Icer

26011 0 13

Icer November 18, 2016Specialization: master in the construction of plasterboard structures, finishing work and laying floor coverings. Installation of door and window units, finishing of facades, installation of electrical, plumbing and heating - I can give detailed advice on all types of work.

After finishing, the room must meet safety requirements

Today we will figure out how a boiler room is finished - in a wooden house, a building made of brick or blocks. You will receive solutions that can be implemented on your own and there is no need to pay for the labor of builders, especially since in this room the requirements for the quality of work are much lower.

In the photo: tiling is a win-win solution for the boiler room

Plaster is no worse suitable for finishing than tiles

Regular water-based paint is also suitable for painting walls.

Open and closed heating circuits

Typical boiler room circuits are divided into “open” and “closed”. An open circuit is cheaper to install, but operating costs are significantly higher. In a closed system, the coolant is heated directly in the system, and the pump circulates it.

The main difference between these systems is that in an open system, the coolant in the expansion tank comes into contact with air. This means that some of the heat is lost.

The closed circuit (the most common) is labor-intensive to install, but due to its tightness, heat loss tends to zero.

Home boiler room design

A significant part of the family budget is spent on heating the house. Therefore, at the design stage of the system, one should strive for its maximum optimization by performing an accurate calculation of the boiler room layout for suburban housing.

It will be necessary to calculate all options for the location of equipment, including the boiler, expansion tank, radiators, as well as taking into account the features of wiring and circulation.

When designing a boiler room, it is necessary to proceed from the requirements of regulatory documents. In the room where the boiler is installed, additional heating is often installed, since the heat generated by the unit itself is not enough (+)

A well-designed schematic diagram of a boiler room should reflect all the elements and the pipeline connecting them.

The standard drawing includes: boilers, pumps - make-up, network, circulation, recirculation, tanks - condensation and storage, heat exchangers, fans, fuel supply and combustion devices, control panels, heat panels, water deaerator.

Possible circuit options

When drawing up a typical boiler room diagram, you can take as a basis one of two options for heating networks:

- open

- closed.

Installation of an open circuit is less expensive, but is more expensive during operation. The second option is more complex at the initial stage, but coolant leakage is practically reduced to zero, since the system is sealed. This scheme is used in most private houses.

The closed system includes a boiler that provides hot coolant to both the heating system and the water heating circuit, a closed hot water supply pipeline.

The circulation of the coolant is carried out here forcibly by means of a pump. This allows, when installing pipes, without particularly worrying about slopes, to lay them in a way that is more convenient.

Requirements for the boiler room

There are 2 types of requirements put forward for a boiler room in a private house - general and specific, depending on the category of fuel used.

The first type of requirements include:

- A maximum of 2 boilers can be installed in one room, regardless of its area.

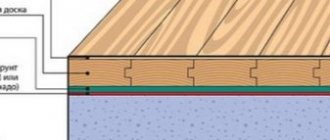

- When constructing and finishing a boiler room, it is unacceptable to use materials that do not meet fire safety requirements. For the construction of walls it is necessary to use brick or concrete blocks, and for finishing - plaster or tiles. The floor must have a concrete or metal covering.

- Ventilation and flue must be suitable for the installed equipment. Special requirements apply to ventilation when using gas-powered equipment. In any case, the air in the room must be circulated and renewed at least 3 times within 60 minutes.

- A prerequisite is the presence of a window and a door that opens outward. It is possible to have a second door leading to the utility room, but it must be done in accordance with fire safety conditions.

Boiler room in the house: main types for private properties

The boiler room does not have any specific design. In a private house, you can install any boiler room that the owner himself desires. There are no uniform parameters. The size, location and equipment for the boiler room are chosen by the owner himself.

Heating equipment requires strict control. Often it must be installed separately from the main building, since such equipment is dangerous. Therefore, you need to fulfill certain requirements to protect yourself and your loved ones.

The boiler room, also called the furnace room or boiler room, can be located both outside the house and inside it. It can be placed in many different places: on the ground floor, in the garage, in an extension or in the basement. However, it is best to place it at some distance from a country building.

Type of boiler room by its location:

- A built-in boiler room in a house that does not have a separate room. All equipment (boiler, pump, boiler) can be located in the kitchen or hallway. This option is the cheapest and is only suitable for a small boiler.

- Boiler room built into the house, but located in a separate small room

- The boiler room, which is located in the annex. This option is suitable for equipment that creates a lot of noise.

- A separate mini-boiler room located at a distance from the building.

The cheapest option is a boiler room in the kitchen, suitable only for a small boiler. A convenient option for a boiler room for heating is inside the house, but it is located in a room intended for it. The boiler room attached to the room may have a separate door. The safest is the boiler room, which can be built separately from the main dwelling, but this is very difficult and expensive to do.

