Where are veneered wall panels used?

Veneered wall panels can be made from both wood and various boards. They make it possible to create extraordinary design solutions that look solid and elegant to guests, and will be very budget-friendly for the owner.

Among the areas of application the following objects can be distinguished:

- apartments and residential premises;

- offices;

- administrative buildings;

- entertainment and public facilities.

The wide range of applications of these materials is due to their high performance and aesthetic qualities. In addition, they are distinguished by their wide price range, which will satisfy the needs of most buyers.

Expenses

The cost of such a whim is relatively low, taking into account the bonuses that the user receives. At the same time, it depends on a number of factors in addition to the area that is planned to be decorated. These primarily include the price of raw materials - valuable wood that is used for veneer, and its quantity.

This last factor is important because some creators prefer to veneer both sides of the MDF. This increases not only the amount of natural wood used, but also related materials, as well as the technological processes used in production.

Unique decor for the hallway

Creative wall design at the head of the bed

Additionally, the cost increases when the company that creates the kit to order also develops the design of the premises. These same services can be performed by a hired professional who is fully responsible for the implementation of the design project, and not just for the decor.

The material, which has many advantages, confidently competes with other types of interior decoration

Finally, it is worth noting that veneer panels have plenty of analogues. These include laminated boards and natural wood. However, this particular material is devoid of all possible disadvantages that complicate the installation and operation of the finished product. Convince yourself, appreciate the high quality and wide variety of assortments that will turn your home and office into a fairy tale!

Characteristics and properties

Veneered panels demonstrate high performance and technical characteristics. Among the main properties are the following: biostability, heat resistance and the ability to repel moisture.

Such slabs are completely suitable not only for external, but also for internal work, since they do not harm people in the room.

Differences in installation method

MDF for construction purposes is produced in the form of sheets, tiles and lining. Each type of product has its own dimensions, installation method and is used for a specific type of work. At the same time, they all retain the same technical characteristics: environmentally friendly composition, high strength and elasticity, and good decorative qualities. The difference lies in the sizes and methods of attachment to each other and to the surface of the wall or ceiling.

Leafy

The most expensive of the above types of products is sheet MDF. It is the basis for creating highly artistic panels or relief inserts. The sheets are large in size - height up to 2.8 and length up to 2.05-2.9 meters. When ordering from the factory, sheets can be made to individual sizes and with an exclusive design.

Sheet MDF is used for wall decoration in large rooms to create a certain decorative effect of a seamless finish. The sheet is mounted directly on a leveled and antiseptic-treated wall end-to-end, as it does not have connecting grooves. The best option is to partially include such finishing in the wall cladding due to the bulkiness and price of the material.

Tile

MDF tiles have similar technical characteristics. The difference from sheets is in the shape of a square or rectangle of various sizes: from 0.5 x 0.5 meters to 0.95 x 0.95 meters. The tiles do not have connecting grooves and are mounted on a prepared wall. Convenience of working with this product – convenient for installation dimensions and light weight. If the installation of sheet MDF requires the participation of two or more workers, then one person can handle laying the tiles. It is enough to simply calculate the required number of pieces for finishing, knowing the area of the surface to be finished and the size of the tile.

The surface texture has standard colors and sizes like tiles. It is convenient to make mosaic panels from MDF tiles of the same type, but with different colors or textures. The versatility of this finishing material lies in its ability to be used in rooms of any size and configuration. On the finishing materials market, MDF tiles are presented in a wide range and have a lower cost compared to MDF sheets.

Lining

The cheapest and most beautiful slatted material – MDF lining – has gained the greatest popularity. It has excellent technical characteristics and a wealth of decorative finishes. The slats have dimensions from 2.4 x 0.11 meters and beyond. The standard length is 2.6 meters. Lining is used for finishing both walls and ceilings.

There are two types of herringbone laying patterns. The panels are laid at an angle of 90 degrees relative to each other, the ends are adjacent to each edge of the longitudinal side. Another option involves placing the slats at any other angles, while the ends are cut at the same angle and installed end-to-end. This installation requires a certain skill to ensure that the cladding is level with the same slope. You can cut several slats in advance, clean the edge of the cut and begin installation.

The lining is characterized by ease of installation, lightness of the structure and individual elements. Easily shortened to desired size. The side edges are equipped with special grooves for connecting the slats to each other without gaps. To ensure strength and to avoid deformation of structural parts, the rail is mounted on a frame made of beams. This eliminates the need to level the wall and allows you to hide communications inside the frame.

The MDF lath, although easy to install, requires adherence to installation technology so that the lath does not move. The decorative qualities of the coating depend on this. The location of the slats affects the modeling of space. A horizontal arrangement will lengthen the wall or ceiling. A transverse arrangement on the ceiling will make the room wider.

How to choose veneer panels for walls

The issue of choosing veneer panels in each individual case should be decided based on the individual preferences of a particular craftsman and the characteristics of the desired room.

General criteria that can be used to guide your selection are:

- location of panels;

- color spectrum;

- interior of the room;

- price;

- properties and characteristics.

Regardless of the chosen option, the result will be equally high-quality in properties and attractive in appearance.

Classification

There are a large number of different types of MDF panels.

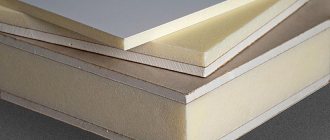

- Whole pressed. They have a pleasant appearance and are highly durable. Smooth on each side.

- Laminated. Unlike solid-pressed ones, on one side they have a strong and wear-resistant laminated film formed under high pressure. The film most often imitates wood (oak, cherry, beech or walnut).

