Possible failure cases

Due to the fact that the procedure for registering with SNT is regulated by the legislator, an interested person can receive a refusal only if there are grounds specified by law. As a rule, the refusal is caused by the presence of violations of the norms of current legislation.

The most common reason for refusal of registration is the absence of a building on the territory of the land plot.

It happens that applicants apply for registration on a plot of land on which a house has not been built. The authorities refuse even when the applicant has the status of the owner of this land.

Such a refusal is lawful and justified. An interested person cannot register on the territory of a site outside a residential building, since this is prohibited by law.

Another common reason for refusal of registration is the construction of residential premises in violation of the norms of current SNiPs and GOSTs, or the lack of required communications.

From all of the above, the conclusion suggests itself that before contacting the authorized body, you should check whether all the requirements imposed by law are met.

Watch the video. What is needed for dacha registration:

Types of material

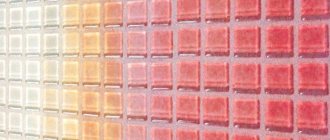

Decorative tiles that imitate brick are made from different materials. Some turn out to be durable, while others have a more presentable and unusual appearance. The main classification includes five types:

- Ceramic tile. A traditional, ageless option that has stood the test of time and has shown excellent results in terms of durability.

- Clinker. Frost-resistant material, which is often used for finishing the facades of houses.

- Gypsum tiles. A beautiful material that can be adjusted at the manufacturing stage.

- Concrete tiles. It is made using the technology of pouring a liquid composition into a mold until it is completely hardened. Concrete is strong, durable, easy to paint, but it makes the room very cold. In general, it refers to materials for rough finishing and is used to create another type of tile - paving.

- Flexible. An innovative option that has a small thickness, but at the same time reliably protects the wall surface.

Not only these materials are used to create decorative bricks. Various hardening mixtures are used, which can be made from natural or synthetic components.

Flexible tiles

Flexible tiles really bend well and their name is not at all an advertising ploy to attract buyers. In terms of plasticity, it resembles foam rubber. The material is made from sand and acrylic with the addition of pigments. The main advantage of flexible tiles lies in the ability to lay them in corners without disturbing the integrity of the fragments, that is, they are simply bent and fixed on the wall. When it is necessary to cut off some part for finishing the edges, the material can be easily cut. Flexible tiles reliably imitate brick and reliably protect the wall surface. It can be used as a finishing material and for decorating the facade of a house, but the difficulty in removing dirt from the surface becomes a serious obstacle to such decoration. Flexible tiles are environmentally friendly and non-flammable, but they cannot be treated with detergents containing alkalis.

From plaster

This option is popular because of its low cost, but in terms of quality it is much inferior to ceramics and clinker. You can make gypsum tiles yourself by first purchasing molds for pouring. The surface of each fragment will have to be treated with a special composition. Unfortunately, the protective layer will not be able to save the material from the harmful effects of moisture for a long time. In addition, any mechanical impact (even a blow with a fist) will cause fragments to split. Plaster is beautiful, but completely impractical. It can only be used as decor for interior decoration in rooms where the air is always dry. Due to the fragility of the material, its surface, after manufacturing, can be decorated with chips and roughness that are characteristic of real brickwork.

Clinker

Clinker is classified as bricks. It is based on a mixture of refractory shale clays and feldspar, which, after firing at ultra-high temperatures, become incredibly hard. The original name was given to the material by the Germans because of the special sound that the elements make when they collide with each other. Clinker tiles are universal and are used for both external and internal finishing work. The material has all the advantages of ceramics, but is stronger and more durable.

Ceramic

Ceramic tiles are no different from regular tiles used in kitchens and bathrooms, except they have a rectangular brick shape rather than the standard square one. The material is made from a special type of clay, which is mixed with quartz particles, pigments and carbonates. Ceramic tiles are relatively light in weight, retain their color even with constant contact with sunlight, and do not react to changes in humidity in the room. The material is durable and strong. Ceramics can have different textures, but matte and glossy surfaces remain the most popular options. The color range allows you to select tiles for a specific interior scheme.

Cladding tiles: looks realistic

There is no shortage of this material in the construction market. Tiles can be made of various materials (glass, gypsum, ceramics, composite, etc.) and are available in different colors. The properties of each material allow the use of such tiles in various rooms of the apartment - for example, such a property as resistance to moisture will be appreciated in the kitchen and bathroom, and its flexibility will make it possible to tile radius corners and other surfaces of non-standard configurations.

