The modern construction market is rapidly evolving, offering the user fundamentally new products. One of the latest innovations is glass-magnesite sheets (SML, novolist, stroylist, magnesite, glass magnesite). The material appeared relatively recently, however, it already confidently competes with such “veterans” as plasterboard and chipboard, surpassing them in a number of technical characteristics.

To better understand the functionality of LSU, it makes sense to familiarize yourself in more detail with the technical characteristics of the material.

Composition and structure of glass magnesite

Glass-magnesium sheet is a monolithic plate made of composite materials. The basic composition includes the following proportion of components:

- Magnesium (oxide) – 40%.

- Sodium (chloride) – 35%.

- Wood shavings, fine fraction – 15%.

- Volcanic glass – 5%.

- Binding components - no more 4%.

Deviation from the specified standards by 1-2% . It is worth noting that to give the slab increased rigidity, it is reinforced with a fiberglass mesh.

The technological process includes the following stages:

- The dry mixture of the listed components is mixed until a homogeneous mass is obtained.

- A saline solution is prepared in a separate container and infused for at least a day.

- The compositions are mixed until a homogeneous consistency is obtained and sent for molding.

- Sheet profiles are rolled with a roller, two-layer reinforcement is performed: the mesh is laid in front of the back or front side.

- Finished products are dried and cut to size.

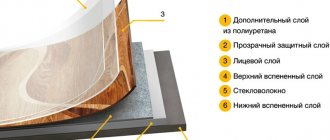

After the final stage, the finished sheets acquire a five-layer structure:

- The back side has a rough surface, providing better adhesion to the surface.

- Fiberglass mesh.

- Filler layer.

- Fiberglass.

- A front profile with a smooth surface, allowing for finishing immediately after installation of the slab.

It is worth noting that this is a reference structure that all manufacturers follow.

Installation features

Installation of glass-magnesium sheets is similar to installation of drywall, but it has its own characteristics:

- The sheet intended for installation must be dry. Wet material bends, making cutting difficult.

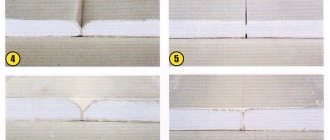

- During installation, a gap of 1/2 the thickness of the sheet is left between adjacent sheets.

- Magnesium glass sheets are secured with drywall screws.

- LSU should be cut on a flat and solid base, laying the sheet with the smooth side up. A jigsaw is best suited for this. For sheets of small thickness (up to 6 mm), the use of a knife is allowed. Having cut the sheet along the marked line, it is broken off, cleaning the edge with sandpaper.

- Before screwing in a self-tapping screw, a high-density sheet must first be drilled to the size of its head. Otherwise, the screw will not be able to crush dense material and will not hide flush.

- The gaps between the sheets and the installation points of the self-tapping screws must be puttied, then rubbed and covered with a primer.

- The smooth surface of the resin does not require additional grinding. Therefore, after installation, you can immediately begin finishing.

Scope of application of sheet construction and finishing materials based on magnesium binder

Considering that the material has very good technical characteristics, glass-magnesite sheets are widely used for interior and exterior decoration, private and multi-storey buildings. In particular:

- Internal partitions.

- Doorways and arches.

- Ventilation ducts.

- Multi-tiered ceilings.

- Chimneys.

- Finishing of bathrooms and baths.

- Permanent formwork for pouring lightweight concrete.

- Floor coverings.

It is worth noting that the sheets have minimal weight, so installation work can be done on your own.

Classification. Types of LSU

Glass-magnesite sheets are produced by domestic and European manufacturers. In this case, the products are divided into several classes that determine the strength and, accordingly, the cost of the product. Material made outside of Russia is marked with letters of the Latin alphabet, indicating the density of the structure.

It looks like this:

- Strength class A – 1,750 kg/m3.

- Strength class B – 1,500 kg/m3.

- Strength class C – 1,250 kg/m3.

- Strength class D – 1,000 kg/m3.

