Wood, which was once the most popular material for the construction of homes, is gradually regaining its former popularity. When choosing interior decoration for the ceiling of a wooden house, you have to take into account a number of factors.

What should be the ceiling materials in wooden houses?

Ceiling systems in wooden buildings have structural specificity. You need to choose in advance how to make the ceiling in the house, what materials to use. Most often we are talking about light beam floors and plank flooring. To fill the distance between the beams, special insulation is used.

When choosing what can be used to sheathe the ceilings in a wooden house, you should take into account the following wishes for its characteristics:

- Light weight, good insulation and sound insulation characteristics.

- Safety. The ceiling finish must be durable, reliable and fire resistant. It should not contain harmful toxins.

- Durability. The long service life of the ceiling system will make it possible to forget about repairs for a long time.

- Aesthetics. It is recommended to select a finish that matches the design of the walls. In this case, you can achieve unity of style, which will help create comfort and attractiveness.

Most often, natural materials are used in wooden houses to promote good air circulation inside the ceiling finish. It is very important that the design fits well into the overall style of the room’s decoration.

Requirements for materials for finishing ceilings in a wooden house

The ceilings of a wooden house have their own design features and are lightweight structures made of beams and flooring assembled from boards. The space between the beams is usually filled with thermal insulation material.

The ceiling finish should be light, retain heat and provide sound insulation.

Basic requirements for materials for finishing ceilings in a wooden house:

- Safety. It is necessary that the materials for finishing the ceilings are strong and reliable, and also meet fire safety requirements and do not emit harmful substances both in normal and heated states.

- Durability. The longer the finishing material for the ceiling lasts without the need for repairs, the better.

- Appearance. It is necessary that the materials for finishing the ceiling are in harmony with the walls, creating a unified design and making the rooms cozy and attractive.

Ceiling in the living room of a wooden house, trimmed with wood Source sharanavti.ru

Preference should be given to natural materials that can ensure sufficient air circulation inside the ceiling structure.

In addition, the combination of finishing material with the general style of the premises is important.

Preparatory activities

Before installing the selected ceiling system, the surface of the ceiling is impregnated with special antiseptic liquids. If there is consistently high humidity in the room (bathroom, kitchen, bathhouse), additional treatment with a waterproofing agent is carried out. It is important to provide fire protection to the surface. For these purposes, special impregnations containing fire retardants are used.

Wooden ceiling cladding is processed in the same way. This allows you to significantly extend the life of the elements and protect them from possible deformation. Before installing the sheathing, thermal insulation of the ceiling is carried out. For these purposes, it is allowed to use any insulation. They can be installed under a decorative surface or in the attic. During the preparation process, wiring and other communications are laid.

Ceiling installation with decking

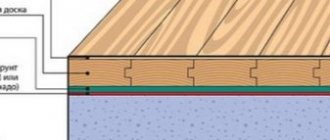

The floor ceiling is mounted on a crown without overlapping beams. This method is used when arranging small ceilings. The floor ceiling is made from boards 0.5 cm thick or more. This is a mandatory condition, because a hydro- and heat insulator and individual parts of the attic or attic floor will be laid on top of the ceiling board.

Prices for ecowool

ecowool

Floor ceiling diagram

The floor ceiling is mounted on the load-bearing walls of the room or on a wooden beam. The timber is attached to the walls with a distance of 1.2-1.5 cm from the edge. To install the timber, brackets made of reinforcing rods are used. Additional fixation is carried out using self-tapping screws or nails.

Floor ceilings are often made from lining with a tenon joint. A vapor barrier, insulation, and moisture protection for the attic floor are laid on top of the floor ceiling. Insulation materials are attached to the attic walls using staples. The last step is laying the plank flooring to assemble the floor in the attic or loft. The flooring is attached to the wall in the same way as the ceiling material.

Features of finishing materials

When choosing a suitable option for covering a wooden ceiling, not only quality and cost are taken into account, but also compliance with the overall design style of the room. In some cases, additional sheathing is not used at all (the insulating layer is laid on the attic side). Thanks to the open beams on the ceiling surface, you can create an original country house style (the so-called “country” style).

