Adhesive sealant for seams, gray

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

What are silicone wall holders (video)

Silicone Velcro are modern holders that ensure reliable and secure fastening. If done correctly, suction cups can last for many years. It is important that the material from which they are made is of high quality. You should check that there are no roughness or bumps on the surface of the Velcro. You should also pay attention to the surface of the tile itself - it should be smooth. Any defects will lead to the fact that the suction cup will not hold and will often fall off. The suction cups hold well if they are attached to the sealant.

The best posts

Adhesive sealant for seams, brown

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

Especially often, mold occurs in various seams, which is understandable, since the flow of air there is difficult.

Therefore, reliable sealing of seams is also the prevention of mold in the apartment.

On straight sections of walls or floors lined with ceramic or other tiles, special cement-based grout mixtures (they can be colored) or epoxy compounds are used to fill the tile joints when there is strong chemical aggression or large mechanical loads.

Elastic sealing materials are used at seams between dissimilar materials or in places of possible deformations of the building (internal corners of rooms, half-wall junctions).

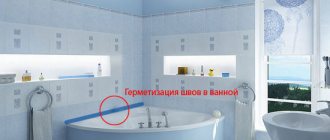

The seams between the bathtub and the tiles, all joints: the sink to the wall, the toilet to the floor, are usually sealed, and all openings for communications are also sealed.

However, recently craftsmen have also been using sealants for gluing tiles, as well as for filling tile seams.

When laying tiles on silicone sealant

Ceramic tiles as a type of finishing material have been used by people for centuries. Thus, already in Ancient Rome, the houses of wealthy citizens were decorated with granite and special slabs. Nowadays it is difficult to find a human home that does not have tiles. It is used to decorate kitchens, bathrooms, saunas, hallways and corridors. At the same time, in order for the tile to be durable, it is extremely important to follow the correct technology for laying it.

Not so long ago, in our country, tiles were laid only on cement mortar. However, this method is not very good; therefore, when tiles get old, they often fall off the walls. Today, special mixtures are used during masonry; they have excellent adhesive properties and allow tiles to be attached to literally any surface.

However, there are exceptions, for example, painted walls cannot be laid with tiles using adhesive dry mixtures, so in such cases craftsmen use silicone sealant. Let's consider the advantages of this method of fixing tiles.

Is it possible to use sealant for gluing tiles and grouting joints, and what is it for?

Tiles are the best choice for finishing bathroom walls and floors. For the floor, tiles made of more durable porcelain stoneware are also sometimes used.

However, in any case, this tile must be glued with something and the seams between the tiles must be filled.

Important!

The width of the joints between the tiles depends on various factors: the size and shape of the tiles, the designer’s intentions, and technical capabilities. Typically, wider joints are left for large or shaped tiles. Standard size tiles (up to 60 cm on a side) are usually laid with joints of about 6 mm wide. Seams narrower than 3 mm can be difficult to fill with grout, so they are rarely used; Seams wider than 12 mm are also usually not made, because there is a risk of cracking.

Typically, special tile adhesive is used to glue tiles. It is applied in a layer of a certain thickness, making it possible to further level the tiled surface. On the floor, tiles must be laid with cement-based adhesive so that the coating can withstand mechanical loads.

Tiles on walls are sometimes glued with sealant rather than glue.

In this case, the sealant, unlike tile adhesive, is applied to the tile in a thinner layer, so it will not be possible to further level the coating. The sealant dries quite quickly, which, on the one hand, allows you to carry out work quite quickly, on the other hand, it requires a certain skill.

Another disadvantage of gluing tiles to sealant is the high price of the latter, compared to tile adhesive.

Why use sealant to glue tiles?

The fact is that in some cases it is justified.

If the tiles are laid on a movable base or a base made of material subject to vibration due to shock loads, deformation from moisture or temperature changes (for example, wood, plasterboard, asbestos cement boards), an elastic connection is required, which cannot be provided with tile adhesive, and sealant in this regard will be appropriate, as it has the necessary elasticity.