What you can’t do without in a boiler room

Actually, the boiler itself, in which the coolant is heated. For large houses, you will need to install a collector that distributes coolant between separate groups of heating devices.

An expansion tank (tank), a water heater, a supply pipeline and shut-off valves that regulate the parameters of the heating system are also required.

Don't forget about automation to control the functioning of the system. Of course, the automation unit costs extra money, but these costs will quickly pay off.

Any heating system includes two interconnected systems - a chimney (removes exhaust gases) and ventilation (an influx of fresh air, which increases fuel combustion).

No. 3. Types of boilers for boiler rooms

Many of the nuances of arranging a boiler room depend on what type of boiler will be used.

According to the type of fuel, boilers are divided into:

- gas , operate on natural or liquefied gas, are characterized by high efficiency and ease of control. They can be converted from one type of gas to another. The optimal choice for most private homes;

- solid fuels (coal, firewood, peat, briquettes) are more economical in terms of operation, but you will have to constantly monitor the system and add fuel;

- on liquid fuel (diesel). Such boilers are usually installed where it is not possible to use natural gas or supply liquefied gas. If, over time, a gas pipeline appears in the area, then such a boiler can be converted to work with gas;

- electric boilers are the safest, most convenient and silent, but also the most expensive. It is not profitable to heat an entire house with them, but they are suitable as a backup heat source.

According to the installation method, boilers are:

- wall;

- floor

Wall-mounted boilers in a compact housing contain such necessary elements as automation, sensors, expansion tank, etc. Boilers with a power of up to 60 kW are produced in a similar design. If the boiler power does not exceed 35 kW, it is allowed to be installed in the kitchen or hallway. Wall-mounted models are often more sensitive to water conditions. Floor-standing models can be of any power; they are indispensable for heating large areas.

What power does the boiler need? It is better to entrust the calculation to specialists who know that many parameters need to be taken into account. To roughly understand how much power the equipment will need, you can use the rule that for every 10 square meters of house area you will need 1 kW of boiler power. If it is to be used in a hot water supply system, then another 10% must be added to the power. To ensure that the boiler does not operate at the limit of its capabilities, another 20% is added to the obtained value.

Gas boiler houses

Increased requirements apply to gas boiler houses (instruction MDS 41-2.2000 and SNiP II-35-76), and gas boilers are subject to mandatory certification.

Remember that obtaining permits will require strict compliance with all regulations and standards. For example, the presence of a gas detector in the room.

Boilers less than 30 kW can be placed in the kitchen provided:

- have good ventilation in case of gas leaks. At the same time, the kitchen window area is at least 0.5 sq.m., and the width of the doorway is from 0.8 sq.m.,

- kitchen walls should be made of fireproof materials,

- The minimum room area is 6 sq.m. with ceilings higher than 2.5 m.

Screen for a heating radiator - a review of the best ideas and recommendations from designers for selecting screens for a heating system- Chimneys for gas boilers - main types and step-by-step instructions for do-it-yourself installation (video + 100 photos)

Double-circuit gas boiler: the best models, recommendations for choosing and installing a boiler with your own hands (105 photos)

For powerful gas boilers (exceeding 30 kW), you will have to allocate a separate building.

Electric boiler rooms

The safest type of fuel is electric. It does not require a dedicated ventilated room, due to the absence of any combustion products.

In addition to a very high efficiency (up to 99%), electric boilers are distinguished by their ease of installation, almost silent operation and ease of maintenance. The disadvantages include the need for a stable, powerful power supply.

Electrical sources of thermal energy are connected to heating radiators. Temperature adjustment is carried out either using a burner or using a servo-driven mixer.

Solid fuel boiler room

According to building codes, there should be no solid fuel boilers in living rooms and kitchens. The extension should be correctly placed next to a blank wall, as shown in the photo of a boiler room in a private house. For high fuel power, independent buildings are built.

Components of an effective solid fuel heating scheme:

- corresponding heat generator,

- boiler piping, including a circulation pump, three-way valve, safety group,

- chimney,

- storage water heater,

- automation unit,

- fire extinguishing complex.

Coal, peat or firewood are solid fuels. In the case of coal, it is important to remember that coal dust in high concentrations is explosive. Therefore, it is important to protect the electrical wiring.

No. 1. Types of boiler houses by location

Of course, there are safety requirements that must be observed when arranging a room such as a boiler room, but they still give us the right to choose in matters of the type of fuel, size and location of the furnace room.

