The remarkable construction properties of gypsum have been known since ancient times. In addition to statues and monuments, ancient architects often used this material in the construction of buildings, engineering and military structures, and widely used it in finishing work.

Today, gypsum remains the same popular mineral in construction. The well-known plasterboard is made from it, which is necessary for interior decoration.

But not everyone knows that this material has a serious competitor - gypsum fiber (GVL), which in its technical characteristics significantly exceeds plasterboard.

Two big differences

That's what they'll say in Odessa. And they will be absolutely right, since all the advantages of gypsum plasterboard over drywall are visible to the naked eye.

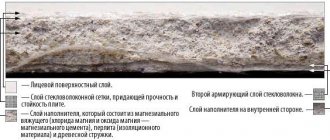

Drywall is a layer of compressed gypsum, covered on both sides with construction paper (cardboard).

GVL slabs are not covered with cardboard. The fibers in them are produced from paper waste, which is thoroughly crushed and then mixed with gypsum and special additives.

The mixture thus prepared is then pressed. The result is not just compacted gypsum, as in dry plaster, but a material reliably reinforced with fiber.

Gvl Harm to Health

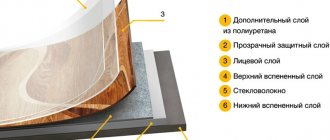

There are also several other types of drywall: moisture- and fire-resistant. They have a slightly different composition because they contain special additives. The core of moisture-resistant plasterboard contains hydrophobic additives, and the gypsum core of the fire-resistant material is reinforced with glass fibers, contains crystallized water and fire-resistant elements. Each of the additives and impregnations used undergoes the strictest quality and safety control.

- First, the tape is glued, which is necessary to compensate for changes in the material due to temperature changes. It needs to be fixed along all the walls of the room in the place where the gypsum fiber boards will be laid. If you have not leveled the floor or insulated it, then treat it with a deep-penetrating primer.

- Next, we fix the sheets to the finished base using glue and self-tapping screws (they need to be screwed in every 35-40 cm around the perimeter of the gypsum fiber 2 mm inward). Make sure that the sheets are laid evenly; the seams should not extend less than 20 cm.

- The surface is being prepared. The old coating is removed. True, not all masters advise this, considering it an unnecessary waste of time and effort.

- Using a level, plumb line and pencil, mark the wall. For vertical racks take a ceiling profile. The guides are mounted in areas adjacent to the floor and ceiling.

Frame method

- The brackets are attached to the racks with self-tapping screws, and the profiles are aligned using a folding cutter. The profiles are attached to the ceiling with dowels in increments of 60 cm or slightly less.

- GVL are installed from bottom to top or top to bottom with a small gap between them.

In the gypsum fiber boards cut according to the markings, cutouts are prepared for switches and sockets. The height of the GVL should provide gaps in the lower part of approximately 8-12 mm. They will be closed in sections after the main slabs are installed. For greater reliability, the plates are tightened with self-tapping screws.

In order to make sure that drywall is harmless, you first need to find out what this material is made of. Sometimes on the Internet you can find simply crazy statements about the enormous harm of this convenient type of finishing. “Drywall is harmful to health,” write people who are little familiar with this building material.

- The acidity pH level is the same as that of the skin. Therefore, this lining is comfortable for the body and almost never causes allergic reactions .

- Drywall is resistant to fire and the risk of fire in a building finished with plasterboard is minimal.

Standard sizes

According to GOST R 51829-2001:

Thickness: 10, 12.5, 15, 18 and 20 mm.

Length: 1500, 2000, 2500, 2700, 3000. 3600 mm is often on sale. (Not included in the list approved by the resolution of the State Construction Committee of the Russian Federation)

Width: 500, 1000 and 1200 mm.

The most popular are gypsum fiber board sheets with a thickness of 10 and 12 mm, a length of 2500 mm and a width of 1200 mm.

There are also non-standard slabs, both small and large format. So, for flooring it is best to use sheets more than two centimeters thick.

Characteristics of gypsum fiber sheets

As mentioned above, gypsum fiber sheets (GVL) are made from building gypsum and cellulose waste paper. GVL comes in two types: regular sheets and moisture-resistant.

Also, gypsum fiber sheets, like various other building materials, have their own specific properties:

- GVL tolerate indoor humidity well; if necessary, they have the ability to absorb part of it and release it if there is a deficiency;

- The heat absorption coefficient of GVL is at a low level, as a result of which this material is quite warm to the touch;

- GVL, like plasterboard, has high fire safety performance. Read about which is better: gypsum fiber board or gypsum board in another article in a construction magazine;

- Installation of gypsum fiber sheets makes it possible to avoid many labor-intensive processes, as well as significantly reduce the time required for finishing work;

- Using GVL will allow you to reduce financial resources for finishing and avoid a large amount of waste.