Mounting on a moving base

Most modern materials are highly mobile. They can become deformed, move in different directions, vibrate, etc. These materials include wood or plasterboard sheets.

The glue on these bases will crack. This circumstance will lead to the dismantling of the tiles.

Silicone sealant retains its elasticity over a long period of time, which prevents deformation.

Adhesive sealant for seams white

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

Adhesives for tiles, stone and insulation

Tile adhesive ensures the strength of fixation of the finishing material, makes the structure durable, resistant to negative external influences: both mechanical and atmospheric. When choosing, you should take into account many factors; only this approach will provide a truly high-quality result.

Features of choosing the best tile adhesive

When purchasing, you need to be guided by the following factors:

You should also focus on the group to which the tile adhesive belongs:

The Leroy Merlin chain of stores offers products from the world's leading manufacturers at very low prices. To choose the best option, contact our trained consultants for help.

Leroy Merlin offers a wide selection of goods at low prices for residents of Moscow, as well as the cities of the Moscow region: Balashikha, Podolsk, Khimki, Korolev, Mytishchi, Lyubertsy, Krasnogorsk, Elektrostal, Kolomna, Odintsovo, Domodedovo, Serpukhov, Shchelkovo, Orekhovo-Zuevo, Ramenskoye , Dolgoprudny, Zhukovsky, Pushkino, Reutov, Sergiev Posad, Voskresensk, Lobnya, Klin, Ivanteevka, Dubna, Yegoryevsk, Chekhov, Dmitrov, Vidnoye, Stupino, Pavlovsky Posad, Naro-Fominsk, Fryazino, Lytkarino, Dzerzhinsky and Solnechnogorsk. You can order the necessary goods online with delivery to all these cities or visit one of our retail stores in Moscow and Moscow Region.

Adhesive sealant for seams black

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

Criterias of choice

Before purchasing any construction sealant, you need to know the conditions in which it will work.

The right choice requires answering the following questions:

- for external or internal work you need a sealing compound;

- what materials he should bind;

- will the dimensions of the seam closed by it change due to external loads (how much and how often);

- whether the sealant will be exposed to temperature, and how high this temperature will be;

- whether the seam will be affected by moisture (constantly or rarely);

- degree of contamination of the seam (whether the joint will be cleaned of rust and dust);

- Is the seam supposed to be painted?

- should the composition contain antibacterial additives;

- acceptable level of environmental friendliness.

Let's give a simple example of such an analysis. Let's say we need to seal the joints between the boards laid on the floor in the apartment. Obviously, for this you will need to buy a sealant intended for interior work.

Its elasticity should be maximum (the seams constantly change their size). The composition should not be very sticky, otherwise we will not be able to dismantle the boards. In addition, the purchased composition must be environmentally friendly, moisture resistant and designed to seal littered seams.

In terms of chemical activity, the sealant should not be aggressive, otherwise the varnish will suffer after such work, and the remaining substance will not be able to be cleaned from the surface. To ensure that the treated seams do not stand out, it is better to buy a colorless sealant.

Adhesive sealant for seams, gray

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

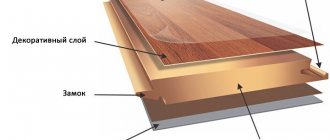

Types of compositions for processing laminate locks

The flooring market offers a large selection of specialized compounds for treating laminate joints:

- Sealant gels;

- Silicone sealants;

- Acrylic sealants;

- Wax compounds;

- Mastics;

- Grout;

- Liquid plug.

What to choose?

Sealant-gel for laminate

Specialized sealants have become very popular among compositions for treating laminate locks. They are sold in stores that sell flooring. They are usually packaged in tubes of 125-150 grams and look like regular toothpaste. The consistency of the composition is more like a gel for gluing laminate panels. The color can vary from matte white to completely transparent.

Main properties of gel sealant:

- Use at temperatures from minus 20 to plus 40 degrees;

- UV resistance;

- Water resistance;

- Elasticity.

