You can update the interior or facade of your home without resorting to unnecessary costs - just arm yourself with a roller or brush. The main thing is to correctly calculate the paint consumption per 1 square meter of wall surface. They are coated with different compositions, which means the costing will vary.

If you want to change something in the interior, you can simply repaint the walls.

Why is it worth calculating paint consumption in advance?

The amount of material required must be calculated in advance, before the start of repair work.

If you do not resort to preliminary calculations, you may encounter the following problems:

- there is excess paint left or, conversely, there is not enough material;

- The required color is not available for sale or the batch has run out (the color may differ in another batch);

- the paint from the previously purchased manufacturer is no longer available;

- the surface texture required the application of an additional layer;

- the flow rate inside and outside turned out to be different, etc.

Description of service

Painting a plinth is coating a decorative element in the form of a narrow strip with a paint and varnish composition. It is carried out using special devices.

It may be necessary to paint the baseboard for the following purposes:

- Giving the surface an original texture.

- Additional protection of decorative items from wear.

- Hiding minor defects (scratches, stains).

- Giving the product a color that most closely matches the interior of the room.

- Masking of docking points.

It is important to paint the baseboard carefully so as not to spoil the finish of the walls or ceiling. Therefore, it is better to contact professional painters.

Consumption rates for different types of dye

Depending on the composition of the material, paint consumption per square meter can vary significantly.

The consumption rate will depend on several indicators:

- Covering power, or covering ability of a pigment. The substrate must be completely hidden, without veins or gaps in the surface on which the coating was applied. The fastest results can be achieved with paint with 1st class of hiding power.

- Viscosity (thixotropy). To reduce material consumption, solvents (water, white spirit, etc.) are added to the composition. At the same time, the high viscosity reduces the amount of drips during application.

- The thickness of the layer that will remain after the evaporation of volatile substances.

- Texture (smooth or rough) and absorbency of the substrate. Concrete and brick, unlike primed wood and metal, will require 10% more coverage.

- Tools. Paint consumption when working with a roller is higher than with a brush. For rough surfaces, you will need a long-haired tool.

- Colors. Light colors are easier to cover than dark ones to lighten. In the latter case, the number of layers can be increased.

- Working conditions (air temperature, humidity). At high humidity, the substrate takes longer to dry, but material consumption is reduced. In a dry and warm room, more solution may be required.

Paint consumption depends on its texture.

Oil based paint

Using oil paint is the most budget option. Average consumption for 1 layer is 120 g/m². The amount depends on the type of surface on which the composition will be applied. A rough base of material will require more material. You also need to take into account the color of the coating. White paint, for example, wears out faster.

The main components of oil paint are drying oil (binder), pigment, fillers (barium sulfate, barite, talc).

Drying oil can be:

- natural (from vegetable, flax or hemp oil);

- artificial or without oils (carbonal, synthol);

- mixed, i.e. with the addition of solvents (oxol).

When in an oil or similar synthesized substance, the mineral-based pigment settles at the bottom of the jar. Therefore, the solution should always be stirred before use.

The advantages of this type of coating include:

- low cost;

- natural ingredients in the composition;

- resistance to temperature changes;

- hydrophobicity;

- durability.

Among the disadvantages are:

- Strong smell;

- drying time;

- the possibility of cracks forming on the surface;

- decrease in color intensity under the influence of external factors;

- air impermeability through the coating.

Oil paint is applied in 2 layers. If necessary, their number can be increased. The next layer is applied after the first one has completely dried (after 24 hours). If the paint is still sticking, then you should wait a few more hours before starting work.

Oil-based paint is suitable for all types of surfaces: wood, metal, concrete, brick, plaster, plastic, glass. It is traditionally used for painting entrances, cosmetic repairs in government agencies, etc.

Oil paint is suitable for all types of surfaces and must be applied in two layers.

Alkyd enamels

This dye is based on alkyd resin and solvent. The material consumption per layer will average 100-130 g/m².

The paint has a high degree of resistance to weather conditions. It can withstand high humidity and high temperatures. The surface treated with this composition can be washed, so it is suitable as a floor paint (for example, PF-253).

