Have you decided to repair the walls in the boiler room yourself? In this case, we recommend that you familiarize yourself with photos, videos and technology features, and the selection of suitable materials for a room that has increased requirements.

It's no secret that the most reasonable solution in terms of comfort and safety, finishing the room, installing heating equipment and monitoring its operation is to move the boiler room outside the house. This measure does not provide 100% safety, so it is important to dwell on some more important points that are still poorly regulated and documented, but at the same time significant in terms of work on setting up a room for an autonomous boiler room. We will look at them in more detail.

- What is important to consider before carrying out work in the boiler room? It’s good if you buy boiler equipment in advance, which will allow you to familiarize yourself with the requirements for the placement of the boiler (they are indicated in the passport).

- Decide on the location of the pipes and holes for the chimney, adjust the dimensions.

- Is the equipment you have chosen capable of guaranteeing the required temperature in the room and will there be enough power to heat the house?

- The dimensions of the boiler room are determined by the following parameters: the total volume of the room should not be less than 15 square meters. m, ceiling height is not less than 2.5 m, the area for installing the boiler is not less than 4 sq. m. m.

- The preferred location for the boiler room is along a blank wall (if this is not possible, window and door openings in the wall must be sealed).

Attention! Even if you have planned that the room will not be heated with gas, the dimensions of the boiler room must still be set according to the requirements that are presented when installing a gas boiler.

It is worth noting that the use of gas equipment up to 30 kW does not imply the construction of a separate room intended for the boiler room. The instructions do not prohibit the installation of such a unit in the kitchen if it meets all the criteria, which, by the way, are also quite strict.

Do-it-yourself wall repair in a boiler room: photos and finishing options

The main requirement for the walls in the boiler room is that the finishing must be made of non-combustible materials. Finishing for future wall cladding is done with a plaster mixture. It is unlikely that you will be able to find something better than finishing with ceramic tiles.

The material is highly resistant to flame and temperature. But keep in mind that the tiles are only suitable for walls, and not for floors, because the boiler room equipment is heavy, and porcelain tiles are not able to cope with such an intense load.

When operating a boiler room, coolant must be discharged from the system, for which the boiler room must have a drain to the sewer network. It will be more convenient to work in it if cleaning is so easy.

It is allowed to use gypsum fiber sheets using gluing technology. Today, KVL (xylolite-fiber sheet) is especially popular. It is an environmentally friendly product that does not contain asbestos and harmful compounds, and does not emit toxins even when heated. It can withstand very high temperatures, up to 100 degrees, and has increased flexibility, which is important when covering curved surfaces. Not afraid of moisture and large temperature changes (frost-resistant).

Sheets of different materials act only as a basis for finishing the walls. The surface after covering must be plastered. A layer of plaster can protect the material from negative influences.

Additional fire resistance to the walls is given by a fireproof, heat-resistant layer of plaster. It is gray in color, but the room is allowed without elegant decor and decorations, the main thing is that the surface treated with it can withstand an open flame for 30-150 minutes. Plaster retains its fire-retardant properties even after it is painted with water-based paint.

First, a structure is constructed from fire- and moisture-resistant sheets, followed by the process of plastering and painting the walls. The windows in the boiler room can be wooden or plastic (all burn). The only difference between them is that plastic releases toxic substances and melts, while wood does not. You can choose it taking into account the climatic characteristics of your area.

There can be several doors in the boiler room, from the boiler room to the street and into the house. The door to the street must have reliable protection against penetration from the outside.

Everyone knows how seriously protected thermal power plants are, which cannot be accessed so easily. The boiler room in the house should also be a sensitive facility that will be difficult to penetrate. Wherever solid fuel is used, it is necessary to protect the house from fire with an additional fire-resistant metal door installed between the boiler room and the living space, which can withstand fire for up to an hour.

As for lighting, it should be simple. The main requirement is functionality. Install a regular lamp or wall lamp, and if necessary, you can always take a flashlight with you.

Repairing boiler room walls with your own hands: ways to insulate them

There are strict requirements for the room where the boiler room will be located. This is explained by the fact that boilers operating on gas, liquid or solid fuel are classified as hazardous objects. Open fire implies increased fire safety requirements. And gas is classified as an explosive substance, which, of course, is also reflected in the arrangement of the boiler room.

In principle, insulating a boiler room is no different from insulating a garage and consists of successive stages. To achieve maximum effect, experts recommend insulating all main surfaces of the building - the roof and walls.

