Drywall sheets are a type of building material that is incredibly popular.

Using it you can perform all types of work - leveling walls or making interior types of partitions. Often, it is with the help of drywall sheets that all kinds of structures or arches with a high degree of complexity can be formed.

When building such structures, quite often there is a need to minimize the number of joints between sheets of drywall.

Workflow Features

Let's figure out what advantages milling drywall has over the classic version of the work, and also consider all the features of working with cutters.

Pros and cons of this option

Drywall milling has the following advantages:

- Saving time . The use of the technology we are considering reduces the time spent on the construction of boxes and corners by 2-3 times. Everything is done much faster and easier, in addition, the likelihood of damage to the material if all recommendations are followed is practically absent;

Making corner joints with a router is very easy

- Possibility of constructing boxes of any size and configuration . There are no restrictions on the complexity of the design, the main thing is to correctly understand the markings and make grooves in the required places;

It is better to train on designs of simple forms, and when you already have experience, you can move on to more complex options.

An experienced craftsman can make structures of very complex configurations without cutting the sheet into pieces

- The number of open ends is reduced . This makes the structure neater and greatly simplifies the work of puttying and finishing. In addition, you do not need to reinforce all bends with corners, which reduces the cost of the project and reduces the time spent on putty with metal elements;

- Possibility of creating structures without a frame . If there is no load on the box or corner protrusion, then you don’t have to reinforce such elements with a profile. They themselves will have good rigidity and will last for many years without deformation.

You can make blanks in advance if you need a lot of identical elements, this is very convenient

The only downside is that you will have to spend money on a cutter and router. But if you are doing renovations in your home, then it is easier to rent a power tool. The price of the service is low, so you will save significant money.

The working process

Let's figure out what you need for work:

- A 90 degree drywall cutter is a special device that is used to make perfectly straight corner joints. The cost of equipment varies from 1000 to 4000 rubles. For household needs, the cheapest option is also suitable - even it will be enough for ten years of occasional use;

Drywall is a soft material, so the cutters practically do not wear out during use.

- Manual frezer . As I wrote above, if you are not involved in professional installation, then it is easier to rent a power tool. The work usually only takes a few days, so rental costs will be minimal. The main thing is to make sure that the shank of your cutter fits the equipment.

A manual milling cutter is a simple and convenient device for making grooves in plasterboard and gypsum boards

Instructions for doing the work yourself look like this:

| Illustration | Description of the stage |

| The strip is cut out . Its width should correspond to the distance from the edge of the router to the center of the cutter. This element is needed to transfer dimensions and precise location of equipment. You don't have to measure the offset; a ready-made pattern will help you do this quickly. | |

| The rule is set . To determine the exact offset of the stop element, use a previously made rail. This way you can set up the design accurately. | |

| The rule is followed by hand, the router is installed on the edge of the sheet . It is very important to hold the guide so that it does not move and you do not make a crooked cut. |

The cutter rotates clockwise, so during operation the router always pulls to the left. It is on the left side that the rule needs to be made.

Choosing a router

What is a milling cutter?

In addition to the most common and universal vertical manual router, there are also several highly specialized types on the market:

Although hand routers were originally created for woodworking, modern routers are also capable of processing artificial stone, plastics and soft metals. A router can hardly be called a universal tool, but many operations that are performed with a router are almost impossible to do with anything else. All this makes the router an indispensable tool for any craftsman. Here is a short list of the capabilities of a manual router:

It would seem that since the device of the router is so simple, then the different models should differ in price only slightly, and even then only due to different engine power. In fact, milling cutters of the same power can cost either 6,000 rubles or 30,000 rubles. What is the difference between expensive and cheap models? The quality of the materials from which they are made and the variety of accessories included in the kit. A cast, not stamped, sole, precise positioning of the accessories and the head of the router, light and clear, without play or distortion, the movement of the head - these are the signs that distinguish a high-quality professional tool. Expensive milling cutters are able to provide greater precision and accuracy in processing parts and give the craftsman more processing options. In addition, the professional models add some features that are not found in the basic models.

Characteristics of milling cutters

Spindle rotation speed.

The cleaner the processed surface should be, and the harder the material being processed, the higher the rotation speed should be.

