Adhesive sealant for seams, gray

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

Stage No. 3: final

After applying the grout, you should immediately begin cleaning the tiles. The ideal moment is when the mixture has dried a little and become matte (usually after 10-20 minutes).

Need to:

- Moisten a rag (sponge) with water or a special cleaner for epoxy grout.

- Wipe the tiles diagonally towards you (so as not to wash the grout out of the joints). After each pass, you need to rinse the sponge with water.

- When the grout is completely dry, you can rub the tiles with a terry cloth.

Finished tiles:

Adhesive sealant for seams, brown

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

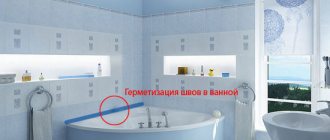

Especially often, mold occurs in various seams, which is understandable, since the flow of air there is difficult.

Therefore, reliable sealing of seams is also the prevention of mold in the apartment.

On straight sections of walls or floors lined with ceramic or other tiles, special cement-based grout mixtures (they can be colored) or epoxy compounds are used to fill the tile joints when there is strong chemical aggression or large mechanical loads.

Elastic sealing materials are used at seams between dissimilar materials or in places of possible deformations of the building (internal corners of rooms, half-wall junctions).

The seams between the bathtub and the tiles, all joints: the sink to the wall, the toilet to the floor, are usually sealed, and all openings for communications are also sealed.

However, recently craftsmen have also been using sealants for gluing tiles, as well as for filling tile seams.

Tips and tricks

For exterior work, silicone sealant is more often used, the properties, characteristics and description of which meet the requirements, and the price of the product occupies an average niche between acrylic and polyurethane mixtures. The method of applying all products is standard - preparing the surface, filling the seams with sealant, removing excess mass.

When performing work, builders recommend adhering to some recommendations:

- You need to carefully check the expiration date of the composition and the quality of the sealed packaging.

- It is necessary to carefully read the manufacturer's instructions - for what work the composition is intended.

- It is worth giving preference to proven brands whose products are in demand among customers.

- Mixtures are purchased with a small margin from the calculated consumption of the product.

- For large volumes of work, it is better to choose tubes for a mounting gun, which speeds up the process of applying the product.

- Before treatment, the surfaces must be cleaned of dust and debris, and a sealant must be applied if necessary.

- It is not recommended to carry out outdoor work at sub-zero temperatures or during rain or snow.

- To prevent the sealant from getting onto adjacent areas of the facade, cover the length of the seam with masking tape.

- The joints are filled with mortar until the mixture stops penetrating into the seam, which indicates complete filling.

To improve the adhesive properties of the surface being treated, the edges of the gaps are pre-primed. Using a construction gun allows you to use mixtures economically. It is necessary to take into account the drying speed - the seams can be painted after the composition has completely cured.

An important advantage of facade sealants is resistance to adverse operating conditions and durability. If the sealing technology is followed, the treated surface acquires a monolithic structure and additional mechanical strength. Sealants create an effective protective barrier against precipitation and heat blowing out of rooms.

Sealing external seams (2 videos)

Sealant for external seams (16 photos)

Is it possible to use sealant for gluing tiles and grouting joints, and what is it for?

Tiles are the best choice for finishing bathroom walls and floors. For the floor, tiles made of more durable porcelain stoneware are also sometimes used.

However, in any case, this tile must be glued with something and the seams between the tiles must be filled.

Important!

The width of the joints between the tiles depends on various factors: the size and shape of the tiles, the designer’s intentions, and technical capabilities. Typically, wider joints are left for large or shaped tiles. Standard size tiles (up to 60 cm on a side) are usually laid with joints of about 6 mm wide. Seams narrower than 3 mm can be difficult to fill with grout, so they are rarely used; Seams wider than 12 mm are also usually not made, because there is a risk of cracking.

Typically, special tile adhesive is used to glue tiles. It is applied in a layer of a certain thickness, making it possible to further level the tiled surface. On the floor, tiles must be laid with cement-based adhesive so that the coating can withstand mechanical loads.

Tiles on walls are sometimes glued with sealant rather than glue.

In this case, the sealant, unlike tile adhesive, is applied to the tile in a thinner layer, so it will not be possible to further level the coating. The sealant dries quite quickly, which, on the one hand, allows you to carry out work quite quickly, on the other hand, it requires a certain skill.

