The essence, pros and cons of bark beetle plaster

The presence of a mineral filler in the composition lightens the weight of the material; it does not put pressure on the façade of the building. The composition attracts with its strength, environmental safety and reliability. The coating does not fade when exposed to direct sunlight.

Fireproof properties reinforce the safety of the solution; it is also not afraid of temperature changes and adverse weather conditions. The affordable material is protected from infection by fungus and mold, and has a wide range of colors.

Considering the simplicity of internal work, one cannot ignore the disadvantage of bark beetle plaster, which is expressed in the labor-intensive nature of facade decoration and inability to repair.

Consumer opinions and reviews

“... I took it for testing, for finishing a fireplace, with a grain of 2.5 mm. Despite the fact that it was my first time working, two years have already passed without incident. The plaster was easy to apply, but without gloves it scratches the skin.

The drawing was done on a whim, first creating a sample. The impression is good, and the price is quite reasonable. It’s bad that dust accumulates in the rough surface during use...”

Zelentsov Sergey, 41 years old, crane operator

“...My son and I were making walls in the hallway. Previously, there was washable wallpaper, which our Barsik shamelessly tore up. He couldn't handle the new finish. It took a little more than the amount indicated on the package. Probably because we are not specialists and did this kind of work for the first time. But I liked it...”

Anisimov V.M., 62 years old, pensioner

“...They entrusted the plastering to the builders. We made walls in the corridor and on the loggia. It turned out great, but there is no warmth or comfort in this plaster... It is more suitable for a southern house with stone floors and an abundance of sunny colors. But, it’s worth admitting, even after three years the walls are in perfect condition...”

Baeva Tatyana, 34 years old, manager

“...We used bark beetle plaster for the interior decoration of a country house. We took silicate, domestic. They hired guest workers, but construction workers in the past.

The decorative effect is, of course, impressive. And I was pleased with the color of the plaster. But the mood was spoiled by a crack that appeared 4 months later. The craftsmen said that this was due to glue from another company, which we used to putty the bolts. Who knew about this..."

Gizzatullin Kamil, 45 years old, dealer

Criterias of choice

The basic selection criterion is the type of base. Concrete surfaces are finished using cement-lime and cement mortars; there are no restrictions for brick surfaces. To improve the adhesion of both types of surfaces, a reinforcing mesh is applied to a 5 cm layer of the mixture.

Wooden walls are finished using lime-gypsum mortars, where clay can be added as a plasticizer.

It is important to comply with the permissible norm of the last component so that cracks do not form on the finished surface. Plastering a wood base also involves the use of reinforcing mesh.

Decoration of gypsum blocks is carried out using lime-gypsum or gypsum types of plaster; reinforcing mesh is not required. The use of cement mortars is highly undesirable here.

It is most difficult to work with gas and foam blocks, as they are characterized by low adhesion. To achieve reliable and long-term adhesion of materials, it is advisable to fill the surface with a special mesh and use mixtures with strengthening additives.

When choosing a finishing material, most experts prefer gypsum compositions, as they exhibit optimal performance characteristics. This type of bark beetle does not shrink and cracks do not form on it. The material has high sound and heat insulation properties. The only limitation: the gypsum mixture cannot be applied to concrete walls, it will quickly fall off, and it also requires high-quality preliminary waterproofing of the base.

Benefits and Features

Ceiling plaster with bark beetle

The special components that make up the decorative mixture provide the finishing material with a large number of positive properties and advantages. Among these, several main ones can be identified:

- practicality;

- water-repellent properties;

- antiseptic properties;

- strength;

- ease of application (all steps are performed by hand, without outside help);

- decoration of any type of surface;

- masking minor defects;

- environmental friendliness.

Will help you quickly transform your interior

An important advantage and positive property of plaster is the ability to quickly transform the interior. Using it, you can create any pattern or design, and then paint it in the desired shade, which will match the decoration on the walls and ceiling.

When using decorative plaster, there is no need to carefully prepare and level the ceiling surface.

Preparatory stage

Before applying bark beetle plaster, you need to clean the base surface from greasy stains, dust and dirt, and old finishes. Cracks and defects are leveled using lime, gypsum, and cement mortar. In the process of sealing large seams, they are widened with a grinder and filled with gypsum putty. Walls in areas with high humidity levels are coated with antifungal compounds.

To improve adhesion, apply a thick acrylic primer to the surface using a brush, roller or spray gun. This composition will help adjust the absorbency of the base and speed up the uniform drying of the bark beetle. This measure is not necessary for cement-lime and concrete walls; here it is enough to wet the surface with water an hour before starting work.