Sometimes the parameters of the timber or logs used in the construction of a home are such that it is possible to do without additional thermal insulation. Wood is characterized by the presence of such specific qualities as the ability to absorb excess moisture. Its release occurs when the air becomes too dry. Wood is a good insulator and provides good noise protection.

Most often, lumber, supplemented with plywood, lining, veneer panels or solid wood, is used as ceiling finishing in wooden houses. In the case of external insulation of the walls of the house, their surface is hidden by the finishing. In cases where it is not designed to look like wood, the ceiling can be decorated with plastic, plasterboard or suspended ceilings.

Installation of ceiling panels

A panel ceiling is made up of panels assembled independently on the floor. Then the panels are lifted and installed on supporting beams, additionally connecting them together. In this way, a solid structure is obtained from individual components. The production of panels begins with the assembly of a body from timber and boards.

General diagram of panel ceiling installation

The following are placed sequentially in the box:

- vapor barrier;

- heat insulator;

- waterproofing agent

The last layer is attached to the bars around the perimeter of the body. Next, the panel is lifted and attached to the ceiling beams. The individual panels are combined into a single structure by sheathing made of finishing material. Insulation must be laid between the individual panels to conserve heat during the cold season. If a single panel is heavy, it is better to assemble them directly on the ceiling in the same order.

Lining

This material for finishing the ceiling in a log house is lightweight and environmentally friendly. This finish goes well with the walls of a wooden house. To reduce the cost of purchasing material, you can choose lining made from inexpensive wood. Installation of lamellas is facilitated by longitudinal tongues and grooves on the end faces.

Classification of lining:

- Extra. The most suitable material for sewing up the ceiling in the house. Expensive wood is used as a manufacturing material.

- A and B. There may be minor imperfections in the finish. This does not in any way reduce the strength characteristics of the material.

- C. Budget option, for the manufacture of which inexpensive wood species are used. The finishing surface contains flaws and a large number of knots.

Interior finishing with clapboards

Finishing ceilings with clapboard is very popular because this material is economical, convenient, quite durable and aesthetically pleasing. The main thing is to choose the right lining for a specific room. This is done taking into account the properties of the wood from which the lining is made. The wide range of manufactured linings will allow you to make the right choice from an aesthetic and technical point of view.

Pine lining has a low cost, has fairly high performance characteristics and an attractive appearance. However, pine wood actively releases resinous substances under strong thermal influence. Therefore, pine lining is not used in rooms with high temperatures (kitchen, sauna, bathhouse, bathroom, rooms with fireplaces).

Types of lining

Linden lining is noticeably more expensive. At the same time, it tolerates thermal effects better and is not afraid of very high temperatures. Larch lining is less susceptible to rotting. Therefore, it is used for loggias, terraces, verandas, etc., semi-enclosed spaces.

Oak lining is an expensive material. However, the performance properties and original texture will justify all the costs. It is not without reason that oak lining is used for cladding rooms in luxury buildings.

, alder, hornbeam, cedar, aspen and other types of wood are used to make lining . Before making a choice in favor of a specific type of wood, you need to carefully study all the properties of the material, rules for working with it, aesthetic qualities, etc.

Veneered panels

A material very similar to lining. The difference concerns the use of inexpensive wood for the manufacture of panels, which is covered with a thin veneer of expensive species on top. This allows you to imitate the luxury finish of a wooden ceiling in a private house. The dimensions of veneered panels differ from the lining.

Slat ceiling

For a slatted ceiling, you can use “Block House” type material. From the outside, their surface imitates timber. An important advantage of this material is the complete absence of cracks and seams during installation. In the factory, Block House slats are impregnated with special compounds to prevent fire, moisture, fungus, etc. Therefore, they go on sale completely ready for installation.

Prices for slatted ceilings

slatted ceiling

Block house

To install a slatted ceiling, it is necessary to install a sheathing made of tin profiles or planks of wood. The slats are attached to the frame using a locking connection. The necessary communications and insulating materials are placed between the rough sheathing and the slatted finish.

Plastic panels

The most budget option for finishing ceilings in a log house. Plastic panels are easy and quick to install. During operation, they are easy to maintain and replace in case of damage.

