Wood, under the influence of negative factors, over time loses its natural attractiveness and deteriorates its performance characteristics: it fades under the influence of UV; deformed from excess moisture; rot when pathogenic microflora multiply.

To give a rich shade, preserve the structure, protect against destruction and extend service life , a special wood stain is used. Read more about what types of compositions there are, how to prepare them and what are the features of processing wooden surfaces.

Features and color characteristics

Oak takes on darker colors over the years. Obtaining a variety of color options is possible through the use of various technologies. Tones can be cold or warm, the brightness of the structure can also be adjusted. There is wood with a natural color that is close to black. To recognize the oak, you should take a closer look at the picture.

Obtaining a variety of color options is possible through the use of various technologies.

Oak colors and shades

The color palette of the material is large. There are very light options and black ones. This diversity is possible due to the use of different material processing techniques. Modern technologies help to obtain a large number of color solutions.

Modern technologies help to obtain a large number of color solutions.

Whitened or bleached oak

White oak cannot be found in nature, although in the production of furniture they often resort to obtaining this color scheme. The oak itself has a darker color, even if we are talking about young trees, by the way, they are not chosen for production.

To create a similar effect, they resort to treating the material with chemicals. Next comes soaking it in oil and applying varnish.

To create a similar effect, they resort to treating the material with chemicals.

Golden oak

Oak wood is distinguished by its straw color, which helps to obtain, by slightly staining, a golden color. In nature, such coloring can occur under the influence of sun, wind and water.

Oak wood is distinguished by its straw color, which helps to obtain, by slightly staining, a golden color.

Dark oak

The natural dark shade is characteristic of a number of wood species, usually found in Europe. Also, a similar effect occurs when a tree sits in water for a long time; such wood is considered valuable. They call it “moraine”, we are talking about a hundred-year period.

A similar effect occurs when a tree sits in water for a long time; such wood is considered valuable.

Black oak

The most expensive is bog oak, which has lain in water for more than a thousand years. Such conditions lead to superior strength characteristics. The wood also acquires a black color, which looks luxurious and presentable.

The most expensive is bog oak, which has lain in water for more than a thousand years.

Choice of stain color.

Each stain color has its own code, which corresponds to the international classification, and a name that matches the type of wood whose color the stain copies. For example, stain “Chestnut”, “Walnut” or “Cherry”. But it is very short-sighted to choose a stain only by its name or picture on the label, as an unexpected result may result. There are special reasons for this:

1. If stains of the same color and code were made by different manufacturers, then they may have different shades. For example, the water stain “Larch” manufactured by “Tsaritsyn Paints” has a pinkish-brown tint, and “Larch” produced by “Novbytkhim” has a soft yellow color. Various stores have samples that have been painted with different stains. Such samples will convey the color of the stain much more accurately than the picture on the label.

2. The natural color, structure and density of wood can also affect the result of staining

. For example, stain on mahogany will look much darker than on maple (if the stain used was the same tone). This is because mahogany wood has a darker shade than maple wood.

The same test with pine and maple samples will demonstrate that pine wood stains faster and more intensely. Pine has softer and more porous wood, while maple is dense and hard. For this reason, it is easier for dyes to penetrate into pine wood.

The texture of the wood also affects the degree of staining. Oak has a pronounced structure, so it quickly darkens from staining, as coloring substances penetrate into the recesses of the veins. But the main part of oak wood, which is outside the veins, is colored more slowly and not so brightly.

Examples of interiors in wenge color

In the dining room and kitchen, it is better to use a classic scheme, according to which dark shades are given a place below head level. In this case, the room will seem more spacious. In addition, dark brown has a relaxing effect, which is not entirely appropriate in the kitchen, where the housewife needs a lively mood for preparing holiday dishes.

Wood tones are not necessarily present in furniture and flooring. Wenge can find a place for itself on the ceiling in the form of a tier of a multi-level ceiling. This solution is quite suitable for high walls. In this case, black wall cabinets are hidden, creating a niche effect, and do not compete with the nobility of the African guest.

What to do if you want dark brown walls? Maintain this shade in the chandelier, chandelier and tabletops. Decorate the walls and floor in creamy tones. Decorative accents of red, burgundy, and green are allowed.