Another disadvantage of gluing tiles to sealant is the high price of the latter, compared to tile adhesive.

Why use sealant to glue tiles?

The fact is that in some cases it is justified.

If the tiles are laid on a movable base or a base made of material subject to vibration due to shock loads, deformation from moisture or temperature changes (for example, wood, plasterboard, asbestos cement boards), an elastic connection is required, which cannot be provided with tile adhesive, and sealant in this regard will be appropriate, as it has the necessary elasticity.

Kinds

The range of facade sealants presented on the construction market is impressive. They are produced by domestic and foreign companies in entire lines of products. The classification of products is complex and takes into account the division of sealants into types according to several criteria:

- Degree of readiness – one-component and two-component mixtures. The former are immediately ready for application to joints and seams, while the latter must be pre-mixed, strictly adhering to the proportions.

- Based on their properties, they are classified into frost-resistant, rubber, waterproof, and heat-resistant compounds. When choosing a product, you need to consider the area of use of the sealant.

- In terms of color variety, there are transparent, colored, white sealants of the classic type and colored decorative mixtures in a wide palette of shades.

But the most important feature by which façade sealants for external use are classified is their component composition. Certain properties and characteristics of mixtures are given by fillers, modifiers and plasticizers, as well as special additives.

Silicone

Elastic, waterproof silicone-based pastes withstand temperature changes well. The structure resembles a plastic rubber material. There are silicone sealants for external seams of acidic, neutral and antiseptic types. Acetate mixtures have optimal strength, universal neutral products are suitable for any surface, and fungicidal pastes protect facades from the formation of fungus and mold. According to the technical specifications, silicone sealant for external seams retains its properties over a wide temperature range and successfully withstands most negative factors.

Acrylic

Among all sealing compounds, acrylic mixtures are the most environmentally friendly. The main area of application is interior work. But if modifying additives are introduced into the acrylic façade sealant or the mixture contains silicone or latex, the product can be used for external treatment of walls and structures. In this case, the water-repellent characteristics of the sealant and resistance to low temperatures are improved. Acrylic pastes are characterized by vapor permeability, light structure, and the possibility of finishing by painting or plastering. Compositions for external use have good adhesive properties.

Polyurethane

Polyurethane-based products are ideal for sealing interpanel seams - after hardening, the sealant acquires properties characteristic of high-quality rubber. Advantages of the compositions: elasticity, good resistance to mechanical stress. External seams treated with a polyurethane mixture effectively resist destructive processes upon contact with water, withstand sudden temperature changes, and do not shrink after vulcanization. The only drawback of polyurethane products is toxicity, but for outdoor work this disadvantage is not decisive.

A separate type of product is adhesive-sealants of different colors. Black glue is designed specifically for outdoor work (façade and roofing), as it has good resistance to ultraviolet rays. Transparent products are used for window structures, and white products are used to insulate plumbing joints.

Note: To seal the outside of the seams with sealant, you can use bitumen mixtures made on the basis of bitumen polymers. Such products have the properties of rubber and adhere well to facades made of various building materials.

Adhesive sealant for seams white

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

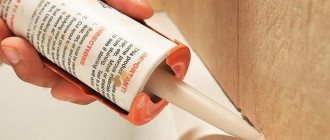

Sealing the joint between the bathtub and the wall using polyurethane foam

Filling the seam between the bathtub and the wall with foam is one of the easiest ways to solve the problem.

Especially compared to the outdated solution method. And one-component polyurethane foam, which has excellent water-resistant qualities, is best suited for these purposes. You just need to work very carefully, since polyurethane foam that gets on tiles, painted surfaces, or even hands is extremely difficult to clean off later. The “foam” process of sealing seams is simple:

- first the seam is cleaned, degreased and thoroughly dried;

- the foam in the container is shaken properly and poured into the cavity of the leaking joint;

- 40 minutes are allotted for complete foam drying in a room with high humidity;

- excess foam along the edge of the bathtub is carefully removed with a painting knife;

- Then the sealed joint is designed at the discretion of the master.

Important: during the drying process, the polyurethane foam increases in volume several (up to 30) times. Therefore, it is necessary to clearly measure the amount of composition to be laid.

