A damp, poorly ventilated bathroom environment is corrosive to most building materials. Therefore, it is important to take into account their moisture-proof properties, giving preference to those that are more stable.

Manufacturers of ceramic tiles have done everything in their power to ensure that this finishing option is optimally suited for bathroom decor. The tile does not allow or absorb moisture, but water penetrates into the seams between it, violating the integrity of its structure, the adhesive layer and creating a favorable environment for mold growth. To protect these vulnerable areas, construction grouts are used.

Description

Water-repellent impregnation for seams LITOLAST in a 0.5 kg package is a waterproofing agent that is used for seams and facing materials. Used for processing brick, ceramics, concrete structures and other materials. It prevents the penetration of moisture, but does not affect the vapor permeability of treated surfaces, as it is absorbed without leaving a film.

Advantages:

- does not provoke adverse reactions;

- does not change the color and tone of the surface;

- In addition to moisture protection, it prevents the development of fungus, efflorescence and mold.

In the Leroy Merlin store chain you can profitably buy LITOLAST water-repellent impregnation for seams in a 0.5 kg package and other compounds for treating facing materials at affordable prices.

How to make the right choice

Grouting is a critical process that completes the laying of tiles. Unsightly seams can disfigure even the most expensive tiles. Grout transforms the appearance of the bathroom and prevents the penetration of moisture, the growth of fungi and the formation of mold.

Based on all this, the grouting composition is selected in the store. Cheap mixtures, as a rule, do not provide sufficient protection for joints, therefore, when purchasing inexpensive grout, you need to add antifungal, dirt-repellent additives and sealant yourself.

When buying grout, pay attention to what coatings it is intended for. Most expensive grouts are produced as universal ones, designed for processing joints between ceramic tiles, mosaics, concrete tiles or porcelain tiles.

The trade includes materials from Russian and foreign manufacturers. Among them are the following brands:

- "Ceresite". German manufacturer of building mixtures with more than 100 years of history.

- "Atlas".

- “Mapey.” Italian manufacturer producing mixtures for household and industrial use.

- “Sopro.” German grouts are also of high quality.

It’s easy to get confused in the variety of brands and manufacturers, so the choice must be made based on the popularity and demand for a particular grout. In this matter, it would not be superfluous to consult a professional.

Grouting tiles in the bathroom

Why do you need to treat tile joints? The bathroom has the highest humidity, which means that when making renovations, it is necessary to use materials that have good moisture resistance. Rubbing on the seams protects the finish from moisture, mold, dust and dirt. Accordingly, if you cover it with a protective mixture, the service life will be extended.

In order for a material to protect the coating well, it must have the following properties:

- waterproof; a good choice would be a material with high protection against water penetration under the facing material;

- degree of absorption of excess moisture;

- what will be the shrinkage of the grout itself to the base;

- strength.

Modern manufacturers offer several types of grout. There are four main types of grout for tile joints:

- cement joint protection;

- epoxy;

- silicone surface treatment;

- varnish for grouting on joints.

Surface treatment with silicone grout in the bathroom is used only if the joints are porous. Do not use this sealant on ceramic tiles. The purpose of this material is to seal the coating.

Carefully polished white tiles in the bathroom

Updating the sealing of joints

If over time the seams become dirty, there are two ways to give a fresh look to the tiled surface in the bathroom.

Coloring with pencil

You need to wash the seams with cleaning products, wait for them to dry and cover them with a water repellent. Construction stores sell a special pencil for grouting, made in the form of a marker. The product will do an excellent job of cleaning tile joints in the bathroom, since the solution included in its composition can destroy mold and prevent the formation of fungus.

When cleaning tile joints, many housewives use not only industrial cleaning products, but also resort to old folk methods:

- To eliminate fungus or mold that has appeared on the seams in the bathroom, you need to treat the surface with a solution of vinegar, ammonia and water softener.

- Another remedy for removing moldy stains is alcohol. It must be applied to the joints with a small brush (an old toothbrush will do), leave for a while and wipe off the dirt.

- An aqueous solution of antifungal drugs (Nystatin) will also help to remove mold in the bathroom. To prepare the solution, simply dissolve the tablet in a small amount of water.

- To bleach light-colored joints, you can use regular household bleach with chlorine. Simply fill the seams with mortar and brush them.