Can wenge make friends with toffee? Yes, if you mix it with golden veins. A dark shade will emphasize the depth of the niche in the kitchen set. And so that he does not feel lonely, we will give him a door, a chandelier and lamps as companions. The chocolate napkins are the icing on this cake.

I really want tsavo, but the kitchen is small. And the hostess likes there to be a lot of light and space. What to do?

The solution is actually very simple. Order a white set with a horizontal contrasting stripe on the fronts of the wall cabinets. If you want even more contrast, use the same shade in the fronts of the lower cabinets. At the same time, white or steel narrow stripes will create movement dynamics. An excellent solution for modernity.

To relieve the feeling of hospital sterility, lay cocoa-and-milk colored tiles on the floor.

Wenge is a great place for creative ideas. At the same time, this color loves to be surrounded by milky and creamy tones interspersed with natural pink, purple, red and yellow shades. Create exquisite interiors that are characterized by luxurious simplicity and VIP class elegance.

Price of stains and reviews about them

buy a water-type stain for 20, or for 1080 rubles. The price depends on the name of the manufacturer, volume, and type of solution. It can be regular or concentrated. The latter is an intermediate stage between liquid stain and powder.

It is clear that the concentrate is more expensive than a simple solution. Also, the price of stain is increased by its foreign origin. There are domestic offers for 20 rubles per 500 milliliters.

Alcohol stains, as a rule, are 20 percent more expensive than water stains. Nitro compounds cost the same. For half a liter they ask from 150 to 600 rubles. For acrylic stains you have to pay from 200 to rubles per 0.5 liter.

By the way, there are transparent mixtures. These only protect the wood and emphasize the texture, but do not paint it. The price of half a kilo of wax stain starts from 300 rubles. They ask a little less for oil dyes based on natural plant extracts.

The price must correspond to the quality. Consumers discuss this on the Internet, citing reviews of specific stains from specific manufacturers. However, when getting acquainted with the information, it is worth considering the correct choice of mixture.

Some people criticize stain only because they chose it for the wrong wood. It has already been said that even the best gel will not penetrate dense oak, and wax will only cover it on top.

Application methods

There are four main ways to apply stain:

- Rubbing painting. The composition is applied to the surface, after which it is rubbed over the entire area. Recommended for use when processing porous wood species.

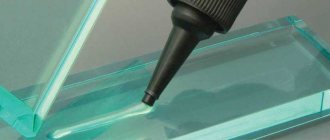

- Sputtering. When staining wood by spraying, a manual or automatic sprayer is used as a tool for applying stain.

- Processing with a foam roller. This method avoids the formation of streaks and helps to distribute the mixture evenly over the entire surface.

- Processing wood with a paint brush. The method allows you to obtain a deeper and richer color of wood, but is not suitable for all types of impregnation.

- Before painting a surface with stain, it is necessary to remove old coatings from it, and then degrease it better.

- The surface made of coniferous species (for example, pine) must be deresined.

- It is necessary to paint wood with stain and remove excess only in the direction of the wood structure.

- It is recommended to cover the surface with 2-3 layers, while for the first layer a small volume of the mixture should be used.

- After the first layer has dried, the surface must be sanded and the raised lint removed, and then, if necessary, apply subsequent layers (each subsequent layer is applied only after the previous one has completely dried).

The approximate drying time for oil-based impregnations is about three days, and for water-based and solvent impregnations - 2-3 hours (depending on how many layers were applied). It is recommended to divide large areas of the surface to be treated into small areas and paint them in stages. To avoid the possibility of defects forming on the surface, the composition must be diluted. A solvent is used for this.

Plywood stains perform a purely decorative function. Therefore, if you are in doubt about whether to choose stain or varnish, it is recommended to use them in combination. Before covering the surface of the plywood, it must be moistened, and it is recommended to heat the mixture itself.

After covering the wood with stain, it should be treated with varnish (layers should be very thin to avoid the possibility of smudges). The tool you can use is a brush, roller or sponge. Wood varnish will enhance the protective properties of the impregnation. By following these recommendations, you can easily stain wood at home.

Preparation for applying stain: making a color test.

After purchasing the stain

, but before starting the coloring itself, it would be useful to make a color sample. Its necessity is that it will help you understand whether a given stain is suitable for the surface. In addition, the test will allow you to find out what color you will end up with and will help you decide on the number of layers to apply.

To make a color test, you will need a board treated in exactly the same way as the wood that is to be painted. Undoubtedly, the type of wood of the sample must coincide with the main surface.