Materials

There are many suitable materials for cladding the ceiling in a wooden house. You can choose finishing materials to suit any budget. Mostly, owners of wooden houses prefer wood finishing, but other methods should not be excluded. The easiest option is to cover the ceiling with plaster and paint. You can choose white, which will go well with dark wood in the house, or warm pastel colors, which will go well with light wood.

Another inexpensive way to decorate the ceiling is to decorate it with plastic panels. This is a reliable, practical and cheap material, and it is quite possible to carry out such repairs on your own. In addition, the modern design of such panels is very diverse. You can choose white or colored options, glossy or matte panels, and even products that imitate wood.

If you have a house with low ceilings that you want to visually raise, tension and suspended structures will not suit you. If there is enough space, then it is worth considering this option. Stretch ceilings will allow you to hide all the flaws of the rough finish, apply any designs to the ceiling, and also create unusual lighting in the room - for example, you can build lamps under such a ceiling or even create images from colored LEDs.

Finally, it is quite possible to decorate such ceilings with wooden beams or make a coating that imitates wood.

If you decide to decorate the surface with wood, this can be done using timber - such a finish will create an authentic atmosphere of a country house. In addition, ceilings are often finished with clapboard - it is easy to install it yourself, since it has joints with recesses for your convenience.

If you are looking for a budget option, the ceilings can be sheathed with plywood or OSB boards: often such finishing can look no less good than solid wood. The surface can be decorated with carved patterns and beams of different heights.

Stretch ceiling

The material used for the ceiling in the house is PVC film or fabric without seams. Stretch ceilings are convenient because even if a wooden house shrinks, they retain their configuration. However, if the stretch ceiling in a wooden house with beams is seriously damaged, the canvas must be replaced.

Finishing the ceiling in a wooden house: several examples in the photo

Solid ceiling Source yenni.biz

Slatted ceiling in a wooden house Source projecty-domov.ru

Original slatted ceiling design Source houzz.es

Decorating the ceiling with varnished beams Source nauterre.com

Wooden ceiling in country style Source ceemat.ru

Slatted wooden ceilings

Before covering the ceiling in a private house with a slatted system, preliminary arrangement of the sheathing will be required. When attaching slats and lamellas, it is possible to create a continuous surface without gaps. For joining, decorative panels are equipped with closed grooves. Joining with gaps is also possible when open type grooves are used.

Sometimes these gaps are decorated with special decorative inserts. Rack suspended structures make it possible to lay utility lines (electrical wires, air ducts, various cables) between the decorative surface and the base. Thermal insulation material can be used to fill the free niche.

Plasterboard ceiling

Drywall is a relatively cheap and aesthetic material. An important advantage of drywall is heat resistance. Drywall is not difficult to work with and is easy to install. Modern technologies make it possible to apply the required image onto plasterboards. Using plasterboard it is easy to make multi-level ceilings with irregularly shaped elements. This will allow you to create an interesting composition on the ceiling that supports the main design line of the interior.

The main disadvantage of drywall is its hygroscopicity. Therefore, it is better not to use this material in particularly damp areas.

Drywall is laid on the ceiling using suspended technology. Therefore, first you need to install the lathing from a galvanized profile, starting with the wall elements. Internal elements are evenly placed between them in increments of no more than 0.6 m. Sheets of plasterboard are attached to the sheathing. The connections must be puttied.

Suspended ceiling installation diagram

The finished plasterboard ceiling is covered with decorative plaster, painted, covered with veneer and wallpaper. On the finished surface, you can create an interesting composition from beams, slats, overlay panels or similar decorative elements.

How to install lining

Most often, lining is used to decorate a wooden ceiling in a private house with your own hands. This makes it possible to create a closed cladding.

The ceiling lining has the following dimensions:

- Length: 2-4 m.

- Width: 70-150 mm.

- Thickness: 10-25 mm.

By measuring the ceiling in a room, you can quickly determine the required amount of material. If cheap lining is used, it is recommended to purchase spare elements in case serious defects are discovered. The frame for covering the ceiling with wood is usually constructed from pine beams with a cross-section of 40x40 mm. The timber is calculated based on the length and width of the room, the size of the supporting central beams and the number of special fastening clamps.

