builder uses his own calculation system, and it must be taken into account that it is different for different brands of cement.

So, for example, to use the M400 or M500 brand, the required proportions for floor screed in a residential building are 1:3.

The required value of cement consumption is calculated from the product:

- room length;

- thickness of the screed layer;

- area of the room.

To the obtained value it is necessary to add about a quarter of the calculated amount of materials. Because the finished cement mortar gives sediment. If you decide to use ready-made mixtures, then the approximate consumption volume will be 17-20 kg per 1 m2, taking into account that the permissible thickness of the screed will be 1 cm.

What will be the consumption of mortar per 1 m2 of screed with a thickness of 30 mm? For example, let’s take a room area of 12 m2. The grade of cement used is M400. Now let’s calculate the volume consumption of the finished solution:

- 12 * 0.03 = 0.36 m3,

Let's calculate what the cement consumption will be for a given area. According to the standards, 410 kg of cement of a specific brand is used per 1 m3:

- 410 * 0.36 = 147.6 kg. Or 3 bags of standard packaging of 50 kg.

We also calculate the required amount of sand and water for the solution:

We take the proportions 1:3, which means you will need 9 bags of sand, with the same weight. For every kilogram of solution, 0.2-0.5 liters of water is required, which means that for the entire volume of the solution you will need:

- 147.6 * 0.2 = 73.8 liters.

The dry solution should be mixed thoroughly before adding water. It should also be mixed immediately before applying to the floor. In this case, a trowel and shovel are used.

When mixing, the dry components of sand and cement decrease in volume due to water, therefore the final mass of the solution is much lower.

It should be taken into account that 1 liter of ready-made solution requires approximately 1.5 kg of cement. This means that from one bag you will get only 36 liters of the finished mixture. That is why another 25% of dry material is added to the final calculated figures.

If you want to further strengthen the screed, add PVA glue to the solution; it will act as a plasticizer.

For more information on how to prepare a screed solution, watch the video:

Preparation for DSP consumption

The screed solution is prepared by adding water to the bulk substances. Most often, builders prepare the composition directly on the site, but you can purchase a ready-made composition (it is more expensive).

In addition to the presented components, the factory mixture contains plasticizers and other additives. Thanks to them, the solution becomes homogeneous. Some brands can be used at low temperatures, because they contain frost-resistant substances.

Different manufacturers' products differ in some characteristics. The ratio of substances depends on the purpose. When concreting, sand is taken in smaller quantities; masonry requires a larger mass of the substance.

For better adhesion of the components, it is recommended to mix the solution by hand. The standard ratio of sand to cement is 1:3. In some cases, other proportions are used (1:2 or 1:4).

Calculating cement for screed helps save money on purchasing materials. The final indicators are not always accurate, because sometimes there is no data on the density of substances.

Types of material:

- M100. Used for leveling. Consumption is 550-570 kg/m³.

- M150. For laying bricks and cinder blocks, installation and concreting (570-590 kg/m³).

- M200. The mixture is intended for masonry and installation (590-620 kg/m³).

- M300. Filling areas with increased load and concreting (620-660 kg/m³).

- M400. For installation of high-strength concrete structures (660-710 kg/m³).

When calculating the amount of materials per 1 m2, it is possible to determine with great accuracy the brand and quantity of the substance. You can replace one type of composition with another, without deteriorating the quality of work.

Additional nuances

Screed is a special type of mortar that requires certain standards and ingredients. It is necessary to strictly observe the proportions so that the finished screed is of good quality. Strictly follow the requirements for material consumption. Saving cement can have negative consequences.

Today, river sand is rightfully the most effective building material. Here are the density characteristics of this material.

Deep penetration primer is designed to give the surface ideal evenness, smoothness and better adhesion between the finishing material and the primer. Here you will learn about the different types and technologies for using primers.

Wall panels for interior decoration appeared not so long ago, but have already gained popularity among the population. By clicking on the link, you will become familiar with the materials and areas of application of the panels.

Basic calculations of proportions are carried out on a calculator after taking into account all the data about the room.

It is necessary to correctly calculate the area of the room and the height of the layer. This data will help you clearly determine the required amount of dry material for the screed.

During work, various cement grades can be used, and each has its own material consumption shown in the table:

Mixture composition

The traditional brand used for floor screed is M200 from the M400 category. If the screed is not laid evenly, then during the drying process it will become covered with cracks; in order to avoid this, the place where small cracks appear must be moistened with water.

Nuances of calculations for potting composition

In addition to the fact that the resulting mass needs to be increased by 25%, there are several difficulties. We decided to make a small checklist for this case:

- the surface to be poured above the pipes should not be thinner than 5 cm, but if it is higher than 15 cm, then heating the base will become much more difficult;

- granite chips added to the composition will help maintain (optimize) energy efficiency;

- when pouring the composition over the existing foundation, the maximum permissible load on the foundation (support) must be determined in order to avoid its mechanical destruction;

- Finally, the redevelopment of residential sites must be carried out within the framework of the law.

