How much does drywall weigh?

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Drywall is a building material that consists of three layers: gypsum filler between sheets of cardboard. This material is very popular in construction. In the article you will find out how much 1 sheet of drywall weighs with normal area, volume and density.

Why know the weight of drywall

To determine the mass, we take the sheet area - 1 m2. The weight also depends on its parameters: thickness, area and properties. It happens:

- Ordinary (gypsum board)

- Moisture resistant (GKLV)

- Fire resistant (GKLO)

- Moisture and fire resistant (GKLVO)

Regular or standard - used for indoor work. Humidity should not exceed 70-75%.

Moisture resistant – allows you to work in damp areas. They can cover walls and ceilings in the bathroom and kitchen.

Fire Resistant - Can be used as secondary fire protection.

The weight of drywall is worth knowing in order to:

- Correctly calculate the load on the frame to which the cladding will be attached, and also decide how many fasteners will be required

- Understand whether you have the strength to do the installation yourself or ask someone

- Calculate what the load on transport will be during transportation of the material

- Decide how many loaders will be needed to bring in all the sheets

The characteristics of the material are as follows:

- specific gravity about 1200 – 1500 kg/m3

- thermal conductivity is in the range of 0.21-0.32 W/(m*K)

- strength with a thickness of up to 10 mm is approximately 12-15 kilograms.

How much does drywall weigh according to GOST?

The specific gravity of GKLVO and GKLO is from 0.8 to 1.06 kilograms.

You can calculate how much a plasterboard structure will withstand, knowing the mass and volume. You should not always rely on GOST.

How much does 1 m of 2 sheets of different types weigh?

To answer this question, let’s look at the types of drywall:

- Wall. It has a thickness of 12-12.5 millimeters. The sizes vary: 2000x600 mm, 2500x1200 mm and 3000x1200 mm. The weight of one sheet depends on the size: 15, 37.5 and 45 kilograms, respectively.

- Ceiling. It has a thickness of 9 to 9.5 millimeters. The dimensions are the same as for the wall one. Specific gravity is 11.4, 28.5 and 34.2 kilograms.

- Arched. The thickness of the sheet is about 6.5 millimeters. The size is the same as the previous ones. The specific gravity is 7.8, 19.5 and 23.4 kg.

How much does a 9 mm thick sheet of plasterboard weigh per 1 sq.m? Or how much does a 12 mm thick sheet of drywall weigh per 1 sq.m?

Take a look at the following plate:

The volumetric weight of gypsum boards is calculated using the formula:

weight = thickness of one sheet * 1.35

How much does a package of drywall weigh? Quantity per pack

Now that we've figured out the weight of one sheet, let's see how much a pack weighs.

It is supplied without packaging, with an average quantity of 50-60 sheets. They are stored in packs that stand on a pallet. Then the question arises: how can all this be transported? There is a price tag here. Alternatively, you can rent a truck to move materials without worrying about increased prices due to volume.

Let's take a look at the table:

The Gazelle’s carrying capacity is 1.5 tons, so one package of medium-thick sheets can fit.

KAMAZ has 10 tons, 7-8 packs fit.

The truck has 20 tons, you can transport about 15-16 packages.

We hope that the article will clear up all the points and explain all the subtleties.

So, if you decide to make a renovation, then drywall is what you need. From the main one: plasterboard with a thickness of 12 mm, the weight of the sheet is 10 - 13 kg. The weight of 12.5-thick drywall is about the same. Before purchasing packages, we advise you to calculate the volumetric weight per 1 sq.m. and decide how you will deliver it to where it is required.

Specifications

The indicators of gypsum board slabs are regulated by GOST 6266-97:

Size. The standard width is 60 cm and 120 cm, GN 6 (GKLD) can be 90 cm. Length varies from 200 to 400 cm, depending on the type, thickness – 0.65–2.4 cm. Classic thickness: 9.5 – for ceilings and 12.5 for walls, but GKLO has dimensions of 15.4 mm, and the arched variation is 6.5 mm.

