Silicone sealant is used for construction and repair work. The material fills the voids and seals the seams. To make a competent calculation of the consumption of silicone sealant per 1 m of seam, use the table data. It indicates the main parameters of the material. In the process, calculation methods are taken into account, what factors influence consumption and the manufacturer of the sealant. Be sure to pay attention to advice and recommendations from experienced professionals.

Silicone sealant

Table of consumption of silicone sealant per 1 m of seam: how to calculate consumption + online calculator

Silicone sealant is widely used in various fields of activity. The material fills voids, seals seams, is well applied to various surfaces, and at the same time prevents the penetration of moisture, which prevents the development of fungal formations and mold. Before work, you need to know the consumption of sealant. To determine the indicator, influencing factors, methods, and manufacturers are taken into account.

Acrylic facade sealants

Sealant Sazilast 11 is used to seal joints with deformation up to 15%. Its advantage is its low price and extremely ease of use. The sealant does not contain solvents and is one-component. The ability to give the sealant any color led to its use for decorative purposes. In particular, such compositions are now widely used for sealing around the perimeter in the structures of wooden, metal and plastic window blocks as an internal vapor barrier layer. Being packaged in small containers, Sazilast 11 is widely used for indoor repairs.

Sealant consumption per 1 m of seam

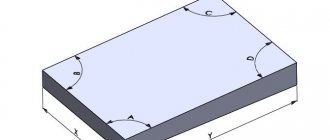

The main parameters of the seam that are responsible for its consumption are width and depth. Optimal values for use in corner joints between an acrylic or metal bathtub and a tile wall would be a joint 6 mm wide and 3 mm deep. With these parameters, you will need an average of 20 ml of silicone sealant per 1 meter of seam .

Let's look at an example of calculating the consumption of one standard package of silicone sealant with a volume of 310 ml per seam, depending on its shape (more about the shapes below). For the most optimal oblique seam when applied to the corner joint of a wall and a bathroom, the numbers are presented in the table:

| Seam width, mm | 6 | 10 | 15 | 20 |

| Seam depth, mm | 4 | 7 | 10 | 14 |

| Seam length, m | 11.6 | 4.2 | 1.9 | 1 |

| Package volume, ml | 310 | 310 | 310 | 310 |

The classic semicircular seam will be less expensive, since it has standard proportions of the width and depth of the seam - 2 to 1

Consumption table for semicircular seam:

| Seam width, mm | 6 | 10 | 15 | 20 |

| Seam depth, mm | 3 | 5 | 10 | 10 |

| Seam length, m | 16.2 | 5.8 | 2.6 | 1.5 |

| Package volume, ml | 310 | 310 | 310 | 310 |

To achieve this, you should use a special spatula with a 6 mm edge and correctly trim the spout of the silicone sealant tube. The spout is cut as follows: place a six-millimeter edge of a spatula against the spout at an angle of 45° and cut the plastic with a construction knife just above the place where the diameter of the spout coincides with the dimensions of the rib.

Tips and tricks

If you want to remove sealant from a particular surface, then you should dissolve it. Special types of solvents for such compositions can be found in many hardware stores.

Some consumers are wondering how to dilute such sealants to make them more liquid.

There is no universal recipe here. Some people use white spirit for this, while others use gasoline.

Roofing compounds cannot be used for interior work as they are toxic.

Wear glasses and gloves when handling polyurethane sealants. If necessary, you should also wear a respirator.

If after application you notice that the adhesive layer needs adjustment, then you have another 20 minutes left for this work while it dries.

Process Details

Calculation of product consumption

Quite often, due to incorrectly determined dimensions of the joint, as well as a lack of experience in applying a polyurethane-type composition, there is even an overconsumption of the substance. At the same time, the increased level of consumption of the sealing agent will not be the only disadvantage due to ignorance of the technology. If the seam itself is filled with sealant incorrectly, its service life will be significantly reduced. First of all, you should definitely evaluate the depth and width of the seam in order to determine the consumption of the sealing compound. In bathrooms, as well as sanitary facilities, suitable indicators for sealing gaps between walls and metal/acrylic bathtubs, as well as tiling on the wall, would be a seam 0.6 cm wide and 0.3 cm deep.

