Knauf Fugen putty (formerly Fugenfüller) is intended for interior work. Its main component is gypsum, plus proprietary additives to slow down setting and increase the plasticity of the mixture. Technical characteristics allow the composition to be used when filling joints after attaching drywall, unevenness and cracks on wall surfaces.

Knauf Fugenfuller packaging

Features of use

Knauf brand Fugenfüller (Fugen) putty is stable after drying and does not form cracks. Consists of natural eco-friendly materials that are harmless to human health.

Characteristics:

- The manufacturer's recommended layer thickness is 1-3 mm. If used to seal gypsum board joints, it is applied twice;

- The consumption when working with different surfaces is different: to process drywall joints and screw heads you will need 0.25 kg; consumption for tongue-and-groove tiles – 1.5 kg/m²; continuous gypsum board coating – 0.8 kg/1 m² with a layer thickness of 1 mm; leveling plastered walls (consumption depends on the level of roughness) – 1 kg/1 m².

Extra options:

- Fraction size – no more than 0.15 millimeters;

- Compressive strength – 3.0 MPa;

- The level of bending strength is 1.5 MPa;

- To obtain a finished solution weighing 1.3 liters, you will need 1 kg of the powdery contents of the package.

The mixture is available in three varieties:

- regular "Fugen";

- "Fugen GV";

- Fugen Hydro.

Commercially available varieties

Depending on the location where the material is applied, you should choose the appropriate type of putty. The manufacturer offers putty for gypsum fiber sheets - Knauf Fugen G.V. and material for work in places with high humidity - Fugen Hydro.

The first option is intended for sealing seams and minor irregularities. In terms of its composition, this mixture has almost the same composition as the universal remedy. The differences lie in the permissible thickness of the applied layer and the consumption of the prepared substance.

To cover seams and joints, up to 600 grams of mixture is required. With a continuous application of raw materials 1 millimeter thick, up to 1.2 kilograms will be required. Otherwise, the material has similar characteristics to the universal mixture.

The second material contains special additives that allow it to be used:

- For the purpose of gluing moisture-resistant drywall to a flat surface, as well as puttying and gluing gypsum raw materials.

- For filling joints between sheets of plasterboard in damp rooms.

- As an element for filling cracks or depressions in concrete floors.

- For filling and installation of tongue-and-groove moisture-resistant slabs.

The remaining characteristics are no different from the universal composition of Fugenfüller putty. The maximum thickness of the applied layer should not exceed 5 mm. A moisture-resistant analogue will cost twice as much as universal products.

Positive qualities and disadvantages of Knauf putty

Pros:

- The product is suitable for working with drywall;

- The resulting seam is durable, and its creation requires low material consumption;

- Gypsum is a clean material that does not pollute the environment;

- After drying, the putty firmly adheres to the surface being treated;

- It's easy to work with her.

Flaws:

- Dries quickly. True, this is not always a disadvantage of the product;

- Cannot be used for large bends - maximum 3 mm;

- Complex grinding process.

Recommendations for working with gypsum putty

Gypsum putty has one property that affects the entire work process - it dries quickly. Therefore, it is more economical to use dry mixtures, since undiluted powder can be stored for a long time.

Work moment

Gypsum mixture Knauf Fugen (Fugenfüller) is applied exclusively to flat surfaces. But to smooth out cracks and roughness, the layer should be maximum - 3 mm and applied twice.

The mixture is diluted in a small clean container. The thicker the structure of the putty, the less likely it is to form lumps. But this consistency is used for repeated application, and for the first layer a more liquid one is prepared; lumps do not play a special role here, they are leveled out when distributed over the surface.

For puttying, narrow spatulas are used: 15-20, 20-25, 30-50 cm. Which one to choose is guided by the unevenness of the surface being treated.

Putty "Fugen Hydro"

From the name it is clear that the Fugen Gidro material is moisture resistant due to hydrophobic additives in the mixture. Suitable for:

- filling joints between sheets of moisture-resistant plasterboard (GKLV, GKLVO);

- gluing moisture-resistant drywall to a leveled surface, gluing and puttying gypsum products;

- filling cracks and depressions in concrete floors;

- installation and puttying of moisture-resistant tongue-and-groove slabs.

USEFUL INFORMATION: Wall preparation: how to remove old plaster

The characteristics and consumption are the same as the universal Fugenfüller composition, with the exception of the maximum layer thickness, which is 5 mm.

Available only in 25 kg bags. The price for moisture-resistant putty is almost 2 times higher than for regular putty.

Dilution of Knauf brand gypsum putty

Dilution rules and consumption are indicated on the manufacturer's packaging.

You will need a small clean container, a bucket will do. Pure cold water is poured into it (0.8 liters of liquid will require 1 kg of powder). Afterwards, pour out the required amount of putty evenly and little by little. The quantity should be such that the dry mixture exceeds the water level. Allow the putty to settle and soak in moisture for about 2-3 minutes. The mixture is mixed by hand, but you can use a mixer.

Correct structure

The use time for the solution is 30-40 minutes, so do not mix a large amount.

Fugen (Fugenfüller) (putty), 25kg

Surface preparation

KNAUF sheets must be firmly fixed to the supporting base (frame).

When puttingtying gypsum board joints formed by cut edges with a chamfer removed, treat the edges with KNAUF-Tiefengrund primer. When puttingtying gypsum board joints formed by longitudinal unedged edges, clean the surface of the joints from dust without moistening. When completely puttying, clean the surface from dirt, dust, exfoliation and remove any form lubricant residues from the concrete.

