Upon completion of the renovation work, the stage of installing furniture and household appliances in the room begins. And the problem arises, how to attach heavy objects to drywall? Especially if there is empty space between the load-bearing wall and the finishing, then this is a major headache. How to attach a heavy wall cabinet with dishes to a thin wall made of fragile material, or what to do with hanging a TV? The situation is not hopeless, and there are several main types of fastening materials with which you can hang various large objects on a plasterboard wall.

In order for the repair process to proceed successfully, it is necessary to think through all the details in advance, and even at the stage of installing drywall, provide places for installing drywall.

An integrated approach to fixing to drywall

For starters, why can't drywall hold hanging objects? In fact, plasterboard sheets are quite strong and can withstand high destructive loads from 15 to 60 kgf, depending on the thickness of the sheet. Also, partitions are usually made in two sheets, which further increases their strength.

However, the density of plasterboard is only 80 kg per cubic meter, which is 6-8 times less than the density of wood. This means that you can drive a screw into a plasterboard wall, but the screw will not hold a heavy object. To attach heavy objects to drywall, special technologies must be used.

What screws should I use?

To carry out proper installation, it is necessary to select certain screws. What to look for when choosing?

- Screw length. As a general rule, after screwing a screw into drywall, it should extend one centimeter from the back side. If you use a regular wall gypsum board with a thickness of 12.5 mm, which is attached to a profile with a thickness of 0.4 mm, then it is easy to calculate that 3.5x25 mm self-tapping screws will be suitable for installation . If the sheathing is carried out in two layers of gypsum board, then you need to give preference to longer self-tapping screws 3.5x35 mm. During repairs, some people immediately take longer screws to fasten one layer of gypsum plasterboard. This approach is irrational, because more money will be spent on fasteners than it could be.

- Thread pitch. It is recommended to use wood screws, as they are easier and faster to screw in. Also, beginners often have problems due to the frequent thread pitch, due to which the sheet core deteriorates and the fastening becomes unreliable.

- Material and coating. It does not matter how to secure a self-tapping screw in drywall if it is made of low-quality material or the necessary coating is missing. It is advisable to use black phosphate screws. They have proven themselves well, are quite durable and are not exposed to the external environment.

- Head and slot. Everything is simple here, because the self-tapping screws sold have a special head so that they can be screwed in flush. The slot is made specifically for a shaped screwdriver. It will be extremely difficult to find screws of another type.

Correct installation will not play any role if poor fasteners are chosen.

Attaching heavy objects to plasterboard using embeds

The classic technology for attaching a heavy object to a plasterboard wall (partition) is the use of pre-installed embedded elements in the frame of the structure. This technique is used if you need to install a sink, a heating radiator on drywall, hang furniture cabinets or shelves, hang a heavy picture or a bulky sconce.

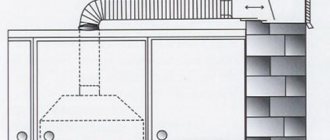

Mortgages are also used to install the inside of air conditioners. Frame designs with embedded parts make it easy to install an air conditioner in a room without special fasteners for hollow structures. Also, embeds allow you to quickly remove and repair refrigeration equipment and air conditioners, just like on a regular wall.

I described the essence of the technology in the article installing a sink on drywall. At the stage of installing the frame for the partition, a proprietary wooden traverse is installed between the racks or boards are simply mounted. After sheathing with sheets, the embedded elements are not visible and, if necessary, they are used as platforms for a canopy.

This technology is the most reliable, but requires prior coordination and planning. Mortgages must be installed exactly at the location where heavy objects are installed and during installation of the structure.