- Strength class E – 700 kg/m3.

- Strength class F – 500 kg/m3.

- Strength class G – less than 500 kg/m3.

Russian manufacturers produce products of three classes: “Premium” , “Standard” , “Economy” , which are similar to European standards A , B , C/D , respectively.

Products of a lower class are not produced by domestic enterprises, since they contradict GOST for finishing materials.

Recommendations for selection

The main thing to consider when choosing LSU is the division of the material into classes. Density, strength and durability depend on the class or assortment.

- Premium class (A);

- Class standard (B);

- Economy class (C).

Premium products are endowed with the greatest strength (1200-1300 kg/m3). They contain a large proportion of magnesium oxide (40%). At the same time, magnesium chloride is added at least 35%. As the grade decreases, the percentage of magnesium also decreases.

Advantages and disadvantages of a construction worker

The characteristics and properties of glass-magnesite sheets make them quite competitive in the Russian and world markets. Unlike analogues, the material has the following advantages:

- Resistance to almost any external influences without loss of properties.

- High elasticity.

- Non-flammability: at temperatures up to 1,000 the material does not ignite.

- Particularly low weight.

- Long service life - up to 50 years .

- Environmental Safety.

- Easy to install and process: any tool can be used.

- Neutrality to pathogenic microflora: wall mold, fungus.

The obvious advantages include the low cost of materials, which attracts the attention of buyers to the material.

The disadvantages include:

- Possibility of material delamination.

- Fragile corners, which requires careful installation.

- Relatively low moisture resistance.

It should be clarified that these technical nuances are typical only for Economy class products.

High-quality glass magnesite

If you are thinking about how to distinguish a high-quality glass-magnesite sheet, then you need to pay attention to the color, which should be beige or yellowish. The edges of the materials should not be brittle, and the water after exposure to the sheet should not become cloudy.

Sources:

- https://derevyannie-doma.com/instruktsii/steklomagnezitovyy-list-primenenie-nedostatki-plity.html

- https://greensector.ru/strojjmaterialy/steklomagnievyjj-list-sml-primenenie-kharakteristiki-montazh.html

- https://planken.guru/otdelka-i-montazh-fasadov/steklomagnievyy-list-harakteristiki-i-primenenie.html

- https://bydom.ru/news/read/steklomagnezitovye-listy—osobennosti—razmery-i-harakteristiki-materiala.html

- https://fb.ru/article/214929/steklomagnezitovyiy-list-primenenie-nedostatki-i-preimuschestva

We recommend: Antiseptic for wood - which one is better to choose and what to make it from?

Typical sizes of glass-magnesium sheet (GSM)

Considering that the material is manufactured using identical technology, manufacturers try to adhere to the same size. The standard external dimensions of the slab are 1,220*2,440 mm . The thickness of the LSU depends on the scope of application of the material and varies between 3-20 mm .

Enterprises engaged in the production of glass-magnesium sheets can manufacture products according to customer sizes, but such products are usually not available for free sale.

And now about our unique SML houses Neo Ver3.0

“The most capital of the prefabricated ones. The fastest of capital"

We recommend Neo SML houses made from new generation panels of a high degree of readiness (this is its official name) if:

- We need a modern house with high ecology ;

- there is no main gas on the site, and you need a house for permanent residence, which can be inexpensively heated even with electricity ;

- you need to quickly build a finished house and move into it, but you are not ready to buy a SIP or frame - we build Neo SML-houses on a turnkey basis in 3-4 months, a warm circuit in 1-1.5 months;

- I want aerated concrete, but there are reasonable doubts or there is no main gas for heating - our permanent house can be inexpensively heated even with electricity!

- I want a permanent house, but the site has weak soils - our houses can be built on all types of foundations, including lightweight options;

- you need an individual house designed specifically for your site and your family needs - this is how we design houses (including remotely);

- you need to optimize the budget of a finished house “TURNKEY” - the cost of our turnkey houses will pleasantly surprise you!