- Clinker tiles. This brick wall decor has the most realistic look. But, unlike natural brick, the weight of the wall will be several times less, which is very important in apartment buildings. On sale you can find various shapes, sizes and textures of clinker tiles to suit any design idea. Suitable for decorating smooth surfaces.

- Plaster. The most common option for interior decoration of brick walls. Unlike the previous option, the price of gypsum tiles is quite affordable along with excellent aesthetic characteristics. The most common color is white; such tiles are ideal for loft-style interiors. But besides white, you can find gray, beige, brown, green, red, etc. Disadvantages include fear of moisture and fragility.

- Ceramics and glass. The main advantage of tiles made from these materials is their resistance to moisture. Therefore, it is often used in the bathroom and kitchen. If the tile is used to decorate a kitchen apron, then you should take it from tempered glass in order to add resistance to temperature changes to the list of characteristics.

- Flexible tiles. It is made of composite materials and has a number of successful performance characteristics: it is not afraid of water and shock, has a long service life and simple installation, which can be performed by people without experience in construction work. This material is often used to finish the external and internal corners of doorways and arches, so the listed characteristics are very important.

If we compare all the options for finishing materials with imitation brickwork, then tiles will occupy a leading position in this rating due to their excellent decorative properties

DIY brick wall

Gypsum tile manufacturing technology

An assortment of shapes and colors of cladding is presented on the building materials market by various manufacturers. In industrial production, plasticizers are added to the raw material mixture to ensure the strength of the products; The gypsum solution placed in the molds is subjected to additional firing.

Insufficient strength is indicated by the shedding of material on the back side of the product with little friction.

The home manufacturing process includes the following steps:

- preparation of forms;

- mixing raw materials;

- pouring and drying;

- finishing of products.

Preparing forms

Matrices for pouring raw materials can be purchased in specialized stores or made with your own hands:

- assemble the base and formwork from laminated chipboard, secure the connected elements with self-tapping screws and coat the cracks with silicone;

- apply markings and glue to the base of the model (in the form of stone or brick) so that the distance between the sides and forms is at least 15-20 mm;

- cover the surface of the models and the wooden base with two layers (with an application interval of 1-2 minutes) of Vaseline or special lubricant;

- mix the silicone compound with the catalyst and fill the model with the composition;

- within a day the form is ready for use.

Instead of a compound, you can use silicone sealant, but workpieces made from this material quickly lose their appearance and stretch. Acrylic sealant is not suitable for making molds.

Mixing raw materials

- prepare the components in the following proportions: gypsum (6 parts), slaked lime (1 part), warm water (at the rate of 0.7 parts of liquid per part of gypsum);

- Combine dry materials in containers and gradually pour in water, continuing to thoroughly mix the solution with a construction mixer (at low speed) until it acquires a paste-like consistency.

Pouring, drying and finishing

- coat the mold with grease and fill it with the resulting mass, level the surface with a spatula;

- place the matrix with the blanks in a dry, ventilated, darkened room for a day;

- remove the frozen tiles and sand their surface with sandpaper.

REFERENCE! If during the mixing process a large number of air cavities have formed in the mass, carefully move the template several times from side to side, when the bubbles come to the surface, remove the top layer of the mixture with a spatula.

Advantages and disadvantages

Surface cladding made from gypsum tiles has the following advantages:

- the low weight of decorative elements allows installation on any surface;

- environmental friendliness of the material;

- soundproofing properties;

- simplicity and ease of installation;

- if necessary, it is possible to replace individual elements;

- possibility of self-production;

- the thermal conductivity coefficient of gypsum elements is low, which gives a feeling of pleasant warmth upon tactile contact;

- creating a comfortable, soft interior color.

Flaws

- the material is highly susceptible to impact loads and requires careful handling;

- low moisture resistance;

- impossibility of installation on wallpaper.

How to lay bricks with your own hands?

Installation of decorative tiles in the form of bricks begins with checking the level of the floor covering. If there are flaws, you need to mark a straight line and outline it with a pencil. Bricks must be laid in the direction from bottom to top

It is very important to note that the joints should not overlap each other. The cladding is laid out in a checkerboard pattern

It is extremely difficult to compose a complete composition in advance; everything is done at the place of work. Therefore, bricks are chosen in different shapes and sizes. If a coincidence occurs, you can slightly trim the decorative element and sand the edges to create a realistic effect. The adhesive mass can be applied both to the surface and to the tiles

When laying, it is very important to press harder on the brick. Due to this action, the cracks in the seams and possible empty space in the wall will be filled.