The type of final coverage depends on your choice and can be:

- matte;

- glossy;

- semi-matte.

PF-115 enamel based on artificial (pentaphthalic) drying oil has become widespread. It has a rich color palette. Consumption – from 100 to 200 g/m². It will take less paint to process a metal surface (up to 110 g/m²), wood will absorb more (up to 180 g/m²). If the composition has thickened, then it is diluted with solvents (white spirit, solvent, etc.).

The durability of the coating allows the enamel to be used for road markings. To do this, alkyd-styrene resins are added to the composition. Such materials are marked MS. For painting cars, paintwork materials based on glypthal varnish (GF) are used. Melamine-alkyd mixtures (ML) can withstand particularly high temperatures.

Due to the durability of the coating, alkyd paints are used for road markings.

Acrylic-based compositions

Acrylic enamel consists of a dispersion of acrylic resins. It belongs to water-dispersion paints. In addition to water and polymers, it contains pigments and various additives that improve the properties of the material. The coating hardens due to the polymerization of resins.

Acrylic paint on metal works well on rust. The coating contains both the primer and the coloring agent itself. But the main advantage is a corrosion converter that slows down the oxidation process.

Acrylic-based compositions can be used indoors and outdoors. Among water-dispersed ones they are the most economical. The consumption will be 115-120 g/m².

When painting a metal surface with rust, acrylic enamel works well.

Water-based paint

Water-based paint contains pigments and particles of polymers or minerals. It is used for painting almost any prepared surface. Unlike oil paint, water-based paint dries faster. The second layer can be applied after 1.5-2 hours.

The composition is suitable for rooms with high humidity (bathroom, swimming pool). It’s easy to calculate consumption based on the manufacturer’s data. On average, 1 liter is enough for 10 square meters. m. Some varieties are able to cope with a volume of almost twice as much - up to 18 square meters. m.

For 1 layer you will need up to 150 g/m² (average). For interior finishing, the consumption will be less than for exterior work. For wallpaper with a complex texture, material costs may be higher.

Depending on the type of water-based solution, per 1 sq. m, different amounts of material are consumed. In terms of consumption, the first place is occupied by the latex variety and polyvinyl acetate. The lowest indicator is for acrylic and silicone paints. Average values for silicate.

Water-dispersed compositions, which include water-based emulsion, fit well on wallpaper for painting. A liter of material can cover a surface of up to 8 m² on average. Before applying the composition to glass wallpaper, it is better to use a primer. This will reduce consumption. Requirements for preparing the base may be indicated on the packaging.

Water-based compositions are used in the production of fire-retardant paints and varnishes. They are used for wood, metal, cable coverings. For example, the ability of such compositions to reduce the flammability of wood and materials based on it is tested using a special “Ceramic Pipe” installation. If combustion continues after the end of the test or charring of the entire sample occurs, then the fire retardant function in this case is considered ineffective.

Due to high humidity, when painting bathroom walls, it is better to use water-based paint.

Facade paint

Exterior paint is commonly called façade paint. It must withstand both temperature changes and precipitation. To do this, it must contain special compounds that will preserve the coating for as long as possible.

Facade paints include:

- organosoluble (oil paint, alkyd enamel, etc.);

- water-soluble (acrylic, silicone, latex, etc.).

The first group is mostly used for outdoor work, since the organic solvents in the base of the material are quite toxic. Paints of the second type are also used for interior decoration. They are less harmful to health and dry faster.

The durability of façade paint, consumption during application and quality of finishing will largely depend on atmospheric conditions. At low temperatures (less than +5°C) the coating may crack. In hot weather, the volume of composition used will increase. The air temperature should be above +15 °C, humidity – up to 80%.

Depending on the type of dye and the number of layers, the consumption will be 160-250 g/m².

Facade paint can withstand temperature changes and precipitation, and its consumption depends on the type of dye.

What tools are needed?

The amount of paint needed depends on the painting device used to apply the layers to the wall. One or more tools are used for these purposes:

1. Brush – applies the composition in a thick layer with inevitable smudges. The most expensive painting method with the maximum consumption of finishing coating. 2. Roller - reduces the time of painting work, therefore it is used for painting a large area. Paint is used sparingly. 3. Spray gun - evenly distributes the paint over the entire surface of the wall and quickly applies a thin layer. Option for lean renovation. 4. Sponge – used for decorative finishing of the coating. Increases consumption because when decorative painting a thick layer is applied to the wall.

