Drill with a hole saw (circular saw) into the drywall.

The fastest and most convenient way. Drywall crowns are sold in almost all hardware stores and construction markets. The price of the set, depending on the number of blades, diameter and manufacturer, ranges from $2 to $30. The most popular sets with 7 blades with a diameter of 26, 32, 38, 45, 50, 63 mm with one holder, cutting depth up to 18 mm. The price of this set is $2-5:

For holes of larger diameter (for example, for installing lamps), you can buy a set with blades with a diameter of 60, 67, 74, 81, 95 mm with a cutting depth of 32 mm. This set costs $5-8.

To drill a hole of the required diameter (or close to it), you must first remove all the blades, turning each one slightly clockwise and pulling it towards you, select the blade of the required diameter and insert it into place. Drilling takes from 3 to 10 seconds; it takes longer to select the blade. Marking and drilling are done from the front side of the drywall. Holes can be drilled both on plasterboard sheets screwed to the frame and on sheets that are not secured in the designed position.

It’s very convenient, but it happens that the sets don’t have blades of the required diameter. For example, to install a socket box, the hole must be as precise as possible so that the socket box does not dangle later. In this case, you can use a combined method: first drill a hole with a crown, and then adjust the hole to the desired size with a knife. How this can be done is shown in the video:

If you are only interested in drilling, then you do not need to watch the entire video.

However, you may not have a crown at hand, it doesn’t matter, there are other ways to make a hole in the gypsum board:

What to use to make holes in drywall for lamps - the issue is resolved

Another option for making holes in drywall for lamps is to use a special tile drill. Despite the fact that such use of attachments of this type can be considered inappropriate, there are no difficulties in performing the task. The nozzle can be adjusted within a certain range, so its purchase can be considered a universal solution. If for some reason the above methods are impossible to use, the problem can be solved in another way.

So, for example, a series of holes are drilled using a regular drill according to the markings. They must be performed at a distance of several millimeters from each other. Next, with a light blow of the hammer handle, the inner part is knocked out, and the remaining irregularities are removed using coarse sandpaper. Drywall has proven itself to be a universal finishing material. Thanks to its excellent performance characteristics and comparative ease of use, it can be used to solve a wide range of problems.

However, there are some peculiarities in handling it. For example, when you need to cut a round hole in drywall, certain difficulties may arise. How to correctly carry out the necessary actions will be discussed further. In addition, you can use a simple stationery knife. As a guide, you can take a round object of suitable diameter, such as a saucer or bottle.

Several passes with a knife are made around the improvised template, resulting in a fairly neat hole. So, if there is a need to make a technological or decorative hole in a sheet of drywall, then you should take into account that the problem can be solved in several ways. The choice of option should be made based on specific conditions and the availability of tools. If you don’t know what is the best way to cut drywall, then from our experience we can tell you that in most cases, it is best to use a good utility knife.

But sometimes you have to use other tools. For example, a drywall hacksaw is convenient to use for cutting holes of various shapes.#1. First you need to determine what you can use to cut a hole in the drywall.

There are several ways to do this. To do this, you can, for example, use a crown, a ballerina or a small hacksaw. The first method that will be discussed is using a special crown to make a hole in the drywall.

It is the most correct of all, recognized as the fastest and most effective. The vast majority of craftsmen resort to it in cases where it is necessary to drill a circle in drywall. Cutting a circle with a knife is not an easy task. First of all, you need to choose the right knife that is designed for such work.

Next, you will need to accurately mark the circle on a sheet of drywall to avoid inaccuracy in the work and an unsatisfactory result. Next, you need to cut out with maximum precision what is drawn on the drywall. Before you make a hole in drywall, you need to know what kind of material it is. Drywall is a material that consists of a two-layer sheet of cardboard and a core of hardened gypsum with fillers.

This material is intended for cladding, creating partitions, and is used when installing ceilings in rooms with normal air humidity. The depth of the slot made in the first stages of preparation is important. The deeper the slot, the less effort you will have to make to ensure that the sheet breaks off in the right place.

If the circle you want to cut is large enough in diameter, then it will be better to cut the cardboard inside the outline into segments.