Working with him is not at all difficult. The gel for gluing laminate joints is applied in a thin layer to the ridge of the lock, and the panel is immediately connected to those already laid. After this, as usual, a hammer is made to seal the joint. Excess sealant squeezed out of the lock must be immediately removed with a dry cloth or, after drying for a short time, cut off with a plastic spatula.

How to properly use the gel sealant, carefully read the instructions for use of the selected composition.

Laminate panels glued together have a number of advantages:

- The gel increases the water resistance of the floor covering, preventing even a few drops of liquid from getting onto the inner surface;

- Due to good elasticity, after prolonged use, the structure of the floor will not collapse;

- The flooring will not lose its appearance, even if the room is left without heating in winter.

What is silicone sealant for laying laminate flooring?

It consists of the following components:

- Silicone rubber is the basis of the composition;

- Adhesive primer that enhances adhesion to the surface;

- Plasticizer that increases elasticity;

- Vulcanizer, which makes the frozen composition look like rubber;

- Antifungal agents;

- Dye.

The consistency of silicone sealant is similar to a creamy mass. It is thicker than gel. Depending on the dye used, the composition may have different colors. The most common colors of sealants are white, beige, black and transparent.

Basic properties:

- Elasticity;

- Durability;

- Resistance to moisture;

- Resistance to elevated temperatures.

If you need to replace one of the laid panels, this will not create problems. Silicone sealant does not bond them as tightly as other products. Laminate panels with sealed joints can be separated without problems. Silicone-based protection is safe for both the flooring installer and the occupants of the home. The only exception is individual allergic intolerance to one of the components of the sealant, but this is noted in isolated cases.

It is important to choose the right color of the composition in order to hide the joints of the laid laminate panels as much as possible.

Acrylic sealant can be used as a means for gluing laminate panels. It includes:

- Acrylic;

- Calcium carbonate (chalk);

- Titanium dioxide (to give a snow-white color);

- Plasticizer;

- Other additives to improve properties.

Acrylic sealant is made on a water basis and does not contain toxic substances harmful to humans. This makes its use absolutely safe, environmentally friendly and easy to use.

Acrylic sealant is inferior in popularity to silicone, but has a number of advantages:

- The cost is lower than that of gel and silicone analogues;

- High adhesion to porous surfaces;

- UV resistance - does not turn yellow over time;

- Acrylic has the property of vapor permeability, which allows condensation to erode from the inner surface of the floor covering;

- Easy to use - you can easily touch up after styling, and wash off excess with warm water;

- More aesthetic seams than silicone sealant;

- After drying, the treated surface can be painted.

In addition to the advantages, there are also several disadvantages due to the manufacturing technology and composition of the product:

- Limited use - only in heated dry rooms (if the composition does not contain additional components that ensure frost resistance and moisture resistance);

- After a few years, acrylic sealant becomes brittle and begins to peel off from the treated surface.

The use of acrylic composition is varied, but it is most suitable for processing seams and joints indoors. Acrylic-based products are resistant to exposure to low temperatures, outside air, and the contact of significant amounts of moisture on the surface.

Read the labels on the packaging carefully. If the markings “moisture-resistant” and “frost-resistant” are found, then the use of such acrylic sealant in rooms with high humidity and for outdoor use is allowed.

Acrylic colored sealants are selected taking into account the shade of the floor covering. The correctly selected composition will provide a high degree of camouflage of treated seams.

Acrylic sealant is packaged in buckets, tubes or cartridges. This is a universal composition that has many uses in everyday life. In addition to being used for gluing laminate panels, colored acrylic sealant is often used:

- in the process of assembling furniture;

- for sealing seams and cracks in wooden walls;

- to eliminate gaps when installing plumbing fixtures;

- for filling joints of various types of floor coverings;

- at junctions of any building structures.