Before decorating the ceiling in a wooden house, it is necessary to arrange the lathing. Work on its construction begins with marking the perimeter of the room. It is necessary to mark a line along the walls at a certain height. To control the accuracy of construction activities, a water or laser level is used. Next, a guide beam is installed on the finished sheathing using nails or self-tapping screws. The task becomes much easier if you drill through holes. Another option is to use a furniture corner.

A guide in the form of a nylon thread or fishing line is stretched along the lower part of the guide beam between the walls. This makes it possible to obtain a flat plane of the supporting structure. The support beam is installed at regular intervals, focusing on the guide thread. Decorative panels are installed on the finished frame.

The first and all subsequent elements are fixed to the sheathing using small nails or self-tapping screws. To achieve a good fit of the skin, individual elements are tapped with a rubber hammer. Dense placement of lining in the area of walls or load-bearing structures is prohibited. It is necessary to leave a certain distance in case of expansion of wooden elements with increasing air humidity. Decorative plinth is used to mask cracks.

Video description

For more information on how to decorate the ceiling in a wooden house with clapboard, watch the video:

Further along the bottom of the guide beam from wall to wall, a nylon thread or fishing line is pulled as a “beacon”. This is necessary for alignment in the plane of the supporting structure. The supporting beams are attached at an equal distance, guided by a stretched fishing line.

Fastening the lining to the frame Source emupauto.ru

All that remains is to fasten the lining panels to the frame: the first strip and all subsequent ones are attached to the sheathing at the points of contact with nails or small screws. To tightly join the panels together, you can use a rubber hammer.

It is impossible to sheathe the ceiling close to the walls and load-bearing elements. There should be a small gap in case the wood expands as humidity increases. The gaps can be covered with decorative plinth.

Slatted ceiling made of lining Source kakpotolok.ru

Budget methods of ceiling finishing

When choosing the appropriate option for covering the ceiling in a wooden house, the cost of the material is of great importance. In cases where the budget does not allow the purchase of expensive natural materials, they can be replaced with cheaper imitations. For example, inexpensive plastic panels are available in a wide variety of colors and textures. The wood-like plastic surface goes well with wooden walls.

Using white panels without seams, you can create a surface that is in no way inferior to expensive stretched fabrics. Another option for a budget material for finishing the ceiling in a wooden house is MDF panels laminated to resemble a wooden texture. Pine lining, when properly designed, resembles finishing made from valuable species. To do this, it is impregnated with stain and varnished. You can do the same with plywood sheathing.

Inexpensive options for finishing the ceiling in a wooden house

When choosing what to decorate the ceiling in a private home, you need to focus not only on the appearance and other qualities of the material, but also on the price category.

If you need to save a little, then an alternative to expensive finishing materials can be their imitation. For example, a ceiling made of plastic panels can be of any color and texture. Wood-like plastic looks good in combination with natural wood on the walls.

Wood-look plastic panels Source alterwood.com.ua

White seamless panels can compete with expensive stretch ceilings.

White plastic panels Source russian.everychina.com

MDF panels laminated to match the texture of wood are also suitable for wooden walls. It is easy to pass off pine wood lining as a valuable type of wood by impregnating it with stain and opening it with varnish. The same can be done with plywood.

Additional decorations for the ceiling

The ceiling decoration can be made so unusual that it will transform the entire interior. This is achieved through various combinations of materials and elements.

For this, the following materials are used for the ceiling in a wooden house:

- Decorative panels

. This refers to wooden elements made to order for a specific room. The cost of such finishing is quite high. Solid wood, decorated with beautiful carvings, can be used as raw materials. - False beams and beams

. To decorate a wooden ceiling in a private house, it is enough to correctly use the elements of the ceiling structure. For example, if you make the beams dark and the ceiling fabric light, you get a very effective finish. This way you can achieve a visual increase in space. In cases where the beams are covered with sheathing, imitation timber is used. - Alfrey finish

. This is the name given to the decoration. To accomplish this, several methods are used: images can be rolled with a roller or printed using a stencil. Sometimes panels are pulled out and painted surfaces are trimmed. This is a rather rare way to decorate the ceiling in a wooden house inside, which goes well with the classic vintage design. In modern styles it is practically not used.