Running ruler for plasterboard sheet sizes

What does the weight of 1m2 of gypsum board depend on?

It is important to emphasize that the mass of building material of the type presented varies according to the purpose of the sheets. For example, the weight of reinforced drywall is much higher than that of standard and arched plasterboards

The weight of drywall sheets is affected by the length, width and thickness of the material. Since gypsum board is a filler wrapped in cardboard sheets, the percentage of components will be as follows:

- 90-94% of the mass is gypsum;

- 4-6% of the mass is cardboard;

- 1-2% of the mass is occupied by various additives (PVA, starch, etc.);

Based on the specified proportion, the mass of the drywall sheet will change depending on the proportion of the listed components. The composition may not be the same for different types of gypsum plasterboard. Conventional, moisture- or fire-resistant ones require a filler with various additives that enhance the operational capabilities of the building material.

Thus, the weight of sheets such as GKL, GKLV and GKLO will be different, even taking into account the fact that the length, width and thickness will be the same. The weight of the sheets is also affected by the humidity of the room in which they are stored.

Types of material

- GKLVO - sheets have increased moisture resistance and fire resistance. The sheets themselves are green with red markings.

- GKLO - gray sheets with red markings, used for cladding rooms where it is necessary to meet the requirements for increased fire resistance.

- GKVL sheets have increased moisture-resistant characteristics. The outer part of the cardboard is impregnated with special compounds that prevent the formation of fungus and mold. The leaves are green with blue markings.

- GKL - classic sheets. They are covered with cardboard on four sides, and the core consists of gypsum. There are no additional impregnations. The leaf is gray with blue markings.

How much does a sheet of drywall weigh?

- Eco-friendly material - does not contain harmful impurities.

- High fire resistance (even with ordinary drywall).

- Easy installation - no need to hire a special team.

Initially, plasterboard was used only for leveling walls - this was its intended purpose; now it is increasingly used as a structural material. Construction is a responsible business, therefore there is a special GOST 6266-97 that determines the weight of each type of plasterboard sheet. According to GOST, an ordinary sheet should have a specific gravity of no more than 1.0 kg per 1 m2 for each millimeter of thickness; for moisture-resistant and fire-resistant products, the range varies from 0.8 to 1.06 kg. For high-quality repairs, it is preferable to have an idea not only of the options for using drywall, but also of its characteristics. Drywall today is very popular as a construction and finishing material.

It is convenient to use, durable, practical, and easy to install. Our article is devoted to the features and characteristics of this material, and, in particular, its weight. Has good ductility. Therefore, plasterboard is an ideal material for constructing non-standard forms of partitions, niches, multi-level ceilings and original design elements.

This is an excellent way to quickly level out uneven surfaces, saving traditional plaster and your time. When installing a metal frame, you must also take into account that in the future you may have to hang a massive chandelier or ceiling lamps on the plasterboard, which will also increase the load on the suspended ceiling. Sheets of such plasterboard can be long from 2500 to 4000 mm, width 1200 mm and thickness 12.5 and 15 mm.

These sheets weigh from 10 to 16 kg.7. Drywall is afraid of moisture and dampness. There are many types of material that are resistant to humidity, but during storage it is still worth ensuring the room is dry, and also ensure a temperature regime of at least +5 degrees.

Damp drywall must be dried

This event is extremely important. You can dry either by simply laying the sheets out in a ventilated place or by using hot air blowers.

A huge number of various devices and devices are currently used to lift drywall to floors.

Their main purpose is to simplify and speed up work, to ensure lifting and transportation of sheets to the required height. A standard sheet has an area of 3 square meters. meters. By manually measuring the walls, you need to calculate their area and subtract the area of windows and doors from the total area.