Application of the composition is carried out similarly to other types of sealants. It is allowed to apply a thick layer up to 15 mm wide, as well as the use of additional sealing cords. This is especially true when sealing seams between flooring and walls and between different types of flooring. For example, between laminate and tiles.

Wax for laminate

Along with sealants, various wax compositions are often used to improve the performance properties of laminate flooring. What is remarkable about wax for joints and how relevant is its use?

There are laminate models on the market that are already impregnated with wax at the production stage. Such products are very convenient to use, since no additional work needs to be done during installation. Natural wax repels water, preventing it from entering the unprotected part of the panel - the lock. This increases the water resistance of the floor covering and expands its scope of application. However, you have to pay for convenience - wax-impregnated laminate is more expensive than usual.

If you want to save money, but at the same time ensure high resistance of the floor to moisture, you can treat the locks yourself during installation. How to properly wax laminate seams?

For greater savings, you can use paraffin. It has similar properties and method of application.

Work should be carried out in a warm room to minimize the drying time of the composition. Laminate wax is heated until it flows. The liquid composition is applied in a thin layer to the laminate lock and is immediately connected to the already laid lamellas. A brush is used as a tool, which will help to evenly distribute the composition over the surface.

Before the wax hardens, you need to line the laid panel.

To increase the drying time of the wax, the laminate panels can be heated. For example, on a battery or a household hair dryer. Do not use a hair dryer, as its outlet temperature is too high - the lamella may be damaged.

Before you begin installation, you should think about how to remove any remaining wax from the laminate. To do this, use a regular dry cloth and a rubber or plastic spatula.

Impregnation based on natural wax is an excellent option for processing seams. It resists moisture and sand and dust getting into the seams between the slats. At the same time, the wax does not interfere with the disassembly of the floor covering, since it does not actually glue the lamellas together. Laminate treated with wax has a longer service life.

Mastic

When the floor covering has already been laid and it is necessary to improve its tightness, a special mastic for laminate flooring comes to the rescue. A distinctive feature is not only the grouting of joints, but also the elimination of small scratches, as well as the creation of a protective layer.

The use of a mastic composition perfectly protects against water, temperature and the appearance of defects during prolonged use. It is best to use transparent mastic. It will give the flooring the appearance of a new floor.

Mastic for laminate flooring is available in liquid or spray form.

The liquid composition resembles an emulsion. Its application is carried out along the seams of the panels with a brush or sponge.

The spray is simply sprayed from a can and, if necessary, rubbed with a sponge to form an even coating.

Grout

Another product used after installation is laminate grout. It is designed to treat cracks, chips and errors that arise when arranging the floor. There are many color options on the market, you can easily match the shade of your flooring. Therefore, grout for joints is suitable for almost any laminate. The composition has the consistency of a paste. The grout is applied with a plastic or rubber spatula to the cracks, cracks and other defects of the laminate floor. Excess composition is removed within 30 minutes using the same spatula and dry cloth.

If time is lost, wiping off excess grout will require a lot of effort and special solvents.

Liquid plug

A new modern material for eliminating cracks when laying floor coverings is liquid cork. This product consists of fine cork chips mixed evenly with a binder component.

Due to its composition the material:

- is environmentally friendly,

- has a high level of elasticity,

- has good thermal insulation,

- resistance to temperature changes;

- not afraid of deformation,

- resistant to mechanical damage;

- high adhesion to various materials.

Liquid stopper has a lot of different uses, but the main area is filling gaps and cracks more than 2 millimeters in width. Therefore, it is used to seal seams between different floor coverings (for example, between tiles and laminate), at the junction of walls and floors, for cladding walls and facades, as well as for insulating window and door openings.

The use of liquid cork for laminate joints is just one area of application. The composition is available in the form of a cartridge for a gun, which is used to apply the sealant. Before use, the seam is treated with oil and then carefully filled to the top with liquid stopper. Excess material is cut off with a knife after hardening. After this, it is advisable to sand the surface.

This treatment with liquid cork will provide the floor with reliable and long-lasting protection from moisture accumulation.