Typically, several types of tools are used in painting work. This is due to the presence of corners, heating radiators and types of painting. All these nuances must be taken into account when calculating the amount of paint.

What to consider when making calculations

When making calculations, the following criteria are taken into account:

- room area;

- type of original surface;

- tool or method of application;

- type of paint and its basic characteristics.

Room area

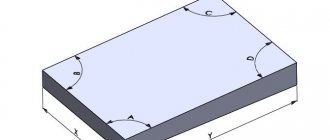

To calculate the amount of paint, it is necessary to determine the area of the surfaces to be treated. To do this you will need to measure the length, width and height of the walls.

If only the walls are to be painted, then the total area of the surfaces to be painted is calculated by multiplying the perimeter by the height. Knowing the source data, all that remains is to substitute them into the formula:

P = (a+b) x 2; S = P x h.

According to SNiP IV-2-82 for finishing works, the area of window and door openings is calculated from the outer outline of the frames, and then subtracted from the area of the walls.

Surface texture and material

How many liters of paint will be used during painting depends on the type of surface.

From the point of view of tactile perception, the substrate can be of 2 types:

- smooth;

- rough.

The first is less porous, so its absorbency will be lower. It is no coincidence that the base is puttied and sanded before painting. But sometimes the relief texture becomes a decorative element.

Main surface types:

- cement-concrete (brick, plaster, cinder blocks, etc.);

- metal;

- wooden;

- plastic;

- paper

Painting concrete, drywall, untreated wood, and wallpaper for painting will require more material. Metal, plastic, primed wooden base will require less cost.

When painting metal, you will need less paint than when painting drywall.

Powder paint is often used to process complex terrain and metal structures, although its application requires special equipment (pneumatic tools and a polymerization chamber).

Good material for painting:

- small parts (machine disks, pipes);

- metal furniture (cabinets, racks);

- metal fences and stairs;

- household appliances (refrigerators, cookers, washing machines, etc.).

The paint protects against corrosion and provides electrical insulation. This composition is not used on wood and plastic, because the melting temperature in the chamber reaches +200° C. Powder paint consumption is 100-140 g/m².

Tools used

Various tools are used in painting:

- brush;

- roller;

- spray gun (spray gun), etc.

The choice depends on the scope of work. A roller and a spray gun are suitable for processing large surfaces. When painting small parts, window frames and doorways, it is more advisable to use a brush.

The spray gun uses paint and varnish most economically. The principle of its operation is characterized by a non-contact method of application. A special gun sprays the paint under pressure and allows it to be evenly distributed. An aerosol can works similarly.

To avoid paint getting onto adjacent surfaces, use masking tape. When working with spray guns, you may need a mask and goggles. Cotton gloves will protect your hands.

The spray gun uses paint sparingly.

Original surface color

The original color of the coating also matters in paint consumption. If the substrate and paint are light, it will be easier to achieve uniformity.

It is more difficult to paint over a dark base, for example, with white paint. More layers will be needed.

Careful preparation of the substrate for painting will help reduce effort and costs. If the old coating remains, it is better to remove it, sand the surface and prime it. The extra hours of repair will pay off in savings on material consumption.

Dye color

The shade of the pigment, like the color of the substrate, contributes to the cost. The density of light dye is less, so it is consumed faster. If white paint weighing 1 kg can cover up to 10 m², then the same amount of black paint will cover a space twice as large (up to 20 m²).

As an example, the table shows the dependence of oil paint consumption on color.

| Color | Surface area covered by 1 liter of paint, m² |

| Red | 5-10 |

| Yellow | 5-10 |

| White | 7-10 |

| Green | 11-14 |

| Blue | 12-17 |

| Brown | 13-16 |

| Black | 20 |

Type of composition

Depending on the composition, paints are used for interior and exterior finishing work. Some are more suitable for interior solutions, others - for updating facades.