External wall insulation

It is recommended to insulate the walls of a boiler room in a private house from the outside. This is directly explained by the fact that the internal space is reduced, the likelihood of condensation is eliminated and the choice of thermal insulation materials is expanded. When thermally insulating a boiler room from the inside, it is not recommended to use flammable and combustible insulation materials. These include polystyrene foam, polystyrene foam, and polyurethane foam. They can be used exclusively for external insulation. If they are used as internal thermal insulation, then high-quality finishing of the boiler room will be required, eliminating the possibility of fire. Typically, external insulation is carried out during the construction stage of a building, but it can also be done in a finished building.

Finishing the ceiling in the boiler room

The boiler room in a country house is located in the basement or a separate room with access to the street. The last option is preferable. A dedicated room is more practical and safer. In the event of a fire, the fire will not spread to the residential floors and utility rooms, which will allow you to leave the house without hindrance.

Decide in advance where the chimney will be located, the diameter of the outlet openings and pipe connections. Be sure to read the boiler instructions. The technical requirements describe in detail the operating conditions, installation location and other nuances.

Professionals also recommend thinking about whether the purchased devices are enough, or whether additional expenses will be required. The financial issue is relevant, especially for new owners. Extra spending can throw you off schedule, and the long-awaited housewarming party will have to be postponed again. To prevent this from happening, control the process.

Meet with the foreman at least once a day and ask what has been done now and determine plans for tomorrow. It’s great when you cooperate with a specialized company. This way you have a much better chance of getting what you want. Of course, something will have to be adjusted. This is normal workflow. Contact companies that have been operating on the market for at least 5 years, and do not forget to check the contractors.

Be sure to look around the space. Typically, a boiler room is installed in remote rooms. The average area of a room is four square meters, with a volume of approximately 15 cubic meters.

If desired, the ceiling can be left without any finishing, but this is a completely extreme case, which should be resorted to for the sake of austerity. As a rule, under the ceiling in the boiler room in the house there is a whole system of pipes, wires and other communications. To prevent them from spoiling the appearance of the room, you can build a structure from moisture- and fire-resistant plasterboard, like on the walls, and then plaster and paint the surface.

A rough floor screed differs from a finished floor screed in that its filling involves small flaws. You don't have to try to make it level, since its main purpose is to equalize the difference in height. This is a kind of base intended for finishing coating.

We suggest you familiarize yourself with How to fix lining on a wall without lathing

Basic floor screeds in the boiler room:

- prepare the base of the floor;

- set beacons, calculating the floor level;

- prepare the base for the upcoming pouring;

- stir the solution;

- pour the mixture;

- wait until the screed dries.

The initial stage of repairing the floor in a boiler room with your own hands involves removing skirting boards, damaged flooring, as well as dismantling the old screed. In order to get rid of the screed, we recommend using an electric jackhammer.

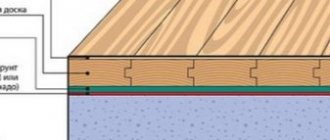

Thanks to its power, this device allows you to prepare for further work. A 10 cm sand cushion is used as the basis for the structure, after which crushed stone or gravel is poured. After this, it is worth laying the membranes for waterproofing so that they extend slightly onto the wall. The surface must be covered with expanded clay. Then sound and body insulation boards are laid.

A mandatory measure before pouring is reinforcing the base, which allows you to increase the strength of the screed. The reinforcement process itself is carried out using a steel rod or metal mesh. Then it is worth proceeding with the leveling itself. As mentioned above, the screed under the equipment in the boiler room must be at least 5 cm.

Fastening beacons for screeds

The result of the screed depends on how correctly the beacons are positioned. The beacons must be secured by starting from the highest point of the floor. In this case, the screed layer will be thin, but not less than 0.6 cm. Often, a 27x28 guide profile is used as beacons. T-shaped profiles, which are used to level the floor, are best suited for this purpose. To secure the beacons, use a solution with alabaster or exactly the same solution as for the screed.

The solution must be spread in small portions. Beacons located on the floor form several maps, that is, these are several distances between marks, depending on the length of the profile used.

Lighthouses should be placed in parallel rows. As soon as all the beacons are placed on the solution, alignment is performed using a level for this purpose, which should be zero in any position. Height adjustment is made using spacers. When you level the surface, you need to be patient and wait until the solution used for fixing dries completely.

When the beacons are installed, you can begin the screed process. First you need to mix the mixture according to the attached instructions. At the same time, you can dilute the solution from cement and sand yourself. For a good kneading, add the mixture to the water, but not vice versa. For 10 kg of mixture use 2 liters of water. The solution is mixed in a bucket using a hammer drill or drill with an attachment. This way you can quickly and effortlessly achieve a uniform consistency.