You will see a detailed description of the process of sealing a joint using foam by viewing this review:

Adhesive sealant for seams black

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

Adhesive sealant for seams, gray

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

Adhesive sealant for seams, brown

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

Important!

In order to properly glue the tiles to the sealant, careful preparation of the base is required: it must be leveled and primed.

In the case of a moving base, grouting of joints is also carried out using a sealant, and not a conventional cement joint, which can crack.

What types of sealants are used for grouting joints in bathrooms

An important characteristic of bathroom sealant is its resistance to moisture. It is also necessary that the sealant has the following properties:

- high adhesion to different types of building materials;

- thixotropy;

- elasticity;

- resistance to mechanical damage;

- resistance to chemicals;

- durability;

- resistance to the formation of mold and fungi (antibactericidal properties);

- ease of use.

Therefore, for sealing tile seams, as well as for gluing tiles, polyurethane sealants are mainly used.

Important!

It is necessary to ensure that the sealant is intended for use in wet areas. Acrylic and latex sealants are not recommended for grouting joints.

Polyurethane sealants can be used to seal seams; They are especially often used to replace old seams. Polyurethane sealants have high adhesion and are very flexible. They are easy to apply and allow seams to be painted. In addition, they can be colored.

How to fill tile joints with polyurethane sealant:

Preparing the base.

- Clean the surface from fats, oils, dirt, dust, remnants of previous sealants and other contaminants. For highly porous, fragile surfaces that are subject to immersion in water or heavy physical and mechanical loads, use primers for concrete foundations. The material can be applied without a primer; in case of doubt, an adhesion test is recommended.

- To adjust the depth of the joint and prevent three-way adhesion into the joint before applying the sealant, an elastic cord of closed-cell polyethylene foam is required.

- It is recommended to protect adjacent surfaces from contamination with masking tape.

Execution of work.

- Tools: hand or pneumatic construction guns. Follow the instructions for using the pistol. Apply the sealant in a slow, uniform motion, carefully filling the gap so that the seam is free of air.

- Within 15 minutes after filling the seam, the surface of the sealant is smoothed with a spatula moistened with soapy water, while removing excess material. Then you need to immediately remove the masking tape and clean the surrounding surfaces.

- Freshly applied sealant has a soft surface that can be damaged by sharp or hard objects, so it is not recommended to subject it to mechanical and abrasive loads during the polymerization time.

- After applying the sealant, the seams should not be subjected to stress for 24 hours.

Specifications

Since sealants for external joints are exposed to a different set of factors than mixtures for internal use, they have completely different properties.

Auxiliary building materials of pasty consistency differ in composition and technical characteristics:

- High resistance to sunlight.

- Maintains integrity during temperature changes.

- Elastic structure that reaches at least 125%.

- High tensile, tensile and compressive strength.

- Resistance to the negative effects of chemicals.

- Low thermal conductivity and good vapor permeability.

- High adhesion to any surfaces of walls and facades.

- Fast curing, retention of shape during deformation.

- Maintainability, dense filling of cracks, painting.

The use of sealant for interpanel seams and joints is carried out in order to insulate the interior from the penetration of moisture and cold. Not only viscous compositions are suitable for this, but also special non-hardening materials. After application, they retain an elastic structure reminiscent of rubber - tapes, strands and cords. When heated, such sealants soften slightly and then return to their original structure.

Note: Professional-grade façade sealants are produced in bulk tubes for large-scale work using a gun. Household compounds are used for hermetically sealing joints on small surfaces.

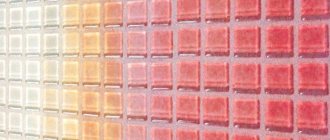

Colored sealants: what are they for?

Bathroom renovation is not only about increasing the functionality of the room, but also about implementing decorative and aesthetic ideas. Since the color of the tiles can be different, it is necessary to consider the color of the grout.

Polyurethane sealants are also available in different shades. For example, CEMMIX Facade Adhesive-Sealant is available in eight shades (there are even red, blue and green), and Seam Adhesive-Sealant from the same manufacturer is available in four.

What to do if there is no suitable shade?

As a rule, sealants and grout mixtures of the same color are selected, the color range of which is very wide. It is strictly forbidden to mix sealant with tinting pastes or other colored fillers! In the production of colored polyurethane sealants, compositions are selected that ensure unchanged technical characteristics of the final product.