The board is covered with one layer of stain. After drying, a second layer is applied to 2/3 of the sample. The third layer is applied to 1/3 of the board. After the stain has dried, the board is coated with two layers of varnish. By comparing the brightness of the color of each part of the sample board, the optimal number of layers for a certain surface is selected.

In order to choose the best option, you need to do several test stains. Several boards are painted with different stains and after that the final choice is made.

Varieties

You can cover absolutely any wood surface with stains - pine, oak, maple, birch and so on. But you still need to know the types of this product, because each type of stain has certain properties.

Water

The presence of water in the composition of the stain is considered the main constituent ingredient. The group of water-based impregnations is considered the largest. Typically, these products are prepared in finished form or in powder form. The powder can be diluted in water independently according to the attached instructions.

Positive traits:

- Due to the fact that this product has a neutral base, it does not have increased toxicity and does not have any harmful effects on health;

- Availability of a wide range of shades with natural texture. Using these types of products, you can create shades from the lightest to deepest, which will help recreate a natural look and deepen the tone. This quality also gives the surface an expressive and noble appearance;

- It is easy and simple to apply, with minimal product consumption;

- Suitable for any type of wood - pine, birch, oak, maple, walnut, cherry;

- Not high cost.

Alcohol type stain

This product is available in the form of aniline dye, which is dissolved in denatured alcohol. This type of stain is sold both ready-made and dry in powder form, which must be dissolved.

This product has the advantage of drying quickly. However, this quality provides some qualities when manually applying the mixture to wood; after drying, greasy stains often form. Therefore, many builders recommend using a spray gun when using alcohol products.

Oily

In these products, all oil pigments are dissolved in solvents or White Spirit. This composition provides a number of advantages to this type of stain:

- When painting, it provides tinting of wooden surfaces in various colors;

- Oil mixtures are convenient to use at home;

- The composition adheres well to the surface and can be applied with any tools;

- The oil stain evenly enters the area of the wood structure, while forming a protective film on the surface.

Acrylic and wax

Wood stain, which is made from an acrylic or wax base, is new to the construction market. This product has proven itself positively among many consumers and professional builders. This is due to the fact that this mixture, after application, creates high protection for the base from negative influences and premature wear.

Features of the composition:

- After application, this type of impregnation forms an insulating film on the surface of the wood, through which moisture and other negative substances do not penetrate;

- Various color characteristics. Compared to other varieties, this composition has a variety of colors from natural to bright exotic tones;

- These types of stains are used by many modern furniture designers. These products are used to paint the external facades of cabinets, tables, and chairs made of different types of wood.

With whitening effect

It is not always necessary that the wood be dark in color; sometimes it is required that, on the contrary, it have a slightly whitish color. In these cases, impregnations based on hydrogen peroxide and acids are suitable. With their help you can get a light, bleached color of wooden beams. Typically, these solutions are used to prepare the surface for further painting.

Stain is simply a necessary thing to improve the quality of wood. This product protects the base from rapid wear and destruction. The main thing is to choose the right product and carefully read the instructions and characteristics of the composition. But which mixtures to choose all depend on what they will be used for - to improve color or for protection. It is better to first study the properties of each type of stain.

What is stain used for?

If you have never used this product, then you probably often wonder: what is stain and what is it for?

Wood stain or stain are special compounds that are used to tint natural wood during its finishing. This product is produced in the form of a liquid, which, during use, is applied to the surface and absorbed into the area of the outer layer of the wood, thereby changing its color.

Important!

It is worth noting that, unlike paints and varnishes, stain does not form a film on the surface of the wood; its composition enters the wood. The degree of penetration of this product depends on the type of wood and the quality of the stain.

Since wood has a multi-layered texture, in which the layers have different levels of density and permeability, all this leads to coloration of the wood with varying degrees of intensity.

After staining, the wood acquires its obvious natural qualities. It is this property that has made this product popular among many restorers, furniture manufacturers, and specialists in finishing wood products.

Depending on the properties and composition of the stain, there are several purposes for this product:

Colors and effects

Stain is used to treat wooden surfaces. When it is mentioned, a brown surface immediately appears. For many consumers, this color seems to be the most relevant. Having studied the features of the product and its color range, it becomes clear that this product has a wide variety, which allows you to give the interior a new and unique look. Thanks to the wide variety of assortments, any colors and shades can be selected.