In addition, finishing walls and other structures with gypsum fiber sheets will make it possible to prevent static loads due to their low weight. This characteristic of gypsum fiber sheets is especially important when used for reconstruction of old buildings, where any load on structural elements is simply unacceptable.

When finishing the floor, gypsum fiber sheets will increase the heat and sound insulation properties of the surface. GVL is very convenient to use in rooms with complex configurations. These are not all the positive aspects of the finishing material in question.

Gypsum fiber sheets are rectangular elements sanded and impregnated with a primer on the front side.

It is important to know that due to grinding and special impregnation of gypsum fiber sheets on the front side, subsequent coatings can be applied without prior priming of the surface

Types of gypsum fiber sheets

Today, the industry produces several types of gypsum fiber foxes. All of them have special properties and have the following geometric dimensions:

- Standard gypsum fiber sheet - length 2.5 m, width 1.2 m, thickness 10, 12 mm;

- Small-format gypsum fiber sheet - length 1.5 m, width 1 m, thickness 10.12 mm.

It is advisable to note that, if desired, you can always order gypsum fiber sheets in other sizes, other than the nominal ones. GVL are easy to use: they are easy to saw and cut, and can be planed. Gypsum fiber sheets have slightly greater strength than plasterboard, so their use is more extensive.

GVL are supplied to the consumer with a longitudinal straight edge (SP), as for the main characteristics of gypsum fiber sheets, they will be indicated below.

Read with this

- What are GVL, GKL, GKLV and where is it best to use them?

- Types and sizes of drywall (using the example of the Knauf classification)

- Properties and structure of OSB boards: their size, quantity in a pack and application

- Facade made of corrugated sheets

- Fasteners for walls made of cellular and hollow material

- How to choose a changing table for a newborn

- Foam cutter

- Making a fireplace out of boxes for the New Year with your own hands

- Interventional insulation for timber and logs

- Features of stove bricks and recommendations for its selection

Classification and technical characteristics. Marking

GLV slabs are divided into standard ( GLV ) and moisture-resistant ( GVLV ).

The former are well suited for interior decoration of industrial and residential premises, in which there is a normal temperature regime and fairly dry air.

Moisture-resistant sheets are treated with a hydrophobic solution, thanks to which they can be effectively used in all wet rooms (kitchen, toilet, bathroom), as well as in attics, basements, garages and many other construction sites.

Both standard and moisture-resistant gypsum boards have a rectangular shape.

They can be with direct ( PC )

And folded ( FC ) edges.

Marking

The marking is applied to the back of each gypsum fiber sheet and looks like this:

- The sheet type (GVL/GVLV) is indicated first.

- The group of type and manufacturing accuracy (A/B) is indicated

- Edge type (see above). PC or FC.

- Dimensions.

- Standard

Transcript example

GVLV-B-FK-3000 × 1000 x 15 TU 5742-004-03515377-97.

Moisture-resistant gypsum fiber sheet, group B with seam edge. Size 3000 × 1000 mm. Thickness 15 mm.

General information

There are several types of sheets:

- GVL – simple, i.e. standard.

- GVLV – moisture resistant.

The width, length and thickness of the material are specified in GOST. The nominal lengths will be 1.5, 2, 2.5, 2.7 and 3 meters, and the width of the sheets will be ½, 1 and 1.2 meters. Permissible deviations will be 0.4 cm, 0.5 cm in width, and approximately 0.03 cm in thickness. The sheet shape is a rectangle. The most popular sheets are 2.5 and 3 meters, and the width of the material used is 1.2 meters, and the thickness is 0.95 and 1.25 cm.

Materials for gypsum boards

The company uses gypsum as the main panel element. The gypsum binder used in construction is made from natural stone and obtained artificially. Gypsum stones are subjected to temperature treatment, and products made from gypsum binder are pure construction material. In order to achieve performance, components are added to the gypsum, and this will also improve its quality.

Characteristics and properties of materials

Drywall must withstand minimum permissible loads, and the main supplier of plasterboard sheets will be the Knauf company, and the sheets can withstand a load of 730 N. The mass of each sheet is 29 kg, and the fire resistance of plasterboard will be 1/3 hour. A company like Knauf developed fire protection products for interior decoration. Knauf FIRELINE was able to release a line of materials that can include:

- Coated sheets.

- Panels that are not treated.

The material has acoustic properties such as absorption, reflection and vibration. Fire-resistant products have the following components - decorative surface (varnish, veneer or laminate), drywall and substructure.

Differences between GKL and GVL

We suggest that you first consider a simple gypsum board, what it is, and how it differs from gypsum plasterboard. Drywall is made from gypsum with special additives and a cardboard finish. Depending on the area of use, the material has different qualities and composition. For visual distinction, products must be painted and labeled. There are such types of drywall:

GKLVO.- GKLO.

- GKLV.