To speed up the process, it is better to do the screed together: someone is pouring it, and someone is preparing a new solution. First, the alignment is carried out with a trowel, after which it is pulled together along the beacons towards you. It is good if the screed is carried out continuously, that is, as soon as the solution is poured, it is necessary to prepare its second portion.

When making a screed, you do not need to remove the beacons; let them remain in the solution. But the guide profile should be removed as soon as the screed dries a little. The holes left by the profile are sealed when the screed has completely dried.

How to check the condition of the screed?

You must wait 3-4 weeks for the solution to harden. At this time, you need to monitor the condition of the finished screed. Moisten the surface with water every day for two weeks. This is done so that cracks do not form when the cement dries. You can avoid cracks by adding a plasticizer to the solution.

Porcelain stoneware appeared on the building materials market relatively recently, but has already managed to gain high popularity. Its performance characteristics make it possible to use the material for interior decoration. Porcelain stoneware flooring is highly resistant to mechanical damage and the effects of chemicals, is environmentally friendly and durable, not to mention its texture.

We invite you to familiarize yourself with the Canopy in the bathhouse with your own hands, a step-by-step guide

In its appearance, porcelain stoneware resembles natural stone, but in terms of properties it has gone much further. So, for example, choosing porcelain stoneware tiles for a boiler room allows you to avoid problems such as premature abrasion of the coating or cracks.

When finishing the floor in the boiler room, it is worth laying porcelain tiles. This material is characterized by fire resistance and high strength, as well as ease of use.

In terms of practicality, the best option for finishing the floor in a boiler room is ceramic granite, which has a matte surface in light shades. Footprints are not visible on them, dust is less noticeable, and cleaning such a matte light floor is much easier, since there are no stains from the rag on the surface. Laminate, parquet boards, linoleum and carpet are sources of increased danger: the slightest spark and such materials can burst into flames.

It is unlikely that the owners will often polish the floor in this room, and dust can harm some boiler models. Electric and gas boilers can be mounted directly to the wall, while solid fuel ones may require a special podium. It will protect the boiler from dust from the floor and contact with water when pipes leak. It is best to make a podium from bricks, and then finish it with porcelain tiles.

Suburban construction poses questions that need to be answered before work begins. The issue of heating and water supply is at the forefront. Photo and video materials will help you correctly calculate the required ratios of the area of the house that needs to be heated, the thickness of the roof, the characteristics of thermal insulation materials, and the number of windows.

Is it possible to do the installation of gas equipment yourself and only then invite specialists from the gas service to draw up the necessary documentation or entrust this important work to professionals. The results obtained are correlated with the construction site, the infrastructure surrounding the site, in particular accessibility to various types of fuel, and It’s a good idea to track the advantages and disadvantages of various types of boilers and their operational problems, which is not easy to do without the appropriate knowledge.

The most rational solution with regard to safety and comfort, room decoration, installation of heating equipment and control over its operation is to move the boiler room outside the residential building. This measure does not guarantee sufficient safety, therefore, on some important points, which are still poorly documented or regulated , but significant in terms of practical work in arranging a room for an autonomous boiler room, should be stopped and considered in more detail. So:

- What needs to be considered before starting work in the boiler room? It is better to purchase boiler equipment in advance, which will allow you to view the requirements for placement of the boiler by the manufacturer in the passport.

- Adjust the dimensions and decide on the placement of technological holes for the chimney (see) and pipe supply.

- Will the selected equipment be able to provide temperature conditions in the boiler room and will its power be enough to heat the entire house?

- The location for the boiler room is chosen along a blank wall; in the absence of such possibilities, door and window openings in the wall are sealed.

- The dimensions of the boiler room are determined by the following parameters. The total volume of the building should not be less than 15 m³, the ceiling height should not be lower than 2.5 m, the area allocated for installation of the boiler should be no less than 4 m².

- The use of a gas boiler up to 30 kW does not require the installation of a separate room for a boiler room in a private house. The instructions do not prohibit the installation of this unit in the kitchen if its premises meet a number of very strict rules.

Requirements for the boiler room

It is believed that the most preferable option for resolving all issues would be to construct a separate room for installing all heating equipment and monitoring its operation. In addition, this will allow you to make the walls, floor and ceiling from the material required for this. That is, you don’t have to redo anything.

There are certain nuances that it is advisable to foresee in advance. In this case, it does not matter at all whether the boiler room is located in a separate building or inside the house.

- Based on the area of the facility, you need to immediately calculate the required boiler power.

- It is advisable to purchase all equipment in advance.

