Even in new buildings, it is rare for the walls to have no roughness or uneven areas. In order for the walls to become smooth and the surface to get rid of defects, putty is used in construction work. This is one of the final stages of finishing, which will prepare your walls for wallpapering or painting, creating and demonstrating the ideal evenness of the surfaces. However, the prevalence of this type of work does not in any way reduce the number of mistakes that newcomers to the construction industry make. This article will tell you how to choose the putty that is suitable for your walls, how to correctly calculate the putty consumption per 1 m2 of wall, and will convince you that it is not only possible, but even necessary to putty the surface with your own hands.

photo from the site https://otdelka-expert.ru

Features of putty and plaster

Plaster and putty mixtures differ in composition, purpose, and rules of application.

In combination, the use of these materials allows you to level the base, eliminate cracks and chips. The plaster layer precedes the putty layer. The compositions are used to perform high-quality repairs of surfaces for applying decorative plaster with marble imitation, silk-screen printing, performing artificial aging techniques, etc.

Careful leveling and step-by-step surface treatment are necessary before painting the bases with paints and varnishes (water-dispersed, alkyd, acrylic). Painting after treatment of the base is carried out promptly. After preparation, paint consumption per 1 m2 is reduced.

According to its technical characteristics, the putty is durable, resistant to moisture, and quick-drying. The material can be used to seal gaps and small cracks in the base. When choosing a mixture, it is important to consider its purpose (for interior or facade decoration).

Factors affecting material costs

Obviously, the larger the surface that needs to be puttied, the more building material will be needed. As a rule, manufacturers indicate on the product the consumption of putty per 1 m2. But you need to be critical about this because:

- the indication is approximate;

- The area of work is far from the only factor influencing the required quantity and consumption.

What else should you consider?

- Surface quality. The presence of microcracks, roughness and scratches, their depth, initial curvature. The better and smoother the base, the less building mixture is needed.

- Base material.

- Place of putty work and correct choice of mixture. If the room is damp, or outdoor work is being done, then cement-based putty is used. It is applied in a thick layer, so you will need more of it than plaster. The latter is used only in dry and warm places. Moreover, you can find a putty mixture that is already ready for use (no need to dilute it). The consumption of such a mixture is less, but the price is more expensive.

- Qualification and experience of the employee. A professional needs less material to work with.

- The end result you are striving for: wallpaper, painting, whitewashing, etc.

- Type of putty material. Today there are: universal;

- starting;

- finishing

What determines the consumption per 1 m2 of wall?

The following parameters affect the putty consumption:

- The condition of the wall panels - the greater the number of protrusions, cracks, rough areas, uneven blocks, the greater the consumption of the putty mixture will be (since the thickness of the composition increases).

- The type of subsequent finishing is painting, whitewashing, wallpapering. Tinting surfaces with paint requires a large consumption of putty per 1 square meter. m.

- Experience of a specialist - beginners in finishing work consume more putty mixture, unlike workers with experience.

- Place of work - when finishing facades and panels in rooms with high humidity, facade putty based on cement powder is used, the consumption of which is higher than gypsum. When performing interior finishing work, dry gypsum mixtures are used, which must be diluted with water, and ready-made putties, which are characterized by low composition consumption.

- Puttying stage - to eliminate unevenness and cracks in the base, a starting solution is used, which has a high consumption. The universal putty mixture has a lower value. Finishing putty is used to level the prepared base for painting or wallpapering, so it is consumed in a small amount.

- Substrate type - wall panels will require more putty than ceilings.

- Composition of the material - more products based on cement powder are required than alkyd putties. Gypsum putty has increased consumption. Less need to order adhesive putty.

When calculating the volume of material, it is necessary to take into account that part of the solution will remain on the tools and in containers for diluting the mixture.

What determines the required amount?

When using, the area being treated is taken into account. The layer thickness should not exceed 1 cm, otherwise the material will begin to crack and crumble. The volume is determined by the quality of the surface. This building material is used to obtain a leveled plane, ready for final processing.

Factors affecting material costs

The volume of required building materials is affected by the following:

- If there are cracks or dents, more building materials will be required.

- What the surface is made of.