The composition of paints and varnishes includes the following components:

- binder base (film formers);

- pigment;

- fillers (microcalcite, talc, koalin, chalk, etc.);

- additives (antiseptic, fire retardant, etc.);

- solvents (water, white spirit, etc.).

The more components, the higher the quality of the product. Paint can contain up to 20 components.

Pigment is one of the components of paint.

Covering power of the coloring composition

The ability of paint to create an opaque coating is called hiding power. It is checked visually and experimentally.

The traditional test is the “chessboard”. A substrate of squares of dark and light shades is coated with dye. At the end of the test, the base should not be visible. The difference in cell brightness (contrast ratio) will help determine coverage.

There is no need to conduct experiments yourself, because... this indicator is indicated on the bank. Depending on the manufacturer, this pigment characteristic can be expressed in g/m² or l/m².

The covering characteristics of the composition are divided into 4 covering classes:

- 1 class (overlapping ability – 99%);

- 2nd grade (98-99%);

- 3rd grade (95-98%);

- 4th grade (below the 95% mark).

Buying paint with a low hiding power will not save money. And not all manufacturers put such markings; they often indicate only the consumption of the composition for a particular surface. In this case, the spread in the range of indicators will be significant.

Dry residue

The solid paint layer that remains after the base has dried (the volume of non-volatile substances) is called dry residue. The higher the number, the more environmentally friendly the material is, meaning it contains fewer solvents (volatile organic compounds, or VOCs). The use of paints and varnishes with low solids levels may increase the concentration of ozone in the atmosphere. All this has negative consequences for the health of people and animals. The development of respiratory diseases is especially dangerous.

The table shows the values of non-volatile substances.

| Dry residue indicator | Percentage content, % | Thickness of 1 layer, microns | Optimal number of layers | Environmental impact |

| Low (LS) | 40 | 20 | 3-4 | Negative due to high content of volatile substances |

| Average (MS) | 50 | 30 | 2 | Moderate exposure, less volatiles |

| High (HS) | 60 | 10 (the second is applied 40 microns thicker) | 1,5-2 | Minimum |

| Ultra High (UHS/VHS/HD) | 80 and above | 5 (first layer – thin; second – thick, up to 50 microns) | 2 | Minimum volatile substances |

Today, it is prohibited by law to produce products with low residue levels. The material costs in this case turn out to be unreasonably high, not to mention the environmental consequences. To achieve optimal coating thickness, up to 4 layers are required.

The most environmentally friendly materials are labeled “Low VOC” (minimum volatile substances). But also from a practicality point of view, paints with high residue rates are able to cover a larger surface. In addition, the low solvent concentration allows for fewer layers to be applied. In this case, even 1 layer will be enough to form a durable film.

Today in Russia the production of paints with low solids is prohibited by law.

Dye Density

Density is calculated using the formula: p = m/V, where m is the mass of the substance, and V is its volume.

For different types of paints and varnishes, the density varies from 0.9 to 1.6 kg/m³. For example, for PF enamel this figure is 0.9-9.2 kg/m³, and for acrylic paint - 1.45-1.55 kg/m³.

The density of the dye also depends on external factors (air temperature, pressure, humidity level) and the mass of the color pigment.

Types of colors, how to choose, how to dilute and how to choose a color

Color is added to the paint to give it a color that matches the style of the room.

Types of pastes are divided into:

- inorganic;

- organic.

The second ones on the list have bright tones. At the same time, the choice of color palette is quite large. But, despite this advantage, there is one drawback - they quickly fade when exposed to sunlight.

Inorganic pigments are produced in limited quantities; their colors are dull, but they retain their color properties for a long time.

How to choose a color for painting walls? To do this you need to do the following:

- Explore the proposed catalog.

- In the absence of a color code, it is not necessary to experiment with obtaining a tone in a store, since the color obtained in this way will differ from the one created in everyday conditions.

- The color must be mixed with a small portion of the color base.

- When lighting a room artificially, it is recommended to use organic pigments, and when natural color predominates, inorganic ones.

- The products of a foreign manufacturer are not necessarily better than domestic ones. Russian manufacturers produce tinting pastes of no less quality than the products of their foreign colleagues.

