Home » Finishing and insulation

25.05.20190141

Wood-fiber panels are familiar to almost every person, although he may not be aware of it. It is these panels that are almost always used to decorate the back walls of furniture. To make such panels, remnants of different types of wood are used, which are strongly compressed and molded to fit the desired slab.

Today, these panels are widely used not only in the furniture industry, but also in interior decoration. The fiberboard panels themselves are an inexpensive material that can be easily cut to the desired shape and can be easily mounted. But the panels have a flat surface, and it becomes unclear how to attach one to a wall that is not ideal.

- What are fiberboards attached to?

- How to install fiberboard if the wall is crooked

Cladding walls with fiberboard panels - 3 ways

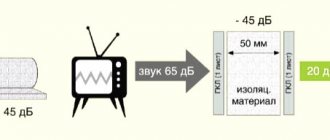

The use of fiberboard panels for walls is one of the most popular methods of finishing a vertical surface today. Natural wood retains heat perfectly and has soundproofing properties. During the cold season, the product does not allow the walls to cool down and maintains an optimal level of humidity.

Wood fiber panels are the best material for sheathing. As a rule, flat panels are used for cladding vertical surfaces.

Universal material

Hardboard can be used in a variety of areas of construction:

- To form a subfloor under laminate, linoleum, parquet, carpet, and so on;

- For insulation of walls and roofs in wooden and frame-panel houses;

- For noise and sound insulation, as well as for finishing rooms with special requirements for acoustics (home theater, for example);

- For finishing of premises;

- In the production of furniture, interior doors and various containers;

- As a basis for paintings and so on.

Therefore, always pay attention to the markings, as there is no point in buying super-hard laminated hardboard for laying a subfloor.

Overview of types and sizes

The market offers a wide variety of products for decorating a room. Fiberboard has advantages that make the material stand out among its competitors . Using panels, you can get a coating that imitates other materials, choose colors and even texture. Fiberboard is a safe type of cladding that does not harm human health and the environment. Manufacturers often use the dry method to make panels.

It is impossible not to highlight the ease of installation, since you can work with the material yourself without outside help. There are different installation options, each of them has its own characteristics. As for the cost, the panels are offered at an affordable price, which has contributed to the increased demand for the material. Thanks to fiberboard, you can insulate the room and also obtain sound insulation. If you choose the right wood fiber panels that meet high requirements and standards, their service life can reach 10 years, and this is not a short period.

To make the use of cladding possible in a room with high humidity, it is necessary to select a special type coated with a protective impregnation. It is also important to observe storage conditions so that the material does not deform, which is why products are often attached to the sheathing using self-tapping screws.

Stacked wall panels are one of the most popular types of fiberboard. With this material, work is carried out very quickly; you can choose a decor option from a wide range. It is important to pay attention to the dimensions of such boards: the thickness can be 6–25 mm, and the length reaches 4 m, the width range is 15–30 cm. Thanks to the choice of such parameters, you can complete finishing of any complexity. A locking connection is used for fastening. On the market you can find a product with double-sided coating, so the protective functions are ensured.

Sheet moisture-resistant panels are presented in large format, so they can be used in large rooms. This type of finish is often chosen to decorate a kitchen backsplash. This material is attached with precise edge adjustments.

The tiled variety of fiberboard is a finishing material with parameters of 300X300, 150X600 and 980X980 mm. Docking is used for fixation, but you can find panels with a locking connection. If you need decorative design of a room with interesting combinations, you can safely choose slabs that fit into the bedroom, living room and other parts of the house.

The laminated panel is offered in sizes 2850X2070X3.0 mm. Such sheets have a protective film, which is created from melamine or acrylic resin. This coating is decorative and is offered in a variety of colors.

The adhesive composition should be selected taking into account the properties of the surfaces that need to be joined.

Leveling walls in a wooden house with your own hands

Candidate of Sciences, jack of all trades, permanent expert of the site, a real, and not abstract (unlike other resources) person.

Houses made of wood will never lose their relevance. After all, wood is a unique building material. In addition to the fact that it can store the energy and warmth of nature, it is also beautiful. There is one more feature: it does not lose its attractiveness for a long time. Absorbing time, it ages gracefully.

In addition, wooden walls are warm, quiet, and cozy. Therefore, the idea of covering rounded logs or profiled timber with another type of finishing is somewhat barbaric. But in a private house there are several wooden walls that sometimes still have to be leveled: the bathroom and the kitchen. In the bathroom you need to get a flat surface for tiles, in the kitchen - for wall cabinets and an apron. Another thing is old houses, with untreated, cracked logs. Here, the alignment of wooden walls for a different type of finish is dictated by necessity.

What are fiberboards attached to?

Before you figure out what to do with an uneven wall and panels, you need to understand what your mounting options are in general. DV panels can be fixed to the wall in the following ways:

- Using glue;

- On an installed wooden frame;

- Directly to the wall using self-tapping screws.

From the listed methods, it is obvious that the easiest way is to glue the sheets directly to the wall, but in this case the wall must be flat. If the wall is not prepared, the fiberboard will not adhere evenly to the surface and, of course, will fall off over time. This means that in order to make working with fiberboard easier, you will have to worry about leveling the walls. But is this always necessary?