Auxiliary Tools

Before you screw a self-tapping screw into drywall, you need to think about tools that can make the job easier. Let's look at what tools and devices you can use:

The curly screwdriver is a classic of the genre. With its help, the pressure is always easily controlled. With such tools, the screws will be screwed in as needed. The main disadvantage is the complexity of the work. It will take a lot of effort to tighten several hundred screws with a screwdriver;- A screwdriver has long become an indispensable tool during repair work using gypsum boards. At first, it will be difficult for a beginner to screw in the screws to the required depth the first time. It will be necessary to adjust the power of the screwdriver so that the screws are fully tightened, but do not break through the sheet of drywall. Unfortunately, not every tool has a power regulator;

- The belt screwdriver is known only to professionals. This tool is quite expensive for an ordinary person doing repairs at home to afford. With a belt screwdriver, many questions regarding how to secure a self-tapping screw in drywall disappear. This tool has a special tape where screws are already inserted. You just need to place it on the drywall and press a button, and the self-tapping screw will be squeezed out of the tape and screwed into the surface;

- bit with limiter. A similar device is used on conventional screwdrivers to ensure that the self-tapping screw is recessed to the desired depth. A bit with a limiter should be used by anyone who is faced with the need to screw self-tapping screws into drywall for the first time.

A belt screwdriver will speed up the process of screwing screws into drywall

Fastening without embedded traverses

The planning of repairs does not always coincide with its implementation, and it is often necessary to attach heavy objects to drywall after finishing work, when it is no longer possible to install the mortgages. What to do?

In this case, you need a fastener that will create a support platform on the end side of the sheets. The support will rest on a large surface of the sheet and will make it possible to attach (hang) a heavy object.

For such fasteners, special folding fasteners are used. If desired, you can make them yourself.

I showed an example of such fasteners in the photo. This is how the fastener works. A hole is drilled in the plasterboard wall according to the diameter of the folded fasteners. The fastener is inserted into the hole, opens there, and the mounting bolt or hook remains on the surface.

Bookmarks

This option is excellent for fastening large and heavy objects or plasterboard finishes. The main thing is to plan at the renovation stage where and what will stand and hang.

By bookmarking we mean fastening to the main load-bearing wall or inside a light frame partition made of wooden slats or bars.

To do this, you will need a hammer drill and standard dowels with self-tapping screws (as an option, dowel-nails). Holes are punched along the intended surface and bars are secured to dowels, which are then covered with sheets of material. The main thing is to make a plan where the installed bookmarks are located, so that there are no problems with finding them when subsequently hanging furniture and equipment.

Bookmarks are wooden blocks that are laid in advance at the installation stage for later fastening of heavy objects.

Important. If there are walls made of gas or foam concrete blocks, the embedded bars should be attached not to standard plastic dowels, but to special metal “crocodiles”. Ordinary ones simply will not hold up in fragile walls, and after a while the block, under the weight of the weight of the hung object, will come off the wall.

Bookmarking is a great option, but what to do if the home is already finished or you need to rearrange or move items to other places?

Other mounting methods

To reduce the expected load, you can use special dowels. They are suitable for mounting on drywall in one layer, paintings, prints, and decorative elements. This type of fastener is called a spring crepe dowel. It can be a plastic butterfly dowel or a metal spring dowel. The principle of operation is the same, insert the dowel into the hole, when screwing the screw (bolt) into the dowel, the “ears”, the “wings” of the dowel move apart, creating a support platform.

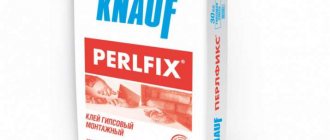

Chemical anchor

Fastening using a chemical anchor, a threaded rod and a mesh plug of the sleeve is done as follows. Mark a place on the drywall and drill a hole with a hammer drill. The drilled hole is cleaned of debris with a vacuum cleaner, and the edges of the sheet are processed with a stationery knife. A nozzle is placed on the container with the chemical anchor, inserted through the drywall into the hole in the supporting panel and filled with solution. Then, using a threaded rod, insert a plastic sleeve and fill the mesh cartridge 2/3 with solution. Cut the pin to the required size and screw it into the sleeve. After the chemical solution has hardened, place the bracket on the stud.

This type of fastening is used for all types of load-bearing walls:

- Wooden;

- Concrete;

- Brick;

- Foam block.

The connection can withstand a load of 50 kg.

Types of dowels for drywall

This fastener is used in many repair and construction works. For drywall, there are some types that will create fixation strength, while the surface will remain pristine.