- You should pay attention to the neck of the bottle, it should be narrow, this will make dosing easier.

- A palette of water-based paints will not be superfluous when purchasing diluted pigment, it will be easier to navigate in order to get the expected shade.

What are the different paint colors from modern manufacturers? Well-known brands of tinting pastes include:

- Tikkririla. The products of this company are designed to obtain the expected result after initial dilution with the base. In total there are more than 2000 tones from this manufacturer. The manufacturer offers a choice of a number of shades for painting facades.

- Natural Color System (NCS) - the color is made according to the standards of Swedish and Norwegian manufacturers. There are only 6 primary colors in the range: yellow, black, red, green, blue and white. Other tones are derivatives of them. Based on the letters and numbers printed on the containers, it is easy to decide on the choice of color.

- Tex is a company that produces pastes based on pigments produced outside the Russian Federation. They are versatile and are used to add color to water-based paints, putties and added to whitewash. Used for interior work and painting facades.

- Rogneda is a network of Moscow organizations that produces products for artistic purposes and adding tone to paint, plaster or putty. The color of this company is resistant to exposure to the sun and negative temperatures, and also has high adhesion properties.

- Elakr is a color for façade paint. It is resistant to negative environmental factors and resistant to light. Ideally stored at sub-zero temperatures. Most façade paints are produced on a white base and require diluting to give them color.

Is the color white or not? Basically, the manufacturer produces colored pastes in light and rich colors, but in some cases there is also a white color. It is typically used to provide weather resistance and abrasion protection for advertising lettering and graphics.

Important! Products for water-based paints have gained the greatest popularity, but for other types of paint bases it is not difficult to purchase the appropriate pigment.

Detailed instructions for calculating dye consumption

You can calculate the amount of dye either manually or automatically. In both cases, you will need initial data that will need to be substituted into a formula or empty cells of a special calculator.

Examples of calculations

Example 1. Painting a surface of 15 m² in 2 layers.

| Paint type | Safety factor per 1 m² | Consumption, l |

| Water-dispersed | 0,12 | 15 x 0.12 x 2 = 3.6 |

| Acrylic | 0,15 | 15 x 0.15 x 2 = 4.5 |

| Oily | 0,2 | 15 x 0.2 x 2 = 6 |

Example 2: Painting a surface area of 24 m². The manufacturer indicated paint consumption at 120 g/m². We multiply the area by the consumption and get 2.88 kg. 2 layers will require up to 6 kg of paint.

Example 3. Let's clarify the calculations. We divide the hiding power (120 g/m²) by the dry residue (55%) and multiply by 100%. We obtain the required volume of paint per 1 m² (218 g). Next, the result must be multiplied by the total area (24 m²). We get a little more than 5 kg.

Calculator

If you doubt your own calculations, you can use a calculator. You just need to enter the data and the computer will display the result. Most of these services can be found freely available on construction sites. Online calculations are a kind of specialist consultation, which does not require financial investments.

The wall paint consumption calculator contains the following parameters:

- type of paint;

- surface type;

- length;

- width;

- height.

Separately, you can calculate the paint for the ceiling and floor. Parameters may vary between online programs, so it’s best to always leave a small margin.

Surfaces for painting.

If all factors are taken into account, then the calculations are quite simple. The better the surface is prepared for painting, the less paint consumption will be. When the wall is already painted in a brighter or darker color, and the painting will take place in light colors, the consumption will increase significantly. In this case, there are 2 options.

- The first way out is to get rid of the old coating, remove the old paint, and prepare the surface for painting in a light color;

- The second way out is to increase the number of layers that will be applied to the surface.

It is worth noting that the second method is not as effective, since with increasing layers the paint will take much longer to dry, and its quality will deteriorate.

How can you reduce consumption?

To reduce paint consumption, carefully prepare the surface. The cracks can be eliminated using putty, after which the dried base can be sanded. If you use a primer or antiseptic, the coating will lie smoother and the absorbency of the substrate will be less. This will also prevent the appearance of fungus or rust.