Treat the surfaces of plasterboard and gypsum fiber sheets, gypsum and cement plasters with KNAUF-Tiefengrund primer. Treat concrete and smooth surfaces with low absorbency with KNAUFBetokontakt primer to improve adhesion (adhesion). Primers are applied by brush, roller or spray. After application, allow the primer to dry: K NAUFTifengrund - 3 hours, KNAUFBetokontakt - 12 hours. Avoid dusting the primed surface.

Work order

Conditions of work

The temperature of the base and air in the room during work is at least +10°C. Puttying of gypsum board joints should be carried out under operating temperature and humidity conditions after completion of all work related to its modification, which eliminates linear deformation of plasterboard sheets. For example, if a self-leveling floor or leveling screed is installed in the room, then puttying should be carried out after they have dried.

Preparation of putty solution

Pour the dry putty mixture into a container with clean cold water, spreading it evenly over the surface until dry “islands” appear (approximately 1 kg of putty per 0.8 liters of water). Allow 2–3 minutes to moisten the poured material and mix with a spatula-trowel or mixer at low speed until a homogeneous creamy consistency is obtained, without adding more dry mixture. If it is necessary to prepare a solution for installing Knauf gypsum boards in large volumes, mixing the dry mixture with water should be done with a mixer at a low speed to avoid the entrainment of air into the solution and deterioration of its strength in the hardened state. The water temperature for mixing the dry mixture should be in the range from +5°C to +30°C. Warmer water degrades the water-holding capacity of the putty and can cause cracks in the putty. It is not allowed to add other components to the putty mixture, as this leads to a significant deterioration of its properties! Do not use a thickened putty solution; adding water and stirring will not restore its working properties. Contaminated containers and tools help reduce the length of time the material can be used. The duration of maintaining the working properties of the putty solution before thickening begins is at least 30 minutes.

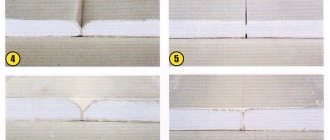

Puttying gypsum board joints

Sequence of operations when forming a joint:

- applying the first layer of putty;

- laying a special KNAUFKurt reinforcing tape or perforated paper reinforcing tape on the putty layer by pressing with a spatula, while avoiding the formation of folds and bubbles;

- applying a leveling layer of putty to the hardened and dried first layer. Puttying should be done using a spatula ~150 mm wide, preferably with a handle adapted for screwing in protruding screws, which allows you to quickly eliminate possible installation defects during puttying;

- sanding the joint after the putty has dried.

Continuous puttying

When completely filling flat concrete and plastered surfaces, apply the first layer of putty mortar and level it using a wide spatula. Apply a thinner leveling layer of putty to the hardened and dried surface of the first layer. Installation and sealing of KNAUF-gypsum board joints When installing KNAUF-gypsum board, KNAUF-Fugen solution is applied to the groove of the bottom row of slabs and to the vertical end groove. The solution that comes out is immediately removed and used in the future. Upon completion of the installation of the partition, the joints of the slabs are puttied with KNAUF-Fugen mortar.

Recommendations

After the putty has hardened and dried, remove any unevenness using a grinding tool (a grater with a sanding mesh). For high-quality painting, a layer of finishing putty, for example KNAUF-Rotband Finish, KNAUFR-Rotband Pasta Profi, should be applied to the putty surface.

Before applying a decorative coating (paint, wallpaper, decorative plaster), treat the putty surface with KNAUF-Tiefengrund primer. When covering areas of the KNAUFsheet surface that are exposed to water with ceramic tiles, the application of KNAUFFlechendicht waterproofing is required.

All tools and containers used during the work must be made of stainless materials.

Equipment and tools should be immediately washed with water after finishing work.

Storage

Store bags in a dry place on wooden pallets. Use material from damaged bags first. Shelf life in undamaged packaging is 6 months from the date of manufacture. The date of manufacture is indicated on the side of the bag. The packaging and product must be disposed of as household waste after the expiration date.

Surface preparation and application

Preliminary preparation of surfaces is mandatory, since otherwise cracks and unevenness will appear on the dried putty. To begin with, they get rid of the old finishing - wallpaper, plaster. The base is cleaned of dirt, mold and grease. Afterwards, a layer of special primer is applied using a roller; its choice depends on the type of base.

To work with finished putty, monitor the room temperature; it should exceed +10 degrees. Avoid drafts and exposure to moisture.

Puttying gypsum board joints is carried out in several stages: the first layer is applied, then reinforcing tape or a small special mesh is applied and pressed in with a spatula to avoid the formation of folds or bubbles. The final stage - applying the second layer, is done on the already dry surface with gentle movements.

If you need to cover the entire surface area of the walls, use a wide spatula (150 mm).

Knauf Fugenfüller Gv

The composition of the powder mixture is gypsum and polymer additives. Fugen Gv is used for sealing seams, gluing gypsum fiber boards, and leveling other defects in gypsum fiber sheets.

Packaging Fugenfüller Gv

- The surface must be cleaned, and the gypsum fiber sheets themselves must be firmly fixed.

- Fugen Gv Knauf putty can be diluted, like others based on building gypsum.

- The contents of the powder are poured into cold water, allowed to brew for 2-3 minutes, and only then kneaded by hand. Operating time – 40 minutes.

- There should be no sudden temperature changes during repair work. The seams are filled with GV putty, the excess is wiped off.

- After complete drying, apply a second layer. At the end of processing, roughness and unevenness are eliminated using sandpaper and mesh.