At the same time, some materials (for example, plastics, tough metals, some types of wood) cannot be processed at very high speeds. Some types of nozzles also have their own speed requirements. Based on the above, if the router is intended to be used for various operations or with different types of materials, then you should choose a model with speed control.

It should also be borne in mind that the spindle speed may drop under load; to prevent this phenomenon, some (mostly professional) models are equipped with the option of maintaining speed under load.

To prevent jerking when starting the engine, there is a soft start

– milling cutters equipped with this function, although they will cost more, will last longer by reducing the adverse effects on the engine. And there will be less risk of damaging the part due to a sharply moving cutter.

overload protection feature to extend tool life.

which comes into effect when the permissible engine temperature is exceeded. This function can be implemented in different ways - from LED indication to forced power off, but in any case it will not be superfluous.

Maximum milling depth.

A parameter that directly affects the power of the tool, and therefore the weight and price. Therefore, it is reasonable to start choosing a router by determining exactly the required maximum depth. For most furniture manufacturing work, for example, a milling depth of 45-50mm is quite sufficient.

Additional equipment

Choices.

If you need a tool for a variety of household work that does not require high precision and quality of milling, a basic model priced from 3,500 to 8,000 rubles will suit you.

If you are going to use a router professionally to make furniture or interior doors, pay attention to models from manufacturers specializing in the production of professional tools. Such a router will cost from 8,000 to 20,000 rubles, depending on the characteristics and configuration.

If you are going to use a router for metal work, you should pay attention to models with a high speed. Such a tool can be selected in the price range from 3,800 to 13,000 rubles.

If you need a powerful professional router for working with heavy cutters and large milling depths, get ready to shell out 20,000 to 30,000 rubles.

If you are a professional furniture maker and you don’t yet have an edge router, pay attention to this type of tool - it can significantly speed up the processing of edges and provide them with the best appearance. Such a tool will cost you from 7,500 to 15,000 rubles.

Conclusion

You learned how to make perfect corners in plasterboard structures yourself and spend a minimum of time on it. The video in this article will clearly show the workflow so that you understand it even better. If something is unclear to you, ask in the comments.

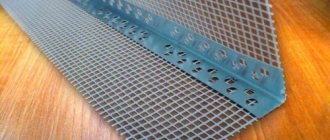

The most popular material for finishing rooms is plasterboard. It is used for the installation of curved structures, arranging gypsum plasterboard ceilings, leveling walls and erecting partitions. This material is so versatile that any structure can be built from it. The only inconvenience is adjusting the joints, which takes a lot of time. This is what V-shaped cutters for drywall of various sizes look like. But there is a tool that minimizes labor costs for fitting sheets - a drywall cutter. Thanks to this device, you can make even holes in the slab, or cut complex configurations with cuts.

Full contents of the material

GKL milling

Drywall is incredibly popular because it allows you to quickly perform various types of work: erect a partition, level a wall, make a structure of almost any type. But when creating structures from gypsum plasterboard, it is necessary to minimize the number of joints. Each joint requires labor in its careful fitting, priming, reinforcement, and puttying. And this takes a lot of time, especially if there are a lot of joints - then the repair can take a long time.

A very convenient modern way of cutting sheets is to mill plasterboard. It allows you to quickly create not only a variety of holes in gypsum boards, but also make structures of any configuration with the minimum possible number of joints and cuts.

Types of milling machines

This tool can be divided into 2 types:

Disk

This type of tool is intended for cutting gypsum boards along straight lines. Thanks to the disc, there are no chips or nicks on the cut, and the work happens quickly. But the Strong cutter is not suitable for products with complex structural shapes.

Shaped

This is the main tool for milling gypsum boards. Using a shaped tool, you can cut out complex geometric grooves or holes, which can be oval or round.

- V groove cutter for plasterboard expert, straight – for drilling holes at an angle of 90 degrees and forming grooves. With its help, you can drill holes of various complex shapes;

- T-shaped cutter - used in the same way as the first option, only the diameter of the holes can be the maximum possible;

- Edge cutter - to create a chamfer along the edge of a plasterboard board, the profile of this cutter can be different;

- U-shaped cutter, fillet. Used to create grooves with a semicircular bottom and holes of unusual configuration in drywall;

- The Festool 90 degree V-shaped plasterboard cutter cuts corner grooves between the sides of the cut, this is the configuration often used when installing plasterboard structures.