Preparatory work

In all materials recommending how to properly level walls in a wooden house from the inside, preparatory work for any type of surface leveling is carried out according to the same algorithm:

- electrical wiring, lamps, sockets, switches, and various fasteners are removed from the walls;

- the wood is cleaned of dirt, especially greasy stains. If it doesn’t work with household chemicals, radical means come to the rescue - a plane or an ax;

- areas damaged by rot or fungus are removed mechanically - combed off;

- cracks in the corners of the house and between the crowns are additionally caulked - the operation is mandatory;

Cladding walls with fiberboard panels - how to do it

When the type of panels has been selected and their purpose has been taken into account, finishing can begin. First, the fiberboard must adapt to the microclimate of the room - so it is allowed to lie in the room where it will be installed for several days. This prevents deformation of the material.

The wall panel is fixed to the surface with clamps, mastic, and nails. It's better to install a sheathing. Although glue is suitable for smooth walls.

Main cladding methods:

- Fixing with locks on the panels themselves is a popular method. During manufacturing, the sheets are equipped with fixing elements at the ends and sides. This method of attaching the trim speeds up assembly and installation and does not require much effort. In this case, the elements are securely attached to each other; the joints do not require additional treatment against corrosion.

- Frame installation is also in demand. The panels are fastened with nails. Installation begins from the corner, then the panels are fastened to each other.

- Mastic or adhesive composition is the easiest installation with a perfectly level base. The glue is applied to the walls with a notched trowel, the layer thickness is several millimeters. The sheets are pressed tightly to the surface.

Useful tips

- Regardless of the mounting location, treat the sheathing timber with high-quality primer. This will increase the service life of the entire structure.

- Fasten the panels in a locking system, which will create a beautiful decorative look.

- Cover the joints with decorative inserts.

- Combine wall panels with wallpaper or decorative plaster. This will bring novelty and variety to any interior. Thus, the appearance of the room can be changed if desired. In this case, financial investments will be minimal. You just need to replace the wallpaper or repaint the wall.

- Attaching a vapor barrier under the sheathing will help avoid condensation on the walls.

- A vapor barrier is a film that protects against the formation of condensation.

- A certain batch of goods must be purchased simultaneously and from one manufacturer. Because different manufacturers use their own technology. As a result, the properties and composition of a material with the same name may differ from one company to another.

- It is convenient to use a jigsaw to cut out arches and other elements.

Types of glue

There are several types of glue, the actions of each of them are aimed at ensuring that wall panels for interior decoration fit as tightly as possible to the walls. From the list below you can familiarize yourself with the types of this glue.

Compounds for MDF stickers

This type of glue has a significant advantage - versatility. This glue can be applied to stone, metal, wooden products and others . This glue contains the following substances: Titanium, Moment and others.

A special series containing liquid nails

Experts have developed a special series of glue that is ideal for construction work and gluing MDF even on a concrete wall. The glue can be used not only by professionals, but also by amateurs. In addition, experts have invented an addition to glue: a construction gun, which is very convenient to use and greatly simplifies working with glue.

The composition includes the following substances: Installation, Liquid Nails, Macroflex and others.

The presented components are distinguished by super-strong fixation and durability. Beginning builders are recommended to use glue from the “Liquid Nails” series in their work. They are perfect for mounting your panels.

This material has a fairly wide range of advantages. The adhesion of the two products is high-quality and durable.

Using glue is very easy and does not require special skills; the glue is used very sparingly during work, due to which it can be applied in thin layers and eliminate any defects.

Preparing the fiberboard surface for wallpapering

To glue the rolled material, it is necessary to process the fiber boards in the following sequence.

Pre-priming

The entire surface of the walls is coated with a primer using a roller or wide brush. As a primer for fiberboard, it is better to use ordinary drying oil, after which it dries, they begin to putty the walls.

Coating with drying oil will increase the adhesion of the fiberboard and prevent the boards from absorbing moisture from the putty.

Wall putty

Fiberboard puttying is carried out in three stages:

- All joining seams are covered with a polymer mesh. Putty is applied to the mesh and pressed against the seam. Using a spatula, smooth the mixture evenly over the entire surface of the seams.

- The places where the cladding sheets are attached are puttied with a starting mixture. Before doing this, check the fastening points so that the heads of the self-tapping screws or screws are recessed into the cladding.

- Then the entire surface is covered with finishing putty. Use a narrow spatula to scoop up the mixture and transfer it to the wide blade of another tool. The putty is applied in a circular motion with a wide spatula.

Subsequent work should begin after the leveling coating has completely dried. The final layer of putty should not exceed a thickness of 1-2 mm.

Final priming

After the leveling coating has dried, the slabs are primed again. For final priming, it is better to use a water-based product.

The primer is applied with a wide brush or sprayed with a spray bottle.

Features of applying liquid wallpaper

Working with this material differs from the previous process in the technology of the last stage. This variety must be laid with a spatula and a trowel according to a pattern identical to puttying. To do this, the pre-prepared mixture is distributed into sections in an even layer.

The technique of gluing liquid wallpaper is similar to applying putty

There is an opinion that when using liquid wallpaper, putty is not needed, but the technology should not be violated.