During operation, excess paint may drip onto the floor. Every missed drop is a waste of material. You don’t need to take too much paint on the brush (it’s enough to lower the tool into the jar by 1/3 of the pile), and the roller should be squeezed out more thoroughly on a special cuvette platform.

In addition, if you pay attention to the hiding power class and the dry residue indicator, you will be able to obtain an opaque, homogeneous layer at minimal cost.

The right tool will also help not only reduce costs, but also reduce labor costs. A roller will be indispensable for the ceiling and walls, and a brush will cope with painting small details. Special spray guns will save material consumption when processing large surfaces, especially facades.

We study and use the tinting table: color for water-based paint for walls

The tone of the painting material offered by the manufacturer does not always satisfy the consumer.

To give the desired shade to the composition, water-based paint color is added to its base.

… VKontakte Facebook Twitter Google+ My world Contents:

- What are colors

- Types of colors, how to choose, how to dilute and how to choose a color

- Sequence of tinting

- Features of the use of colors

- Useful video: mixing color with paint

Color Mixing Chart

- Articles, repairs, instructions

The choice of paint today is good, but if you need a rare shade that is not on sale, you will have to mix several tones. We offer a color mixing table, which indicates which tones and in what proportion should be mixed to obtain the original shade.

Some tips:

- — The color of the paint manufacturer does not always correspond to the classic one, so the proportions may vary slightly,

- — Keep in mind that acrylic paint darkens when drying, as water evaporates and increases the concentration of pigment,

- — Do not spread all the paint at once - do a test spread,

- — The best mixing option is to use a mixer (attachment to a drill).

| Visual display | Color name | Mix to get it |

| Pink | 90% white + 10% red | |

| Royal red | 5-10% blue is added to red | |

| Tomato red | Add 5% brown and yellow to red | |

| Crimson | Blue base + a little white, brown and red in equal proportions | |

| Chestnut | Add 5% brown and 3% black to red | |

| Red | If you want to lighten red, add white | |

| Orange | Add up to 30% red to yellow | |

| Yellow | Yellow - lighten with white, darken with red and brown | |

| Olive | Green base + 10-20% yellow | |

| Turquoise green | Add up to 25% blue to green | |

| Bottle green | Yellow + 20-40% blue | |

| Turquoise blue | In blue 10-15% green | |

| Royal blue | In blue 10-15% black and 2% green | |

| Dark blue | Blue + 5% black and 2% green | |

| Grey | In white to 5% black | |

| Medium brown | Add red and blue to yellow in equal portions, add white if you want to lighten it, darken it with black. | |

| Golden brown | To yellow we add 10% blue, white and red, the more yellow, the higher the contrast. | |

| Mustard | In yellow, 5% black and red + 1-2% green | |

| Beige | Add white to brown while stirring until the desired tone is obtained, add yellow for brightness | |

| Pink gray | In white up to 5% black or red | |

| Gray-blue | In white up to 5% light gray + 1% blue | |

| Green-gray | In white 5% light gray + 1% green | |

| Gray coal | Black is added to white until the desired tone is achieved (with constant stirring) | |

| Lemon yellow | In yellow 5% white and 1-2% green | |

| Fern green color | Add black, green and white paint in equal parts to white | |

| Forest green color | Green is diluted with black (up to 5%) | |

| Emerald green | Yellow diluted with white (less) and green (more) paint | |

| Light green | Yellow is diluted with white (5%) and green (10%) paint | |

| Aquamarine | Add up to 35% green and 5% black to white paint | |

| Avocado | Add black and brown paint to yellow in equal parts (up to 10%) | |

| Royal purple | Red color is diluted with yellow and blue paint | |

| Dark purple | We dilute the red tone with black and blue paint | |

| Mandarin, orange | In yellow paint up to 10% red and up to 5% brown | |

| Reddish chestnut | Red is diluted with black and brown | |

| Orange | White diluted with red and brown | |

| Burgundy red color | Add 5-10% yellow, brown and black paint to red paint in equal parts | |

| Plum | In red, 10% black and blue and 5% white | |

| Chestnut | Add white, red and black paint to yellow in equal proportions | |

| Dark brown | In yellow paint 10-20% each of red, white and black | |

| Black | Black is lightened to different shades of gray with white |