Ceiling installation with filing

The ceiling is hemmed directly to the floor beams using beams or lathing. Minor irregularities are eliminated by placing wooden wedges under the sheathing elements in problem areas. Only electrical wires can be hidden under such a ceiling. In this case, fire safety rules must be carefully observed.

Circular saw prices

a circular saw

Installation of a false ceiling begins with laying a vapor barrier film. This film is stretched on the floor beams from the inside of the ceiling and secured with staples using a construction stapler. The film sheets must be laid overlapping. The joints of the sheets are taped with construction tape.

false ceiling

If expanded clay or other bulk material is used to insulate the ceiling, the vapor insulator is laid after installing the lower backing layer. In this case, work is carried out from the outside of the ceiling. In this case, the film covers both the lining materials and the floor beams.

Next, a layer of sheathing sheet material is laid on the inside of the ceiling. This can be a hemming board, chipboard, plywood (0.5-1 cm thick), etc. Decorative material is attached on top of the rough hemming. If the ceiling is finished with clapboard, additional filing is not required. If you choose good quality material for hemming, you can refuse the decorative coating. Hemmed sheets or boards are varnished or painted.

Installation of hemming material

Roll or fill insulation is placed between the floor beams on top of the vapor barrier. To protect against moisture, a waterproofing material is laid over the insulating material. This is usually roofing felt or polyethylene, which is attached to the floor beams with brackets. Next, the top layer of rolled sheathing is laid. Thanks to this, the floor of the attic or attic is obtained.

To avoid deformation of the sheathing material, a temporary board flooring is installed during the work, on which you can walk freely. As the work progresses, the flooring moves to the area to be finished.

MDF panels

When looking for how to decorate the ceiling in a wooden house, you should pay attention to MDF cladding panels. MDF is a good wood substitute. This material is made from finely ground wood waste, which is held together into a board by urea resins added to the mixture and lignin, which is released from the wood fibers during the heating that accompanies the molding of the material.

MDF successfully competes with natural wood due to its advantages:

- ease of use;

- dimensional stability;

- resistance to rot and insects;

- very wide design possibilities.

Cladding panels from it can be made of different sizes - from narrow strips, like lining, to large panels, the size of which is limited only by the convenience of their installation and the ability to provide slack, which is necessary in order to avoid warping of the skin.

MDF panels are decorated with painting or vinyl film, onto which any pattern is applied. The wood grain pattern is just one of many options. In addition to the pattern, a texture can be imprinted on the surface of the slabs, which also serves as decoration. Moreover, any relief can be created on the surface of this material using milling, which further expands the design possibilities.

Here we have significantly moved away from the priority of “wood” design in the interior. The dominance of wood in the interior decoration of a wooden house is very popular, but not mandatory. In addition, wood combines very well with modern materials, which can also be used when creating an interior.

Plaster

- inexpensive and accessible

- wide range of colors at your service

- practicality

It is difficult to discourage our people from using various types of plaster in their houses and apartments. It is also suitable for ceiling structures in private wooden houses as a finishing material. The general complexity of the plastering procedure does not scare off the owners, who are heart and soul for this option.

Drywall

- attractive with the possibility of individual design and two-level structures

- refresh the room and bring it as close as possible to modern design trends

In fact, plasterboard structures are a universal option for all occasions. Including for finishing the ceiling surface in a wooden house. However, they require good compatibility with the rest of the interior details, so if you have retained a slightly popular provincial style, then it is better to find a more friendly finishing material from those listed above. At the very least, they will definitely look much more organic.

Stretch ceiling

- suitable for installation only after the building has settled

- seriously reduce the height of the room

It is difficult to find something more beautiful, varied and impressive than a stretched canvas with an original photo print and an intricate arrangement of lamps along the area of the ceiling structure (see examples of stretch ceilings with a 3D photo drawing). But there are several points that should not be missed in any case: since a constructed building subsides over time, suspended ceilings should be installed only a few years after construction, and the fact that polyvinyl chloride does not allow air to pass through well can contribute to the appearance of dampness and fungus in the room.