When choosing a color, you should be guided by the fact that the composition will appear differently on different surfaces. Even if the samples presented in the store show a certain color, it is better to first test it at home on a small area of the surface being treated and make sure that the tone matches. Although the manufacturer indicates the tone on the packaging, the color may appear differently on different surfaces, as natural materials absorb the composition and acquire completely new shades.

By treating the surface with water or alcohol stains, you can achieve a natural effect. When choosing a product, you should consider what effect you plan to achieve. You can improve a room in a matter of hours by applying oak or ebony color to the surface. Mahogany will look redder after treatment, while maple, due to its density, will hardly change color when applied.

When applied to the porous surface of poplar, its color will change. The oak will have a distinct pattern due to its structure. Often neutral tones are chosen for processing. You can choose dark shades and take the color of mocha, walnut, mahogany or cognac.

Treatment products for wooden surfaces come in a wide variety of colors, making the old coating immediately more interesting. Surfaces treated with oak, beech, cherry and teak stains are original.

Not only store-bought stains are used to treat wood; the surface can be treated with products obtained from plants.

- Larch is suitable for giving products a red tint; a decoction of its bark will help achieve this effect. The tree will become redder if you cover it with a decoction of onion peels.

- Ground walnut shells will help you achieve unusual shades. The powder is boiled and soda is added at the end of cooking. When fringe is added, a rich reddish tone is obtained. If you add acetic acid, the color will turn gray.

- When using walnut powder and apple tree bark, you can achieve a brown color; when adding alum, the color will become dark brown.

- When applying a decoction of unripe buckthorn fruits, you can get a golden hue.

You can achieve a varied color palette and get an interesting rich color, such as wenge, Oregon, pine or a stain like stained oak, black, using stains based on tea, coffee and vinegar.

- The use of coffee allows you to achieve a brown tint. Coffee beans should be ground and baking soda added, or instant coffee should be made and applied to the surface.

- You can add a dark brown color using regular tea leaves. The strength of the brew affects the color saturation.

- The ebony effect can be achieved using metal and vinegar. To do this, metal products are poured for at least 2 days and left in a well-ventilated place.

- To give the product cherry shades, potassium permanganate is used. After treatment with potassium permanganate, at the rate of 50 g per 1 liter of water, the surface is varnished so that the material does not fade in the sun.

The color palette is so diverse that it is difficult to decide which color to take. You can stick to neutral shades or choose a colorless option. The color palette allows you to use unusual shades: yellow, green, orange, emerald green. Blue stain, white or blue - this is not a complete list of colors for updating wooden surfaces.

How to make it yourself

Making your own stain helps you experiment with shades and get the most unexpected results.

Based on plant materials

Methods for making wood impregnation:

- The bright red color is obtained from a strong decoction of onion peels.

- The brown color is made from dried walnut skins. The shells are crushed into powder, boiled for 10 minutes in water, and filtered. Dissolve 1 tsp in the finished broth. soda To make a red impregnation, potassium bichromate is used instead of soda, and vinegar essence is used for gray impregnation.

- Birch trees are painted red using a decoction of larch bark.

- Light brown comes from nut shells and apple tree bark.

- Black stain is obtained from a boiled mixture of oak, willow and alder bark.

- Anthracite black is made from vinegar, oak bark or walnut.

- The golden-yellow tone comes from a decoction of unripe buckthorn fruits.

From coffee, tea and vinegar essence

Using strong tea, coffee beans and vinegar, you can create a wenge, Oregon or pine stain:

- Mixing equal amounts of ground coffee beans and baking soda produces a rich brown color.

- Light wood can be treated with strong black tea.

- You can make a black-gray stain using metal nails and acetic acid. The nails are placed in a container and filled with acid for 5-7 days. Insist in a dark place.

Based on chemical components

Impregnation preparation options:

- The board becomes brown after treatment with slaked lime solution.

- The dark cherry tone is imparted by a solution of potassium permanganate. You need to dilute 50 g of potassium permanganate in 1 liter of warm water.

- A deep yellow tint is achieved by treating the material with a decoction of barberry roots with the addition of alum.

- Green wood is obtained by combining decoctions of poplar shoots and oak bark.