Application area of plaster

Bark beetle, like other decorative plasters, is a finishing material, so it is applied as the last layer. It is well suited for bases made of concrete, brick, plasterboard, cement. The main thing is that the substrate is durable, does not crumble or sag. It is not recommended to use this plaster on wood and metal, and on plastic and glass the pattern may not form correctly.

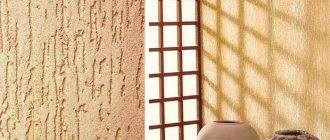

Bark beetle plaster is excellent for interior decoration - finishing walls, highlighting certain parts of the room, individual zones. It can also be used to decorate arches, columns, niches - it all depends on the decorator’s imagination. You can use different shades of plaster or cover the walls with areas of different grains, which will give a variety of visual effects. The bark beetle looks no less good when decorating the facades of houses, buildings, structures and even multi-story structures.

Tools and materials

The first step is to select beacon limiters, which are plastic or metal profiles with holes. Their depth varies between 6-10 mm, the standard length is 3 m. The shape can be L or T-shaped.

Basic working tools:

- putty knife;

- self-tapping screws;

- rule;

- metal scissors;

- plumb line;

- dowels;

- roulette;

- level;

- foam and plastic graters;

- perforator with a nozzle for mixing the solution.

In order to apply the bark beetle to the wall you will need a spatula.

The lime mixture is formed from lime and sand in proportions 1:4, 1:3, 1:2; cement - made of cement and sand in ratios 1:2 or 1:3. The clay working mixture includes 1 part clay and 3-5 parts sand, the gypsum solution is mixed from lime and gypsum, 1 part and 2 parts sand.

Construction tape will be a convenient auxiliary material. With its help, you can divide a large wall into several working sections, protect the surrounding surfaces from plaster, pause work by gluing the outermost strip, and then start from the same place by cutting off a strip of mortar.

Specifications

Characteristics with a layer thickness of 2.5-3 mm

| Fraction | 2.5-3 mm |

| Consumption of dry mixture per 1 m² | 2.5-3 kg |

| Creating a reinforcing layer, consumption per 1 m² | 2.5-3 kg |

| Working at temperatures | -5 °C to +25 °C |

| Shelf life of the finished solution | 2 hours |

| Flexural strength after complete drying | from 2 MPa |

| Compressive strength after complete drying | from MPa |

| Vapor permeability | from 0.1 mg/(m×h×Pa) |

| Drying time | 28 days |

According to the composition of the components for the construction market, Bark Beetle is produced based on:

- acrylic - polymer binder.

- potassium silicate - liquid glass.

- cement and lime.

The first type, acrylic plaster , due to its excellent adhesion, is able to withstand moisture in rooms with high humidity - showers, swimming pools, jacuzzi; It has an elastic surface, low vapor permeability, looks more impressive on the wall, but requires an application technique that is accessible, to a greater extent, to a professional.

The second type, silicate plaster with a high level of vapor permeability, due to water-repellent additives; has excellent protective properties, is durable, and comes in a variety of colors and shades.

The third type, mineral plaster , is a mixture of cement with the addition of quartz chips, characterized by frost resistance, fire safety and properties that are most in demand for finishing facades.

Subtleties of preparing the mixture yourself

The material is sold in the form of a ready-made mixture or a dry composition that requires dilution. In the second case, to prepare the working solution, you need to strictly follow the instructions on the powder packaging: it is important to observe the temperature regime, the correct sequence, and proportions of ingredients. At this stage, it is permissible to introduce color, but you need to correctly calculate its quantity so that subsequently all batches of the mixture have the same shade.

First, the specified volume of water is measured; its temperature should not go beyond 21-23°C. For each kilogram of powder, take no more than 0.25 liters of water, but the proportion can be changed by the manufacturer depending on the components used. The container should be convenient not only for mixing, but also for further use of the solution.

A measured amount of powder is added to the water, and a trowel is used for manual mixing. To speed up the process, use a construction mixer turned on at medium speed. The mass is affected until it becomes homogeneous; the presence of excess moisture on the surface, lumps and dry residues is unacceptable. As a result, the working solution should resemble thick sour cream.

Too dry a mass will cause inconvenience during the application process, its consumption will increase, and the material will roll off the tool. The liquid solution will leave streaks, it will drain, leaving no opportunity for the formation of a characteristic textured pattern.

How to choose the right composition

When choosing plaster, you need to focus on the following characteristics: grain size, type of composition and time of its useful use.

Grain size affects not only the appearance of the coating, but also the consumption of material. This is explained by the fact that the thickness of the plaster layer must be no less than the size of the fractions. This means that the larger the fraction, the more material will be required for work.

Another important parameter is the type of composition. Suspensions are convenient to work with because they do not require preparation. Thanks to special additives, they are distinguished by their plasticity. But they cannot be stored. Their cost is higher than that of dry plasters.