Plastic

- simple installation, accessible even to beginners

- nice surface design

Probably, although this option for finishing the ceiling has certain advantages, it can only be recommended to the enemy. The reason is still the same - the fact of the artificial origin of the finishing material entails poor air circulation between the layers and the rapid appearance of mold, bad odor and mildew. In addition, such plastic panels strongly emphasize geometric correctness, which may not fit well with the free interior of a wooden house.

Sheathing with boards or clapboard design options and installation technology

Before making a ceiling in a private house, please note that for covering it in a wooden building it is better to choose a board, wooden lining or MDF. Plastic panels in this case will be inappropriate. For an original design, you can choose laminate, and in a house made of timber, a block house looks great

For an original design, you can choose laminate, and a block house looks great in a house made of timber.

Advantages:

- Environmentally friendly. The panels, like the boards for the ceiling in the house, are made from wood material without the use of resins and harmful phenol.

- Design. The color, texture and width of the cladding can be selected for each specific interior.

- Water resistance. The material is not afraid of moisture, which makes it possible to install it in bathrooms, saunas, and kitchens.

- Easy care. To clean the lining, simply wipe it with a damp cloth without using cleaning agents.

- Functionality. All necessary communications can be easily placed inside the structure of such a ceiling.

Technologically, the installation process is practically the same and includes several stages:

- Construction of the ceiling frame. In wooden houses for this purpose they make lathing from bars. In rooms with possible sudden temperature changes (bathroom, kitchen) and a high risk of deformation of the wooden base, it is better to use metal profiles.

- Before you line the ceiling with a board or clapboard made of wood, it needs to be kept in the room for several days for acclimatization.

- The material is cut to the length of the room. In this case, it is necessary to provide a gap of 3-5 mm. It is needed to allow free expansion of the slats with possible changes in temperature and humidity.

- The installation of the first ceiling element begins from the wall opposite the entrance to the room or from the window.

- The board is nailed to the bars, or with self-tapping screws if the base is a metal profile. The lining, which is attached using the tongue-and-groove method, must be fixed into the groove every 20 cm. From the groove side, the panel is attached to the frame using clamps. This metal plate is attached to the frame with self-tapping screws or a nail on one side, and its second part has a recess into which the panel fits. All subsequent strips are assembled in this way.

- The last plank needs to be cut not only in length, but also in width, not forgetting to leave gaps from the walls. In addition, it must be secured in the same way as the first.

- Holes for spotlights can be made before or after installing the panels on the ceiling.

- Final finishing work includes the installation of lamps and plinths, the function of which is to embellish the interior of the room, as well as hide the seams between the ceiling and the wall. If desired, the material can be coated with colorless varnish.

How can I hem the ceiling?

The interior and style of the room largely depend on the material with which the rough ceiling will be covered. In addition, the specific features of the repair location should be taken into account.

You can hem the ceiling with the following materials:

- Drywall. GCR is affordable and quite easy to use. It is glued to the rough ceiling or screwed to a spatial frame made of a steel profile. Please note that in damp rooms only moisture-resistant drywall should be installed. External putty of the assembled surface is required.

- Plastic panels. These products have a presentable surface and are light in weight. As a rule, they are fixed to a frame made of timber, steel or plastic profile. If the base is well leveled, then the panels are glued to it using liquid nails.

- Wooden lining. This type of finishing has a pleasant and beautiful appearance, is environmentally friendly and durable. The slats can be attached either to a solid base or to a frame. Fixation is carried out using thin nails without heads or self-tapping screws.

- MDF panels. The front part of these products can imitate wood, natural stone, sky or plants. Fastening is carried out using special clamps (clasps), which press the edge of the slats to the base or frame.

- Plywood. Before installation, plywood sheets must be treated with an antiseptic and primer. If installation is carried out on a frame, then the joints of the sheets should be on its guides. After installation, seams are sealed and painted.

- Siding. Plastic siding is an ideal material for finishing non-residential and damp rooms, such as a bathroom, summer kitchen, garage and balcony. Installation of this coating is quite simple and does not take much time.

The choice of material for lining a rough ceiling depends on the purpose of the room, the taste and financial capabilities of the owner of the building.