- The timber turns dark brown from the juice of wolfberries and copper sulfate. Berries with Glauber's salt give a scarlet color, with potash - green, with soda - blue.

- Black stain for oak and mahogany is made from potassium dichromate (chrompic). Pour orange powder into a glass bottle, add hot water and shake until completely dissolved.

- The green-herbal color is obtained by adding 50 g of verdigris to the vinegar essence. The mixture is boiled for 10 minutes.

With whitening effect

Stains are used as a base before painting wood. Whitening impregnations can be prepared in the following ways:

- Based on oxalic acid. Staining is performed on light or bleached wood. To prepare, add 9 g of acid to 180 g of warm water. After application, the surface is washed with a solution: 10 g of soda and 30 g of lime are diluted in 200 g of water.

- Based on hydrogen peroxide. Not suitable for dark rosewood, mahogany and oak. For bleaching, use a 30% peroxide solution.

Kinds

Depending on the material that is the basis of the composition, several types of stain are distinguished.

One of the most common types is aquatic. This product is available on the shelves of hardware stores in two versions:

- dry;

- liquid

The first is a powder for dilution with water. It must be strained before use. Otherwise, particles of undissolved pigment will prevent you from applying the product in an even layer. The second option is a ready-to-use liquid, poured into various containers.

Water stain is economical, does not require special skills during application, and is inexpensive. Its advantage is non-toxicity and absence of unpleasant odor. It is ideal for interior work. The treated surface will dry in just over 12 hours.

Be sure to take into account the peculiarities of such finishing material. Penetrating deep, it lifts the wood fibers. Due to this, the product acquires a spectacular natural look. However, this impact is negative and shortens the life of the wooden covering. The problem can be dealt with if, before applying the composition, treat the wood with water and after a day clean it with an emery cloth.

Alcohol stain is also sold in dry or liquid form. To dilute the powder, ethyl alcohol is used. The peculiarity of this composition is quick drying. Therefore, it is often used for working with wood outdoors. If you need to process the product indoors, good ventilation is necessary, since the stain has a specific pungent odor.

The base of oil stain is usually linseed oil. White spirit is used for dilution. This composition allows you to paint wooden surfaces in a variety of shades. The stain is easy to apply, penetrating deep into the wood and protecting it from moisture. In this case, you can use a brush, as it does not leave streaks. The only drawback is that it takes a long time to dry.

Wax stains are environmentally friendly and safe for human health. This determines their high cost. They can be used not only for painting wooden surfaces. They can restore or correct errors in wood flooring.

The thickest type of stain is gels. They are applied to soft wood surfaces. It is difficult to distribute this composition with a brush, so special tampons are used. Mainly, gels are used for outdoor work. They will “revive” benches and gazebos in the garden and add uniqueness to the façade and fence.

Acrylic stains are based on resins. The product is an emulsion. It is easy to apply. Penetrating deeply enough, the composition protects the surface from the negative effects of moisture. A diverse range of shades will allow you to bring all your most secret ideas into reality. At the same time, the processed product will not fade under the sun's rays and will retain its color saturation for a long time. Acrylic stains are economical, but expensive.

A special type of stain is stain. It is based on organic solvents, dyes and pigments. The stain dries quickly and gives an even shade that is resistant to fading.

Hydrogen peroxide or acid is the basis for whitening stains. This composition is designed to make the wooden surface lighter for further processing or painting.

Varnish for coating wooden surfaces

Varnishes that are used to coat wood come in several types:

- Alkyd.

- Polyurethane.

- Acrylic.

- Nitrovarnishes.

- Alcohol.

- Oily.

- Parquet with acid hardener.

Alkyd varnishes must be diluted with a solvent . The surface treated with this product is protected from fire and water and does not fade in the sun. Thanks to acrylic varnish, a film is formed that does not allow the wood to wear off and slows down the aging of wood.

Nitrovarnishes, although they dry much faster, however, are not able to withstand the negative effects of ultraviolet radiation and moisture for too long. Polyurethane varnishes are characterized by increased wear resistance and form a durable film on the wooden surface that dries very quickly.

Relatively recently, oil-based varnishes were very popular, but nowadays they are used most often for treating floors. Their main advantage is their low price. Such varnishes must be diluted with drying oil, and they take a very long time to dry. Such a new product as acrylic varnish, which is universal and easy to use .