- The place where the repair is carried out, the composition used. The cement mixture is required in a larger volume than that made on the basis of gypsum. For exterior repairs or in conditions of high humidity, a larger amount is needed than in a dry room.

- It is important what experience the employee has. A master will need less quantity than a beginner.

- The purpose matters: painting, whitewashing, wallpapering or another.

- Type - it can be starting, finishing or universal.

Taking into account all the reasons mentioned, the amount of putty required may differ for the same area.

Consumption of starting putty

Such mixtures are applied to plastered surfaces and precede the finishing stage. Often the compositions differ in large fractions, because made from gypsum powder and lime. The consumption of the starting putty mixture is high, so manufacturers produce the material in 25-42 kg bags. To dilute 1 kg you will need up to 400 ml of water, the consistency of the material is pasty.

When applying the mixture to a wall panel with a layer of 1 millimeter, the consumption of starting putty will be up to 1-1.4 kg per 1 m2. Typically, 1 package weighing 30 kg is enough to carry out initial puttying of an area of 20-20 m² with small defects. However, if the panels are damaged, the thickness of the putty will be at least 0.5 cm, so a bag will be enough for 4-7 m² of area.

It is recommended to determine the required thickness of 1 layer before puttying work. The standard value is no higher than 0.5-1 cm. If the layer thickness is exceeded, the finishing mixture may shed.

You can calculate how much material is needed taking into account the technical characteristics of different products:

- Knauf HP Start putty can be applied in a layer of 10-30 mm; with a coating of 10 mm, about 7.5 kg will be required for an area of 1 m²;

- Ceresit CT 29 starting mixture is applied with a thickness of 2-20 mm; with a layer of 1 mm, up to 20 kg of product will be required;

- Polimin SHG-11 mixture is used to make a 3-10 mm coating, the consumption with a 1 mm layer will be more than 1 kg;

- SATYN PW-01 - permissible coating up to 8 mm; with a layer of 1 mm, product consumption will be 1.3 kg.

Consumption standards for putty compounds

In addition, when calculating the consumption of the required amount of putty mixture, you can focus on the following indicators:

Recipes for putties for application to wood surfaces.

- Typically, when processing 15-20 sq.m., about 30 kg of solution is needed. If the floors have a very uneven or curved surface, the amount of starting putty required may increase slightly.

- Universal putty is usually sold in 20 kg bags. This volume is enough to treat an area of 20-25 m2. When finishing floors with a universal mixture, treatment with a finishing composition is no longer necessary. It is necessary to use finishing putty only when applying elite and capricious finishing materials.

- As a rule, the consumption of finishing putty is of the smallest importance. Here, about 20 kg of composition is enough for an area of 40-50 sq.m.

https://masterfasada.ru/youtu.be/P4tyyrxueM8

Knowing the types of putty that will be used for certain work, and using the information presented above, you can easily calculate how much finishing solution will be required for the job.

Consumption of universal putty

The universal putty mixture is applied to the pre-treated surface. Therefore, the use of finishing putty is not necessary. The putty consumption per 1 m2 is 1200-1500 g. Products are sold in packages, the bag weighs 20-25 kg. To finish about 15-20 m² of wall panel, 20 kg of mixture is required.

You need to know what the putty consumption is depending on the manufacturer:

- Stabilll PSZ-11 - when applying the material in a layer of 0.1 cm, up to 1.2 kg per 1 m² will be required. However, the consumption of the product increases due to the layer-by-layer coating.

- Sniezka Acryl-Putz - when applying a layer of 1 mm, up to 1500 g/m² will be required.

- Knauf Multi-Finish - gypsum products are used at the rate of 1200 g per 1 m². A package weighing 25 kg will be enough for a base area of 20 m².

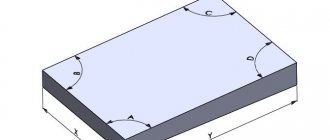

Wall putty: consumption per 1m2 according to the formula

In order to calculate how much material you will need, you need to know the perimeter area of the room, as well as the height of the walls. To make an accurate independent calculation, you must:

- Measure the height of the wall, its length under and above the door and window openings.

- Calculate the sum of the lengths of all walls.

- Number of layers of putty.

- Take into account the thickness of the walls and the number of irregularities on them as a correction factor.