If these parameters are met, then the consumption of silicone-type sealant per 1 meter of seam will be 20 ml. Most often, sealants are sold in standard packaging with a volume of 0.31 liters. To understand the optimal consumption of a regular pack of silicone sealant in order to fill oblique seams and corner joints of walls. Here you can use the data in the table.

| Width in cm | 0.6 | 1 | 1.5 | 2 |

| Depth in cm | 0.4 | 0,7 | 1 | 1.4 |

| Seam length in meters | 11.6 | 4.2 | 1.9 | 1 |

When filling standard semicircular seams with polyurethane sealant, the consumption of sealant per seam will be much less, since it will differ in the classic proportions of the depth to width ratio, such as 1 to 2. Other main indicators for standard sealant packaging are described in the table.

| Width in cm | 0.6 | 1 | 1.5 | 2 |

| Depth in cm | 0.3 | 0.5 | 1 | 1 |

| Seam length in meters | 16.2 | 5.8 | 2.6 | 1.5 |

In order for the seam to be filled correctly, neatly and evenly, you should cut the spout on the sealant tube according to the instructions, use a spatula with an edge of 0.6 cm. Trimming should be done very simply - you need to place the edge of the spatula tool at an angle of 45 degrees relative to the spout. Using a utility knife, cut the plastic above the area where the rib size matches the diameter of the spout. To make accurate calculations of sealant consumption, you can use a special online substance cost calculator. All basic data should be entered into the system (we are talking about the depth and width of the seam), and the result will be given automatically.

To determine the consumption of silicone sealant, you need to use a simple set of convenient formulas, one of which makes it possible to determine the required volume of sealant and the many substances required to treat all seams and surfaces:

- The volume of sealant V is equal to the length of the seam multiplied by the thickness and height.

- The mass of the sealant will be determined as the product of the resulting volume of sealant R and V, with R being the density of the sealant and the average value being 1.5 tons per cubic meter.

It is enough to carry out calculations using the formula for one linear meter of seam. Once the value is determined, it must be multiplied by the entire length required for sealing. To calculate this value, just use a simple tape measure.

Average consumption

The consumption of the product for sealing, fastening, and sealing seams will largely depend on the base material with which work needs to be done. Depending on the type of materials, you can find out about the standard size that will be used during construction and installation work. On average it is 0.6 cm.

In certain cases it is necessary to determine this value individually. If the joints have large parameters, for example, width and depth, then use a special silicone cord for the work, which will act as a seal. Its use will be especially relevant when working with wood bases. The average calculation of the consumption of a substance makes it possible to determine suitable containers in which it will be sold.

To avoid unnecessary consumption, for example, if the width and depth of the opening is 0.5 cm, and the length is approximately 10 meters, then 0.25 kg of sealant will be required. For this reason, you can safely buy a bedside table with a consumption of 0.3 kg, leaving a little in reserve.

It is important when carrying out work after performing average calculations of the consumption of the sealing agent that such indicators should be observed when applying the product. For this reason, you should prepare the surface in advance, clean it of any remaining dust, debris and other substances, and also degrease it. Both sides of the surfaces that are adjacent to the seam should be covered with masking tape to prevent sealant from getting on them.

After this, you should correctly make a cut on the tube with sealant, and after preliminary placement in the mounting gun. If all preparation work and consumption calculations are carried out correctly, then the substances will ideally lie evenly in the cracks and be leveled with a spatula. It doesn’t matter whether repair or sealing work is being carried out inside or outside, silicone sealant is selected for external work or for solving household problems. It is very important to spend a little time on a preliminary calculation of the composition consumption and to become familiar with the correct technology. This way, all craftsmen will be able to not only avoid overuse of substances, but also save money, and also carry out work on filling joints as efficiently and quickly as possible.

Features and characteristics of sealants

Using a silicone or polyurethane composition, it seals various joints and seams, as well as other required areas inside and outside the room.

Silicone compounds have the following properties:

Resistance to ultraviolet radiation.- Resistance to negative environmental factors.

- Excellent level of adhesion to all types of surfaces.

- Resistant to temperature changes -50...+210 degrees.

- Possibility of application at operating temperatures -31…+61 degrees.