Return to contents

Applications of the festool V-shape cutter

When a person creates a box or partition from gypsum board sheets, the corners will be constructed from several elements, two or three. Drywall is attached to a metal profile, resulting in a right angle.

If you use a Festool V-shaped cutter when constructing the box, then it is not necessary to cut the sheet of drywall; it is enough to make a cut and glue its edges together while bending the sheet.

The result will be a structure without joints. This method has a number of advantages that are obvious:

This is what a festool V-shaped drywall cutter looks like

- Quick installation - assembly is much faster; the material does not need to be pre-cut and then joined.

- The number of joints becomes much smaller, thereby making the finishing process much easier and faster. As for the corners, in this case there is no need to make reinforcement and spend money on a perforated corner.

- If the structure of the plasterboard box is not load-bearing, then it can be installed without a frame made of profiles. It is worth noting that as soon as the adhesive on the joints dries, the corners will become very strong.

Thanks to this device, you can make structures of various shapes. To do this, you need to correctly mark the sheet of drywall and make cuts with a Festool cutter. If the work is expected to be large, then you can prepare all the corner structures at once, and then simply install them.

Working with a V-shaped cutter

The best result for milling will be work done on a special machine, but it is expensive and is used only on a large scale. In order to create corner parts from plasterboard using a Festul cutter, you will need:

- waterproof plasterboard;

- table for cutting material;

- machine;

- cutters of different diameters;

- vacuum cleaner;

- clamps;

- rule;

- work clothes;

- respirator and gloves;

- priming;

- masking tape;

- hot melt adhesive.

Important! When working with a router, you need to remember that it is pulled to the left. Bosch drywall cutter, rotates clockwise.

Therefore, the stop should always be placed on the left side, the router will be pressed against it, and the work can be done with one hand.

The working process

The work itself on processing drywall can be divided into two stages:

Preparation

- A wide strip is cut from plywood - a measure, the width of which will be equal to the distance from the stop edge to the central part of the cutter, for ease of cutting.

- A rule is fixed to the edge of the table using clamps - this will be a stop for drywall when milling, you can fix a long level.

- The router must be adjusted according to the thickness of the gypsum board sheet, so that when cutting the sheet, the top layer of cardboard and gypsum layer are cut, while the cardboard underneath remains intact. A small amount of gypsum residue is allowed, approximately 0.4 mm.

Example of drywall milling - If there are a large number of small parts that need to be made from drywall, you can prepare special measurements for each cut; with them the work will progress faster.

Read also: Soldering iron for home needs

As soon as the preparatory work is completed, you can proceed directly to the formation of the cut.

Main works

- Calculate how many cuts are needed, on which side of the sheet and at what distance they will be from each other. This must be done very carefully, because if you make a mistake, the material will be damaged.

- If there are supposed to be joints between elements on the plane, then you should immediately remove the edge; after forming the cuts, this will be inconvenient.

- Draw the lines along which the milling will take place.

- Place the sheet on the table in a rule or level, and you need to attach a cutting measure to it, which was prepared in advance from plywood.

- Position the cutter against the left edge and run the cutter along the entire plane of the sheet.

- Make a reverse cut in the same place, so the cut will be clean, without jagged edges.

- If it is necessary to mill the sheet on both sides, then the material is carefully turned over so as not to tear the cardboard.

- Prime the plasterboard section; the brush should be semi-dry.

- Apply adhesive to the joints on both sides, give the structure the desired configuration, and check the corners.

The process of gluing plasterboard sheets - Use masking tape to secure the model in this position and let it dry.

Important! Only moisture-resistant drywall is milled, since it does not get wet when priming and has a more durable cardboard surface.

Pros and cons of this option

This process has several advantages:

- Boxes and corners are assembled several times faster when using this technology. It is almost impossible to spoil the material if you use the cutter correctly;

- Any design can be assembled using milling technology; there are practically no restrictions on complexity. You are required to correctly draw out the sheet and carefully assemble the structure; Options for calculating drywall sheets

- There is no need to carry out work on reinforcing the corners, which significantly reduces the time for finishing work and reduces the cost of repairs significantly;

- There is no need to waste time constructing the frame, since the box turns out to be quite stable and rigid. It will stand for many years without deformation, unless there is an external load on it.