Preparing the ceiling structure for finishing

To prepare the ceiling for finishing, it needs to be insulated. The insulation will be located under the sheathing. If electrical wiring was not installed during the construction of the house, it is installed before finishing the ceiling and walls. Wooden materials are processed by various means:

- antiseptic against the appearance of pathogenic microorganisms and mold;

- moisture-proof to prevent the formation of condensation and protect a room with high humidity from water;

- fire retardant impregnations to prevent wood from burning.

Wood materials

It is clear that completely covering ceilings with high-quality materials is much more expensive than painting a wooden ceiling in a house and being content with that. Not everyone can afford decor made from precious wood, but there is an alternative that is affordable and gives room for creativity.

Decorative slats

Decorative slats look great on the ceiling.

Today in building materials stores you can find inexpensive and very attractive planks, bars and slats at affordable prices.

The choice of what can be used to decorate the ceiling in a wooden house quickly and tastefully is very rich.

- The slats have exclusive grooves on the surface. Make sure that they match the entire purchased batch. There should also be no bending, chips or cracks, or a large number of knots.

- The mosaic on the ceiling made from scraps looks great. You just need to come up with a design in advance and saw off the required number of elements.

- The planks can also be placed on a rough base, but it is still better to design a wooden frame.

- You can add a noble color to the ceiling with stain or tint varnish. It is advisable to saturate the coating with an antiseptic, otherwise the fungus will multiply due to humidity.

Lining

In the photo, lining is a traditional material for cladding walls and ceilings of wooden buildings.

Perhaps our most popular material for covering anything, from housing to utility rooms.

When we remember how we can make a ceiling in a wooden house, lining is the first thing that comes to mind.

- The buyer is offered two types of material - standard and euro-lining. The latter is of better quality, more attractive in appearance and, accordingly, more expensive. The Euro type is equipped with deeper grooves, but both have a tongue-and-groove connection.

- As a plus, we can note the presence of air duct grooves on the back side of the slats.

- Installation is simple, even a sloppy ceiling will look decent after it. Especially if not the cheapest and low-grade lining was used.

Combination of ceiling and walls

But do not forget that finishing the ceiling with wood must be in harmony with the cladding or painting of the walls.

It would be better to avoid wallpaper or materials with any decorative print. There are many other options, including combined ones. For example, one wall can be painted a plain light beige color, and the other can be covered with wood or a block house (panels that imitate a log).

Wood combines most favorably with natural, simplest materials:

Wooden walls, without a doubt, remain a priority. But plastered and white-painted surfaces look no less impressive with a wooden ceiling.

Metal is used as decor in the room, for example, tables, built-in lamps, a bulky chandelier or a fireplace portal with bronze candlesticks. A room with a ceiling lined with wood gives the designer unlimited possibilities and flights of imagination.

Materials for ceiling insulation

The design of the house may include insulation of the main ceiling, especially if the decorative ceiling is placed under the roof rafters and copies its conical shape. In this case, the insulation is installed under the roof slopes.

Until recently, only polystyrene foam , mineral wool and glass wool . Now a new generation of materials has appeared that make thermal insulation faster and better.

Internal ceiling insulation with foam plastic

Insulating the ceiling with mineral wool from the inside

Basalt wool insulation has proven itself well in operation . It is sold in the form of slabs, from which pieces are then cut out to the desired size. Basalt wool covered with foil is produced in rolls. The foil is designed to prevent moisture from reaching the insulation. It must be said that before you begin insulating the main ceiling and constructing a decorative ceiling, you need to make sure that the roof is not leaking and, if necessary, repair it.

Basalt wool

Another modern insulation is penoizol . This is a urea-formaldehyde foam, which is obtained by foaming resin. The foam is created using special equipment and pumped into the cavities behind the rafters and insulation. To fix the insulation, a special internal sheathing is made, covered with thick plastic or other material that can hold the foam until it hardens. Foam is able to penetrate into empty cavities and gaps between insulation boards, creating complete tightness and providing ideal thermal insulation.

Ceiling insulation with foam insulation

Plywood

Several layers of wood and veneer glued together are plywood.

Depending on the veneer used, the texture on the front side changes. The thickness of the sheet varies, depending on the number of layers. After impregnation with a special solution, it becomes moisture resistant.