By taking all this into account, you guarantee yourself an optimal result with minimal risks. You can also perform calculations using a special calculator. By entering the initial parameters, you will find out the result much faster, and all the above aspects will be taken into account.

Step-by-step instructions for preparing a cement-sand mixture

The work itself is not as difficult as calculating the proportions for the finished solution. Ideally, the work should be done in pairs. While you are leveling the screed, your partner is making a new batch of mortar.

It is advisable to screed one room at a time, because uneven drying of the mortar will lead to the formation of cracks or inconsistencies in level.

So, instructions for performing floor screed:

- At the first stage, it is necessary to clear the room of everything unnecessary, including garbage. A hard broom, brush or vacuum cleaner is suitable as a handy tool.

Cleaning the premises

- Fill cracks , if any, so that the solution does not go to waste. Here it is better to use polyurethane foam.

Puttying cracks

- After completing the preliminary work, we move on to marking the floor and installing beacons. It is imperative to determine the highest points of the floor, because the thickness of the layer in this place must be at least 0.8 mm, otherwise the screed here will begin to crumble.

- as marks . Screw one in at the highest point, leaving the cap on the surface as a beacon. We do the same with other notations. Then check the evenness of the level by placing a ruler on the screws; if there are inaccuracies, they can be easily corrected by adjusting the screw.

Installation of beacons

- After placing the beacons, we begin mixing the solution . To do this, you must have calculated in advance the required amount of material. Before applying the solution to the base, it must be thoroughly moistened with water, of course not to the point of puddles, but thoroughly.

Preparation of the solution

- This way the adhesion to the base will be much better. As you work, you need to additionally treat the dried surface with water before laying the solution. If desired, the builder can pre-prime the base.

- The next stage is pouring the solution. You need to fill from the far corner of the room opposite the exit. Otherwise you will have to walk on the screed. After pouring, they begin to level the surface using the rule, focusing on the placed beacons.

Filling and Alignment

- After finishing pouring, cover the surface with plastic wrap for 12 hours.

- After curing for 12 hours, you can begin to grout the surface.

Grout

- All beacons can be removed, and the remaining marks can be sealed with the same solution so that there are no flaws left.

By following the basic rules when screeding, you will quickly get the job done.

Standard consumption rates

One bag 25 kg

The average consumption of cement for plaster is indicated on the packaging, taking into account a layer of 10 mm, and is individual for each manufacturer. If we apply a solution with a thickness of 2 cm, then we multiply the amount by 2, etc.

d. For plaster, the average consumption is 8.5 kg per square meter. m.

If we take a 25 kg bag, then 8.5:25 = 0.34% of the amount of the bag will spread the plaster per 1 m2.

Let us consider in the table the calculation of cement consumption for plastering walls depending on the thickness of the applied layer at a standard consumption rate of 8.5 kg per square meter. m:

Layer thickness, cm Mixture consumption, kg Mixture consumption in a bag weighing 25 kg, % 2 cm 8.5 * 2 cm = 17 kg. 17 kg: 25 kg = 0.68 = 68% of the bag 3 cm 8.5 * 3 cm = 25.5 kg. 25.5 kg: 25 kg = 1.02 = 102%.

One bag may not be enough for such a layer. 4 cm 8.5 * 4 cm = 34 kg. 34:25 = 1.36 = 136%. You need to purchase 2 bags. One will go completely, 1/3 of the second will be used.

If you need to calculate the consumption of materials for a thicker layer, multiply the resulting amount by the layer thickness.

Marble chips give the “Bark Beetle” mixture a relief

The composition for finishing bark beetle plaster contains marble chips, which results in a relief surface with an interesting structure. Standard consumption ranges from 2.5 to 4 kg. Each manufacturer indicates these indicators on the label.

Venetian plaster is applied in a layer of several millimeters, resulting in a small mixture consumption of 70 to 200 grams per square meter. m. Working with such material requires experience; in order to apply it to the surface efficiently, it is better to invite a professional.

Gypsum compositions are consumed in a ratio of 9 kg per square meter. m. The calculator for the amount of plaster on our website will help you quickly calculate how much of this material will be needed for finishing work.

When purchasing a plaster mixture, you need to add 10% to the calculated amount of material so that you don’t have to run to the store during the work.

Calculate the layer thickness

We determine the difference in the surface relative to the vertical plane using a plumb line or installing beacons.

Methods for determining the curvature of walls:

- We lower the plumb line from the ceiling, find the most protruding point of the wall, then measure the depth of the depressions.

- We use long, even slats as beacons; we apply them to the wall and see how crooked it is; We measure the depressions on the wall.

For clarity, we give an example of calculating the thickness of a layer of cement plaster for a wall with an area of 12 square meters. m.

Let’s say we installed 4 beacons and measured deviations along the plane of 2, 3, 4, 5 cm.

We add up the depths of the depressions on the walls and divide the resulting result by the number of beacons: (2+3+4+5): 4= 3.5 cm. The thickness of the plaster layer will be equal to 3.5 cm.