Important! Do not start making complex structures without experience. Start practicing on small pieces of material. This method also has disadvantages. When installing corner elements from plasterboard, you will have to buy tools and accessories for them. If you need to make repairs in your apartment, then it is easier to contact a rental point for construction tools for drywall. The rental service is inexpensive, so you will save a lot! The video shows the process of milling and sealing gypsum plaster joints.

Recommendations for choosing cutters

When choosing a cutter, you should first pay attention to the manufacturer. A high-quality European-made product costs an order of magnitude higher than its Chinese counterparts, which is compensated by the higher quality of the products. Nevertheless, there are Chinese-made samples of fairly good quality; when choosing them, you should ask the advice of knowledgeable people or look for reviews on the Internet.

When choosing a cutter, first check the shank diameter to match the available tools.

When buying cutters for the first time, you should not spend money on an expensive option with a wide range of applications. A set of several basic cutters at a reasonable price at the start will allow you to try out the tool without fear of ruining it.

The kit can then be supplemented with the necessary types of cutters based on experience and work needs.

The use of any cutting tool requires extreme caution. First of all, you should read the instructions, even if you have already used a similar tool before. Each model has its own differences and its own safety technology.

Types of machines, cutters and areas of their application

There are two main types of routers: disc and shaped.

Disc router

A disk router is used to create straight grooves or to cut plasterboard sheets. The advantages of a disk router are the speed of work and the cleanliness of the cut. The plaster is cut very smoothly and without jagged edges. However, a disk router is not suitable for creating grooves of complex shapes.

Shaping router

The main milling of gypsum boards is carried out with a shaped router. It is used for cutting grooves of complex geometry, as well as round or oval holes. In principle, when using a router, the shape of the hole can be any. You can also make chamfers on plasterboard sheets using a router.

Drywall cutters come in different shapes and sizes, depending on what exactly needs to be done:

- The slot cutter is straight. Used for drilling grooves and holes located at right angles to the plane of the sheet. Can be used to create both pinholes and drill holes of complex shapes.

- T-shaped slot cutter. Used for drilling grooves and holes located at right angles to the plane of the sheet. Can be used to create both large-diameter pinholes and drill holes of complex shapes.

- Edge cutter. Allows you to make chamfers on the edge of a plasterboard sheet. May have a different profile.

- U-shaped fillet groove cutter. It is used for drilling grooves with a rounded bottom profile, as well as for drilling straight point holes and holes of complex geometry.

- V-shaped fillet groove cutter. Used for drilling triangular slots with an angle between cuts of 90°. This type of cutter is the main one in the manufacture of plasterboard structures.

Read also: Is it possible to cook cast iron with conventional electrodes?

Preparation of tools and workplace

Before you start cutting sheets, you should prepare everything you need:

- Any milling machine with a power from 1 kW to 1.5 kW is suitable for cutting drywall. It will be difficult to work with a more powerful machine, and the chance of spoiling the material will increase.

- If the milling machine does not have a dust collection device, you need to attach it yourself and connect a vacuum cleaner to it. Otherwise, when cutting, a cloud of dust will rise, which will spoil visibility and complicate cutting, as well as complicate breathing.

- For convenient and high-quality work, protective equipment is necessary. These are at a minimum safety glasses, but it is also advisable to wear a simple blade respirator

The workplace should be organized as follows:

- you need a smooth, flat surface, such as a table;

- a stop is installed on one of the edges of the table, which can be made from several boards - securing the material will ensure dimensional accuracy;

- a suitable cutter is selected - the most common type is the V-shaped one, which allows you to obtain an even edge of the correct shape.

Possibility of using a V-shaped cutter

Creating partitions or boxes from plasterboard using the classical method assumes that the internal and external corners will be made up of two sheets. Accordingly, if, for example, you need to make a U-shaped box, then at least three separate pieces of gypsum board will be used, which will be attached to the metal profile at right angles to each other.