Cork compounds can be used both as primary compounds for sealing joints and as auxiliary compounds in places where it is not possible to use a sealant or the sealant does not provide the necessary aesthetic requirements.

Popular posts

- Ceramic tiles from China Chinese tiles from the Official Dealer Arranging your own home takes a lot of time and effort, because everyone…

- Sealant for wood Sequence of work Pre-clean wooden surfaces using a spatula and a brush. The seams are sealed in a certain sequence:...

- Bathroom tiles with flowers Bathroom tiles with flowers: features of the ornament Design in a floral style always brings notes of spring,…

- Silicone sanitary sealant Silicone sanitary sealant white in Moscow - 1491 products Company from Moscow, delivery (tomorrow) 140...

Adhesive sealant for seams, brown

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

Important!

In order to properly glue the tiles to the sealant, careful preparation of the base is required: it must be leveled and primed.

In the case of a moving base, grouting of joints is also carried out using a sealant, and not a conventional cement joint, which can crack.

What types of sealants are used for grouting joints in bathrooms

An important characteristic of bathroom sealant is its resistance to moisture. It is also necessary that the sealant has the following properties:

- high adhesion to different types of building materials;

- thixotropy;

- elasticity;

- resistance to mechanical damage;

- resistance to chemicals;

- durability;

- resistance to the formation of mold and fungi (antibactericidal properties);

- ease of use.

Therefore, for sealing tile seams, as well as for gluing tiles, polyurethane sealants are mainly used.

Important!

It is necessary to ensure that the sealant is intended for use in wet areas. Acrylic and latex sealants are not recommended for grouting joints.

Polyurethane sealants can be used to seal seams; They are especially often used to replace old seams. Polyurethane sealants have high adhesion and are very flexible. They are easy to apply and allow seams to be painted. In addition, they can be colored.

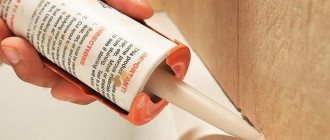

How to fill tile joints with polyurethane sealant:

Preparing the base.

- Clean the surface from fats, oils, dirt, dust, remnants of previous sealants and other contaminants. For highly porous, fragile surfaces that are subject to immersion in water or heavy physical and mechanical loads, use primers for concrete foundations. The material can be applied without a primer; in case of doubt, an adhesion test is recommended.

- To adjust the depth of the joint and prevent three-way adhesion into the joint before applying the sealant, an elastic cord of closed-cell polyethylene foam is required.

- It is recommended to protect adjacent surfaces from contamination with masking tape.

Execution of work.

- Tools: hand or pneumatic construction guns. Follow the instructions for using the pistol. Apply the sealant in a slow, uniform motion, carefully filling the gap so that the seam is free of air.

- Within 15 minutes after filling the seam, the surface of the sealant is smoothed with a spatula moistened with soapy water, while removing excess material. Then you need to immediately remove the masking tape and clean the surrounding surfaces.

- Freshly applied sealant has a soft surface that can be damaged by sharp or hard objects, so it is not recommended to subject it to mechanical and abrasive loads during the polymerization time.

- After applying the sealant, the seams should not be subjected to stress for 24 hours.

Question for the experts: can tiles be glued to silicone?

Moderator: Nimh69

Question for the experts: can tiles be glued to silicone?

writer » May 12, 2015, 10:02 pm

Re: Question for the experts: can you glue tiles to silicone?

tiler in Minsk » July 17, 2015, 11:04

Re: Question for the experts: can you glue tiles to silicone?

plitka-brest.by » March 24, 2021, 12:25

Re: Question for the experts: can you glue tiles to silicone?

aykon » Mar 30, 2021 10:51 pm

Re: Question for the experts: can you glue tiles to silicone?

plitka-brest.by » March 31, 2021, 12:46

here we are talking about gluing tiles onto silicone at home to a concrete slab or plaster))) somehow I doubt that I would glue tiles to silicone at home)))

Re: Question for the experts: can you glue tiles to silicone?