It is used for both external and internal work. This varnish should be diluted with water, and it does not have a strong odor. With its protective qualities it resembles alkyd varnishes, but is much more economical to use . But alcohol varnishes are used only for the restoration of antique furniture.

Preparing the wooden surface

It is recommended to apply stain and varnish only to smooth and sanded surfaces. Regardless of whether the coating should be painted - new or old, it must be carefully inspected. All detected cracks, seams and knots should be processed and eliminated .

If gaps are also found between the joints and seams, they are sealed with special putty . As soon as it dries, to remove possible unevenness, the putty areas are sanded again using fine sandpaper.

One should take into account the fact that it makes no sense to putty on raw or under-dried wood, much less treat it with stain or varnish it. Such wood begins to deform and the applied layer always becomes unusable.

Features of wood stain: what is it for and what properties does it have?

Wood is distinguished by its natural beauty and warmth, environmental friendliness and the ability to create comfort around itself. To preserve all these properties of the material and extend its service life, special means are used, including stains.

Thanks to stain, you can significantly extend the life of wood products

These compounds improve the decorative qualities of wood, and also provide reliable protection against various pests and the negative effects of environmental factors. Before you start choosing the right option, you need to understand what stain is and what its purpose is.

Stain (stain) is a special product intended for wood processing. Most often, the composition is sold in liquid form, but in rare cases it can be in the form of a dry powder. Mostly dark stain. It is used to give wood various translucent shades. At the same time, the texture of the material and its natural pattern do not change at all, since the product penetrates only into the top layer. Stain emphasizes the natural beauty of wood and enhances its attractive aspects.

This tool allows you not only to change the appearance of the material, but also to protect it from the destructive effects of external factors. It is the versatility of the stain that has made it so popular.

Stain (also called stain) can give wood different shades

Why do you need wood stain? This composition is used in the following cases:

- Toning a material while maintaining its texture and wood pattern - the composition lifts the fibers of the material without radically changing its natural pattern.

- Wood bleaching - this property is used in the process of restoration and restoration of damaged and old products made of wood. Such stains are also used in cases where it is necessary to make the shade of the material lighter or to prepare its surface for colored varnishing.

- Imitation of elite wood species on budget materials.

- Protecting the material from damage by parasites - the antiseptic properties of the stain prevent the development of putrefactive processes (elimination of fungi, bacteria and mold) and the proliferation of insect pests.

- Strengthening the structure of the material.

- Moisture protection of wood - stain protects the material from the negative effects of moisture, and some types of compositions create a water-repellent layer on the surface (partially).

- Extending the service life of wood products.

- Creating a finishing effect using different types of wood by combining shades.

Varnish protects wood from aggressive weather influences

Drying oil has similar properties, but after processing a film forms on the surface of the wood. This product is not able to penetrate deeply into the pores of the material, but it covers them well from the outside. Unlike stain, drying oil cannot be used as an independent finishing agent. It is intended for preparing wood before painting.

Wood varnish is very different from stain. It forms a stable film on the surface of the material. Moreover, the formation of the protective layer occurs only after the solvent contained in its composition has completely evaporated. After drying, oil-based varnishes form a film on the surface that is durable and elastic. This coating is quite difficult to remove even with white spirit.

Like any other finishing option, the varnish will have to be renewed periodically, and for this it is necessary to remove the previous layer. This requires some effort, so varnish is used in cases where the impact of atmospheric factors on wood is too aggressive and the use of stain is impractical.

Drying oil is similar to stain, but is not used as an independent coating

Treating wood before applying stain.

Before applying stain, the wood must be prepared. There are several processing stages:

1. First you need to remove the old coating, if any. This is done by scraping and sanding the boards. This process will not only remove the old coating, but also level the wooden surface.

2. Clean the surface from grease and oil stains. To do this, you need to wipe the problem areas with a rag soaked in white spirit or gasoline.

3. Coniferous wood must be deresined before staining. It is necessary to remove resin from the wood structure, which may interfere with the absorption of the stain.

. There are several types of solutions for degumming:

Dissolve 50 g of potassium carbonate and 60 g of soda ash in 1 liter of water heated to 60 degrees.

Dissolve 50 g of caustic soda in 1 liter of warm water. Treat the surface with the resulting soda solution.

Mix 750 ml of distilled water with 250 g of acetone.