- The place for the boiler room inside the house should be located along a blank wall. If there are window openings, they need to be blocked. The same applies to doorways.

- The door to the boiler room is selected according to the required size. The main rule is that it must be fireproof. A simple interior fabric will not do.

- The dimensions of the room are determined by special standards: • thus, the total volume of such an object must be more than 15 m³; • the distance from floor to ceiling cannot be less than 250 cm; • the area on which the boiler will be installed starts from 4 m²; • all these requirements apply to all types of heating devices.

- The best wall finishing material would be tiles.

If a gas boiler with a power of up to thirty kW is used, then it will not require a separate boiler room in a private house. It can even be placed in the kitchen. Naturally, for this you will also have to follow a number of certain rules.

Advice! It is better to initially contact an organization that checks compliance with all rules and regulations for the installation and operation of boiler equipment. This is the only way to protect yourself from subsequent reworking of all the work done.

Construction of a separate room

Before you start building a hotel boiler room, you need to make a plan for it, which is agreed upon with the gas service workers. Also, this object must be included in the technical plan of the site.

- the structure being erected must have a foundation; it must not be adjacent to the house;

- a separate platform is arranged for the boiler, which should be twenty centimeters above the floor;

- there must be a direct exit from the premises to the street;

- A hood must be selected separately, which can be done independently.

On a note! There are special modular designs. They already include everything you need. But their cost is quite high.

Boiler room project

You must first agree on the plan with the gas workers. The building stands on an autonomous foundation, not connected to the house - which means you have carefully studied the SNiPs and so far you are doing everything correctly.

The boiler must have its own foundation. The elevation of 20 centimeters is laid out from bricks and finished with tiles. The floor is cemented and sand is added to the solution.

The hood is selected based on air exchange. The power of the device should be twice the volume of air passed per hour. You can independently make a hole in the ceiling about 10 cm in diameter and insert a pipe.

We suggest you familiarize yourself with How to finish a brick stove

The part facing the street is covered with mesh. A check valve is installed inside. The homemade hood is ready. But before you get started, talk to knowledgeable people. This will not only help you avoid mistakes, but also save money.

Finishing the boiler room

According to all existing standards, all surfaces of the room must be made of non-combustible materials.

- If the walls were made of wood, then this design requires more careful processing. To do this, they are impregnated with fire-resistant compounds and covered with reflective thermal insulation. They are then covered with fire-resistant plasterboard.

- The floor must be leveled; for this, a mixture of cement and sand is used.

- Waterproofing should also be provided. The floor is covered with special materials (rolled or coating), and a section of the wall is grabbed at a height of ten centimeters.

You also need to pay close attention to the decoration of the walls; they will be exposed to the greatest impact:

- The walls are pre-cleaned and unnecessary objects are removed. So, the windows along the wall where the boiler will be located are completely blocked.

- Now you can begin the process of applying the first layer of plaster, it will allow you to smooth out any defects.

- Putty is used as the finishing layer. With its help, it is possible to prepare the surface for final processing.

Ceramic tile

Ceramic tiles are considered the best solution for the final finishing of walls in a boiler room. It meets all the properties required for this type of coating. This material is resistant to large temperature changes. Even an open flame cannot change its positive properties. It is not for nothing that it is used for lining stoves and fireplaces. But still, the tiles for the boiler room need to be carefully selected. To do this, it is advisable to make sure before purchasing that it has the necessary certificates of conformity.

What and how to finish the ceiling

According to the requirements of SNiPs, the roof and ceilings of the boiler room are made of non-combustible materials. The owner chooses further design at his own discretion. You need to understand that designer delights are inappropriate here. Simple, safe and functional decor is expected. We offer several options.

Plaster and paint

This is the simplest option. Plaster is applied to the ceiling. The number of layers and their thickness depend on the condition of the base. Usually several of them are required to smooth out possible differences in heights and other irregularities. Putty is applied over the plaster lining. It finally levels the surface so that it can be painted. There can also be several layers of putty, but most often there is only one finishing layer.

Further work is carried out only after the base has dried thoroughly. Afterwards it is primed. One or two layers of primer will improve the adhesion of the base and reduce paint consumption. The paint is applied after the primed base has dried. An important point is the choice of coloring composition. According to safety requirements, it should not ignite. Therefore, all products based on solvents or oils must not be used.

A good solution is a silicone compound. This is a water-dispersible preparation made on the basis of silicone. After drying, a plastic thermal insulating film is formed on the base. It has high adhesion to different types of substrates.