- Know the thickness of one layer of putty, taking into account base defects.

photo from the site https://vesti-ukr.com

The following formula is used:

R= N* k (( L1+L2+L3+L4)*h+(L5*h1))

Where R is consumption per 1 m2,

N is the consumption rate of the selected type of putty when used on a surface without noticeable defects.

k is the correction factor (here you need to take into account the time it takes for the putty to dry and deteriorate, the thickness of the walls, the number of irregularities that need to be repaired, because all these points increase consumption), where k of the average surface = 1.5.

L1 – L4 is the length of the walls, excluding areas above door and window openings.

h – height of surfaces.

L5 – length of the surface above the openings.

h1 – height of surfaces above openings.

Don't forget about slopes

If you plan to putty slopes, then their area must also be taken into account when calculating the putty consumption per m2. Despite the small size of each of them, the total deviation can be significant, especially if the external walls are of significant thickness.

Consumption of finishing putty per 1 square meter

This mixture is intended for leveling ceilings and walls before painting or applying decorative plaster. The material is produced in the form of a powder or a finished composition, packaged in buckets of 8-25 kg. To prepare a solution from dry material, you need to dilute the powder in water in a ratio of 1:0.5.

The consumption of finishing putty differs depending on the technical features of the compositions of different manufacturers:

- Vetonit LR+ - dry powder contains polymer components, sold in 25 kg packaging. For a coating of 1 mm, the consumption will be about 1200 g per area of 1 m². The layer of finishing material should not be more than 1-5 mm.

- Knauf Satengips finishing - sold in packages of 25 kg. The minimum layer size should be 0.2-5 mm. To cover an area of 1 m² with a layer of 0.1 cm, 1000 g of material is required.

- Volma - products of this brand are used for finishing plastered concrete surfaces, slag concrete walls, tongue-and-groove slabs, as well as for decorating facades. An area of 1 m² will require up to 1200 g of mixture.

- Knauf Uniflot - the material is used for interior finishing work, correcting joints between sheets of drywall. The coating does not crack, does not shrink, and is applied in a layer of 1-5 mm. For finishing ceilings, up to 300 g/m² is enough; for partitions, up to 500 g/m² is required. Package size: 5-25 kg.

How much is needed for external and internal walls?

To determine the volume, it is necessary to take into account the characteristics of the area to which the composition is applied. Start-up costs for a façade wall are significantly higher than for an interior wall. Usually the norm is per sq. m is 1 kg or more.

Costs of starting putty

The start is used for leveling. With its help, cracks, chips, and other damage are eliminated. Often the composition uses gypsum or lime.

Usually for every sq. meter you need 1-1.4 kg of composition. This amount is calculated based on a depth of 1 mm. Typically the bag volume is 30 kg. It is enough for 20 sq. m.

The thickness depends on the quality of the material. If there are many defects, then the start can reach up to 5 mm. In this case, spending will increase. Consumption will increase to 4-8 kg per square meter. meter. The thickness must not exceed 1 cm.

To reduce consumption, you need to pre-level the surface. To do this, plastering work is carried out.

For exterior work, the composition is applied to brick, wood, and cinder block. Here the consumption of starting personnel is much greater than for internal work. Usually it exceeds 1 kg per 1m2, sometimes significantly.

Finishing putty costs

It is necessary for the final stage of preliminary wall finishing. Paint will be applied to the finish and wallpaper will be hung. It is not intended to smooth out uneven surfaces, but only to make the wall smoother.

The finish is usually applied to the start. In rare cases, it is used on top of a universal composition. If the wall is smooth and has no defects, then it can be applied immediately. The consumption of finishing putty per 1 m2 is usually less than the starting putty.

It is sold both in the form of a dry powder and in finished form. The last option is the highest quality and most expensive. Sold in packages of 25, 17, 8 kg or smaller. For a coating 1 mm thick, the consumption of finishing putty per 1 m2 of plaster is 1-1.5 liters.

For external walls, the consumption of such a layer is approximately the same as for internal walls. This is due to the fact that it is applied to a flat, prepared surface.

Costs of universal putty

This material is not used for professional finishing. Using a universal mixture, rough leveling is performed. The quality of the resulting surface is inferior to that obtained when using start and finish.