Then the resulting number (if necessary) is rounded up and divided by the area of the standard sheet. Please note: the weight of the sheet may differ slightly from that indicated by the manufacturer: the material absorbs moisture well, so it may become a little heavier if storage and transportation conditions are not fully observed. One of the characteristics drywall is the thickness. This affects the weight of the sheets

It varies depending on what the drywall is intended for. The thickness limits are 0.65 - 1.25 cm per 1 square. m, while different types of plasterboard material may have different thicknesses

This affects the weight of the sheets. It varies depending on what the drywall is intended for. The thickness limits are 0.65 - 1.25 cm per 1 square. m, while different types of plasterboard material may have different thicknesses.

For example, arched plasterboard sheets are usually 0.65 cm thick, ceiling material is 0.95 cm, and 1.25 cm thick material is used for walls.

- A moisture-resistant type of gypsum board, like a regular one, should not weigh more than 1 kg per 1 mm of thickness.

- The range for fire-resistant and moisture-resistant is somewhat wider and ranges from 0.8 to 1.06 kg per 1 m2.

Initially, plasterboard was used only for leveling walls - this was its intended purpose; now it is increasingly used as a structural material.

Additional information on the topic:

- How to make a beautiful interior partition from plasterboard

- Plasterboard shelving for a children's room photo

- Countertops under the sink made of plasterboard in the bathroom photo

- What is used under drywall to level walls?

- Plasterboard partitions photo interior design in the hallway

Parameters of different types of drywall

There is a GOST that determines how much each type of drywall weighs per 1 m2:

- A moisture-resistant type of gypsum board, like a regular one, should not weigh more than 1 kg per 1 mm of thickness.

- The range for fire-resistant and moisture-resistant is somewhat wider and ranges from 0.8 to 1.06 kg per 1 m2.

The material can also have different thicknesses: from 6.5 to 24 mm. Depending on this parameter, the following types are distinguished:

- Wall, used for covering walls and creating partitions. The thickness of such sheets is usually 12.5 mm.

- Plasterboard sheets for the ceiling are thinner - 9.5 mm.

- The main thing that is required from the arched variety is the ability to easily bend and take the desired shape. This is the thinnest type - only 6.5 mm.

And of course, the weight of drywall depends on such a parameter as sheet area. In construction, I most often use standard sheets with dimensions of 1.2 × 2.5 m. Accordingly, their area will be 3 m2.

You can find gypsum boards on sale in other sizes:

- The length can be from two to four meters, size increments are 50 cm.

- Narrow sheets having a width of 600 mm. They are used to form slopes or cover loggias and balconies.

Weight table depending on type, size and thickness

Drywall from different manufacturers may differ in weight, even if it has the same dimensions and purpose. You can buy building materials Gyproc, Rigips, Lafarge, Volma, Plato, Belgips, Bau Gips, etc. However, Knauf products are the most popular, so we will focus on them. How much a plasterboard sheet weighs can be found in the table.

| Drywall weight | ||||

| View | Sheet size (mm) | Thickness (mm) | Sheet weight (kg) | Weight 1 sq.m. (kg) |

| Wall | 1200x2000 | 12,5 | 22,32 | 9,3 |

| 1200x2500 | 27,9 | |||

| 1200x3000 | 33,48 | |||

| Moisture resistant | 1200x2000 | 12,5 | 24,24 | 10,1 |

| 1200x2500 | 30,3 | |||

| 1200x3000 | 36,3 | |||

| Moisture resistant ceiling | 1200x2000 | 9,5 | 24 | 10 |

| 1200x2500 | 30 | |||

| Ceiling | 1200x2000 | 9,5 | 17,5 | 7,3 |

| 1200x2500 | 21,9 | |||

| Arched | 1200x2500 | 6,5 | 18 | 6 |

| 1200x3000 | 21,6 | |||

| Fire resistant | 1200x2500 | 12,5 | 30,6 | 10,2 |

As can be seen from the table, the weight of gypsum board 12.5 mm varies significantly depending on the type of sheet. The same applies to sheets with other thicknesses. Do not forget that the data provided is not the ultimate truth. It is worth considering that weight will change due to humidity and temperature. These changes are minor, but just in case, it’s worth taking into account a possible error of up to 5% (this also takes into account fluctuations among different manufacturers).