The silicone composition is applied in different ways, depending on the consistency of the paste: with a spray gun, roller or brush. The same product can be used to paint a chimney, valves, ventilation ducts, and pipes. For better results, it is advisable to buy special fire-resistant compounds.

Instagram potolkiengels

Instagram dom_i_vest

Suspended structure

If the height of the room allows, it makes sense to make a suspended structure. Its advantage is that between the rough base and the finishing coating you can lay an additional layer of insulation and place utility lines. The basis of any suspension system is a frame or sheathing. For its manufacture, only metal profiles are used. Wooden slats that can be used for other rooms are not allowed here, even if they are treated with fire retardant.

Begin assembling the frame with markings. Mark the level of the lower edge of the ceiling trim on the wall. At the same time, do not forget about the permissible height of the room. Then marks are placed around the perimeter of the room. This is done using a building level to get an accurate horizontal line. Profiles are attached to the markings. Then install guides under the sheathing. The fastening pitch depends on the size of the room, but usually it is 0.45-0.5 m.

Install utilities, if necessary. Lay wiring for lighting fixtures. Cables can be laid openly in special channels or corrugations. It is attached to the sheathing. If necessary, insulation is placed inside the frame. Most often this is slab or rolled cotton insulation. A prerequisite for selection is non-flammability.

Instagram gips_msk

Instagram otoplenie_krasnoyarsk

The finished frame with insulation inside can be sheathed with finishing material. Choose from several options.

As a result

Installing a boiler room requires a very competent approach. Not only the creation of a comfortable microclimate, but also the safety of all residents of the house depends on this. Thus, you should approach each stage carefully. Savings on finishing materials should not be allowed. It is better to entrust the installation of the boiler and equipment to professionals.

The comfort of living in a private house can be increased by efficiently heating it with autonomous heating systems. With their help, you can regulate the internal temperature, creating a favorable microclimate. There are several types of boilers and types of fuel, but regardless of the chosen option, it is necessary to properly arrange the room with the equipment. The decoration of a boiler room in a private house affects the functionality and safety of the technical room.

TOP 20 best photos of boiler room repairs

Natural gas is not only the most efficient and economical, but also the most risky type of fuel in terms of explosion safety and fire safety.

Therefore, the installation of a boiler room in a private house must be carried out according to strict safety requirements. And if you want your boiler room to have a more original look, we suggest you consider our selection of “TOP 20 best photos of boiler room repairs.”

Basic requirements for a boiler room

The most important requirement is to ensure high-quality ventilation. Even in small quantities, carbon monoxide can cause significant harm to human health.

Moreover, with insufficient ventilation, the boiler may produce less heat, consuming the same amount of fuel.

So, when installing a gas boiler room, make sure there is good ventilation.

If we talk about the location of the boiler room in a country house, then the requirements here will be somewhat “softer” than when arranging this room in multi-apartment residential buildings.

The boiler room is allowed to be installed in a separate building, a specially designated room, in an extension to the cottage or in the attic. To navigate this issue and choose the best design for the boiler room, we recommend looking at our photos.

If equipment designed for liquefied gas is used, then the ground floor or basement is not suitable for installing a boiler room in the house. This is because this type of fuel has a high specific gravity, and sinking into the lower parts of the building will cause an explosion.

This feature of liquefied gas is taken into account before installing ventilation, the design of which is extremely simple.

Gas installations up to 60 kW do not require the installation of a separate room. This heat generator can be installed in the kitchen or in some other room that meets the following requirements:

- room volume - at least 15 m 3 + 0.2 m 3, which goes for each unit of boiler power;

- room height – not less than 2.5 m;

- There is a window with a window in the room.

The walls in the boiler room must be fire-resistant, namely, capable of withstanding high temperatures for 45 minutes.

Boiler room installation

The heating system includes not just pipes and a boiler, but also other important communications and devices for effective functioning, located in the room according to a certain, predetermined and calculated scheme.

Heating consists of:

- Heating boiler – heat generator. The burning fuel in the combustion chamber of the boiler heats the coolant, and heat from radiators and pipes flows from the boiler room into the room.

- Headstock of the water heater. The main purpose of the boiler is to provide households with hot water. A heated coolant circulates through a pipe that runs inside the tank, causing the water in the boiler to heat up.

- A distribution manifold, which consists of a circulation pump, a comb and a hydraulic distributor. The main purpose of the distribution manifold is convenient distribution and circulation of coolants in the heating system apparatus and maintaining the coolant temperature.

- An expansion tank is required to compensate for the pressure in the heating system as a result of heating the coolants.

- A safety group that protects the heating circuit from excess air and excess pressure.