- If the joints are heavily soiled, you can sprinkle baking soda and pour vinegar over them. The foam formed as a result of a chemical reaction will simply push out the dirt, and it can be easily washed off with water.

When working with cleaning products (even those you prepare yourself), you must comply with safety precautions: wearing rubber gloves, and, if necessary, a respirator.

Update

You can update the grout like this. Remove the old coating using a regular construction knife or a special “stitcher”. The choice of tool is an individual matter, the main thing is that the tool does not leave scratches or other damage on the surface of the tile.

If the old layer is very hardened and cannot be removed by normal mechanical action, then the grout can be treated with a special softening compound. It’s worth noting right away that you won’t be able to remove epoxy putty yourself - this is a job for professionals. Then:

- After cleaning the seams, treat the ends of the tiles and joints with a primer;

- perform fresh grouting;

- When the grout is dry, you can begin applying the hydrophobic solution.

To ensure that the lined surface lasts as long as possible and looks like new, it is recommended to renew the grout every 3-5 years.

Many people mistakenly believe that light-colored grout is more susceptible to contamination than dark-colored grout. In fact, they get dirty in exactly the same way, but the dirt stands out more against a light background. It is possible to preserve the aesthetic appearance of a ceramic tile coating only if you follow the technology for laying and grouting it and provide proper care.

Area of use

Tile varnishing is used for the following types of coating:

- cladding with cement-based joints;

- ceramic tiles that absorb moisture, for example, varnished Tuscan tiles or terracotta;

- protection of natural stone or bricks;

- treatment of concrete surfaces, including walls and floors;

- agglomerated or natural stone, all kinds of paving slabs;

- processing of clinker tiles.

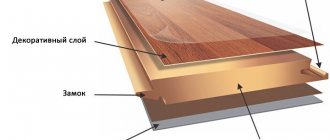

Cement mixture for tile joints

The material, which is based on cement, is traditional; it is used for coating in the bathroom. This type of protection treatment is inexpensive. The cement mixture consists directly of fine cement and other additives. When water is added, the mixture becomes similar in its properties to putty.

If you need a distance between ceramics of at least 5 mm, the grout composition involves adding water. If it is necessary to process a wide seam, then sand is added to the structure, which, in turn, prevents the composition from spreading over the entire surface and holds it in the joint. If there is a large distance between the tiles, then the sand that is added to the mixture being processed should also be coarse.

Depending on your experience and preferences in the field of repair work, you can buy ready-made or dry cement grout.

The ready-made composition is easy to use, it does not need to be diluted, which means it will take less time to prepare it. However, there is one drawback to this - the finished mixture dries out quickly, you need to do everything quickly and carefully, since the entire volume of the jar must be consumed in one hour.

The second grouting option is more relevant - dry. By purchasing one jar of consistency, it becomes possible to use it for several rooms. The only difference is that the dry powder is diluted with water or latex, only in the amount necessary for the use of the room. It is important to note that the latex plasticizer will well protect the material after grouting from the development of various microorganisms. The dry mixture is very convenient for repair work, since you can take the required amount and dilute it, and this mixture can also be stored without problems.

The main advantages of cement grout:

- ease of use of dry and ready-made mixtures;

- wide choice of colors, you can choose the desired shade for the tile;

- resistance to moisture;

- wide range of use.

The disadvantage is that the service life is short. This is affected by pollution, household chemicals and detergents.

Places of grout application

There are several types of seams in the bathroom, between which the application of a protective grout is required. They are conventionally divided into 3 categories:

- There are seams between individual tile elements, but this category requires the most time and material to process. The smaller the details of the tiled layout, the more effort is required to seal them. The mosaic takes up the most attention;

- Joints between the bathtub and the wall. To prevent liquid from penetrating into hard-to-reach places under the bathtub, this space must be sealed;

- Seams of skirting boards, borders, fillets. Sealing the gaps between these elements and the cladding is necessary to prevent water seepage and mold formation.

Builders divide the seams between tiles into thick and thin. Thick ones are those that are more than 5 mm. A thin seam is considered to be if it is less than 5 mm; despite its small size, its sealing is necessary.

Experienced craftsmen advise avoiding thick seams between bathroom masonry elements, since coarse sand is added to the fugue to process them, which reduces the density and strength of the composition.