Usually building materials are sold in bags of 20 kg. This is enough for 15-20 sq. meters of wall. On a layer 1 mm thick, the putty consumption per 1 m2 is 1-1.2 kg of mixture. It is used for working on previously prepared surfaces. In this case, no additional finishing is required.

Consumption of ready-mixes for walls

This putty is used to level ceilings and eliminate small defects on walls. The mixtures contain plasticizers and vinyl components that increase the level of surface smoothness. The material dries quickly after application and does not crack. The advantage of the solution is that there is no need for dilution before finishing work.

Consumption of mixtures from different manufacturers:

- Shitrok - the material is economical. When applying a layer of 1 mm to an area of 1 m², about 50 g of the composition will be required. The putty is easy to apply, does not crack and dries quickly.

- Pufas is a ready-made material from the Ceresit brand, consumed at the rate of 1500-1700 g per 1 m², depending on the thickness of the layer.

- Finished products of the Vetonit brand - when covering the base with a layer of 1 mm, 1200 g/m² will be required.

- Fugenfüller Knauf - ready-made gypsum putty can be applied in a continuous layer. An area of 1 m² will require up to 800 g of material. However, when using a gypsum mixture to finish installed tongue-and-groove slabs, the putty consumption will increase to 1500 g/m².

After what time can putty be applied?

Cement-sand leveling mixtures take quite a long time to fully gain strength - 4 weeks.

But there is no need to wait this long after plastering. Cement gains 70% of its strength in a week. This is quite enough for applying putty and subsequent finishing, including heavy tiles. For example, Knauf Unterputz cement facade plaster 20 mm thick dries within 7-10 days. Gypsum compositions set in 40-60 minutes and dry completely in about a week . For example, the popular Knauf Rotband, applied to the walls with a layer of 15-20 mm, can be puttyed after 7 days. In a humid room or low temperatures, the drying time may increase to 10-14 days.

Drying time also depends on the thickness of the layer, as well as the temperature and humidity in the room. Using construction hair dryers or creating drafts to speed up the process is not advisable - significant cracks can form on the surface if it dries unevenly, and over time the plaster will begin to peel off.

After drying, before puttingtying, the plaster must be sanded - using a special grater with a fine mesh or sandpaper, the wall is processed in a circular motion. In this way, small deposits of the dried mixture, traces of a spatula, and places where layers were applied are removed.

How does surface affect consumption per square meter?

To determine the volume of solution consumption, it is necessary to take into account the base material. The volume of the putty mixture differs when applied to plastered surfaces, concrete floors, plasterboard, wood, chipboard sheets, MDF, etc.

Plaster

The consumption of putty per 1 m2 of plaster depends on the quality of the base, the presence of preliminary preparation and an assessment of the planned thickness of the application layer. You can putty only small areas to correct them, or treat the entire surface with a continuous layer.

To create a smooth base, you will need a layer of 1 mm of starting mixture and 0.5 mm of finishing putty. Each composition should be taken at the rate of 1000 g/m² and 600 g/m². When applying denser layers to adjust the base, the volume of the mixture will increase. For a layer of putty 11 mm per 1 m², up to 11 kg of material will be required. When making calculations, the possibility of applying an additional layer (up to 3 mm) is taken into account.

Drywall

The consumption of putty composition per 1 m2 of drywall depends on the number of joints planned for the implementation of the design solution. When treating with a solution, it is necessary to hide the fasteners and screws that are used for mounting plasterboard floors. The work requires a starting and finishing lineup.

The material is selected in accordance with the operating conditions of the space being repaired:

- In rooms with high air humidity, you will need putty with a cement base, the consumption of which ranges from 1100-1200 g per 1 m².

- For dry rooms (bedroom, living room), polymer putties or gypsum mixtures are used. The former are used at a rate of 600-1000 g/m², the latter are consumed economically - 500-1000 g/m².

- The consumption of putty on plasterboard floors will be reduced if the gypsum board sheets are pre-treated with a primer.

Concrete

Before applying the putty mixture to the concrete base, you must first prime it. The material is applied in a layer of no more than 6 mm, the next coating should be about 3 mm. The standard consumption of putty per 1 m2 is about 1-1.5 kg with a layer of 1 mm. With a thickness of 3-6 mm, up to 2-3 kg of material will be required.