Criterias of choice

Only then will a construction sealant be effective when the operating conditions are taken into account when purchasing it. So decide whether you will use it indoors or outdoors. What materials should be hermetically connected, will the seam need to be changed under the influence of external factors: how often and with what force will they influence. How high will the temperature of the surrounding atmosphere be? Will the sealed seam be exposed to moisture or dirt (how often should you clean it)? Will the cured sealing compound be painted over? What level of environmental friendliness and sterility is required in the room?

For example, for medical and children's institutions, a high concentration of antibacterial additives in the composition is important. Sealing voids in any rooms will require the purchase of sealants for interior work. At the same time, they must be environmentally friendly, resistant to moisture and dirt. Elasticity is an important factor, since when temperature and humidity levels change, the width of the seams will change. If you do not give up the possibility of subsequent dismantling, it is better to buy a sealant with a medium or low bonding density. In this case, the material should not be aggressive, since otherwise removing excess from the surface will cause difficulties. Colorless sealant is universal; it makes the seam invisible.

Adhesive sealant for seams white

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

Adhesive sealant for seams black

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

Adhesive sealant for seams, gray

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

Adhesive sealant for seams, brown

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

Another option is to use a grout color that contrasts or matches the tile. For example, light joints (white, light gray) look impressive on dark tiles, and dark or colored joints on light ones. The color wheel will help you choose a harmonious combination.

Interesting!

The color of the seams can also be matched to any element of the bathroom interior, for example, to match the mirror frame.

Tips for using polyurethane sealants in the bathroom:

- make sure that the sealant is intended for wet areas;

- use sealant for gluing tiles only on movable, level bases;

- think about the color scheme in advance;

- use only high-quality materials from reliable manufacturers, for example, CEMMIX sealants;

- When applying sealant, remember that errors can be corrected within 15 minutes.

A beautiful and functional bathroom is the result of thoughtful actions and the use of high-quality and reliable materials. Their availability is no less important. CEMMIX sealants - Facade adhesive-sealant and Adhesive-sealant for seams can be bought in Leroy Merlin and other construction stores, as well as in bulk from the manufacturer.

You can buy CemPlast, CemBase CEMMIX without leaving your home, with discounts from 5 to 33%!!!!

Buy on Ozon

Buy on VseInstrumenty.ru

Buy on Wildberries

Buy at Leroy Merlin

Or you can find the nearest official dealer in your region on our map

← Sealing joints of external wall panels of buildings: what materials should be used

Installation of expansion joints in concrete floors using polyurethane sealant →

Return to list

Comments

Classification of sealing substances

The most important point is the composition of the sealants. Depending on the main component, they are divided into the following types:

- acrylic;

- bitumen;

- combined (acrylic-silicone, polyurethane-acrylic);

- polyurethane;

- silicone.

Additional components expand or limit the functionality and scope of the composition. This is also the defining feature of the packaging. One-component and two-component products are sold in the same container. And multi-component ones require preliminary mixing of the contents of several packages - here it is important to maintain the correct ratio.

Before deciding which sealant is best, you need to know its characteristics. Some sealants only slightly seal the joint of surfaces, while others glue the seams once and for all - this factor is taken into account if subsequent disassembly of the structure is possible.

Determine whether this will be a static connection or whether it will require movement. In the first case, those that freeze tightly and do not react to any external changes are used (used in furniture assembly, plumbing installation and construction). The second will require a seam sealant with a high level of elasticity.

News

We are always ready to help

Cemmix has opened a free hotline

to help you with any questions related to construction using concrete additives. Call and ask, our consultants are always ready to help!

Hyperplasticizer

Hyperplasticizers are a new type of plasticizing additives for concrete, ensuring the mobility of the mixture above P5. In addition to plasticity, they increase the water resistance and frost resistance of concrete by 2-3 times.