- GKL.

The last option can be ceiling or wall. GKLO is a fire-resistant material, and it also contains reinforcing additives. The sheets are used exclusively in dry rooms, and the marking color for such cardboard is red. GKVL is a moisture-resistant material that is fully impregnated with antibacterial and hydrophobic compounds, and water-repellent compounds are added to the gypsum layer, and therefore it is used indoors with a high level of humidity. The cardboard is green and the markings will be blue. GKLVO sheets are resistant to fire and moisture, and the product combines the properties of GKLV and GKLO, adding hydrophobic components. GVL can have a high density - 1240 kg per cubic meter. The panels are made from reinforced cellulose, gypsum and special additives. GVL from Knauf differs from plasterboard sheets - it creates a healthy microclimate, absorbs excess moisture, is frost-resistant and durable.

Tensile strength of GVL sheets

| Sheet thickness S, mm | Weight , kg/m2 | Bending strength , MPa |

| from 10 to 12.5 | (1.05-1.25) S | 5,5 |

| from 12.5 to 15 | 5 | |

| from 15 to 18 | 4,8 | |

| from 18 to 20 | 4,5 |

Material characteristics

Drywall must withstand the minimum permissible loads. The main supplier of drywall is Knauf. The sheets can withstand loads of 730 N. The weight of one sheet is 29 kg. Fire resistance of drywall is 20 min.

Knauf has developed products for interior decoration with fire protection.

Knauf panels in stock Source alicdn.com

Knauf FIRELINE has released a line of materials that include:

- raw panels;

- coated sheets.

The material has acoustic properties such as reflection, absorption, vibration. Fire-resistant products contain the following components:

- drywall;

- decorative surface (veneer, varnish, laminate);

- substructure.

Characteristics of GVL sheet

| Characteristic | Meaning |

| Humidity, % | up to 1.5 |

| Density, kg/m3 | up to 1250 |

| Surface water absorption, kg/m2 h | up to 1 |

| Thermal conductivity, W/(m °C) | 0,22-0,36 |

| Heat absorption coefficient, W/(m °C) | up to 6.2 |

| Vapor permeation resistance, m2 h Pa/mg | 0,12 |

| Brinell hardness, MPa | from 20 |

| Fire-technical characteristics . SNiP 21-01-97 | GVL, GVLV |

| Flammability group according to GOST 30244-94 | G1 |

| Flammability group according to GOST 30402-96 | IN 1 |

| Smoke generation group according to GOST 12.1.044-89 | D1 |

| Toxicity group according to GOST 12.1.044-89 | T1 |

With a plus sign

In addition to high strength, GVL sheets have many other positive characteristics.

- Environmentally friendly, repeatedly tested and proven.

- High viscosity. You can drive nails into gypsum plasterboards and screw in screws without dowels. They will be held just as firmly and reliably in this material as in wood. It will not be possible to do the same in drywall; you will end up with an ordinary hole.

- GVL sheets do not crumble, which is very convenient when processing them. No special tools are required, leaving little waste.

- Like plasterboard, fiber has a low thermal conductivity coefficient, which allows this material to be used as a reliable thermal insulator for rooms.

- GVL also has good sound insulation. Although here a lot depends on the thickness of the slab.

- Gypsum fiber can be used as a fire-fighting material to protect buildings, communications and various building structures.

- GVL sheets are quite light and therefore do not create additional loads on the load-bearing elements. Due to their light weight, they are easy to carry and install even for one person.

- The bending strength of gypsum fiber is twice that of plasterboard. Therefore, GVL sheets are successfully used in complex structures and intricate interiors: suspended ceilings, arches, decorative ceilings, etc.

- The high frost resistance of GVL has been repeatedly tested in practice. Sheets of this material can withstand repeated freezing and thawing. Thanks to this property, they can be used in unheated structures, for example, country houses.

- If the room is damp, then gypsum fiber can dry it by absorbing excess moisture. Conversely, in a very dry room, gypsum fiber board sheets humidify the air well.

Composition, production and features of plasterboard sheets

Gypsum is obtained by processing sedimentary rock. So pure gypsum is an absolutely natural material.

Cardboard, as you know, is a wood processing product, also a natural component. So if gypsum board is produced in strict compliance with all standards and technological processes, then it is absolutely safe.

Safety is on the conscience of the manufacturer

The bathroom only needs waterproof drywall

However, the “hand of the market” dictates its conditions, and in pursuit of large profits, many manufacturers try to save on consumables or bypass some expensive production cycles. And in this case, the answer to the question whether drywall is harmful or not should be addressed to the manufacturer.

What tricks do building material manufacturers resort to to reduce material costs? For example:

- The use of low quality gypsum with a high percentage of impurities and debris. In this case, the strength of gypsum board sheets decreases significantly. And the composition of impurities can only be determined in the laboratory. Therefore, it is worth purchasing building materials from proven and reliable reputable manufacturers.