If there is a lot of excess, then it must be removed.

It’s easy to stick the tiles onto the base, the main thing is not to get lost, since you only have five minutes to correct the mistake. When processing doorways and slopes, you should draw in advance an approximate drawing with the location of the bricks. This action will facilitate the process of laying the decorative surface. When working with corner joints, you will need to show maximum concentration and make cuts at an angle of forty-five degrees using wort. At the same time, lay the tiles so that the angle is ninety degrees.

After the main work is completed, it is necessary to begin decorative processing of the brick surface. This procedure will be the final stage of finishing. In places where there are defects in the form of chips, cuts, as well as near switches and sockets, it is necessary to fill the voids with gypsum putty. A small spatula will do the job. If there is more mortar on the tile than required, then the excess must be removed with a damp sponge. The same goes for seams. The voids must be filled with base material.

After drying, the seams must be sanded. Sandpaper is suitable for this procedure. The work will take a little longer, but scratches will not be visible on the seams. Gray spots may appear on the bricks themselves after the entire surface has dried. A stiff brush will help get rid of them. After which, at the request of the owners, the surface of the decorative brick is covered with varnish or paint.

You will learn how to lay decorative bricks from the video.

Related Posts

- Clinker tiles for facades: a universal facing material

- How to update old tiles in the bathroom

- The best way to glue plaster figures, means and rules for do-it-yourself restoration

- Is there any benefit to using a tile leveling system? pros and cons, reviews, rules for using SVP

- Alabaster: what is it? how to divorce? where to apply?

- What layer of adhesive is needed when laying tiles?

- 9 types of heat-resistant tiles for fireplaces and stoves: choosing the best

- Features of choosing adhesive for ceramic tiles: tips

- Seamless ceiling tiles: installation and characteristics

- How to dilute alabaster

- Laying floor tiles - step-by-step instructions

- How to glue fiberglass correctly?

- What and how to drill into the tiles so that they don’t crack?

- Decorative brick on the wall +75 photo examples

- Laying mosaic tiles in the bathroom

- Stucco on the ceiling. tools, manufacturing materials and fastening materials. finishing with gypsum, polyurethane and polystyrene stucco molding

- Types of bath skirting boards and their installation

- Cement clinker

- Tiled floor in the kitchen

- How to lay decorative gypsum tiles under brick: features and installation technology

- Decorating the floor in the bathroom: rules for laying ceramic tiles

- Homemade Russian stove on the street under a canopy

- PVC floor tiles

- Installation of heated floor heating mats under tiles

- How to decorate a bathroom other than tiles: the best materials

Read with this

- Clinker tiles for facades: a universal facing material

- How to update old tiles in the bathroom

- The best way to glue plaster figures, means and rules for do-it-yourself restoration

- Is there any benefit to using a tile leveling system? pros and cons, reviews, rules for using SVP

- Alabaster: what is it? how to divorce? where to apply?

- What layer of adhesive is needed when laying tiles?

- 9 types of heat-resistant tiles for fireplaces and stoves: choosing the best

- Features of choosing adhesive for ceramic tiles: tips

- Seamless ceiling tiles: installation and characteristics

- How to dilute alabaster

Specifics of imitation brickwork

Why imitation brick for interior decoration is more profitable than natural stone masonry:

- pressure on the slabs - due to the light weight and thickness of the materials, the load on load-bearing walls is eliminated, which guarantees safe living;

- apartment area - imitation masonry is suitable even for a small square footage, since the volume of the space will be practically preserved;

- price category - this method of wall finishing will cost much less than buying real bricks.

The process of laying materials takes less time and is understandable even to an untrained person. Externally, the surface is almost no different from natural stonework.

"Brick" wallpaper in the living roomSource sense-life.com

Gypsum tiles for brick interior decoration: advantages and disadvantages

Gypsum is a lightweight material that, if necessary, takes on the required shape, structure, and relief. The use of this material in decorating the interior space of a room is a simple, financially feasible and physically feasible task.

Advantages of gypsum stone finishing inside a building:

- A wide range of products differing in texture, price, size and appearance.