- Chimney. The efficiency and safety of the heating system largely depends on the correct installation and calculation of the chimney in the boiler room, which is carried out according to a certain scheme.

- Shut-off valves (to block the ceiling from evaporation of the medium), pipeline.

- A make-up system that controls pressure loss due to evaporation or other leaks.

- Automation, which is an electronic device that controls the gas boiler room in the house.

But, in addition to the correct technology for installing the boiler, it is important to take care of the design of this room, which our photos will help you with.

Premises requirements

Finishing work in the boiler room in the house is carried out in compliance with regulatory requirements regarding the premises in which the boiler is installed:

- the area of the boiler room should not be less than 8 m2;

- the height of the walls of the room should not be less than 2.5 m;

- one boiler room can be designed for one or two boilers;

- an exhaust hood must be installed in the boiler room;

- the fire door must have a width of at least 800 mm and open outward;

- the floor is tiled or covered with steel sheets;

It is unacceptable to store flammable and flammable substances and materials on the boiler room premises, as well as unnecessary items that do not affect the functionality of the room. Passages and space around equipment must be free.

Doors for boiler room

There can be two doors in a boiler room: one leads from the boiler room into the house, and the other leads from the boiler room to the street. For security reasons, a metal door will better protect against burglary, so the street door should be metal, with two locks - a lever and a cylinder. The door that is installed in the house may be wooden, but only if the boiler is electric or gas. Where the boiler operates on solid fuel, it is better to additionally protect the house from fire and install a metal fire door between the boiler room and the living space, which prevents the penetration of fire for up to 60 minutes.

How can you line the inside of a boiler room?

Before deciding what the walls in the boiler room should be like and how to decorate them in a private house, you need to familiarize yourself with the technical characteristics of building materials for their fire resistance. When choosing the best way to decorate block walls in a small boiler room in a country house, it is important to remember that the design of the boiler room is not the determining factor when choosing a material - its practicality comes to the fore. For walls made of aerated concrete, concrete or brick, choose plaster or water-based paint. Tile or metal panels are used as decorative finishing.

Sheathing the walls of a boiler room in a private wooden house is necessary taking into account the low fire resistance of wood and the need to carefully protect it from fire. The wood must be treated with fire retardants before finishing, even if the lumber was initially treated with similar impregnation at the manufacturing stage.

Walls

When choosing a method for decorating walls, it is better to choose a material that is easy to work with. Plastering allows you to immediately solve several issues:

- quickly carry out repairs to the premises;

- level the walls;

- create a monolithic fire-resistant layer that has high strength and thermal insulation properties.

Plaster can be used as a preparatory base for finishing or as a decorative finishing layer. In the second case, you can use paint or decorative plaster applied over the starting smooth layer. The plaster is applied along beacons - metal guides fixed to the wall.

The composition is thrown between the beacons and then stretched using the rule. Before finishing the walls with plaster, the surface is dust-free with a primer - the composition clogs the pores of the base and reduces material consumption.

Tiles in a small boiler room in a private wooden or block house are the best option for obtaining a fire-resistant coating and decorating the interior of the room. It is laid on smooth plastered walls.

Before finishing the surface of the walls with sheet metal, they are treated with protective impregnations and, if necessary, insulated. The insulation is laid between the guides of the sheathing, to which the sheet sheathing is subsequently attached.

The floor in the boiler room is subject to serious loads during operation, so it is recommended to finish it with ceramic tiles or porcelain stoneware. These are the most wear-resistant, durable and fire-resistant materials.

Floor tiles for a boiler room in a private house are selected taking into account the technical characteristics. Color and pattern are not so important, although modern manufacturers offer a wide selection of colors and textures. To make the floor easier to care for and to maintain its attractive appearance for many years, it is advisable to choose large-format tiles. The fewer seams, the more monolithic and durable the coating will be.

Features of choice

The most common tile size is 30*30/60*60. Before purchasing the material, you need to understand how strong porcelain stoneware is, whether it can cope with mechanical loads, and whether it will not deteriorate from falling heavy objects. It is very important to lay tiles correctly, use them correctly and care for them. It is necessary that there are no empty spaces from the screed to the material. In this case, porcelain stoneware can withstand significant load. If there are voids at the bottom, the tile breaks under minimal load.

As with processes such as UPS maintenance, installation of the material should be done by professionals. In a home boiler room, you can use ordinary floor tiles to create a coating. This option is quite budget-friendly; here you can use simple ceramics. This coating will last for decades. If we are talking about a large boiler room, then there is no way to do without the use of porcelain stoneware. It has a higher level of reliability, the material can cope with heavy loads.