Master » 07 Apr 2021, 14:52

It is possible and sometimes even necessary! I glued it to silicone more than once or twice. It holds up well and is difficult to remove later. Example: a neighbor, probably a 70-year-old grandmother, had a tile above the stove fall off in her kitchen. It was glued on cement “cakes” about 30 years ago. The tiles fell off, but the cakes remained. In order not to knock them down, I glued them on silicone, but glue did not work; a layer of glue would lead to the fact that the plane would not be even. The new glued tile stuck out relative to the old one, but when I glued it to silicone, everything was smooth. It's been a year now and everything is fine. Recently I came in to take a look.

Sometimes, not having a special glue for deformable bases, the glue on silicone tiles, on metal, for example, sticks so that you can’t tear it off! The main thing is to know how to glue! Otherwise they’ll drop a drop on the tile and stick it to the dust. then it holds up like crap. And if you rub it into the tiles and into the base, and then glue it, it will last for a hundred years.

Re: Question for the experts: can you glue tiles to silicone?

Nimh69 » Apr 21, 2021 10:42 am

Re: Question for the experts: can you glue tiles to silicone?

writer » 02 May 2021, 13:33

Re: Question for the experts: can you glue tiles to silicone?

plitka-brest.by » 02 May 2021, 13:42

Many people here did not understand the essence of the question:

If you are gluing an entire bathroom, then, of course, it is very stupid to do it with silicone.

And if 2-3 tiles that have come loose are glued to silicone and sealed, then this option may very well be possible.

Re: Question for the experts: can you glue tiles to silicone?

Sergey » June 04, 2021, 11:35

Colored sealants: what are they for?

Bathroom renovation is not only about increasing the functionality of the room, but also about implementing decorative and aesthetic ideas. Since the color of the tiles can be different, it is necessary to consider the color of the grout.

Polyurethane sealants are also available in different shades. For example, CEMMIX Facade Adhesive-Sealant is available in eight shades (there are even red, blue and green), and Seam Adhesive-Sealant from the same manufacturer is available in four.

What to do if there is no suitable shade?

As a rule, sealants and grout mixtures of the same color are selected, the color range of which is very wide. It is strictly forbidden to mix sealant with tinting pastes or other colored fillers! In the production of colored polyurethane sealants, compositions are selected that ensure unchanged technical characteristics of the final product.

How to remove silicone sealant from tiles

The solution to the problem is usually to wash off the silicone sealant from the tiles It is imperative to remove all traces, since this material darkens over time, reducing the decorative aesthetics of the tile.

Purpose of using silicone sealant

The dense, viscous texture of silicone sealant is complemented by the amazing ability to stretch with virtually no tearing.

It consists of a base filler, the role of which is given to silicone rubber. In order to speed up hardening and increase strength, an amplifier is added. Reliable bonding is ensured by the adhesive primer. Plasticity is imparted by a vulcanizer. May contain fungicides that protect against mold, color pigment, and mechanical fillers in the form of quartz dust.

This composition maintains integrity over a wide temperature range: (- 50 ° C) - (+ 180 ° C).

Due to its multi-component composition and high strength characteristics, silicone composition is used in the process of repair work in premises to perform the following operations:

- gluing various planes;

- waterproofing seams;

- hermetic sealing of joints.

It is advisable to remove excess silicone sealant from the tiles immediately, but even in such a situation, traces of the substance may appear after some time. It will be necessary to select methods that allow you to clean the tiles without damaging the surface.

Necessary materials and tools for removing sealant

Before removing silicone sealant from the tiles , keep in mind that this can be done in three ways, for which you first need to prepare the tools and necessary cleaning agents.

Prepare a razor, a sharp knife, a scraper designed for cleaning glass, and a wooden spatula. You will also need a wire wool, a soft rag, food salt or baking soda in a burlap bag.