- Relatively low pricing policy.

- Natural compositions.

- The ability to customize finished tiles to suit the surface features.

- Simple design, wall mounting.

- Light weight of the finished product, which allows it to be used on any surface without the risk of wall deformation.

Disadvantages include such features as moisture absorption, lack of resistance to mechanical damage and crumbling. However, such disadvantages are insignificant, and during operation the material will not require labor-intensive care. If necessary, you can replace damaged burst tiles with new ones without compromising the integrity of the wall.

Finish coating

In order to ensure a long service life, it is worth applying a topcoat.

This can be done after 24 hours from the end of installation so that the glue has time to set. If the room is damp, you should wait a little longer. After this, you will need to wash the stone with a wet sponge and clean the seams. Next, you will need to dilute the grout of the required shade and grout the seams so that they do not stand out against the background of the overall picture. It is better to take the grout a little darker than the stone - this way you can create an interesting and unusual design.

If something goes wrong during grouting, the coating can be washed off with a damp sponge. At the end of the work, wipe the surface with a dry cloth. After this you can enjoy the result.

Today you learned what to glue gypsum decorative stone to and how the methods of gluing it differ depending on the surface. This is not too difficult to do, so even if you are not an expert in repair work, the result will not disappoint you, and the process will be exciting and interesting.

Recommendations when working with gypsum tiles

The final result is influenced by knowledge of all the intricacies of the process. Experienced specialists recommend taking into account the following nuances when working with gypsum bricks:

The increased fragility of gypsum requires caution during installation; When laying decorative bricks in the kitchen, tile consumption can be reduced if the joint width is at least 8-10 mm; You can use scraps of the product, but in areas covered by furniture; The seams can be sealed with glue that protrudes during the process of pressing the brick into the surface of the base, which is done with rotational movements; The last stage is polishing the seams. Also, the joints will need correction, because after drying they change color

Therefore, the joints are painted over with water-based paint and varnished.

The increased fragility of gypsum requires caution during installation

Gypsum tiles for brick: specifics of installation and operation

There are many materials that can be used to decorate and update the interior. Brick-like gypsum tiles are one of the best options, as they have excellent thermal insulation properties, resistance to temperature and humidity changes, and most importantly, are completely environmentally friendly. The article will discuss how best to lay this material and what you should pay special attention to during installation.

Gypsum tiles are an excellent alternative to expensive ceramics

Advantages and disadvantages of gypsum cladding

Covering with artificial stone made of gypsum is superior to its analogues in many respects. The tiles are valued for their beauty, the ability to be installed independently, and their similarity to natural materials. Tiles can be purchased ready-made or made with your own hands using special matrices. These are reusable silicone, polyurethane or plastic molds.

Gypsum is a fire-resistant material on a natural basis. It is classified as an environmentally friendly raw material. Therefore, brick-like gypsum tiles are used for interior decoration of residential buildings.

You can install decorative stone in your apartment yourself.

Decorative stone made of gypsum has excellent decorative qualities, although it is produced from an affordable gypsum-cement mixture. Natural gypsum is much lighter than cement due to its porous base.

The soft natural material in powder form is pleasant to knead in your hands. It is warmer in contact than wild stone made from a cement mixture. As a ready-made tile finish, it is suitable for any interior space:

- bathroom and toilet;

- hallway and corridors;

- staircase space;

- kitchen and dining room;

- separate corners when zoning a studio apartment.

Decorative stone looks interesting in the bathroom.

Similar cladding is found in houses and apartments, hotels and banking institutions, shopping centers and public institutions. This decor is chosen by construction companies due to its advantages:

- The tiles have a low specific gravity, simplifying installation on thin partitions and lightweight architectural structures, where weight overload is unacceptable;

- Thin decorative plates with delightful relief are the best facing material for any surface. This finish can easily hide any unevenness or defects in the walls.

- The material is easy to cut, laid on cement mortar, grouting gives the effect of a continuous rocky surface.

- The raw material has an average frost resistance coefficient. Rocky stone is preferred for interior decoration of country houses where there is no heating in winter.

- The tile resists overheating, which is why it is used in finishing near stoves and fireplaces.

- The relative cheapness and low cost of homemade gypsum decor makes it accessible to the population.

- Due to environmental safety, it is allowed to decorate classrooms and preschool premises with gypsum stone.