The weight of the gypsum board is 3 m. 4 Classification, main parameters and dimensions

4.1 Depending on the properties and scope of application, sheets are divided into the following types: - ordinary (gypsum plasterboard); — moisture resistant (GKLV); — with increased resistance to open flame (GKLO); — moisture resistant with increased resistance to open flame (GKLVO).

4.2 Based on appearance and manufacturing accuracy, sheets are divided into two groups: A and B.

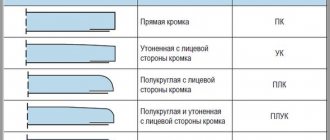

4.3 According to their shape, the longitudinal edges of the sheets are divided into types shown in Figures 1-5.

Figure 1 - Straight edge (PC)

Figure 1 - Straight edge (PC)

Figure 2 - Edge thinned on the front side (ED)

_____________________ * Dimensions are given as a guide and are not considered a defect.

Figure 2 - Edge thinned on the front side (ED)

Figure 3 - Semicircular edge on the front side (PLC)

Figure 3 - Semicircular edge on the front side (PLC)

Figure 4 - Semicircular and thinned edge on the front side (PLUK)

_____________________ * Dimensions are given as a guide and are not considered a defect.

Figure 4 - Semicircular and thinned edge on the front side (PLUK)

Standard sheet size

The standard size of drywall is 2500x1200x12.5 mm, and the weight is about 29 kg. But you can order a sheet of drywall, the size of which will vary slightly depending on the manufacturer. The length of the sheet can be from 2 m to 4 m. The width of the plasterboard can be from about 6 m to 1.2 m.

Each manufacturer mainly offers drywall sheet size:

- 2000×1200 mm

- 2500×1200 mm

- 3000×1200 mm

How do the dimensions of a sheet of drywall affect its weight?

The dimensions of the plasterboard sheet and the thickness of the product affect the weight of the plasterboard sheet. This value can be from 12 kg to 35 kg.

With a gypsum board thickness of 6 mm, the weight of the drywall will be:

- 1200×2000-12 kg

- 1200×2500-15 kg

- 1200×3000-18 kg

With a plasterboard product thickness of 9.5 mm:

- 1200×2000-18 kg

- 1200×2500-22 kg

- 1200×3000-27 kg

With a sheet thickness of 12 mm:

- 1200×2000-23 kg

- 1200×2500-29 kg

- 1200×3000-35 kg

GCR thickness varies from 6.5 mm to 24 mm.

The thinnest type of drywall is particularly flexible, so it is convenient to use for installing complex structures. That's why it is also called arched. Usually, two layers of such material are installed at once, using a standard size of drywall.

GKL with a thickness of 12.5 mm is used for covering walls and forming various partitions.

The width of the plasterboard sheet for ceilings is slightly lighter than that for walls; it can be from 8 mm to 9.5 mm.

Before calculating the required amount of material, it is necessary, first of all, to measure the area of the room. Only then decide what size of products is more convenient to purchase. The option in which you need to cut off an extra strip from the sheet will be more advantageous than the method when you have to grind additional pieces to the sheet. In this way, repair time, profiles and the number of seams are saved.

Installation

If the room has perfectly flat surfaces, the material can be fixed using a special gypsum-based adhesive.

Before installing drywall sheets on uneven surfaces, it is necessary to install a frame. It can be built from wooden slats or made from ready-made metal profiles. The sheets are attached to the frame using screws.

For complex structures, the material is pre-moistened with water for greater flexibility and only then attached to the frame. Moistening can be done using a special roller with needles.