More information about SML panel technology:

- Marked by State support, recognized as innovative, certified .

- Received a Diploma of the National Award in the field of Ecology for the development and production of environmentally friendly products (Skolkovo).

- A report was made about the houses at the Public Chamber of Russia on the topic “Modern energy-efficient construction.”

- On the Moscow-24 in the information program “Life in a Big City”, on NTV about modern heating systems and on the Russia1 channel (videos on the right of the page).

- Houses were built in 40 regions of Russia, from Murmansk to Crimea, from Kaliningrad to Altai.

Technical characteristics of the building material

Glass-magnesite plates are manufactured in strict accordance with established standards. Therefore, the following technical parameters are typical for finished products:

- Sound insulation – up to 44 dB .

- Moisture absorption – 0.34% of the total mass.

- Bending resistance – 16-22 mPa depending on the condition of the material (dry/wet).

- Thermal insulation – 0.14 W/mK .

- Frost resistance – 50 cycles .

- Fire safety class - NG .

It is worth noting that the sheet thickness of 6 mm can resist open flame for up to one and a half hours.

Comparison table with other materials

| Density g/cm3 | Sound insulation coefficient, dB | Moisture absorption (Swelling) | Dry bending strength, mRa | Flexural strength in wet state, mRa | Thermal conductivity coefficient, W/mK | |

| OSB | 0,64 | 18 | 12% | 28 | 13 | 0,33 |

| Fiberboard | 0,8-1,0 | 20 | 18% | 38 | 4 | 0,4 |

| Chipboard | 0,73 | 19 | 22% | 17 | 3 | 0,37 |

| GKL | 0,65 | 35 | up to 30% | 2 | 0,1 | 1,45 |

| GVL | 0,85 | 37 | up to 30% | 5 | 0,3 | 1,4 |

| SML (6mm) | 0,9-1,1 | 44 | 0,34% | 14 | 22 | 0,14 |

GLASS MAGNESIUM SHEET A new step in the evolution of modern construction!

The end of the last century was characterized by the active use of new construction technologies in Russia. One of the important directions was the appearance of GYPSUM CARDBOARD on the Russian market under the leading and Knauf brands. At the moment, an alternative material called glass-magnesium sheet has entered the market, combining and surpassing the best properties and qualities of plasterboard, gypsum plasterboard, DSP, FTP.

The main indicator was its non-flammability, moisture resistance and environmental friendliness. In everyday life you can find it under various names, and as a rule, this material is positioned by consumers and trade organizations only in terms of descriptions on the Internet. In terms of application options, SML is the most economical in comparison with expensive materials of the Knauf and Giprok series; it is a promising replacement for DSP and asbestos-cement boards.

The production of LSU in China, the huge number of differences in technological processes and chemical composition do not provide 100% classification of it in any uniform standards. All that remains is to trust the specialists in this field and show special attention in your choice. It should be remembered that the choice of this material should be made only with professionals in this field. After all, just by composition and production technology, more than 7 different types and subtypes of this material can be distinguished. Magnesium chloride, magnesium oxide, magnesium sulfate, magnesium carbonate. All this can be called magnesium cement (Sorel cement) in the composition of SML.

Application area

- Dry, wet and damp areas.

- Industrial buildings and structures.

- Structures with increased requirements for sanitary and fire safety standards.

- Children's, medical and health complexes.

- Shopping and entertainment complexes.

- Residential and administrative buildings

Conditional classification of material

- Class Standard.

They are characterized by medium density, beveled edge for serpyanka tape, low moisture absorption, high sound insulation, large radius of curvature, high fire resistance and fire resistance, NG-O. - Premium class.

Characterized by higher density, straight edges, stronger material, low moisture absorption, water resistance, NG-O. - Premium+ class.

They are characterized by high density with a perfectly smooth surface for industrial roller application of acrylic coating. It is mainly used for prefabricated structures, shopping and entertainment complexes, NG-O.