Caring for white gypsum board is not difficult.

A wall with stonework looks great in the interior, while the new finish, over the years, becomes covered with dust and greasy residue. If you choose a suitable coating, then dirt on gypsum boards is less noticeable. The old coating can be easily renewed, removed or repainted.

Among the disadvantages is the fragility of the finished facing material. Strength can be easily enhanced with special additives and plasticizers. A brick wall is also susceptible to moisture.

The finished surface can be coated with a colorless water-repellent varnish. Gypsum panels should not be used for exterior decoration. Other cement-based materials are offered there.

Features of the material

Decorative gypsum tiles imitate different types of surfaces. It is almost impossible to visually distinguish it from natural coating, so it is often used to create a unique design. Before gluing decorative bricks, it is worth studying the distinctive features of this material.

The advantages include a large selection of different textures and shades. Thanks to this material, a favorable microclimate is created inside the apartment, which allows residents to feel comfortable. If the coating is made of natural gypsum, then it will no longer be possible to hang anything else on the wall. Heavy material already exerts strong pressure, for this reason only load-bearing surfaces are chosen. There are no such problems with imitation material, since it is very light.

Decorative stone also does not affect people’s health, so it is suitable for bedrooms and other places where residents spend a lot of time. Decorative gypsum tiles can be used for 15–20 years, provided that installation rules are followed.

Among the shortcomings of the product is the lack of a frame, due to which the material quickly deteriorates when pressed or lightly hit. The material is also susceptible to moisture and liquid, so it is not suitable for rooms with aggressive operating factors.

Such tiles are easily fixed even on gypsum plaster. The material is often chosen when large areas need to be treated because it is easy to install.

Installation of tiles under stone on the base

Laying gypsum tiles with your own hands is very simple, after the preparatory work has been done:

- Gypsum tiles under the stone are placed from bottom to top in horizontal rows.

- Laying starts from the bottom corner towards the center.

- Apply a thin layer of adhesive to the wall using a notched trowel.

- Use a regular spatula to apply adhesive to the tiles.

- The tile, according to the markings, is applied to the surface.

- Pressing it a little and leveling it, you need to hold it for 1-2 minutes for the glue to set.

- After gluing the first tile, you need to retreat the seam distance and glue the second tile in the same way as the first. To ensure evenness of the gaps, special spacers are used.

- After installing several rows (5–6), you need to take a short break so that shrinkage occurs, the glue adheres to the surface, and the first bottom row does not become heavier.

- The last to be glued is the cut tile.

After completely covering the surface, all work must be left for a day for the glue to dry completely and fix the tiles to the surface. Watch the video: laying thin stone in an ordinary apartment.

How to glue decorative bricks?

Work begins with marking, determining vertical points from which the vertical and horizontal are drawn. This is done to ensure that the masonry is even. Since they start laying out the material from the corner fragment, the markings are made based on this. To make the lines straight, use a level.

After applying the markings, glue is prepared for the decorative stone from gypsum. It is diluted with water to the consistency of rich sour cream. A primer is first applied to the wall and allowed to dry, only after that the prepared solution is used.

Next, glue is applied to a small section of the wall, and the excess is removed with a spatula. High-quality compositions additionally level the wall, so a person can only apply the material to the sticky surface. Some people spread glue on the tiles so as not to collect the excess later.

If the wall is decorated with decorative bricks, then space is left between the tiles to form seams. Crosses are fixed under the composition so that the tiles do not creep apart. To imitate stone, no seams are formed.

Gypsum decorative brick is quite soft, so during laying it will have to be trimmed in order to join the material. To do this, use a hacksaw, grinder or miter box. Additionally, the bricks are treated with sandpaper to remove sharp corners. At the final stage, the space between the tiles is treated with grout. The mixture is applied with a pistol or a narrow spatula. After it dries, the wall is varnished.

Decorative brick is a safe, practical and cheap material that can be easily used to decorate a wall yourself. It is durable and at the same time copes with various decorative tasks, so it is always in demand in construction stores.

How to make gypsum tiles with your own hands: manufacturing technology

As you can guess from the name, one of the main components of such tiles is gypsum. It is recommended to use material marked as GF 10, since its characteristics fully meet all requirements. This brand of gypsum is quite durable, has a long service life and can withstand loads well.