The main couple of factors on which sealant consumption will depend are the depth and thickness of the cracks. Silicone sealant is very elastic, has a medium degree of elongation, and it can be determined by the level of interaction with a certain type of surface. In order to increase elasticity, this sealant must be provided with adhesion exclusively to two seam sides. If the adhesion occurs on the rear surface, then there is a high probability of a mechanical type breakthrough if deformation of the material occurs.

In order to eliminate this possibility, a special sealing cord is used, which will act as the basis for laying the substance. Most often, sealants can be found on sale in special cartridges with a standard volume of 0.31 liters, and also in file packages of 0.3 and 0.6 liters. Sealants are those substances that cannot be painted. For this reason, you should immediately choose a composition that matches the shade or choose a transparent variety.

High temperature silicone

Bostik Hochtemperatur-Silicon

One-component high-temperature sealant (acetate silicone).

Designed for joints and expansion joints, for internal and external work at temperatures up to +250°C. The sealant does not allow the application of paints. High-temperature sealant is used for sealing sanitary ceramic joints (between tiles and bathtubs, sinks and showers), for sealing glass-metal joints, sealing windows with wooden frames, in buildings with a metal frame and containers, in industry, craft production and home . Under the influence of air humidity, the high-temperature sealant turns into a durable, elastic, odorless mass, resistant to many chemicals and temperatures from -60°C to +150°C. Has excellent adhesion to most materials, including metals, glass, plastics, etc. High-temperature sealant does not adhere to surfaces containing oils, bitumen, polyethylene, polypropylene and Teflon and is not intended for gluing (gluing) mirrors. High temperature sealant can be applied to alkyd resin paint coatings. Due to the large number and variety of varnishes on the market, the manufacturer does not guarantee the results of using sealant in combination with specific varnishes.

Polyurethane facade sealants

Two-component polyurethane sealants are increasingly used in construction due to a number of advantages over other sealants. These sealants have high strength, good elastic recovery, gas tightness, and adhesion to concrete and other materials. The sealant can be applied to a damp surface. But there are also disadvantages - the need to use airtight containers.

The best representatives of polyurethane sealants are Sazilast 24 and Sazilast 25. Sazilast 24 sealant is ideal for sealing joints of building structures with deformation up to 25%.

Sealant Sazilast 25 has extremely high deformation properties, which allows it to be used for sealing joints of building structures with deformation up to 50%.

Consumption calculation

Very often, due to incorrectly determined joint dimensions, as well as a lack of experience in applying a polyurethane composition, there is an overconsumption of the substance. At the same time, increased consumption of sealant will not be the only drawback due to ignorance of the technology. If the seam itself is not filled with sealant correctly, its service life is significantly reduced.

First of all, it is necessary to evaluate the width and depth of the seam in order to determine the consumption of sealant. In bathrooms and washrooms, a suitable indicator for sealing gaps between the wall and a metal or acrylic bathtub, as well as a tiled covering on the wall, would be a seam 6 mm wide and 3 mm deep. If these parameters are met, then the consumption of silicone sealant for 1 m of seam will be 20 ml.

Most often, the sealant is sold in standard 310 ml packages. To understand the optimal consumption of a standard pack of silicone sealant for filling oblique seams and corner joints of walls, you can use the data in the table:

| Width in mm | 6 | 10 | 15 | 20 |

| Depth in mm | 4 | 7 | 10 | 14 |

| Seam length in m | 11.6 | 4.2 | 1.9 | 1 |

When filling standard semicircular seams with polyurethane sealant, the consumption will be significantly less, since it is distinguished by the classic proportions of the width and depth ratio, like 2 to 1. Also, the main indicators for standard sealant packaging are presented in the table:

| Width in mm | 6 | 10 | 15 | 20 |

| Depth in mm | 3 | 5 | 10 | 10 |

| Seam length in m | 16.2 | 5.8 | 2.6 | 1.5 |

In order for the seam to be filled correctly, accurately and evenly, it is necessary to cut off the spout of the sealant tube according to the instructions and use a spatula with a 6 mm edge. Trimming is very simple: you need to place the edge of the spatula tool at an angle of 45° relative to the spout. Using a construction knife, cut the plastic above the area where the size of the rib matches the diameter of the spout.