Density classification

- 750–930 kg/m3 Ideal LSU option for use inside dry and wet rooms. The content of magnesium chloride and magnesium oxide in its composition is approximately the same; upon visual inspection, the structural material is moderately porous and contains wood chips. There is virtually no thermal expansion due to the low density.

- 1000–1400 kg/3 SML version for use inside dry, damp and highly humidified rooms. The content of magnesium chloride and oxide in its composition is shifted towards magnesium oxide by 2/3, which reduces the content of slightly soluble magnesium chloride salts. The structure is more dense. Used on facades for subsequent finishing and cladding. Due to the high density, the installation of facade structures of this material is carried out using a frame-cassette type system, which gives free movement and dynamism of the structure.

Classification by thickness

- 3–6 mm. option for suspended and false ceilings, installation of arches, openings and slopes.

- 8–12 mm. option for wall cladding and installation of partitions. Ideal for installing floors similar to GVL floors.

- More than 12 mm. It is used extremely rarely in Russia due to the specifics of production. Technologically, to ensure additional strength and fire resistance of the structure, installation is carried out in two layers of 6–8 mm.

Installation and finishing options

- Standard installation on the structure of rack and guide profiles with a pitch similar to gypsum boards. Installation of Premium class LSU is carried out using self-tapping screws with countersinking.

- Installation on a wooden structure using building brackets without self-tapping screws (ideal and quick option for suburban construction).

- Installation using Perlfix and Fugenfüller adhesives.

- Sealing and painting are similar to sheets of drywall.

- Excellent adhesion to any type of paint and varnish coatings, adhesive compositions for facing ceramic tiles and porcelain stoneware.

Comparison with analogues by technical characteristics

Options

| Unit | Asbestos cement board | Gypsum cardboard sheet | Cement particle board | Glass-magnesium sheet (GSM) | |

| Density | g/cm3 | 1,6 | — | 1,3 | 1,0 |

| Impact resistance | kJ/cm2 | >2 | — | — | 7,4 |

| Bending resistance force, horizontal | MPa | 14 | 1,98 | 11 | 17,6 |

| Bending resistance force, vertical | MPa | 11 | 3,89 | 7,4 | 21,5 |

| Birth saturation | % | 24 | – | 3 | 28,1 |

| Change in shape after water saturation | % | 9 | 10 | 2 | 0,9 |

| Soundproofing | dB | — | – 40 | – 54 | – 46 |

| Fire resistance (fire holding time) | min. | 75 | 43 | BY | 180 |

| Weight (thickness 6 mm) | kg/m2 | 9 | 4,5 | 7,9 | 5,4 |

Material provided by: smlplita.ru

Subtleties of choosing quality products

To buy high-quality building material, experts recommend following the following criteria:

- Hue . Light gray or completely white color of the panel indicates the use of second-class raw materials. High-quality sheets have a light yellow or beige tint.

- Angles . If the geometry of the slab is broken and the end and corner surfaces crumble, the manufacturer has violated the manufacturing technology.

- Backside . Sometimes the back surface is made of fisiolen (indicated on the packaging). Products on this basis have a reduced level of fire safety.

If possible, you can immerse the sheet in water for several hours. If sediment appears in the water, this is a sign of poor quality products.

How to choose quality material

If a manufacturer grossly violates technology in the manufacture of its products, it will not hesitate to forge documents such as a quality certificate. Moreover, the buyer is usually presented with a copy of it. It is necessary to check such documents, but this does not guarantee the purchase of truly high-quality material. Therefore, you need to be able to distinguish it from a fake by external signs.

A glass-magnesium sheet, the characteristics of which correspond to those described above, must have:

- strong and smooth edges without chips;

- yellowish or beige color;

White or gray color indicates poor quality and the presence of unnecessary components Source stroydesign.info

- different textures of the front and back surfaces;

- reinforcement with fiberglass mesh with small cells.

A material sample immersed in water does not deform after several hours, and the water does not become cloudy.