Other grounds

When processing wooden surfaces, the putty layer should not be more than 2-3 mm. Accordingly, the volume of material per area of 1 m² is 1100 g. To increase the adhesion of wood, experts recommend priming before treating with putty.

After applying and drying the primer, the volume of materials can be reduced. However, it must be taken into account that coating density and consumption are determined by the composition of products of different brands.

Cost rates for different types of putties

The standard depends on the brand and type of material. The following rules apply:

- Sheetrock is suitable for indoor use. It is used to seal cracks and seams on concrete, brick or other walls, and is used for final finishing. At 1-2 mm the rate of expenditure per sq. m is 0.5-1 kg. For a millimeter layer you will need 0.5 kg.

- Vetonit contains sand, polymer components, cement, limestone, mineral additives, is environmentally friendly and moisture resistant. Work is carried out at +10 degrees. The consumption of Vetonit putty per 1 m2 of plaster is 1.2 kg for a millimeter layer. It dries completely seven days after the work.

- Knauf contains lime, gypsum, glue, is elastic, environmentally friendly, and has high adhesion. Can be used for starting finishing, provided that the size of the unevenness does not exceed 3 mm. The standard is 1.5 kg per square meter.

- For external work, the norm is 1.8-1.16 kg per square meter. meter.

- When applying an oil-adhesive composition, 3 kg per unit area is required.

- For the finishing layer, 0.45 kg is enough.

- Adhesive putty will be consumed at the rate of 0.47 per 1m2.

How to correctly calculate consumption per square meter

The basis for calculating the required volume is the information on the packaging. Here they indicate the consumption per square meter. m with a thickness of 1 mm, as well as the minimum and maximum possible thickness of the coating.

A decision is made as to which processing will be performed: start and finish, station wagon and finish, or station wagon only. The quality of the wall and what layer will be required are assessed.

For example, when using “Polimin SHG-11” the minimum layer is 3 mm, the putty consumption per 1 m2 of plaster is 1.05 kg. The master assessed the unevenness of the wall and decided that 4 mm was needed. The standard will be 4.2 kg (4.2 = 1.05 x 4) per square meter. m.

Table describing some putties - consumption rate

The indicators from different manufacturers are as follows:

| Brand | Place of use, description | Consumption rate |

| Shitrock | Interior finishing, the material can be used to correct cracks, chips and as a finishing layer. Characteristics: high ductility, good adhesion | Per 1 m² - about 1 liter with a layer thickness of 1 mm |

| Vetonit | Interior decoration in rooms with dry air. Characteristics: environmentally friendly composition, application at temperatures from +10°C | 1.2 kg/m² with a layer thickness of 1 mm |

| Knauf | Indoor finishing, not applicable for bathrooms and toilets. Characteristics: composition is environmentally friendly, elastic, with a high level of adhesion | For a surface of 1 m² and a layer thickness of 1 mm, 0.8 kg is required |

Advice from material consumption consultants

Professional advice that allows you to get high-quality results when leveling walls with putty mixture at its optimal consumption rate:

- the consumption of the building composition directly depends on the mixture used, the surface being treated (depth of defects, curvature) and the thickness of the applied layer (stage of work). This means that pre-leveling the wall with plaster will help reduce putty consumption.

- you need to take into account the type of room when choosing the type of building mixture. For wet rooms (kitchen, bathroom, toilet), cement-based putty is suitable.

- When independently preparing a composition from a dry mixture, you must strictly follow all the instructions indicated on the packaging. If the putty is prepared incorrectly, this will significantly increase its consumption.

- The thicker the composition, the greater the consumption. But this does not mean that to save money you need to dilute the liquid mixture. It all depends on the goals being pursued. For large irregularities, for example, a thick putty is needed

- no need to apply 10 cm layers of plaster, putty, etc. Under the weight of its own weight, there is a high probability that the building material will crack and collapse

Thus, when puttingtying work you need to take into account many nuances:

- work stage

- condition of the walls

- type of building material

- master's qualification, etc.

But on average, without taking into account the unique circumstances of each specific situation, the putty consumption per square meter is 1 kg.