Dry plaster must be prepared before work. This is easy to do following the instructions. The composition can be prepared in the required volume, and the remainder of the powder can be stored in a closed container.

Application methods and technology

When deciding how to apply decorative bark beetle plaster to walls, you should keep in mind that the technique varies depending on the base. Experts offer manual (for interior work) and mechanized (for facades) methods of distributing the material; it is also permissible to use it on a layer of insulation and further painting.

Handmade

Plastering is done holistically: the wall is processed in one step so that drying is uniform. A monolithic finish is formed that has no differences or seams. Protect adjacent surfaces with masking tape.

Manual application of bark beetle to the wall

Use a spatula to grab a small part of the mixture and distribute it starting from the lower right corner. The tool is held at an angle of 60°, and the wall is processed in rows vertically or horizontally. The mixture is stretched until such a layer is formed that it is possible to create grooves and scratches.

When the surface dries, begin to create a textured design (literally after 20-40 minutes). A plastic trowel helps to form characteristic strokes; if necessary, spray the plaster with water. Next, the surface is rubbed without pressure to mask the joint areas. For proper drying of the bark beetle, it is necessary to maintain a room temperature of +10°C, and the relative humidity should not exceed 80%.

Specifics of mechanized application

In this case, the facing work covers a wide surface: the primer is applied with a spray gun, and the plaster is applied automatically. The nozzle of the latter is held perpendicular and as close as possible to the base, carefully distributing the mass, which is supplied under pressure.

Advantages of the method:

- possibility of forming a thin layer;

- uniform application, optimal adhesion, formation of a durable surface;

- continuous feed ensures high-quality grip;

- the occurrence of air bubbles, the ingress of foreign inclusions, and lumps of dry matter is excluded.

The downside is the large dimensions of the equipment; they are not convenient to use at all facilities. Further leveling is carried out manually; to create a textured pattern, a grinding unit is used in tandem with a fleecy wheel, but in this case it is difficult to achieve a pronounced relief.

Plastering the facade using insulation

Wet facade technology involves the use of insulating materials, reinforcing mesh, and textured plaster. A fiberglass reinforcing mesh with plastic fasteners is installed on the fixed slab insulation; after 3 days you can begin plastering. The operating technology is standard; you just need to protect the façade for two days from contact with precipitation and UV rays.

Wet facade technology

Possibilities for painting plastered surfaces

A coloring pigment can be added at the mixing stage; there is another way of additional decoration - painting a wall with already dried plaster. The first option is relevant when using a ready-made mixture, while calculating the color dosage for dry powder is more complicated.

Acrylic, water-based, or silicate paint can be applied to the finished surface with a roller or brush. The silicate composition is used 3 days after plastering the wall, acrylic - no earlier than 14 days. At the first stage, the entire surface is carefully painted, paying special attention to bulges and depressions; the second layer is a darker or lighter shade; only the upper, flat part is covered with it, avoiding getting the composition into the grooves (the roller should be semi-dry).

Instead of paint, you can use acrylic varnish with color or mother-of-pearl; it is applied with a steel spatula so that the entire plastered surface is decorated with an even layer.

Main mistakes when applying bark beetle

Experts prohibit carrying out facade work in direct sunlight or in rainy weather.

The decorative material can be painted after hardening or contain a colored pigment. In the latter case, many people miss that in order to create an attractive surface, the wall must initially be painted in the same shade.

Uneven stretching of the plaster layer can cause the texture pattern to shift. The mixture contains calibrated grains, thanks to which the ornament is formed. A thin layer will contain too few of these granules.

The plaster is spread in one go so that there are no joints. In emergency cases, the required area is limited using masking tape, and the working staff reach it. When the tape is peeled off, a smooth joint appears, from which the next batch begins to be applied.

The nuances of creating a textured decorative surface

The shape of the pattern on the finished finish is determined by the nature of the movements that are made with a trowel on the plastered base. The classic ornament of wood affected by the bark beetle is formed as a result of arched, circular, uneven movements of the tool in different directions, during the process it must be slightly pressed.

Shape of bark beetle pattern on the wall

The imitation of rough stone, also called travertine, is obtained through short, jerky manipulations, and the trowel must be moved in different directions. The cork ornament is made using a smoothing tool: a tool made of polystyrene foam is intensively moved in a circle with a small radius. The imitation of woven fabric is created by moving the grater crosswise: vertical strokes are formed with a slow and drawn-out movement from bottom to top, horizontal strokes with an energetic short stroke.

The rain-like pattern is formed as a result of continuous long diagonal movements of the grater from top to bottom, starting from the upper right corner. Bark beetle plaster can also be applied in the image of a world map: the first layer is rubbed in the classical way, after it has dried, the second is applied unevenly, making strokes in different directions. The latter are smoothed with a Venetian trowel.