How to lay ceramic tiles

Laying tiles is an expensive job. A good master will charge for this work an amount comparable to the price of the purchased tiles. With patience and perseverance, you can handle this work yourself. You just need to remember that a mistake made at the beginning of work can negate all the efforts made. Therefore, you need to approach this issue very responsibly and carefully.

Stencils for tiles

Ceramic tiles are a universal finishing material. Today, thanks to the development of production technologies, it is about. New types of ceramic tiles have been developed that are more beautiful in appearance and have high durability.

Preparatory work

Installation of equipment requires a level base. Therefore, first of all you will need to level the floor. There are many ways, the choice depends on the design and material of the building, as well as on the desired speed of work:

- A traditional wet screed allows you to get a perfectly flat base, but it dries within 28 days. If the screed has already been poured, it can be leveled with construction self-leveling compounds.

To level the walls, use plaster, plasterboard or CSP boards.

Boiler room in a private house: selection of equipment and arrangement of the room (90 photos)

Heating a country house is an important condition for comfortable living in a house. It is for this reason that the boiler room should be taken care of even before finishing work begins. Today, manufacturers offer various energy generators for heating.

Thus, gas equipment for a boiler room in a private building is designed and equipped in accordance with the most stringent requirements. The main reason is the possibility of explosion.

The second place of honor is occupied by boilers using solid and liquid fuels. Compared to gas appliances, they are not as explosive, however, they must be placed in a separate room. It is important to equip it with a high-quality supply and exhaust ventilation system and it is necessary to provide a special channel for the removal of chimney gases.

Electric boilers are easy to install. They do not require installation in a special combustion room. But in this option there are special rules related to safe use.

Since the requirements for a gas boiler room in private housing construction are the highest, let’s talk about this equipment in more detail. The remaining types of heating installations automatically meet the requirements created for gas appliances.

Boiler room interior

The interior of the boiler room should be primarily functional. When developing it, it is important to think through every little detail. Consider the location of window and door openings, sockets and switches. Choose a light color scheme to make the room look cozy. It is important to think about the lighting - it should be intense and uniform.

Depending on the area of the room, you can provide a storage area in the form of shelving. Furniture must be made of metal. It is advisable to allocate a place for a fire extinguisher in case of an unforeseen fire hazard.

”

Thinking through the interior

When creating the interior of a boiler room, you must be guided, first of all, by its functionality. When thinking about finishing, it is important to take into account the location of windows and doors, the placement and number of sockets, lamps, and switches. To make the room seem warm and spacious, designers recommend using light shades for the walls and ceiling, and making the lighting uniform, but at the same time quite intense.

For the boiler room, it is recommended to choose simple and compact lamps without design frills. It is important to remember that each lamp will be enclosed in a special protective metal frame. An excessive number of lamps is not necessary; it is important that there is enough light in the room and that it can be easily accessed to service the lamp.

When creating the interior of a boiler room, you need to understand that the main thing is the safety and coordinated operation of the heating equipment, so experts do not recommend excessive decoration in this room.

If the area of the room is large, then in a place determined by SNIP standards, you can consider an area for placing shelving for storing non-combustible materials needed in the boiler room. Shelving and furniture in this room should be made only of metal. In addition, the boiler room must provide space for fire equipment and a fire extinguisher.

For information on the requirements for a boiler room in a private house, watch the video.

Fireproof or fireproof building materials

What is fire retardant material? Fire-resistant, fire-resistant or fire-resistant material is a material that, after undergoing chemical treatment, has certain physical properties that allow such material not to ignite instantly, but to hold and prevent the expansion of fire, while naturally reducing the likelihood of a fire in the room where such material is used .

A very important issue from the point of view of arranging a boiler room for the safe operation of a solid fuel boiler and more. The importance of creating a fireproof room cannot be overestimated. So the main negative characteristics of building materials:

- Smoke formation

- Flammability

- Flammability

- Toxicity

Also, all materials are divided into two main types, if we speak in the context of arranging a boiler room: flammable and non-flammable. We are interested in non-flammable or fire-resistant materials.

Installation of a boiler room in a private house: some requirements

To heat a country house you need a boiler room. The arrangement of such a room requires an absolutely competent approach. It is this device that creates the coziness and comfort of your home, as well as its safety. Therefore, you should approach it with special attention.

You cannot save on some materials, and especially equipment. It is better to entrust the installation of the boiler and some additional equipment to professionals. They will do their job competently and efficiently, with all acceptable standards.

The most important thing for this process is the interior decoration of the room. It should be so fire resistant that it can withstand an open flame for approximately 25 minutes. There are also some specific nuances that must be foreseen in advance, regardless of where your boiler room will be located.