What should you pay attention to when purchasing drywall materials?

When purchasing, you must check the integrity of each product. The plasterboard sheet should not be torn or broken. Select metal profiles from high-quality material, sufficient thickness and rigidity. After all, the quality of the entire structure depends on the strength of the frame. Profiles that are too soft bend and break during installation, complicating the process of attaching sheets. Profiles are manufactured in lengths of 3 m and 4 m, but longer options can be purchased to order. The standard size of the drywall sheet can be replaced with a more suitable one in an individual order.

Subtleties of moving and storage

Drywall is a rather fragile material and can be easily damaged. In order to avoid unnecessary costs, it is enough to follow a number of simple rules and recommendations:

- This material can only be stored horizontally on a completely flat base. This rule also applies to transportation. Any pebble or bolt that falls under a stack of drywall sheets will ruin at least one of them. The material will simply break or crumble under its own weight.

- Two people carry the gypsum board in an upright position. If you carry it flat, it will break, unable to withstand the vibration.

- As a rule, they carry the sheet by picking it up with one hand from below, and holding it with the other and preventing it from swinging. But this is quite inconvenient, and problems arise when passing through doorways. Therefore, professional movers use special devices in the form of a kind of hook. They seem to “lengthen” the arm, which makes carrying much more comfortable.

- During transportation and storage, it is necessary to protect the material from moisture.

Size options

Length. The length standard is offered by manufacturers in three standard sizes: 2 m, 2.5 m, 3 m. But in the product lines of some of them there are plasterboard sheets of 1.5 m, 2.7 m, 3.3 m, 3.6 and even 4 meters long. This allows you to choose the most suitable size of plasterboard sheets for your walls to reduce the amount of material waste.

If you ask yourself what size of drywall for walls can be considered the most optimal, then you won’t be able to give a definite answer. In each specific case, different sizes of plasterboard sheets will be optimal depending on the height of the ceiling in the room being finished.

But what you can be sure of is that using long sheets, for example, waterproof plasterboard 3 meters long, is much more practical, since there will be fewer joining seams. Many people consider this size to be the most convenient for finishing work.

Width. Until recently, the standard width for drywall was 1200 mm and was the same for all types of gypsum plasterboard produced by different manufacturers. But today, in the product lines of some of them, small sheets of plasterboard have appeared, the dimensions of which are 600x1200 mm. It is impossible not to notice that the manufacturers have halved the width of the plasterboard wall sheet, which has never happened before.

Of course, the small width of the plasterboard sheet - 600 mm - makes installation easier, but such dimensions are not always convenient to use. Thus, it is not suitable for cladding large surfaces due to the many connecting seams. Typically, in such situations, waterproof plasterboard is used, the dimensions of which are 1200x3000 mm.

Thickness. The choice of this parameter is fundamentally important for high-quality performance of cladding work on walls and ceilings.

- The thinnest gypsum boards - 6.5 mm thick - are used for installing multi-level ceilings, creating arched structures and arranging various niches

- The standard size of a plasterboard sheet is 9 mm thick, it is best suited for hemming flat ceilings; its strength is quite sufficient for this purpose

- GKL 12.5 mm thick is used mainly for leveling walls

- Interior partitions are made from gypsum board with a thickness of 14-24 mm. It is designed for significant loads and provides the necessary sound insulation

Before choosing a facing material for rooms with high humidity, you need to find out the standard dimensions of moisture-resistant plasterboard (length and width have the same standards as regular plasterboard) and what thickness waterproof plasterboard is. It is not customary to use it for ceiling cladding. If you choose moisture-resistant plasterboard for the walls, what thickness it will be does not matter; even its water-repellent properties are not so important. In a room like this, the waterproof finish is usually tile. And as a basis for it, the thickness of moisture-resistant plasterboard of 12.5 mm is quite sufficient.