When making the same U-shaped box using a V-shaped cutter, only one piece of gypsum board will be required. By making only two cuts with a cutter, bending the sheet and gluing the sections, we get the same box, but without external joints.

The advantages of this method are obvious:

- Time costs. Milling drywall speeds up the cutting and assembly of structures significantly.

- The number of open cuts, fastening points and the number of required parts are reduced. This speeds up puttying and priming work. Reinforcement at external corners made in this way is not required at all.

- Boxes and structures bearing minor loads can be installed without a metal frame. After the adhesive layer has dried, the corners formed by milling themselves become quite strong.

- Using a V-shaped cutter, you can make structures of different profiles. To do this, you just need to correctly estimate the number of corners, evaluate which side each of the cuts is located on, make markings and cut the sheet. For large-scale work, you can prepare the required number of corner blanks in advance.

Step-by-step cutting of drywall

To obtain a high-quality result, you must adhere to a certain procedure. After all the preparatory work, you can begin the actual cutting.

There are various methods for cutting plasterboard sheets, which, in essence, are as follows:

- Marking the material. First you need to put on the workpiece the outlines of all the parts that will be cut out. For these purposes, a pencil and ruler will be useful. Sometimes, at the first marking, it seems that there is not enough material, in which case it is worth considering the cutting option again - perhaps it will be possible to reduce costs and place everything on the existing sheet. However, when marking, you should not place the parts too close to each other, since drywall crumbles easily, and an accidental chip can ruin the plan.

- Pre-processing of workpieces. Before cutting to precise dimensions and embossing, whole sheets can be divided into preliminary blanks with rough dimensions. You can cut the sheets using a knife or other tool.

- Preparing for cutting. The workpiece is placed in clamps or rests against a manufactured clamp. Protective equipment is worn. The equipment is connected to the network.

Working with a V-shaped cutter

The best quality milling can be achieved on a specialized milling machine. But this solution is quite expensive and is appropriate only for industrial scale work.

To mill drywall and create profile parts from it on the scale of a repair team or independently, you will need:

- Drywall (better if it is waterproof).

- Cutting table.

- Fraser.

- Milling cutters.

- Industrial vacuum cleaner with cyclone filter.

- Rule.

- Clamps.

- Protective equipment (gloves, respirator).

- Masking tape.

- Primer and brush for it.

- Adhesive: polyurethane foam; PVA; "Uniflot"; hot glue, etc.

Work on milling and forming parts can be divided into preparatory and main ones.

Preparatory work

- For the convenience of further marking, cut a measure from plywood with a width equal to the distance from the center of the cutter to the stop edge of the router.

- Using clamps, secure a rule or level to the assembly table for use as a stop when milling.

- Adjust the router so that the cutter cuts through the entire thickness of the drywall sheet, but does not touch the bottom layer of cardboard. A residual layer of gypsum no more than a quarter of a millimeter thick is allowed.

- If you need to make a large number of parts of the same type, then it also makes sense to cut out measurements from plywood for each of the seams.

Main works

- Calculate the required number of seams, the distance between them and their location on the sheet.

- Saw off a piece of the required size from the gypsum board.

- Using an edge cutter, chamfer the edges at the plane joints in advance.

- Mark the routing lines.

- Mark the edge stop lines of the router.

- Place a sheet of drywall against the rule.

- Attach a cut measurement to the rule.

- Press the edge of the router against the measurement with the left side.

Note! In conditions of free movement, the router moves to the left, so the stop should be located on this side.

- Make the first cut along the entire height.

- Make a second cut along the same groove in the opposite direction - this is done to ensure a clean cut.

- Cut all the grooves on the side of the sheet to be processed.

- If the geometry of the part being manufactured requires milling drywall on both sides, then carefully turn the sheet over and repeat the work.

- Dust with primer using a semi-dry brush.

- Apply adhesive to the joints on one side.

- Place the part so that the joints are vertical.

- Apply adhesive to the joints of the second side.

- Give the part the desired shape, check the geometry of the corners.

- Secure the structure in this position with masking tape until completely dry.

Milling gypsum plasterboard is a very convenient and profitable solution when creating plasterboard structures. This technology, although it requires more expensive equipment, allows you to perform work more accurately and faster than conventional methods of working with plasterboard.