Finishing wooden ceilings with sheets of plywood has not always been popular. Previously, it was used only for rough work.

Now many designers love this type of finishing. If a sheet of plywood is treated with stain and varnished, the result is a surface that looks no different from natural wood. And the cost is several times less.

Laminated plywood is used for decorative finishing. The film used to cover the sheet accurately copies the texture of the wood and is not inferior to it in appearance.

What styles are natural wood used in?

Wood as a finishing material has been used all over the world for quite a long time. Reliability, aesthetics and elegant design allow it to be used in various interior design styles.

The main styles include the following:

- High tech;

- Country;

- Modern;

- Chalet;

- Eco style;

- Japanese style.

High-tech style

The high-tech style is characterized by a clearly defined geometry of objects, but despite this they should not have strict boundaries.

The presence of wood in a high-tech style looks quite urban

Country style

It’s hard to imagine a country-style room without using wood as a finishing touch, and the ceilings are no exception. The finishing material can be either lining or wooden panels, boards or wooden wallpaper.

Natural stone will add elegance and respectability to the interior

A well-chosen color combination of the ceiling and walls, combined with a fireplace, will give the room a truly homely feel.

A snow-white bedroom with wide spacious windows looks simply magnificent

Art Nouveau style

The main task of this style is to combine together different types of materials, natural and artificial. The use of wood is a fundamental component of room design; it can be used on the floor, ceiling and walls. The main thing is that it does not disturb the overall harmony of the interior.

A modern kitchen will always be relevant

Beautiful wide lining with a varnished surface

It will also always be appropriate to use various wooden structures on the ceiling that will harmoniously complement the interior.

An elegant wooden structure on the ceiling will dilute its monotonous surface

Chalet style

This style migrated to Russia from distant Switzerland and France. It would seem that the usual simplicity of the design of wooden houses should have gone unnoticed, but as it turned out, this is not at all the case. The grandeur and beauty of the “chalet” style can charm any connoisseur of beauty.

The predominant tones for this style are: brown, burgundy, dark green and red. It is necessary to use brighter colors with extreme caution so as not to disturb the overall atmosphere of the interior, since the “chalet” style loves natural tones.

Wonderful chalet style interior with beautiful views of nature

Living room decorated in chalet style

Bedroom with chalet style interior with wooden ceiling and hanging beams

Eco style

Eco is a derivative of the word ecology. From here it is not difficult to understand that the eco style provides for finishing only environmentally friendly material created by nature itself.

However, the use of natural materials is not one of the most important conditions for this style; it is very important to preserve their original appearance and appearance. The texture of the wood should be clearly visible, and its color palette should be as close to natural as possible.

Interior design of a country house in eco style

Unfortunately, it is impossible to ensure that wood processing does not involve harmful substances and that their cost does not increase. Wood treated with environmentally friendly impregnations will not be cheap, but believe me, it’s worth it, in return you will get crystal clear air in your home and a feeling of complete solitude with nature.

The use of other natural materials, such as gypsum decorative tiles, is also encouraged.

Floor-to-ceiling windows, a fireplace, a wall lined with decorative bricks, a wonderful sofa with a coffee table are the perfect combination for creating a truly cozy atmosphere in the house

Eco design loves space and good lighting. It is problematic to make the most of all the possibilities of this style in an apartment; a large country house with high ceilings and spacious rooms is perfect for these purposes. Only here you can truly give free rein to your imagination.

It is important to remember that eco style requires good lighting

Wooden ceilings will look good not only in the house, but also in other outbuildings. One style will allow you to avoid sharp boundaries between different zones.

An open terrace of a country house, decorated in the same style as the house, will be an excellent complement to modern design in eco style

Wood wallpaper

Depending on the composition, there are several wallpaper options:

- Natural wood panels

These are small boards that are assembled using special locks without the use of glue. This is very convenient because it allows designers to come up with different patterns from textures by laying panels from different types of wood in a certain order and mixing them together.

They are made by grinding cork oak and then pressing it. Such wallpaper is sometimes covered with veneer.

For the base of such wallpaper, cardboard is used, which is covered with veneer and rolled into a roll. In terms of quality and appearance, they are no worse than natural wood panels.