Cut with a jigsaw.

Using a jigsaw, you can make a hole of any geometric shape and size, if necessary, get a hole as close as possible to a round one; the side surface of the gypsum board is sanded with sandpaper.

If you need to make a hole with a very small diameter (20-30 mm), then it is better to use a narrow saw for cutting holes in the chipboard. There are just limitations: you can’t make a hole on a glued gypsum board with a jigsaw, and if the distance between the base of the wall or ceiling and the front surface of the plasterboard sheet is less than the height of the jigsaw file at the maximum output of the file, then the jigsaw won’t help here either. But it’s not over yet, there are other ways:

Cutting a round socket for a socket or switch

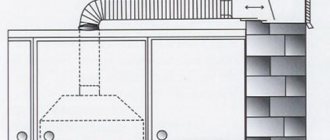

The socket or switch connector, which has a round shape, is cut out using a drill with a special crown attachment of the required diameter, or using a jigsaw or a narrow hacksaw. The first option allows you to carry out the task most easily, requiring only a few seconds of time. Cutting out any openings is often done locally, after the plasterboard sheet has been secured to the sheathing, since otherwise the strength of the material may be compromised and often even a slight distortion during transportation or installation can cause a break.

Note! To mark a round opening, you only need to determine the center of the circle without performing any additional actions.

In the case of cutting holes using a hacksaw or jigsaw, determining the middle is done using a compass, which allows you to draw a cutting line. Next, 2 openings are drilled on the strip with a drill as close to each other as possible. After this, the hole should be carefully connected using a file, continuing to cut along the contour line.

Use a circular drill (nibblers) to drill into the tiles using a ballerina drill.

In fact, ballerinas are designed for drilling holes in ceramic tiles, but if you have one, you can easily use it, especially since you can set the diameter of the hole to the nearest millimeter. The price of a “ballerina” is not high - $2-10, which is comparable to the price of a set of crowns. Ballerinas look like this:

With a ballerina you can drill a hole even in a plasterboard sheet glued to a concrete wall or ceiling, since a ballerina drill usually has a pobedite tip. The only limitation is that the maximum diameter of the hole is limited by the ballerina's shoulder.

A hacksaw blade for metal.

This is the first available remedy. The blade is removed from the metal hacksaw, several small-diameter holes are drilled into the plasterboard and then the blade is inserted into the holes. To work with a hacksaw blade for metal, special hacksaw handles are sold:

If you need to make a lot of holes, then it is better to buy such a handle. The larger the hole diameter, the more convenient it is to work. This method has two limitations: the minimum hole diameter is 50 mm (you can, of course, cut a hole with a smaller diameter, but it’s easier to do this in other ways) and it will not be possible to make holes in a gypsum board glued to a thin layer.

Hole on plasterboard ceiling for lighting fixture

Holes for lamps in drywall are very easy to make. Drywall is a flexible material for finishing and special equipment for its processing is usually not required. You can cut a hole in several ways, using professional drill attachments or improvised means: Holes for lamps on the ceiling in plasterboard This device is used by professional tilers to make holes in ceramic tiles, but it is also great for such pliable material as sheets of plasterboard. An example of drilling a hole with a ballerina circular drill. This tool can be used even if the drywall is already mounted on the wall, using adhesive. There is only one limitation – the diameter, which can only be set according to the length of the ballerina’s shoulder. The method is simple and not labor-intensive.

Insert a wood drill into the drill and drill the maximum number of holes around the entire circumference. Almost every owner has this tool. The work must be done with a blade that is removed from the hacksaw. Several holes are pre-drilled in the drywall around the perimeter of the circle. Sawing a hole with a blade for metal A blade is inserted into one of them and a cut is made. If there are a large number of holes, you can purchase a special handle into which the blade is inserted, then the work will be much easier. After this, knock out the perforated element with a sharp blow - the remaining teeth can be trimmed with a construction knife or sanded with sandpaper.

Drill with a drill with a drill bit with a diameter of 6-8 mm.