When choosing how to clean sealant from tiles , they turn to the list of special substances that differ in chemical activity. When carrying out all actions in such a situation, it is necessary to protect your hands with rubber seals, use a cotton-gauze bandage and glasses, and wear long sleeves. The room should be well ventilated. Basic means are gasoline, kerosene, solvent. Penta-840, white spirit, demonstrates good performance. Dow Corning OS-2 has been successfully used.

This method is the most reliable and effective because it combines mechanical cleaning with exposure to chemicals.

Adhesive sealant for seams white

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

Problems

When deciding how to glue ceramic tiles to plywood, you need to take into account a number of features of the material.

- Veneer is hygroscopic. More importantly, if one side of a thin sheet is wet, it can warp.

- Veneered plywood may delaminate. It is advisable to use adhesives that will saturate the plywood to some depth.

- If we are talking about a partition of a large area, it is worth considering its flexibility and ability to deform under loads. It is advisable that an accidental blow or deflection does not cause the tile to fall. The ideal option from this point of view is to use elastic glue.

The flexibility of the material is worth considering.

Adhesive sealant for seams black

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

Adhesive sealant for seams, gray

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

Adhesive sealant for seams, brown

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

Another option is to use a grout color that contrasts or matches the tile. For example, light joints (white, light gray) look impressive on dark tiles, and dark or colored joints on light ones. The color wheel will help you choose a harmonious combination.

Interesting!

The color of the seams can also be matched to any element of the bathroom interior, for example, to match the mirror frame.

Tips for using polyurethane sealants in the bathroom:

- make sure that the sealant is intended for wet areas;

- use sealant for gluing tiles only on movable, level bases;

- think about the color scheme in advance;

- use only high-quality materials from reliable manufacturers, for example, CEMMIX sealants;

- When applying sealant, remember that errors can be corrected within 15 minutes.

A beautiful and functional bathroom is the result of thoughtful actions and the use of high-quality and reliable materials. Their availability is no less important. CEMMIX sealants - Facade adhesive-sealant and Adhesive-sealant for seams can be bought in Leroy Merlin and other construction stores, as well as in bulk from the manufacturer.

You can buy CemPlast, CemBase CEMMIX without leaving your home, with discounts from 5 to 33%!!!!

Buy on Ozon

Buy on VseInstrumenty.ru

Buy on Wildberries

Buy at Leroy Merlin

Or you can find the nearest official dealer in your region on our map

← Sealing joints of external wall panels of buildings: what materials should be used

Installation of expansion joints in concrete floors using polyurethane sealant →

Return to list

Comments

Removing silicone sealant from tiles is easier than it seems

Even relatively experienced craftsmen have this unpleasant problem - after laying the tiles, excess silicone comes out of the seams (clinker tiles are usually fixed with silicone sealant), and they have to be removed. The worst thing is that this happens at the final stage of work, when all the finishing is done. Therefore, it is unpleasant that the appearance of a room that took so many hours to complete can be ruined so quickly.

If you notice the problem right away, it's okay. Wipe the grout with a rag, no unnecessary problems will arise, it will easily wipe off. But sometimes long weeks pass and suddenly the problem becomes noticeable. The stains appear and begin to seriously spoil the look of the room you worked hard on.

The problem can be solved, there are options for correcting errors and making the coating presentable, although it is best to respond quickly. But if the moment is missed, you need to think about how to remove the silicone sealant from the tiles. Let's consider the main options that are most effective.

News

We are always ready to help

Cemmix has opened a free hotline

to help you with any questions related to construction using concrete additives. Call and ask, our consultants are always ready to help!

Hyperplasticizer

Hyperplasticizers are a new type of plasticizing additives for concrete, ensuring the mobility of the mixture above P5. In addition to plasticity, they increase the water resistance and frost resistance of concrete by 2-3 times.

Where can you glue tiles with regular sealant?

Some people don't even realize that tiles can be glued using a sealant. Currently, the installation of tiles is carried out using special glue. Therefore, many have not even heard anything about silicone sealant.