Boiler room requirements:

- Calculate the boiler power, taking into account the area of the room;

- It is best to purchase equipment in advance;

- Select a door of the required size, which must be fireproof;

- All dimensions of the boiler room must comply with special standards;

- Give preference to finishing material – tiles.

Before starting construction of a hotel boiler room, a plan is made, which must be agreed upon with the gas service. Then, of course, this object must be added to the technological plan of the entire site.

Non-combustible and fire-resistant building materials list:

In particular, fire-resistant finishing materials for walls, which are also suitable for the floor in the boiler room. It is advisable to lay and route heating pipes in layers of heat-insulating, fire-resistant material. Also, such fire-resistant materials are suitable for stoves, if we talk about their finishing and finishing of the room in which the heating device is located:

- Plasters, gypsum, cement

- Natural stone: sandstone and slate

- Concrete

- Aluminum

- Steel

- Granite

- Glass

- Porcelain tiles

- Ceramic tiles

- Mineral wool

- Fire resistant drywall

The above types are also suitable as fire-resistant materials for stoves. By the way, here is a very good video showing in practice the importance of using non-combustible thermal insulation:

Separately, it is necessary to say about special fire-resistant impregnations, which can also be added to the plaster. Even wood impregnated with fire-retardant impregnations does not burn and will not become a source of fire, it will only smolder. After eliminating the original source of fire, smoldering stops. Such impregnations prevent the flow of oxygen into the wood, and therefore prevent combustion.

It is also worth remembering about mineral wool. Today this is the best fire-resistant material. Mineral wool not only does not burn, but is also an environmentally friendly material; even at elevated temperatures it does not emit substances harmful to the environment and humans. There is also special cotton wool for fireplaces and furnaces, and finishing the chimney from the inside. On one side, such cotton wool has a heat-reflecting surface. Capable of withstanding temperatures up to 1000 °C

If we talk about wallpaper, then they are not as dangerous in terms of flammability as it would seem. If the surface under the wallpaper is made of fire-resistant material, then there are no problems. In general, it’s worth mentioning separately about equipping walls in such a way that they are fireproof.

Finishing a boiler room in a private house: photos and materials

Finishing the boiler room is a very important stage of construction. You need to arrange and decorate the premises very competently - this is the key to your safety. To do everything correctly and at the same time beautifully, you need to fulfill all the requirements and adhere to the standards.

Before you start finishing the room, you first need to determine what material you will use for these purposes? There are a large number of materials for this, but the most alternative option is tiles.

After looking at various photographs of individual options for finishing boiler rooms, you need to make a choice or create your own room design and bring it to life.

Non-combustible finishing materials:

- Ceramic tile . This is an ideal solution for wall decoration.

- Porcelain tiles . They usually cover the floor of a boiler room, as it can withstand heavy loads.

- Xylolith-fibrous leaf . This is an environmentally friendly material that can withstand very high temperatures (1000 degrees).

- Fireproof and heat-resistant plaster . It can withstand an open flame for several minutes. It can also be painted in different colors without losing its fire-resistant properties.

The decoration inside the boiler room can be made from inexpensive materials, but they must meet all the requirements. The price of some of them can even be very modest. The main thing for a boiler room is not its finishing, but the equipment. This is what you need to spend your savings on in order to feel safe.

Fire-resistant materials for walls

So: partitions, vertical ceilings, walls should not be hollow inside, for fire safety purposes, if these same walls are made of flammable materials. The exception is wooden structures, which are separated from each other by diaphragms. If we talk about non-combustible materials for walls, then insulation made from such material must be vapor barrier. If the insulation is made of flammable material, then the voids between the sheets of insulation must be filled with slow-burning materials. This way, in the event of a fire, the flame will not spread.

In short: if, for the sake of economy, flammable insulation is used, then it should be separated sectionally by non-flammable gaskets, for example, metal sheets, so that the fire does not spread throughout the entire building.

In this regard, it is worth mentioning especially dangerous flammable materials.

Combustible materials

- Polyurethane foam (Mounting foam) is a very flammable material that emits a lot of fumes and toxic substances when burned.

- Expanded polystyrene (foam) is a popular material for insulation, but do not forget about its dangerous, flammable qualities.

- Bitumen (bitumen roofing)

- Linoleum - releases very toxic substances when burned.

We hope this article will help you create a safe heating system. Non-combustible building materials are extremely important in building a safe and warm home. Forewarned is forearmed! Another important element of boiler room safety is proper calculation of boiler room ventilation.