Any of these solutions must be applied to the surface of the wood in several layers. After 30 minutes, wipe the wood with a cotton cloth and rinse with warm water.

Tinting effects

Depending on the palette of shades used, the type of stain and the desire of the craftsman, you can give the wood a variety of effects. Due to the latter, design possibilities are greatly expanded.

Whitening process

White color is very popular in the interior. In addition, with the help of bleaching, you can restore the normal appearance of old wood, which has lost its attractiveness, but has acquired dark, bluish spots. You can also decorate some interior elements, for example, cover photo frames and paintings with bleaching stain.

Embossed white products that have been treated with special brushes look beautiful (this removes too soft fibers). After finishing the processing, they are covered with a white, light walnut stain. To protect the wood from the influence of atmospheric factors, you can apply white wax on top.

Aging of wood

An interesting option for finishing wood is to give it an aged effect. First, the product must be prepared: remove dirt, sand it, brush off dust. Then a water-based stain in white or another light color is applied to the wood. The freshly applied mixture is removed from some areas with strokes using a sponge. After drying, a finishing coat based on organic solvents is required, and to fix the shade, the pores are filled with shellac primer or wood varnish.

In addition to this method of making wood look old, there is another popular method. First you need to apply white stain, after drying, sand the product, then gently rub in dark wax. This will enhance the impression of great “age” of the coating and bring it closer to the “bleached oak” shade.

Imitation ebony

For this purpose, dark stains are used, which are marked accordingly. The wood is first sanded and polished to achieve maximum aesthetic effect. Then the stain is applied, performing one or two layers. In order for the surface to resemble a black mirror with knots appearing, you need to choose the hardest, most dense, finely porous rocks.

Giving other shades

Depending on the style, features of the interior or landscape, you can give wooden structures a variety of colors

It is only important that they all fit well with each other and do not conflict. The most commonly used non-wood shades are:

- blue - sometimes used as the main coating of finished products, pieces of furniture, gives them a very expressive look, goes well with white and yellow tones;

- gray – used in combination with bright accents, otherwise the product will turn out faceless; if there is an abundance of gray in the interior, there is a risk of depression;

- red – helps to highlight one or more elements from the total mass.

Some people try to save money and paint the wood themselves. Instead of stain, onion peels, alum, infusion of walnuts and other “folk remedies” are used. Unfortunately, the effect is rarely lasting, so it is better to purchase a high-quality composition that will last a long time and without complaints.

Tips for choosing

When choosing the composition and color of the stain, it is necessary to take into account that when applying the same product to different types of wood, each time there will be a new shade. Tips for choosing impregnation:

- Porous and soft woods absorb stain well: hardwoods are deeply and quickly soaked; conifers cannot be changed, but only given a slight tint.

- Dark wood will become even darker after staining. Popular stains include beech, teak, oak and cherry.

- The natural beauty of the board will be emphasized by colorless stain.

- For whitening external surfaces, white wax stain or alkyd-based compositions are suitable.

- The consistency of the composition affects the intensity of the shade. A mixture that is too thick will make it difficult to apply, but will give a richer color. Liquid stains will not provide the desired depth of shade and must be applied in several layers, but in this case the wood will be painted evenly.

- Pigment stains fill the ribs and reliefs of the wood, leaving the rest of its surface less painted.

- For structures with cracks and irregularities, it is necessary to choose special priming compositions with a porosity filler.

- Alcohol compositions are convenient for treating furniture and doors; stains may form when painting stairs and parquet. Stain looks beautiful on walnut and mahogany pieces. Stained paint is not suitable for elements made of spruce, poplar, cherry, birch and pine. To reduce the appearance of possible defects, the top of the object is processed first.

You need to select the stain on a sample of the board that is to be processed. Otherwise, you may get the wrong result.

Video description

Applying stain in different ways

Spraying

Application is carried out using a spray gun. In this case, the color of the stain is selected a little lighter than necessary. The coating is sprayed in several stages until the desired color is obtained. Spraying allows you to achieve a more even texture when painting problem surfaces.

Pouring

Using a brush, a sufficiently large amount of the composition is applied to the surface to be painted. After this, it is left for 15-20 minutes to absorb. The longer the aging period, the darker the color. Unabsorbed stain residues are removed using a clean napkin.

Painting with a brush

This method is used when working with small or carved surfaces. When tinted with a brush, even one layer gives a deep and even color.