To make an accurate calculation of sealant consumption, you can use a special online substance cost calculator. Basic data (seam width and depth) is entered into the system and the result is provided automatically. To determine the consumption of silicone sealant, you can use a set of simple and convenient formulas, one of which allows you to determine the required volume of sealant and the mass of the substance required to treat all seams and surfaces:

- The volume of sealant V is equal to the product of the seam length, height and thickness.

- The mass of the sealant is determined as the product of the resulting volume of sealant V and R, where R is the density of the sealant, the average value is 1500 kg/m³.

It is enough to carry out calculations using the formula for one linear meter of seam. After determining the value, it is simply multiplied by the entire length required for sealing. To calculate this value, just use a simple tape measure.

On video: Working with sealant, consumption and application.

Consumption of facade sealants when insulating an apartment

What reasons influence the climate in the apartment? Of course, the main reason is exposure to various atmospheric influences. If the apartment is properly insulated, then the climate in it will be dry and warm, i.e. favorable for living. And if you haven’t taken care of insulating your own apartment, expect unpleasant surprises. First, with the arrival of the cold season, the walls will freeze. When the walls freeze, the dew point moves inside the room, and condensation collects on the walls. Wallpaper and plaster become damp, and then begin to turn black and fall off. Moreover, microorganisms settle on damp surfaces. They can remain unnoticed for a long time, and when they are noticed, as a rule, it is already too late. Removing mold from an apartment is a very difficult task that takes a lot of time and money.

How to apply sealant correctly

The main thing is not to rush and follow the following instructions:

- They put on a special suit for repair work. Protect your hands with gloves so that the composition does not harm the skin.

- The surface to be treated is prepared for the process. Remove excess water, dirt and dust. Don't forget about degreasing. Painting tape is placed on both sides of the crack to avoid damaging the finish.

- Apply glue with a mounting gun. A special cone is removed from the tube, and the manufacturers seal it. Remove the protection from the spout. Just make a small cut. It should be less than the width of the crack. A stationery knife will help in the work. Make a cut at an angle of 45°. The packaging container is placed in the gun. The cut part is inserted into the tip. Remove the rod. They just press the lever. The cartridge is installed in the free space.

- Apply the material at an angle of 45°. The strip should be thin, then the sealant will dry faster. Both sides are united. Excess composition is removed with a spatula.

Applying sealant

How long the sealant will dry depends on the type and thickness of the seam. Most often it takes at least a day. But a thin film appears on the surface after 20 minutes.

Important! Do not touch the composition until completely dry.

Rules on how to spend money economically

To avoid purchasing additional new packaging, you should use the following recommendations:

- they call a specialist to process the seams; a beginner cannot be trusted with such work;

- if the work is done independently, then carefully prepare the surface for work;

- cut the spout on the tube correctly - this way you can save on material consumption;

- When applying, use a mounting gun.

Working with composition

Completing of the work

In order to comply with the calculated consumption of silicone sealant per 1 m of seam, it is necessary to apply it correctly. For this purpose, the surface is pre-prepared. It is degreased, cleaned of debris and dust. The place where the silicone will be mounted is covered on both sides with masking tape. This will prevent the product from coming into contact with clean surfaces.

Next, the tube of silicone must be inserted into a special mounting gun. The sealant spout is cut off. Its diameter should be equal to the width and depth of the seam. Next, the joint space is simply filled. After this, the sealant is leveled using a spatula.

Having become familiar with the technology of how to calculate the consumption of silicone sealant per 1 m of seam, each master will be able to correctly select the amount of product to carry out the intended work. This will save money and fill the seam quickly.

Calculation example

Silicone sealant, the consumption per 1 m of which is calculated using the above technology, is sold in different containers. To select the right tube for repair, you should make a simple calculation. For example, it is known that the seam depth is 5 mm. The same indicator characterizes its width. The calculation looks like this:

K = 5 x 5 = 25 g.

To carry out repair work, which requires treating 10 m of surface with the presented seam, you will need 0.25 kg of silicone. Tubes that contain 0.3 kg are available for sale. This volume will be quite sufficient to complete the presented amount of work.

Germotex application technology

First of all, preliminary cleaning of seams and cracks from dirt and dust is carried out. When applying the composition, the surface must be dry or with low residual moisture, and the ambient air temperature should not be lower than +10°C.

It is recommended to treat the porous cement-sand base with a polyurethane-based primer, which helps reduce dust formation and enhance adhesion between the coating and the composition. We recommend that you familiarize yourself with the additives for concrete impregnation Aquastone and Aquapol - acrylic paint for concrete.