What is DSP: application, technical characteristics (read more)

If for some reason it was not possible to purchase this particular material, you can additionally compact any other material by adding special strengtheners to it, designed to improve the properties of the material. But even in this case, it is worth considering that such brick-like facing tiles are not used for exterior decoration.

So, let’s try to figure out how to make plaster at home that is suitable for covering surfaces and at the same time quite resistant to external influences. The following materials can be used for this purpose:

- gypsum;

- plasticine;

- paraffin (you can use regular candles);

- cardboard box;

- silicone sealant.

For the manufacture of gypsum tiles, gypsum grade Gf 10 is best suited.

Of course, the easiest way is to use a ready-made silicone mold for tiles, which will significantly simplify the manufacturing procedure and reduce the time spent on it. But in general, you can make a mold for gypsum tiles yourself, using sculptural plasticine.

In order to make a mold, sculptural plasticine is rolled out in an even layer, the thickness of which should be about 20 mm. Then, using the most ordinary brick, impressions are made inside, which will serve as molds for casting.

You can also use paraffin to create a mold for a decorative stone with your own hands. It must be melted and poured into a box of the appropriate size that the brick can fit into. After the paraffin has completely hardened, it can be removed and used as a mold. The same method is also suitable when working with silicone sealant.

Making gypsum tiles is quite simple if you follow the rules for working with the material.

How long it will take to make gypsum stone tiles directly depends on how many molds will be prepared. It's better if there are quite a lot of them. Then fewer approaches will be required to cast the required number of elements.

The process of making gypsum bricks for interior decoration is as follows:

- gypsum must be poured into a container and water added to obtain a solution with a creamy consistency;

- the molds into which the gypsum solution will be poured for hardening must be pre-lubricated with fat or oil so that the elements can be easily removed in the future;

- After pouring the mixture into the mold, shake it gently so that the solution is distributed evenly.

Note! If you notice the presence of water that separates from the plaster after the solution has been mixed, then you need to pour it out and prepare a new one again, following all the instructions prescribed by the manufacturer.

Gypsum tiles are an excellent facing material that can significantly transform the interior of a room. With its help, you can decorate niches, ledges, flights of stairs in an original way, as well as zone the space. The main thing is to choose the right location to avoid contact with moisture and increased mechanical stress. In this case, decorative brick-like tiles will decorate your interior for many years.

Facade panels: finishing the house with brick panels (read more)

Decorative brick for interior decoration and its application

Where can such original material be used?

- A room completely finished in brick. The best option is white: the room does not seem overly cold and gloomy, and the unobtrusive relief is a good decoration.

- A brick wall is the best option for the wall behind the TV or the wall with dishes.

- Decorating a separate area - for example, an area with a sofa and a TV in a large living room, or a kitchen area in a studio apartment will look very beautiful.

- Columns - if your apartment has protruding columns - this is possible in monolithic houses after redevelopment - they will look good with a similar finish. The ideal option would be a combination with a wall in the same style.

- The openings between the windows, decorated with brick, will go well with the columns.

- Corners are often finished with similar material, especially in the hallway - this strengthens the wall, which is touched by scratching the wallpaper, and visually changes the correct geometry and numerous corners of modern hallways and corridors.

- Finishing a loggia or balcony with brick. If this finishing material looks uncomfortable in the living room, then a balcony with greenery outside the window and a soft sofa will be one of the favorite places in your apartment.

- Brick-like facing tiles have been used for interior decoration quite recently. Initially, this material was used to build houses; it is the outer layer of buildings. Then the finishing appeared - you can build from anything, and apply a beautiful finish on top solely for aesthetic purposes. But then views on generally accepted norms were revised, and street style entered our home, firmly settling in the hearts of many adherents of this style.

- Brickwork is beautiful, natural, laconic and simple, it is voluminous and is available in various variations and colors. However, an interior with such decor needs to be thought out very carefully - this is not a cheap material, it is difficult to install, and it will be difficult to redo an unsuccessful design project. It’s not like tearing off old wallpaper and gluing new ones.

Kinds

Diesel boilers are different. Let's get acquainted with the characteristics of various types of such units.

Single-circuit

A single-circuit unit powered by diesel fuel is distinguished by high productivity. Such specimens are intended for installation in a heating system. However, you need to remember that they do not provide heating of water.

If in the future you want to connect hot water supply to such a unit, then you will need to build a special indirect heating boiler into the heating system itself. The main advantage of single-circuit units is that they can heat residential buildings of impressive dimensions.