- Veneered. They are made by gluing natural wood plates onto the surface. All cracks are sealed with a special putty. This is the most popular type of MDF among designers.

There are three ways to make such panels:

- hot method (pressing at high temperatures);

- cold (gluing with the help of special compounds):

- membrane (the most difficult to manufacture, the parts are connected when creating a vacuum).

These varieties are made from high-quality wood especially for bathrooms. Other products can be painted. This is one of the most popular types of MDF. Painting of panels occurs as follows: the finished panel is first primed, then it dries, only after that polyurethane enamel is applied.

Noteworthy are the varieties of 3D MDF. They are not only wall panels: they are often used to trim doors or cabinets. The use of veneer and MDF is popular because they allow you to create the atmosphere of a natural wooden wall with various carved wooden elements. MDF has an affordable price. If you want to get excellent results without spending a lot of effort and money, then it will be an excellent option for you.

To learn how to install MDF veneered wall panels, see the following video.

What are veneered decorative panels combined with?

When deciding on the use of decorative panels, users wonder what is best to combine them with. Among the options with which the panels are best combined, the following points can be highlighted:

- painting;

- wallpaper;

- plaster.

It is desirable that the combination be performed in the same color composition. Depending on the characteristics of the room, combining decorating styles can produce a striking effect. In addition to improving aesthetic qualities, such combinations can also have practical benefits, for example, hiding wires and communications.

Wall finishing with wood veneer: stages of work

First of all, veneer finishing involves pre-treatment of the walls. The surface must be leveled, sanded, degreased and free from any defects. This is an important point that directly affects the quality of fastening the panels to the walls.

After preparing the base, you will need to prepare the veneer itself:

- unpack;

- make markings;

- cut veneer sheets.

In this case, the minimum number of seams should be achieved. It should be remembered that veneer sets are divided into simple and figured. The first ones have a smooth right side, which is glued to the left side of the next sheet. In this case, the direction of the fibers will be parallel, and the pattern and texture will be symmetrical. In the second case, we are talking about patterns, geometric and other figures.

After preparation, glutinous glue is applied to the base, and then the veneer is laid diagonally or across the base. This must be done because the veneer is strongly tightened with glue and after drying, small cracks may form on the surface.

Make sure that the glue does not bleed through the veneer, especially if you are working with thin material. In some situations, it is better to let the glue dry on the base before attaching the veneer. The sheets are laid overlapping each other. To avoid unraveling of the seams during the work, it is recommended to fasten them, for example, with adhesive tape.

After gluing, the veneer should be ground using a special lapping hammer. Movements should be made along the fibers, from the middle of the sheet and towards its edges. In this case, you should strive to squeeze out excess glue, if any.

What are they?

To make the material, ordinary and valuable wood species are used, such as birch, alder, oak, but it can also be an imitation of real wood.

The properties of natural veneer are similar to those of natural raw materials; the material does not require additional processing. In contrast, surrogate veneer (fine-line) is made from inexpensive wood by gluing several layers, pressing and imparting a certain texture, color and ornament. This allows you to create panels of exceptional beauty and originality, although their appearance is far from natural.

Veneered products, as veneer panels are also called, are adapted to different substrates, but, as a rule, these are wood boards, the raw materials for the production of which are waste from wood processing enterprises.

The most common base materials for veneer sheets are MDF and chipboard.

- MDF is a wood-fiber material, especially durable due to its increased density. Such panels are resistant to moisture, safe for human health, and durable in use.

- The basis of the panel can be chipboard. This type of material looks beautiful and has a low price, but is less resistant to moisture and requires more careful care - it can crack if it is not dried correctly.

Decorative 3D veneer panels made using modern technologies are very popular. These are mainly MDF wall boards, additionally protected with a special coating. The polymer film on their surface is resistant to temperature changes and moisture, but such cladding is also virtually insensitive to mechanical stress and deformation.

Volumetric panels are the most popular product, implying high quality and elegant design. When facing walls, they can be painted, given the desired texture, covered with film, varnished in different ways, or the veneer can be made structural by gluing.

Thanks to the content of natural organic components, veneered relief panels allow the walls to breathe, and the method of connecting them using decorative strips (rusts) helps make the joints invisible.

However, this product also has its drawbacks: 3D panels require careful care, they accumulate dust, and are susceptible to aggressive environmental influences. It is also undesirable for them to be exposed to sunlight. In addition, they are more expensive than regular cladding.

By the way, such finishing can be based not only on wood slabs, but also on plasterboard. Fine-line style materials have low flammability and moisture resistance.

You can often find veneered products with a PVC base. Their main advantages are lightness, plasticity, any combination of shades, durability, not counting melting under severe overheating.

How to care

It should be noted that for care use products recommended by the manufacturer. It is important to remember that household chemicals and detergents containing hard abrasive particles cannot be used, otherwise the surface of the panels may be damaged. It is also not recommended to use products containing solvents.

The article discusses the feasibility of using wooden panels for wall decoration, their features and the possibility of combining them with other options.

Flaws

- The material is very thin, so it is not able to withstand external serious physical impacts. And even with light loads it can be damaged;

- Types of veneer with open pores have all the typical disadvantages of wood, including being afraid of moisture. Moreover, the destructive consequences do not even concern him, but the material that makes up the base;

- Fire hazard. If the material is not treated with special fire-resistant impregnations, then it is not recommended to use it in the kitchen or panel room. In this case, wiring along veneered walls must be in special protective boxes;

- Price. In the case of expensive types of wood as a basis for veneer, such finishing will be very expensive. At the same time, it is better to entrust the process to professionals so as not to damage valuable panels during their installation on the wall.