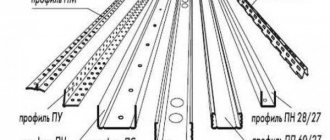

Dowel nail for fastening profiles

The most popular construction dowel nail for attaching profiles and hangers to a concrete wall consists of 2 parts. The first part: the tip - contains 2 sections, it is made of plastic. The second part is the nail, which can be threaded. To install the frame under drywall, dowel-nails of sizes 6/40, 6/60 are used. These fasteners are used to fix the guide profile to the wall. However, to attach the suspensions, it is necessary to use a metal anchor, since a large load is placed on the suspension, which the nylon dowel is not able to withstand due to its technical characteristics.

Dowel-nail for attaching the guide profile to a concrete wall

Dowel action

There are antennae on the plastic part. They straighten out to the sides when a nail enters the tip. The antennae are fixed in the concrete (brick) wall, while firmly holding the mass of the object being hung. The main basis for the use of fasteners is the fixation of profiles to the rough base during installation of the frame under drywall.

Dowel nail Knauf with different cuff shapes

These dowel-nails for drywall have 2 types - regular and restrictive cuff, which prevents the metal nail from “falling in” inside.

| Name | Number of pieces in a pack, pcs. |

| Impact screw 6*40 mushroom head | 100, 200 |

| Impact screw 6*60 mushroom head | 100 |

| Impact screw 6*60 countersunk head | 100 |

| Impact screw 6*80 countersunk head | 100 |

| Impact screw 8*60 countersunk head | 100 |

| Impact screw 8*80 countersunk head | 50 |

| Impact screw 8*100 countersunk head | 50 |

| Impact screw 8*120 countersunk head | 50 |

Video:

Options for fastenings in GVL

Next, we’ll look at the most popular options and what can be screwed into a plasterboard sheet to securely attach various decorative elements.

The easiest option is to find the guide profile using a magnet and screw a steel screw into it with a screwdriver. If this cannot be done, then it is necessary to resort to the help of special fasteners in a sheet of drywall.

The most common type used in drywall projects is the butterfly . In appearance it has the appearance of a butterfly with spread wings. The main material for fasteners is polypropylene. Metal products are also on sale.

Photo of the most common dowel for plasterboard “Butterfly”

Butterfly action for drywall

Initially, a drill is used to make a hole of the required size. You need to insert the plastic part of the dowel there. To do this, the side elements are pressed to the center, the dowel is driven in with a hammer. This should be done carefully. After which a screw is screwed into this part. At the moment of mounting the self-tapping screw, the polypropylene part opens from the back side of the plasterboard surface (as if the wings are spreading to the sides). They rest against the gypsum board, thereby rigidly fixing and distributing the suspended weight over the surface, there is no point load.

The butterfly dowel has a distinctive property - it is possible to dismantle fasteners from a plasterboard surface.

The butterfly has different sizes. Their selection depends on the weight of the item:

- Size 8/28. We will use this dowel to fix a lightweight structure. Self-tapping screws for the butterfly must be purchased separately. For this size, a 3.5/35mm screw is most suitable. The coating on the screw is completely unimportant. The hole for the dowel is made with an 8 mm drill. The inserted fastener has a lock that will prevent the butterfly from completely “falling” inside.

- Size 10/50. Inside the wings of this dowel there are 2 strips that provide additional strength when fixed to the base from the back. This butterfly can withstand a weight of 24 kg. For a butterfly size of 10*50, you should purchase 3.5/55mm self-tapping screws. The hole for this butterfly will need a diameter of 10mm. Installation of butterfly dowels

Molly screw fastenings (MOLLY)

The MOLLY drywall dowel is used when it is necessary to fix a heavy object on the surface. It is perhaps the most reliable mount.

In its structure, Molly differs from plastic dowels in that it has a completely metal frame. The material is galvanized or stainless steel. The dowel consists of a sleeve and a screw. The second part is sometimes selected independently, depending on the assigned functions - it can have an ending in the form of a head, a ring, or a hook.

Molly dowel has teeth for strong fixation on the surface

The sleeve has slots through the entire element, this creates a spacer. In the center of the sleeve there is a thread for a screw. When purchasing a separate screw, you should pay attention to this.

The screw included in the kit has a support washer, which is a kind of limiter - without it, the fastener rotates in the spacer part.