If you work with drywall, then you definitely have a drill and drill bits in the house. In this case, the drill replaces the router, so the diameter of the drill cannot be too small, otherwise the drill may break, and with a large diameter of the drill, unnecessary mechanical work is performed, and it is harder to hold the drill. This method is good because it is suitable for all cases, but you need to be careful when making a hole in this way in a gypsum board glued to the base. In order to make a hole of the required diameter (or dimensions if the hole is not round), draw the contours of the hole on the plasterboard sheet, drill the first hole from the inside of the line and, without turning off the drill, move the drill along the line (leaving an indent of 1 just in case -2 mm, if the hole must be very precise), it is advisable to hold the drill with 2 hands. If it is necessary to obtain a hole as close as possible to a round one, the side surface of the gypsum board is sanded with sandpaper.

Helpful Tips for Successfully Cutting Drywall Sheets

In order to avoid irreparable mistakes when cutting material, it is necessary to take into account some nuances and adhere to a number of the following recommendations:

- When cutting drywall, it is better not to use a grinder, since using it will not only be noisy, but will also generate a huge amount of gypsum dust that will need to be removed.

- If you need to use a hammer when cutting sheets, it should be exclusively rubber, since a metal tool can cause severe damage to the material being processed. When wielding it, you should also calculate the force of the blows without putting in a lot of effort.

- To reduce the number of notches along the cutting strip on the sides of the sheets, it is necessary to hold the knife or hacksaw at a right angle, since the lower the slope of the cutting element, the larger the nicks on the cardboard will be.

- All key cuts should be made before attaching the drywall to the sheathing, since if this fails, the sheet will need to be replaced with a new one. The damaged workpiece can be used when making inserts. The exception is cutting out openings and sockets for sockets and switches, which are best done after installing drywall on the frame.

- It is not recommended to make complex designs in material with thin partitions, for example, openwork mesh, since in this case it is highly fragile.

- When cutting a sheet completely, this procedure is often performed on the floor. After making a cut along its strip, you should place a beam under the drywall, and then you need to press on 2 parts of the canvas, easily breaking the material along the line previously passed by the cutting tool.

From all that has been written above, we can conclude that there is nothing difficult in carrying out work with drywall. Even a person who does not have the relevant experience can cope with this task, and if there are any doubts, everyone can first practice on a small-sized workpiece, making sure that cutting is easy. Having become familiar with how and what to cut drywall at home and adhering to the given technology, the use of high-quality tools will allow you to complete all the work quickly and at a high level, avoiding various mistakes and possible damage to the sheets.

We advise you to study - Which cordless screwdriver is better - compare and choose

Video on how and with what to cut drywall at home with your own hands:

https://youtube.com/watch?v=zvi-QDl8PsU

You may be interested in:

How to lay tiles on plywood on the floor efficiently and avoid defects

How to make drywall moisture resistant with your own hands: an easy way to transform ordinary sheets

How to remove water-based paint from a ceiling qualitatively using thermal, mechanical and other methods

Cut with a knife.

The most difficult, time-consuming and dangerous method for both you and the gypsum board, but sometimes you have to use it. The hole is cut in 6-10 passes with a knife. The blade of the knife extends 5-8 mm (meaning a simple wallpaper knife); during the first pass, the knife is held perpendicular to the gypsum board. During the second pass, the knife is held tilted in one direction, and during the third pass, tilted in the opposite direction. Thus, in 3 passes, a groove is obtained along the contour of the hole with a depth of 2-4 mm. With subsequent passes, the groove deepens until the plasterboard sheet is completely cut through. If you do not use linings, then there is a high probability of the gypsum board breaking off.

Make a tattoo.

If you have children who are doing extremely poorly in school, do not be discouraged, and such children can be of great benefit. Take a meter from the preparation room - a thing similar to a compass, only with needles on both legs, and, setting the meter to the required radius, make punctures in the sheet every 2-3 mm. Using a knife, cut the cardboard on both sides along the contour of the hole. After this, it is advisable to place the sheet on supports so that there is no support under the future hole, but there is support next to the hole. Now, with a sharp blow of a hammer in the center of the contour, you can knock out a hole.

There are other ways, but I think these will be enough for you for the first time, if not, leave a comment, we will take it into account.