Characteristics

Weight, kg 0.532 Application surface material Cement, Tile, Plastic, Glass, PVC, Laminated, Brick, Gypsum, Gypsum board, Concrete Color palette White Country of manufacture Russia Place of use Internal Purpose Internal / external

Prices and availability may vary. Please check the exact cost and availability of goods in stores.

28.00 Set of spatulas Sibrtech white rubber 40/60/80 mm, 3 pcs. 218,00 Kit for removing/leveling sealant Dexter 105,00 Tool for grouting Dexter 212,00 Scraper for cleaning tile joints Dexter 105,00 Electric mixer attachment for paints and mixtures 80x400 mm 118,00 Blade for cleaning Dexter seams 3 pcs. 73.00 Bucket 5 l, food grade plastic 11.00 Crosses for tiles, 1.5 mm, 100 pcs. 18.00 Crosses for tiles, 2 mm, 100 pcs. 176.00 Axton plasticizer, 0.6 l 252.00 Dexter grout trowel, 230x100 mm 315.00 Dexter trowel trowel, 240x100 mm 552.00 Cement deposit remover, 1 l 465.00 Dexter 2in1 folding knife 60.00 Knife 18 mm two-component handle 1 blade 105,00 Spatula for grout and adhesive “2 in 1” 680,00 Axton universal cleaner, 5 l 130,00 Dexter double-sided sponge for cleaning tiles 380,00 Set of sponges for removing grout Dexter 880, 00 NEO table scales, 24.5x16.8x2 cm, chrome 156.00 Dexter masking tape 48 mm x 50 m 140.00 Napkin, 35x35 cm, microfiber, 4 pcs. 620,00 Epoxy residue cleaner Osnovit “Plitsave” SE1 0.5 kg Show all Related products

The best manufacturers

Popular grout manufacturers produce mixtures of all types and colors; there is no point in listing the assortment. And considering that fugues from industry leaders are of equally high quality, it is difficult to compile a rating. It’s better to talk about the nuances of the product.

Ceresit

Under the Ceresit brand, a line of building mixtures is supplied by Henkel. A special component of the product is the antifungal additive MicroProtect, on the basis of which the biocide concentrate CT 99 is also produced. The company also advertises the Aquastatic effect, which any Ceresit water-repellent mastic has. But this is simply the presence of latex.

MAPEI

The products of this Italian company also include anti-mold and waterproof materials of their own design. A certain organic additive BioBlock fights fungi by preventing the development of spores. Water flows off MAPEI grout in drops thanks to Drop Effect technology.

LITOKOL

LITOKOL is also from Italy. It has not been caught enriching the product with exclusive additives, but, among other things, it produces the popular latex additive IDROSTUK for mixing cement mixtures.

ATLAS

The Polish concern ATLAS announces three innovations in its fugues. COLOR PROTECT technology makes the color stable, protects against fading in the sun, and prevents contamination. Hydrophobicity is provided by EFEKT PERLENIA with certain special molecules. Well, where would we be without protection against fungus? MYKO BARIERA is responsible for this.

Protective layer

A good two-component grout initially has a protective layer, which appears as it dries. We draw your attention to two important points.

First: my technical experience has shown that if you rub the grout on a glossy (smooth, non-porous) tile or glass mosaic and, without washing it, leave it for 24 hours until the first stage of drying, a protective layer is formed and the grout acquires a glossy tint. We placed emphasis on glossy (smooth, non-porous) tiles, since the smooth surface does not absorb grout, and grout residues are easily removed without damaging the protective layer, unlike working with porous (rough) tiles. For large tiles it would be good to use masking tape, but this is only done by craftsmen who really love their job.

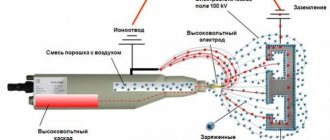

The second important point: if you, following the instructions indicated on the pack, begin to remove the remaining grout after 20-30 minutes, you will erase the protective layer that has not yet formed. Practice shows that even if you touch an uncured seam with your finger, a protective layer will not form in this place, not to mention working with a sponge and a wet rag. If a natural protective layer is not formed, the grout may change its color tone relative to the actual color, resulting in a difference similar to that between glossy and matte colors. Without a protective layer, the matte grout will be slightly lighter. But the formed protective layer itself is very fragile and does not last long: if you apply a slight mechanical force, pick, scratch, then a scratch appears in this place. There are 2 types of additional protection: the first is impregnation for seams, the second is varnish for seams. The fundamental difference lies in the quality and contrasting color change of the grout.