The weight of this material depends on the size of the drywall sheet and its thickness. GOST 6266-97 regulates the mass of one millimeter of sheet thickness with an area of 1 m2. For a regular gypsum board it should be no more than 1 kg. For other types of plasterboard sheets, the range is set from 0.8 to 1.06 kg.

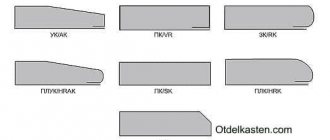

Edge Types

Gypsum plasterboards differ not only in properties, but also in chamfer configuration. Various edge options provide convenient finishing.

The following types exist:

- PC (SK). Direct, the most popular variation, which is typical for wall gypsum plasterboard. It is distinguished by the ease of sealing seams; when joining closely, no processing is required.

- UK (AK). Slimline, has a boat configuration. The resulting joint involves the use of reinforcing tape, which is glued during puttying.

- PLC (HRK). It has a semicircular shape located on the front side of the plate. Provides installation of mortar without the use of reinforcing material.

- ZK (RK). The rounded chamfer is processed similarly to the previous option.

- PLUK (HRAK). Combines the technical parameters of AK and HRK. The edge is semicircular and thinned. For finishing, tape is used along with putty.

Since some of the sheets are cut during installation, the starting configuration of the edge is not of fundamental importance, but with the right choice, you can save time and effort over large areas

The corresponding designations are present in the description on the surface of the slab; the type is indicated next to the type of drywall.

On a note! Although straight edge materials are designed to tightly connect parts, such installation is not always possible, so the chamfer is formed independently.

Why do you need to know the weight of drywall?

Drywall is used in the construction industry due to its many valuable properties and relative low cost. Before you start working with this material, you will need to familiarize yourself with its parameters and characteristics. Particular emphasis should be placed on the weight of the material. It is impossible to answer this question unambiguously, because the sheets differ in size, thickness and purpose.

Many may think that knowing the weight of drywall is not something that plays a decisive role when purchasing, but this is far from the case. It's rare that sheets of drywall are cut outside the home, most people opt to have whole pieces delivered to the job site.

If a multi-storey building does not have a freight elevator, making deliveries using stairs is problematic. In this case, knowledge about the mass of the GCR will not be superfluous. Sometimes you can take three sheets at once, and in some cases even one will be quite heavy.

The weight of a sheet of drywall also plays an important role during the construction of interior partitions, all kinds of niches and other structures. The choice of profiles and the number of fasteners depend on this characteristic.

Having knowledge of how much a sheet of drywall weighs, you can determine the weight of the future suspended ceiling structure, the number of dowels needed and the suspension. Also, information about the weight of gypsum boards will help make calculations of the load on the walls, flooring and ceiling.

The weight of the plasterboard sheet will help you find out whether you can bend the material and how successfully it will turn out. It is known that the greater the mass of the sheet, the more difficult it will be to bend it.

The weight of the gypsum board is primarily determined by the thickness of the sheet. For example, a sheet whose thickness is 12.5 millimeters is very difficult to bend. In the case of a sheet with a thickness of 6.5 millimeters, for example PLATÓ Arka or PLATÓ Arka READY, bending the required shape will not be difficult.

Precautionary measures

Plasterboard sheet is a rather fragile material, it is easy to break or damage. For a comfortable repair or construction, you must follow a few tips:

- Sheets should only be transported and stored in a horizontal position, on a perfectly flat surface. Any debris, stone or bolt can damage the material.

- The plasterboard sheet must be moved only vertically and only by two people to avoid vibration.

- When carrying, you need to hold the sheet with one hand from below, and hold it with the other from above or to the side. This method of carrying is very inconvenient, so professionals use special devices - hooks, which make carrying comfortable.

- The material must be protected from moisture, direct and diffuse sunlight, and heating sources during storage and installation, even if it is moisture-resistant or fire-resistant. This will help maintain the strength of the material and its durability.