Depending on the type of placement in a private house, the boiler room can be::

- built into the house . In this case, all equipment is placed in one of the rooms of the house (usually the kitchen or hallway). In terms of simplicity and low cost of installation, this is the best option, but it is only suitable if you plan to use a low-power compact boiler. In this case, it is not recommended to use a gas boiler with an inflatable burner due to its high noise level, and equipment operating on diesel fuel can cause a lot of inconvenience due to the strong unpleasant odor;

- in an extension or separate room of the house. All boiler equipment is located in a separate room, which is connected to the house by one or more walls. The door to such a boiler room is covered with non-combustible materials. This is the best option in terms of convenience and safety. If the boiler room is adjacent to living quarters, then it is advisable to provide additional sound insulation: SNIPs do not say anything about this, but it will be much more comfortable;

- detached building. All equipment can even be moved into a separate small building, equipped in accordance with all rules and regulations. It will be connected to the house through heating mains. In this case, your hands are free: you can use any type of equipment and not worry about noise or odors. Often such boiler rooms are equipped when a high-power gas boiler is used. The downside is the cost of constructing a separate building and laying communications;

- block-modular boiler room. All equipment in this case is located in a container that can be relatively easily moved from place to place. It is used as a backup or temporary type of heating in enterprises and industrial facilities, but can also be used in a private home.

Ideally, it is necessary to think about the location of the boiler room at the stage of designing a house . If the house has already been built, the number of possible location options is reduced, and because of this, you may be faced with the fact that the choice of heating equipment will be significantly limited. In any case, when starting to arrange a boiler room, it is better to seek help from professionals. In Moscow, the region and neighboring regions, it is engaged in the installation of boiler houses: since 1997, the company’s specialists have commissioned more than two hundred household and industrial facilities. Specialists accompany each facility from design to commissioning. Examples of work and other details can be found on the page https://migplus.ru/montazh-kotelnyh.html.

Liquid fuel boiler houses

Installing such a boiler room in a house is much simpler than installing gas or solid fuel analogues. Such furnaces are placed both inside and outside the house.

High noise and specific smell usually exclude the placement of such a furnace in the kitchen. A reasonable solution would be to allocate a separate room with good sound insulation.

What does an inverter air conditioner mean: difference, myths- Benefits of Drip Irrigation

- How to choose a solid fuel boiler for heating a private house

An absolute plus is that no permits or approvals are required. All that is needed is free access for transport with fuel, as well as regular refueling of the boiler.

No. 6. Requirements for boiler room ventilation

For an electric boiler, ventilation is not particularly needed; in other cases, you will have to carefully study the existing requirements:

- boiler room ventilation can be combined with the general supply ventilation of the house;

- it is necessary to provide 3 times air exchange in 1 hour, i.e. if the volume of the boiler room is 15 m3, then 45 m3 of air should enter it per hour. It is necessary to maintain the combustion process, part of it is necessary for exhaust;

- To organize natural draft ventilation, a hole with a diameter of 13-15 cm is made in the wall opposite the boiler with a boiler power of up to 40 kW and 17 cm with a higher power. A special ventilation pipe with a damper and mesh is placed in the hole;

- if the boiler room is a separate room, then ventilation can be organized thanks to the presence of louvered grilles at the bottom of the entrance door. For 1 kW of boiler power, I provide 8 cm2 of ventilation hole area;

- when using general house forced ventilation, the size of the hole is calculated based on the proportion: per 1 kW of boiler power 30 cm2 of hole;

- forced ventilation should work more efficiently, will not depend on various weather factors, but will consume electricity. To save some money, you can synchronize the operation of the boiler and ventilation so that the fan turns on only when the boiler is running. When using gas and diesel boilers, the fan is placed in the housing to prevent ignition.

Summing up

The legislative framework changes frequently, so already at the preliminary stage of designing a combustion chamber it is important to study all current standards and regulations. When planning to install a powerful furnace, it is wise to contact specialized organizations.

Believe me, saving on the work of professionals often leads to a significant overpayment during operation, as well as extremely unpleasant and dangerous consequences for the life and health of your household. Even if the boiler room is small, be sure to consult with specialists.

No. 7. Modular boiler rooms

If you can’t find a suitable room for a boiler room in your house, the extension seems unaesthetic, and it’s not possible to build a separate building, you can use special modular boiler rooms. They are produced ready-made, have the entire set of necessary elements, so installation takes a minimum of time.

A modular boiler room is a metal container no more than 2.5 m long. It has double walls, and a special felt insulation is used between them. The power may vary, but usually such boiler houses are used to heat rooms with a volume of up to 1300 m3 (with a ceiling height of 2.7 m, this is about 480 m2). Depending on what type of boiler is used, diesel, coal, wood, etc. are used as fuel.

A three-layer metal pipe with insulation leads from the modular boiler room to the house. The standard length is 6 m, but it can be increased. Installation of such equipment is simple. It just needs to be installed near the house (if necessary, the boiler room can then be transported to another place), connected to electricity and filled with water to the heating system. As a rule, such equipment has a backup power supply.