Impregnation in a plastic container (water repellent) is a liquid with large molecule sizes, which is used to treat already dried grout, resulting in a surface protective layer that wears off over time; this procedure must be repeated ad infinitum 2-3 times a year.

Impregnation in metal containers has a smaller molecular size, thereby penetrating deeper into the structure of the grout and strengthening at its base, in contrast to impregnation with large molecules. Not every impregnation varnish is suitable for the job, but only a strictly specialized one; in particular, you should not coat cement grout with parquet varnish just because it is a good varnish! You should also not use polyurethane varnish, which leads to a complete color change. You should only use polymer impregnation varnish - a special moisture-resistant varnish for cement grout.

The protective layer is the final step in proper grout processing. A layer of varnish makes the grout completely moisture-resistant, resistant to cracks, scratches and firmly fixes the color of the grout, making it glossy and rich. The varnish forms a complete and final waterproofing, preventing the very first moment of absorption; this effect is also called the “drop effect”, when moisture falling on such a seam is not absorbed by the grout, but is collected in drops. This varnish provides 100% protection against fungus in damp rooms and eliminates the hassle of cleaning grout on aprons, where grease and fumes love to be absorbed. If you don't like glossy varnish, there is a matte, non-color-changing grout.

And in conclusion, if you buy a more technologically advanced material for filling joints, prepared not on the basis of cement but on the basis of epoxy resin, then you will not need all these complexities with latexes and impregnations. But you will have other difficulties with acids that wash the surface of epoxy residues and with the acquisition of specialized tools. And in my opinion, the most important difficulty with epoxy materials is the catastrophic lack of experienced craftsmen who know how to use this material. But I physically cannot help everyone.

Important rules for caring for porcelain stoneware floors

If simple stains are visible on porcelain tiles, remove with a damp or dry cloth. If the contamination is more complex, then use cleaning products that contain acids. Maintenance of such floors is carried out without the use of abrasives, which are used in extreme cases. Indeed, despite the high strength of the material, abrasive particles that are present in detergents cause harm to the tile surface.

Dirt brought from the street on the soles of shoes also acts as an abrasive, especially if there is sand in the composition, so you should always clean porcelain stoneware floors to prevent further contamination, which is more difficult to deal with. If the dirt is dry, vacuum it up, then wipe the floor with a damp cloth. If you regularly and properly care for such floors, then they will serve faithfully for decades and will not lose their attractive appearance throughout.

But tiles made of polished porcelain stoneware require serious care, because the slightest scratch or minor chip is noticeable on the glossy surface of the tile and spoils the appearance of the floors. Polished porcelain tiles must be constantly cleaned with a vacuum cleaner, soft brushes and wiped with a damp cloth. It is better to use a product designed for cleaning porcelain tiles, polish out minor imperfections on the surface of the tiles and give the flooring a flawless appearance. After this treatment, the seams will not be damaged because the polish does not contain acids.

Treated and untreated tile surface

Epoxy grout

These grouts, as the name of the group suggests, are based on epoxy resin. In addition to it, the composition contains pigments and other components that give color and hardness. This type has many advantages:

- Moisture resistance;

- The density of the joints between the tiles;

- Not afraid of exposure to chemicals.

Now in building materials stores you can buy grouts with various external effects, for example, metallic shine, golden tint, pearlescent.

A distinctive feature of these grouts is their increased viscosity. Because of this, they are more difficult to apply than cement ones. In addition, in case of accidental contact with it, it will be possible to clean the front surface of the tile only with the use of chemicals.

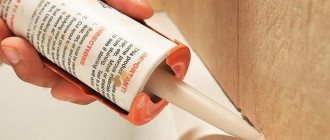

This grout is applied using a special bag, similar to a pastry bag for squeezing out the cream.

If you do not have at least minimal experience working with such materials, then it is better to start with a professional.

The third type, furan mixtures are rarely used in apartments due to their dark color. They are mainly used in industrial premises.

Benefits of using protective and cleaning products for porcelain tiles

High-quality protection of porcelain tiles will extend the service life of the material, so you should not save money on compounds that provide protection to the floor covering. Today there is a large selection of impregnations that ensure the safety of tiles. The advantages of such funds are undeniable:

- Ensure the integrity of the tile structure.