Dual-circuit

Double-circuit heating devices are considered more popular and in demand, since they provide both heating of the home and the provision of hot water supply. Depending on the manufacturer, such designs use a bithermic or separate heat exchanger.

Modern double-circuit boilers powered by diesel fuel often have built-in storage tanks. The main advantage of such units is that they provide the fastest possible supply of water to the user when necessary (that is, immediately after opening the tap).

Wall and floor

Based on the type of fasteners, there are wall-mounted and floor-mounted diesel models. Thus, the wall-mounted model is a small unit that takes up very little free space in the boiler room. Such devices are equipped with 1 or 2 heat exchangers. Modern consumers choose such boilers for their modest dimensions and discreet but neat design.

Floor-standing specimens are the most popular and widespread. Similar options are represented by units with varying power, up to 100 kW or more. Based on very powerful products, entire productive boiler houses are organized that can power several different buildings at the same time or generate heat for industrial or household buildings.

Steel and cast iron

Diesel units are made on the basis of a cast iron or steel heat exchanger. Thus, steel options boast affordable cost and low weight. Such models are in great demand and are found in many homes. However, these specimens have one serious drawback - they do not last very long. For this reason, cheap units are usually equipped with steel elements.

Heat exchangers made of cast iron are installed in expensive and efficient devices. Such models are characterized by massiveness and impressive weight, but at the same time they are not afraid of significant temperature loads. Cast iron is used in the manufacture of not only expensive devices, but also in the production of high-power units - in this case, it is simply impossible to do without such a material due to the significant loads on heat exchangers.

Atmospheric and turbocharged

An atmospheric burner burns fuel with natural waste removal. In this case, the combustion products themselves go into the chimney, obeying the draft

It is important to supplement this device with a high-quality and reliable chimney that goes to the roof. The open combustion chamber is not designed for the presence of unnecessary parts to generate thrust

For this reason, such products are famous for their practicality, durability and low cost.

Turbocharged boilers have a closed combustion chamber. They are designed to work in conjunction with coaxial chimneys. Such units are equipped with a fan, which forcibly “expels” combustion waste and also regulates the draft in the chamber. Thus, fuel is burned efficiently, and there is simply no need to organize a full-fledged chimney. Turbocharged models are more expensive because they have a more complex design.

Universal and with replaceable burners

It is quite possible to convert diesel heating in a private house to gas. To do this, you just need to buy a device equipped with replaceable burners. Such equipment is called universal. It will operate on various types of fuel.

Modern manufacturers also produce versions of diesel boilers that can operate on different fuels without changing the burner. These instances can even be reconfigured to run on gas.

Negative points

The material is not very resistant to humidity, that is, it is not necessary to carry out work in rooms that have very high humidity, since gypsum quickly becomes unusable.

Gypsum tiles are used only in rooms with low humidity

At high temperatures, gypsum deteriorates quite quickly. Surfaces located near heating pipes should not be decorated with tiles. It is better not to decorate fireplaces with this material in situations where they do not have an additional layer of protection. It is better to clad the interior; the facades should not be covered with plaster.

Methods of use

Gypsum materials imitate various textures, including plaster, so they are readily used both for finishing the walls and as a replacement for ceiling cladding. They are not suitable for cladding facades, rooms with high levels of humidity and staircases. For such surfaces, choose brick and decorative stone made from a cement-sand mixture.

Wild stone at the head Source apollo.com

Gypsum tiles in the interior should fit into the color palette and composition of the room. The following options for its use are possible:

- In the living room. The main design technique is an accent wall (or part of a wall). The rest of the wall space is made neutral: monochromatic and as even as possible. For relief decoration, the correct lighting angle is important; it should not be frontal, but falling from above and slightly from the side. Decorating the fireplace with plaster decor also looks appropriate.

Decorating a fireplace in the living room Source pinimg.com

- In the kitchen. In the kitchen space, plaster cladding is used only to decorate the ventilation duct or dining area. The material is not used in finishing the apron and, especially, the sink.

- In the bedroom. Plaster is used to cover the wall at the head of the bed or opposite the bed. The finishing is made light, often white; It turns out appropriate and stylish.

- In the corridor, hallway. In small rooms, gypsum decor is used mainly as edging for door and arched openings.

Decorating a mirror at the entrance Source prom.st