Tips for preparing the solution

When preparing a putty solution, it is recommended to consider the following nuances:

- The composition is prepared taking into account the instructions from the manufacturer. If the proportions are not correct, the consumption of putty may increase. If there is excess water in the mixture, unaesthetic stains remain on the surface. An overly thick solution will take longer to dry than the standard mixture.

- The volume of the putty solution to be mixed is calculated taking into account the use by the master for 30 minutes.

- To prepare the mixture you will need dry putty and water. You also need a container, a construction mixer or an electric drill with a special attachment operating at low speeds.

- To reduce the amount of solution consumed, it is recommended to use clean tools that are wiped after each mixing.

- When preparing a solution to eliminate large deformations, cracks, and chips, the solution is made thicker. However, the cost of funds will increase.

Preparatory work

In order to get a high-quality result at the end of the putty work, you need to carefully prepare for this process.

1. Preparation of the base (ceiling or wall):

- must be durable

- dry

- clean

- without peeling

It is necessary to remove dirt, plaque, plaster residues, wallpaper, looseness, oily inclusions, etc.

The wall or ceiling should not be wet or frozen. Before puttying, be sure to dry the base.

2. Preparation of the workplace. Since the process of leveling walls is a dusty and dirty job, it is necessary:

- cover the floors with newspapers or special film

- It is better to remove decorative items and furniture; if this is not possible, then also cover with film

3. Preparation of tools. You will need a drill with a special attachment (or something you will use to mix the dry mixture manually), spatulas, a container for the composition and a level (if you have to work on leveling the walls/ceiling). All equipment must be clean and dry.

The tool must be washed thoroughly immediately after use, otherwise it may only end up in the trash.

4. Preparation of the building mixture (read more about this below).

How to correctly calculate the consumption of façade putty

Putty consumption per 1 m2 for finishing facades is calculated by square meters. The thickness of the facing surface layer is preliminarily determined. In this case, the curvature of the wall panels can be measured using installed beacons. It is important to consider that the level of facade curvature may vary depending on the area chosen for treatment. The standard thickness of putty cladding for facades is 3 cm.

Accordingly, you can perform calculations based on the indicators indicated by the manufacturer on the packaging. Manufacturers describe the volume of material for a layer 10 mm thick. You will need to multiply the figure by 10 to get the required volume of putty.

When carrying out facade work when finishing a 10 m² wall, about 85 kg of specialized putty for external work is required for a 10 mm layer. If you cover the façade more densely with the solution, you will need to perform calculations. It is necessary to take into account the need to purchase material with a margin of 10-15%.

Thickness of putting putty on drywall

Walls made of plasterboard must be in perfect condition immediately before applying putty. After all, when working with this material, the thickness of the putty applied to its surface will largely depend on the level of quality of the work carried out on the installation of gypsum boards. On the drywall itself, immediately before puttying, there should be no protruding screw heads. If necessary, the screws must be tightened until they are recessed inside the drywall.

Finishing putty application technology

Not everyone knows how to properly apply finishing putty to walls, so let’s look at the technology for this work.

Applying finishing putty

Before starting work, to achieve the smoothest possible surface, install your lantern so that all surface irregularities are visible. Otherwise, the quality of work will decrease significantly. After correctly installing the lighting, you must proceed in the following order:

- Using a spray bottle, spray the surface of the wall with water and wipe thoroughly with a sponge or rag. This will help clean the surface from construction and household contaminants and increase adhesion. It is very important not to skip this procedure, especially if you plan to apply a thin layer of solution. The fact is that on a dry wall the solution sets very quickly, and the dust particles remaining on it will make the layers less even and smooth;

- make a solution of PVA glue with water and carry out priming work. Most experts recommend priming using professional solutions, which can be purchased at any hardware store. That being said, both options are great;

- use a narrow spatula and scoop up the finished putty;

- Working in a vertical direction, apply the mixture crosswise onto the wall;

- completely treat the surface area you have chosen;

- take a wide spatula and stretch the putty, periodically wiping it with a damp cloth. It is necessary to operate at a minimum angle, without pressing too hard with the tool on the surface. Also, it is necessary to ensure that the layer thickness does not exceed 1.5 mm;

- cover the entire surface with the solution;

- let the finishing putty set well and dry;

- Use fine-grained sandpaper to remove any uneven surfaces.