- Protect the tile surface from streaks and oil stains.

- Effectively fights the appearance of fungi.

- The surface of the floor covering, which is lined with porcelain tiles, becomes water-repellent and becomes resistant to chemicals. influences.

- Allows you to effectively and quickly clean the tile surface.

- The operating time of the floor increases.

- The level of abrasion decreases.

- A universal product used for processing various facing materials.

- Impregnated floor tiles look attractive.

- Such products are environmentally friendly, so you can safely use them in your home and not worry about your health.

Attention! Impregnation, which provides care for porcelain stoneware, creates a long-term effect: after applying several layers, you can not repeat such actions for a long time. However, when applying the composition, it is necessary to first test it on a small area of porcelain tiles.

Brief plan

In order not to spend too much time worrying about it, for those who already know how to grout tiles, but just want to briefly remember everything, we’ll lay out a brief plan:

- Selecting the shade of the mixture

- Mixing the solution

- Infusion of the solution (5 -8 minutes)

- Grouting joints

- Removing excess with a rag

- A day later - final cleaning

And for those who want to familiarize themselves with each item in more detail, we advise you to familiarize yourself with the finishing work.

Smoothing seams

While the grout has not yet completely dried, you need to remove excess from the tile joints and give the joints the same appearance.

Wet the fiber sponge and use the damp sponge to gently rinse the seams. This will remove excess grout and smooth out any unevenness. Periodically wet the sponge in water.

Bottom line

Jointing tile joints is not an easy task. By applying the tips from the article, you can achieve good results. Before you start grouting all the seams, you can practice in an inconspicuous place to “get your hand.”

Specifics of the work

After the adhesive has dried, it is necessary to clean the seams from dust and debris. Then the dry mixture is added to the water prepared in the container and stirred with a drill with a mixing attachment. Pour the remaining water into the container and leave for 10-15 minutes. and mix again. When preparing grout with your own hands, dilute enough mixture to last for 25 minutes. work.

The treated space is conventionally divided into sections of 1.5-2 m. For better adhesion, the seams are moistened with a regular brush. Filling the joints with the mixture is done with a rubber spatula. The composition needs to be slightly pressed into the space between the tiles. Areas in corners and hard-to-reach places are treated especially carefully. Excess mixture is removed with a spatula. Dried material is removed with a sponge soaked in water.

Choosing a high-quality grout will help you ensure the reliability and durability of the cladding. At the same time, you guarantee an attractive appearance in accordance with the chosen interior design style.

Technology for caulking joints

When choosing a ceramic tile finish, most often they discuss the characteristics of the tile itself: its design, laying technology and other points. The execution of tile joints is remembered much less often, but it is the quality of the grout that determines how the entire surface will look.

From the variety of related finishing materials, the following types of grout are distinguished.

Epoxy mixtures

They are resistant to chemical attack, temperature fluctuations, mold and mildew, and are easy to remove dirt from. Due to its resistance to aggressive external factors, this grout is widely used when treating rooms with high humidity (for example, in a bathroom or shower).

However, only professionals in their field can work with epoxy compounds, since the consistency of the solution is quite viscous and requires great care.

Polymer compositions

They have significant advantages:

- plastic consistency;

- low shrinkage of seams;

- independence of the speed and quality of hardening from temperature and humidity;

- frost resistance;

- ease of cleaning the tile surface from excess mortar;

- hydrophilic surface.

However, if we compare this composition with epoxy, it is significantly inferior in strength. To increase the strength of the solution, liquid polymers are additionally added.

Cement putty

This is the most common type. It owes its popularity to its reasonable price and simplicity of application technology.

To make grout, just pour the dry mixture with the required amount of water in accordance with the instructions indicated on the package. After the joints have dried, you can remove the white coating formed on the tiles with a regular sponge moistened with water.

Such seams are susceptible to contamination, and under the influence of moisture they can darken or crumble, so to preserve the appearance of the coating they must be impregnated with a special solution with a water-repellent effect. Some craftsmen add a primer when mixing the solution to give the cement composition water-repellent properties.

The grout is applied using a rubber spatula, pressing the solution into the gap between the tiles, or a special bag, which in its principle of operation is similar to a pastry bag.

A grout bag is most often used when working with polymer or epoxy compounds.