Molly mount

To install the molly dowel, you will need a special expanding device.

- It is required to make a hole in the plane with a size selected for the dowel dimensions from 8 to 13 mm.

- Next, a sleeve (collet) is inserted into the hole. It is driven in until the teeth on it rest against the surface.

- After this, the screw is screwed in.

- Use special pliers to pull the screw out. With this action, the end of the collet is attracted to the surface from the back side, the spacer part is activated and fixed.

Molly Attachment Diagram

Depending on the size of the Molly, there are different weight categories. Basically, rolling goes from 25 to 75 kg. You can hang up to 30 kg on a plasterboard surface using this dowel. weight.

The dowel is shown in more detail in the photo

It is possible to purchase a sleeve with a hook for the Molly dowel

Video:

DRIVA dowel with drill

The dowel is made from 2 types of materials: plastic and metal.

Plastic dowels are slightly cheaper than metal ones. For their production, polyethylene or nylon Mark TT 22 is used. This fastener can withstand up to 25 kg. weight.

Driva metal dowel

The metal wood is made from duralumin. It is not as popular as nylon products for one reason - pricing. This dowel carries 35 kg. weight.

The dowel (both types) has a locking device, as well as a screw thread with an acute-angled profile.

Fastening the Driva dowel

To fix the fasteners, you need to make a 6mm hole. but, if the thickness of the plasterboard sheet is 12.5 or less, then a hole is not needed. The dowel is screwed in there using a screwdriver until it reaches the locking head. A self-tapping screw should be screwed into this dowel.

The length of the nylon dowel is 23mm, the metal one is 44mm.

Video:

KNAUF fastenings Hartmut

This dowel has 4 components:

- the anchor strip is a kind of U-shaped galvanized plate;

- there are 2 guide antennae made of plastic;

- plastic locking insert;

- screw M5-60.

Knauf Harmut has a complex design due to which it can withstand up to 50 kg.

KNAUF Hartmut is able to withstand a weight of 55kg. In most cases, this anchor is designed for heavy objects on a plasterboard wall. This is a large-screen TV, a shelf with dishes in the kitchen, and a cabinet for bath accessories in the bathroom.

To install the dowel, a corresponding hole is made in the gypsum plasterboard wall. The plate is inserted into this gap using antennae. When the U-shaped part goes into the hole, the antennae break off. A screw is screwed inside.

Video:

Universal Fischer dowel

This dowel consists of a plastic cylinder and contains a sleeve. There are blades on the side, as well as a powerful end switch. Inside the dowel there is a thread for a screw. Dowel dimensions: length – 27mm, diameter 12.5mm.

The Fisher dowel has a plastic cylinder and sleeve

To install Fischer in drywall, a hole is made that matches the sleeve with a diameter of 12 mm. Fischer is inserted into the hole made and secured with a 6*50 corkscrew screw. When the screw is screwed in almost to the end, pressure begins on the conical part of the sleeve. Ultimately, under the applied pressure on the screw, the sleeve opens in different directions with blades that are pressed against the back side of the gypsum board sheet.

For small and medium loads, the UX universal dowel is suitable. This unique shape allows it to be used for fastening into drywall and other building materials.

Fischer dowel is sold as a set with self-tapping screws

When attached to a standard 12.5mm gypsum board sheet. For example, a board 8mm thick is attached. in this case, the screw from the back side of the drywall came out to a length of 27mm. this shows that there should be a 30mm empty space under the gypsum board.

Video:

The weight supported by the dowel is 16 kg.

Dowel with spring for ceiling mounting

This type of fastener is designed to be lightweight. It consists of several components:

- base – screw with hook;

- spacer component – 2 strips;

- spring strip retainer.

A hole needs to be made. Insert a dowel with pressure blades into it. As soon as the planks go beyond the boundaries of the plasterboard structure, the spring is activated and the planks are straightened, thereby being fixed on the other side of the plasterboard.

Types of folding dowels with spring

This dowel is mainly intended for hanging decorative elements and chandeliers.

If you need to hang a heavier object, we recommend using a special metal anchor and attaching it directly to the concrete.