How to grout correctly

To begin, prepare a set of tools and materials:

- Grout of a suitable shade;

- Silicone sealant for joints, expansion joints and joints of the required color and round section polyethylene foam sealing cord;

- Masking tape;

- Electric mixer or screwdriver with mixing attachment;

- Measuring container or electronic scales;

- Bucket for mixing the grout mixture;

- Master OK;

- Flat rubber spatula or grater with a rubber nozzle;

- A cellulose sponge combined with Scotch Brite or a grater with a replaceable attachment for cleaning the surface from residues of the composition;

- A bucket of clean water or skipper is a special bucket with rollers for squeezing;

- Latex or rubber gloves and a respirator (epoxy and furan mixtures cause severe irritation to the skin and mucous membranes, so you only need to work with them wearing a protective mask and gloves with high bells);

- A knife for cleaning seams from glue residues and a brush for removing dust;

- An acidic product for cleaning the surface of tiles from remnants of grout mixture (cement, polymer).

Tools for grouting.

Filling joints can only begin after the period recommended by the tile adhesive manufacturer has expired. The base must be absolutely dry and clean, so this period is usually 3-7 days. The consumption of the fugue depends on the width of the seams, but on average varies from 100 to 150 g/m².

Cement based grout

Preparation of seams

Tile edges must be cleaned to a depth of at least 2/3 of the thickness, removing any remaining adhesive and old grout. Sweep away the dust with a brush, rinse the surface with water and dry.

If the cladding is porous and not protected by glaze, then the surface is additionally moistened with a sponge or spray bottle, and a test for coloring with pigments contained in the grout mixture is carried out on an inconspicuous area.

Preparing the mixture

Measure out the amount of clean water required according to the instructions, pour it into a container and, while continuously stirring with a mixer, add the dry mixture. After obtaining a homogeneous mass without lumps, let the solution stand for 5-10 minutes, then mix again. The composition must be developed within the period indicated on the label - from 40 minutes to 2 hours.

Seam filling

Apply the prepared mortar to the seams between the tiles with a rubber spatula or float diagonally relative to the direction of the gaps. It must be rubbed thoroughly, without voids, unevenness or gaps. Remove excess immediately with the same tool. 10-20 minutes after the grout has hardened, the surface is cleaned with a damp, well-wrung out sponge.

How long the filling mixture takes to dry depends on the temperature and humidity indicators. The higher the temperature and lower the humidity, the faster the composition hardens. In any case, before washing the surface, you need to check the consistency of the grout by touch to avoid emptying the gaps.

Now you can start processing the corners and joints. Deformation gaps and joint areas must be sealed using a correction cord. Cut off the top of the tube with sealant, screw on the tip and insert it into the skeleton-shaped gun.

It is better to protect the tiles at the joints in advance with masking tape. Apply acrylic or silicone compound to the corners, after 15-20 minutes, moisten the surface with a spray bottle and rub in the sealant with a spatula or jointer, while removing excess. After finishing work, remove the tape and give the compositions at least 24 hours to dry.

Sealing joints.

Final surface cleaning

A whitish residue usually remains on the surface of the tile cladding, which is removed with an acid cleaner. As a rule, masters use concentrated products, but they are also available in the form of ready-to-use solutions.

Apply the cleaner with a sponge according to the instructions on the floor, then rinse with clean water. To improve water-repellent properties, after 5-7 days, treat the seams with hydrophobic impregnations.

Polymer-based grouts

Preparing the base

First you need to make sure that the tile adhesive has hardened, dried, and its traces have been completely removed from the tile edges to at least 2/3 of the thickness of the cladding. Thoroughly vacuum and rinse the surface, dry.

Before starting work on absorbent surfaces (clinker, marble, terracotta, natural stone, unglazed tiles), it is necessary to carry out a test grouting to identify possible problems: staining, staining, change in tile color, etc. If a negative effect is detected, it is better to abandon this type of grouting and replace it with neutral.

Kneading paste

Mix the one-component composition thoroughly with a trowel by hand. Multicomponent mixtures must be handled carefully. Separate the required amount from the base paste, weighing it on an electronic scale with an accuracy of grams. Add hardener or catalysts and mix carefully with a mixer at low speed until smooth. The solution must be developed within 30-90 minutes.

Seam filling

Apply the mixture to the gaps with a float with a rubber nozzle for polymer compounds (with sharp edges) diagonally relative to the direction of the seams, immediately removing excess. The seams must be completely sealed, without voids or irregularities.

After 10-15 minutes, remove excess solution: moisten the surface with water and treat it with a felt or cellulose sponge, rinsing it frequently and thoroughly.