Care instructions

After finishing work, the material must dry completely. As a result, it becomes moisture resistant, which allows you to regularly maintain the coating: clean the surface with a damp cloth, wash the floor.

It must be remembered that cement is less resistant to constant exposure to water.

For this reason, it is recommended to care for the coating, the seams of which are filled with cement-based grout, using a damp cloth.

How to prevent cracking?

To avoid such troubles, it is necessary to mix the material correctly. Use the exact amount of components specified in the manufacturer's instructions. In this case, the finished solution should be characterized by a uniform consistency, without fractions. While preparing the grout, take a break for 5-6 minutes, then continue stirring it.

After finishing the work, while the mixture dries in the space between the tiles, the room should not be ventilated. It is also not recommended to use hot water, as this produces steam, which can negatively affect the properties of the material.

Application of water repellent

It is recommended to apply impregnation no earlier than 7 days after grouting, so that the surface is completely dry. In rare cases, impregnation can change the color of the grout, so to avoid unpleasant surprises, it is better to carry out a test treatment in a hidden area.

The processing temperature recommended by the manufacturer is indicated on the packaging. However, there are general requirements: processing must be carried out at a temperature not lower than +5°C and not higher than +30°C and a relative humidity of at least 80%. Therefore, when working with such solutions in rooms with high humidity (bathroom, sauna, swimming pool, shower), it is necessary to clarify the indicators using a hygrometer.

Applying water repellent to seams

Protective impregnation with water repellents is carried out with a thin brush, carefully along the seam. If the solution gets on the tile, its surface may become cloudy. To avoid damage to the finish, it is recommended to seal the edges of the tiles with masking tape. Water repellents may penetrate into the grout, so a second coat will be required to provide a water-repellent finish.

The nuances of working with floor tiles

It is impractical to apply grout separately to each seam if the products that make up the decorative coating are characterized by minimal dimensions. In this case, the amount of work will increase, since a large number of seams will need to be filled.

It is recommended to use a hand float with a rubber pad on the base.

With its help, you can immediately fill seams in a limited area. The movements should be sweeping. Then you just need to clean the coating from any remaining grout. But this method will not work if the tile is embossed.

What should be the optimal seam width?

The most suitable option is to place the tiles at a distance of 3-4 mm from each other. However, the width of the seams can vary from 0 to 10 cm. Moreover, the absence of seam joints is justified only when tiles with a cut edge are used.

The distance between the tiles should not be made too large, as this reduces the resistance of the grout to loads.

Plasticizers - latexes

It is recommended to dilute cement grout not with water, as written in the main instructions, but with plasticizers (emulsion, the second component). Each company that produces grout also adds a plasticizer to it, but this does not mean that for each grout you need to use only its own plasticizer. Our technical experience has shown that it is best to dilute the grout with a plasticizer on a transparent latex base for unchangeable grout colors or with concentrated latex to change the colors of the grout to a brighter or darker direction.

The plasticizer makes the solution more plastic, which is convenient for the master who works with it, and is important for the final result, since when sealing seams, the grout, due to its greater elasticity, fills the entire seam cavity. If the grout is not plastic and does not completely fill the volume of the joint, then voids may form, ultimately leading to cracks.

Let's consider a latex plasticizer: one type of plasticizer is added to cement waterproofing, and the main liquid component - latex - is evenly distributed throughout the mixture, making it completely moisture resistant due to the crystallization of latex throughout the entire volume of the mixture. Therefore, if you need to achieve a high degree of moisture resistance, then the grout should be diluted with a latex plasticizer. It also makes the mixture stronger in bending and compression - this allows not only to fill seams on seamless surfaces, but also to create very wide seams up to 10 cm. Along with improving the mechanical strength of the material itself, the color fastness to abrasion also increases. The grout does not fade when using cleaning agents during washing. Don’t believe the advertisements and the labels on the packs that say ANTIBACTERIAL cement grout which is diluted with water and is not subsequently covered with anything - nonsense! To achieve antibacterial properties, it is necessary to use moisture-resistant latex and cover the cement joint with special impregnating varnishes.

I would like to note these basic qualities, and ultimately I guarantee you that all the properties of the grout when using latex increase by an order of magnitude. Latexes are also used in expansion joints with positive temperatures (for example, heated floors) and negative temperatures (unglazed balcony or building facade). The only disadvantage of latex is the cost of additional funds.