Germotex is prepared from two components:

- Component B (hardener) is added to Component A (paste).

- Mixing is carried out for 3-5 minutes until a homogeneous mass is obtained.

If there is low fluidity of the resulting composition, then it is recommended to use a solvent in the form of white spirit or gasoline, which will require 80 g per 1 kg of composition.

Filling seams and sealing cracks is done with a spatula and the pouring method, while the depth should not exceed 70-80% of the width. It is necessary to use the prepared product during its viability period - for 40 minutes at a temperature of +20°C. The composition fully gains strength in 5-7 days.

During operation, the temperature can vary from -50 to +60°C.

Attention! When working with the sealing compound, you should use personal protective equipment, and after applying it to the surface, ventilate the room well.

We recommend that you familiarize yourself with the Betopress supplement, find out its properties and uses.

Polysulfide facade sealants

Polysulfide-based sealants are characterized by high strength and elastic recovery, gas-tightness and water resistance, as well as good oil and petrol resistance. They can cure and maintain a high level of properties over a wide range of deviations in the amount of hardener from the optimum. They are distinguished by the stability of the sealant components during storage. The indicated advantages of sealants based on polysulfide oligomers allow them to be successfully used in construction, where the recommended ratio of components, temperature conditions and humidity are not always observed.

Polysulfide sealants include Sazilast 21 and Sazilast 22. Sazilast 21 sealant is characterized by increased resistance to UV rays and weathering. In addition, there is extensive experience in its use for sealing roof elements. Suitable for sealing joints with deformability up to 25%, standard for standard buildings.

The high adhesive properties of Sazilast 22 sealant make it possible to use it when repairing old joints in buildings with joint deformability up to 25%. In addition, it can be applied at fairly low temperatures down to -20C, which is very important in the Russian climate. The sealant can be applied to a damp (but not wet) surface.

What formula is used to calculate consumption?

After the choice of the type of composition has been made, you can begin to calculate the consumption of sealant per 1 m of seam. Calculations are being made by volume and mass, but first you will need the dimensions of the seam, its length, width, depth.

Sealant is used to protect seams from penetration of water and aggressive media

To calculate the volume of the composition, for example, when consuming silicone sealant per 1 m of seam, the following data is multiplied:

Volume = length * width * depth

Next, to find the required mass of consumable sealant, you need to multiply the resulting volume by the density, which is always indicated on the packaging:

Tips from professionals for working with sealant

There are recommendations that are worth considering:

- Before starting work, examine the seam and determine the type. Cracks, depending on their shape, can be oblique or semicircular. The last option looks like a hollow with a depression. The oblique type has a smooth surface.

- Be sure to remove the previous material from the crack.

- For degreasing, use ethanol, acetone or dishwashing detergent.

- When the seam is completely filled, the sealant is leveled with a wooden spatula.

- The masking tape is removed only after the composition is completely dry.

- If the crack is deep, then a sealant is additionally used to save the amount of material.

- When sealing seams yourself, unforeseen incidents occur. The product may drip onto the floor. To remove material from the surface, use white spirit. Dip a cotton pad in the product and wipe off the excess. You can buy a composition for washing off silicone along with the material. If you don’t have either one or the other at hand, then take a rag, soak it in a soapy solution, and remove the sealant. If it has already dried, you can remove it with a knife. But you need to act carefully so as not to scratch the surface.

If you do not calculate the consumption of silicone sealant in advance, then there is a risk of buying more material than you actually need. Before purchasing the composition, make all the necessary calculations. After receiving the results, they purchase sealant and get to work. It is better to entrust the sealing of seams to the craftsmen - there will be additional savings.

90° bent seam

Special technique is needed when processing horizontal seams that abut a vertical corner of the wall. The spatula is applied to the seam at an angle of 70°-80° so that the special cut (or edge) on the surface of the spatula is not visible to you. In this case, the side of the spatula hidden from you should not touch the surface of the seam.

We carry out the movement towards the vertical corner smoothly in the direction where the side of the spatula without a cut is facing. When the vertical angle is reached, we simply continue moving along the perpendicular wall, smoothly leveling the angle of the spatula to the seam to 90°.