Do-it-yourself partitions are easy

- In order to increase the strength of low-quality gypsum, chemical additives and additives can be used, the price of which is much lower than the cost of high-quality pure gypsum.

- Sheets of waterproof and fire-resistant gypsum board are treated with special water-repellent and fire-retardant impregnations. Therefore, chemical components are present in the material in this case. But if a conscientious manufacturer complies with GOSTs and uses approved additives, then the “businessman” will use cheaper, and, therefore, less safe impregnations.

Application

Due to their versatility and excellent qualities, gypsum fiber boards are widely used in construction and renovation of premises. Most often they cover walls, window and door openings, and ceilings. This is done not only to hide communications, but also for fire protection purposes.

GVL sheets are well suited for internal partitions. Due to the high strength of the material, they reliably hold doors and hanging parts.

Moisture-resistant slabs will serve as an excellent substrate for flooring for wooden and reinforced concrete floors. On top of such a structure you can lay tiles, parquet, linoleum, laminate, and other finishing materials.

In the photo above (left side) is the so-called dry screed (expanded clay + GVL)

When using GVL, the flooring process is significantly accelerated compared to “wet” methods, since you do not need to wait for the surface to completely dry for several days, or even weeks.

GKL or GVL - which is better and why

- affordable price for mass buyers. This plus is one of the most important for families on a limited budget. At the same time, the quality of work and durability do not suffer;

- low thermal conductivity coefficient - 0.30-0.34 W/ (m×K). According to this indicator, the material is comparable to wood. In combination with insulation, an excellent thermal insulation layer is obtained;

- Easy to install: no experience required. The main thing is to know the principles of working with the material, which can be easily found on the World Wide Web;

- flexibility. Many will be surprised. After all, the material easily crumbles upon impacts or strong bends. On the one hand, this is true. On the other hand, with the help of gypsum plasterboard you can make any semicircular arches and complex installations (as evidenced by the photo below);

- the price is prohibitive for some segments of the population;

- high specific gravity, as a result of which an assistant is needed during installation. Even though they are smaller in size than drywall, the sheets are much heavier;

- moisture-resistant gypsum fiber sheets can be affected by rot in places with constant high humidity;

- does not bend - can only be used on flat surfaces.

- The surface is being prepared. The old coating is removed. True, not all masters advise this, considering it an unnecessary waste of time and effort.

- Using a level, plumb line and pencil, mark the wall. For vertical racks take a ceiling profile. The guides are mounted in areas adjacent to the floor and ceiling.

You may like => St 228 Ch2 What could be a replacement for St80

Frame method

- The brackets are attached to the racks with self-tapping screws, and the profiles are aligned using a folding cutter. The profiles are attached to the ceiling with dowels in increments of 60 cm or slightly less.

- GVL are installed from bottom to top or top to bottom with a small gap between them.

In the gypsum fiber boards cut according to the markings, cutouts are prepared for switches and sockets. The height of the GVL should provide gaps in the lower part of approximately 8-12 mm. They will be closed in sections after the main slabs are installed. For greater reliability, the plates are tightened with self-tapping screws.

Gypsum fiber is used for finishing ceilings, walls, floors, as well as for cladding wooden structures in order to increase their fire resistance. This material has significant advantages over plasterboard. GVL can be used with virtually no restrictions in wet areas. The physical properties of the material prevent it from igniting. However, plaster is less plastic and less susceptible to deformation, so it is not suitable for decorative finishing of a room.

Separately, it is also worth mentioning gypsum plaster, as gypsum fiber sheet (GVL) is called. This is an environmentally friendly building material. It has high strength and hardness, as well as low thermal conductivity. Therefore, GVL is used for thermal insulation. According to the ignition group, the material belongs to non-flammable substances. When heated, it does not emit harmful substances.

Don't skimp on quality

When purchasing gypsum fiber board sheets, we advise you to follow simple but effective rules. Buy products only from well-known manufacturers who have proven themselves well in the Russian market.

Even if their product is somewhat more expensive, we advise you not to waste time on trifles. Low quality gypsum fiber will cause you a lot of trouble and will not allow you to make repairs at a high level. You will most likely have to pay twice.

Pay attention to the markings of each sheet, since outwardly they are no different from ordinary plates.

Violation of operating rules

The wrong choice of gypsum plasterboard type can lead to its use becoming potentially dangerous. If a material that is not moisture resistant is used in rooms with high air humidity, it becomes a breeding ground for mold growth. It is known that its spores are very harmful to health, as they reduce immunity and cause allergies.

So, taking into account the information provided, we can conclude that the correct choice of the type of material and method of its operation eliminates the harmfulness of drywall.

But for some reason, everyone calmly allows themselves to be put in a cast for a fracture and does not worry about its harm to the body.