- Sheets can be stored outdoors for up to 6 hours, packed in special material and in the absence of frost.

- With low cost and high strength, plasterboard is a very affordable material. The price for one sheet depends on the type of sheet: the cheapest of all types is gypsum board. Due to its low price, it is used most often. The price for a fire-resistant or moisture-resistant analogue is much higher. The most expensive type is flexible arched plasterboard; it has an additional reinforcing layer.

- When determining the repair estimate, it is necessary to calculate not only the amount of material and its weight, but also the cost of constructing the frame.

3388 0 0

When purchasing building materials, we are primarily interested in their quality and cost. But there are other parameters that you need to pay attention to and on which the reliability of the construction or finishing will depend. Let's take an example of how much drywall weighs, what its weight depends on, and why you need to know it at all.

What does size affect?

Choosing the size of your drywall sheet is extremely important because it reduces the amount of material used and overall renovation costs. Among the most important parameters, thickness occupies a special place, because the strength of gypsum plasterboard and, accordingly, the strength and capabilities of the structure itself largely depend on it. The thickness of the sheet should be selected based on the type of work planned. A standard gypsum plaster board for partitions has a thickness of 12.5 mm; it can withstand 50 kg of weight per square meter of sheet without stress, however, a prerequisite is the use of drywall fasteners, and the load must not be of the impact type. Such sheets are used to form walls and decorative partitions.

If you plan to fix several shelves or wall cabinets, for example, kitchen or corner decor items, then it is advisable to give preference to models with greater thickness based on the following data:

- A 14 mm sheet of plasterboard can withstand a load of 65 kg/sq. m.

- A 16 mm plate can handle a weight of 75 kg per 1 square meter.

- Thickness 18-20 mm is used for loads up to 90 kg/sq. m.

- A 24 mm sheet accepts 110 kg/sq. m.

If thick sheets are not available for sale, you can lay standard gypsum plasterboard in several overlapping rows

This may turn out to be simpler and more economical, taking into account the low availability of thick sheets in the open market

It is important to take into account the characteristics of the room in which renovation work is being carried out. If this is an apartment or a private house, then it is quite possible to get by with thin sheets, since the owners of the premises treat it with care and are unlikely to deliberately cause blows and mechanical damage

If we are talking about industrial facilities or warehouses, then the strength of the structure comes to the fore from a safety point of view, so cladding with sheets with a thickness of 14 mm and above is mandatory.

To form interior structures, special gypsum board sheets with a thickness of 6 mm are used. They are flexible and bend well, so they are often used for mounting wavy decorative elements. But for installing arches, this thickness is not suitable, since it will not cope with the load. You should give preference to denser sheets or lay thin gypsum board in several layers.

If the owner of the room plans to hang pictures on the walls, then it is worth purchasing a sheet with a thickness of 10 mm. To mount a plasma TV, it is better to stick to the thickest sheet. Otherwise, the structure may collapse and the TV may break. If the wall is not subject to load, then in this situation it is enough to limit the gypsum board to 8 mm.

Drywall is selected similarly for leveling the ceiling and creating multi-level coverings. It is necessary to know exactly what will be fixed in it, and what load will be per square meter of area. Experts recommend taking thin sheets with a thickness of 9.5 as a base point; they are light in weight, so they do not overload the floors. This material can easily withstand built-in lamps located at a standard distance of 60 cm from each other.

Using information about the mass of building materials

The mass of drywall is found to determine the characteristics of cargo transportation and the nuances of installing sheets

It is important to understand in advance which frame structure will withstand the load and which will not. To do this, the obtained mass values are compared with the nominal tensile strength of the frame elements

As the weight of the structure increases, the thickness of the galvanized frame profile should also increase. The distance between the frame cross members, on the contrary, should decrease

It is equally important to take care of high-quality and sufficiently durable fastening materials: self-tapping screws for plasterboard sheets and so-called “fleas” for joining profiles