If you have no experience, it is better to practice applying finishing putty on small surfaces. Once you are confident in holding the spatula in your hands, you can begin working on large walls.

How to determine how many layers to apply to a wall

The number of layers is usually determined when applying the starting putty, since its task is to level the walls to a level where it is possible to get by with the finishing layer. However, the number of the latter, depending on the effect required, may be different. As for the starting one, for small irregularities it is usually coated once or twice, but in case of serious defects or the need to seal pronounced irregularities, the number of layers can be increased.

Priming Features

Many people ask the question: is it necessary to follow all stages of wall preparation and is it necessary to prime the plaster before applying putty? Priming walls is a mandatory process that provides a number of functional properties. The mixture is a special solution that serves for strong adhesion of materials. When penetrating into a porous surface, the mixture hardens, creating a monolithic compound. The following advantages of the soil mass can be mentioned.

- The adhesive properties of the suspension prevent the destruction of the base layer and the peeling off of decorative elements.

- The resistance of the surface to negative atmospheric factors increases.

- The mixture contains an antiseptic component that effectively fights mold and mildew.

- The amount of finishing material required for work is reduced.

- A thin film is formed on the surface, which prevents the appearance of residual material on the wallpaper and decor.

- The subsequent application of plaster and putty is facilitated.

The choice of primer depends on the type of construction work, the quality and composition of the walls. It is better to first study the instructions for use to determine the most suitable option. The order of coating should be followed, depending on what kind of primer is used. Before applying putty, you must thoroughly clean the walls of old material. Each layer, including plaster, is treated with a primer. This provides higher strength and reduces the risk of wallpaper peeling off and base mixtures falling off.

In most cases, primer comes in liquid form. Some mixtures need to be diluted with water according to the information on the label. Each applied layer must dry well, especially before puttying after plastering and wallpapering.

Putty materials for facades

The consumption of facade putty is determined by the special conditions in which the surface will be used. Since the outer part of the building is exposed to many aggressive influences, primarily of a natural nature, the consumption of the facade mixture will be higher than in cases when it comes to interior decoration. Unjustified savings will lead to the fact that the liquid will penetrate into building structures without any special obstacles, which over time will lead to their rotting and destruction. On average, façade putty consumption is 1.5 kilograms of material per millimeter layer.

Starting putty

Although cement putty is more common as a starting composition, gypsum mixtures have higher performance qualities. The benefits of gypsum are all the more obvious when it comes to rooms with moderate levels of humidity. On average, the consumption of gypsum-based starting putty ranges from 0.8 to 1 kilogram per square meter of a millimeter layer. The consumption per square meter in the case of the starting composition is not so important, since the quality of the surface is much more important.

If the material has many flaws, up to 10 millimeters of putty per layer may be needed. In this case, consumption can increase to 8-10 kilograms per square meter. With such a thickness, at least two pads are needed, because otherwise the solution will simply fall off.

Note! When calculating the required amount of material, it is always necessary to provide a reserve, since it will still not be possible to calculate the exact consumption in advance. Moreover, costs, as a rule, are always higher, and not lower than planned. The recommended stock level is 10%.

Finishing putty

The consumption of finishing putty is usually more predictable, since a more even surface is being processed. As a rule, the layer thickness is from 0.5 to 2 millimeters. The average material consumption ranges from 0.5 to 2 kilograms per square meter.

How to reduce the consumption of finishing material

It is worth noting that the methods given below are unlikely to help radically reduce material consumption, but saving 10 or even 20 percent is quite possible. And in conditions of large volumes of work, this can result in very significant savings. So, the methods themselves:

- You can try to reduce the layer thickness. But it’s better not to do this in exterior decoration. In addition, in this way we may not cover all the unevenness, so it is best to use these methods only on smooth walls;

- Reducing the intensity of plaster on less visible areas of the wall;

- Working at the proper temperature (+5-+25 Celsius) in this case the plaster will not dry for too long and fall off, as happens during cold weather and which greatly increases the consumption of finishing material;

- Try to mix the composition in the right amount. Typically, ready-to-use plaster lasts for 30 minutes, after which it begins to dry out and lose its properties. Thus, depending on the speed of your work and other factors, you need to knead as much as is enough for this particular period of work. Otherwise, we will have to throw away all unused plaster.

Source