Today, it’s rare that anyone doesn’t decorate their own homes. For a long time now, the renovation world has not accepted gray standard buildings and walls, which are accompanied only by a banal whitewash.

People begin to strive for their own individuality in the process of constructing residential buildings, paying preferential attention to appearance. Therefore, when finishing, bark beetle plaster is often applied with your own hands.

It helps to recreate the effect of a coating that has been damaged by bugs (bark beetles). Because of its originality, it is successfully used in construction and repair processes.

Due to the appearance of the walls on which this type of plaster is applied, it received this name.

What tools may be needed.

For any construction manipulations, you must have specialized tools, the list of which is given below:

- Bucket, plastic grater, sprayer.

- Drill equipped with a mixer attachment.

- A spatula or construction spatula for applying raw materials.

- A roller and a container under it to apply the primer liquid.

In order for the bark beetle plaster to lay down easily, you definitely need to stock up on similar construction attributes. For visual completeness and aesthetics, do-it-yourself bark beetle plaster is leveled with a spatula.

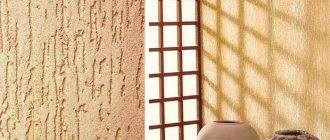

A selection of photographs of decorative decoration of rooms with bark beetles

If you want to choose ready-made solutions for decorating the interior of rooms, we recommend that you look at our selection of photographs with the most successful options for interior decoration. Here you can find interesting compositions for decorating the kitchen, living room and bedroom. Due to its qualities, bark beetle plaster is excellent for decorating rooms of almost any style.

Tyutyunnikov Dmitry

Article verified by a decorative finishing specialist

What kind of raw material is it and what qualities does it have?

Bark beetle plaster is divided into two types - the base of which is gypsum or acrylic material. If the second type can be purchased completely ready-made and diluted, then gypsum plaster is sold exclusively as a mixture of dry substances. It is a composite plaster containing pebbles - small-volume granules.

Important! Each company uses its own method of creating a building mixture. Most often, the role of granules is played by crushed minerals or marble. The grain size of the plaster is measured by the size of the crumbs present, which sometimes reaches a diameter of 3.5 millimeters.

This plaster has its own advantages over other building decorative mixtures; it has the following characteristics:

- If you replace sand with a mineral filler or polymer substances, the finished composition will be particularly light. This factor will allow you to avoid excessive load on individual structural elements of the facility.

- Bark beetle plaster is an environmentally friendly product that does not contain harmful substances.

- This raw material can withstand severe climatic conditions. It does not fade in direct sunlight, without releasing toxic components even at 55 - 60 ° C.

- It is very durable, resistant to mold, resistant to chemical liquids of moderate concentration, as well as aqueous solutions. When dirty, it is easy to clean with water; it does not tend to crumble under the weight of precipitation.

- "Bark beetle" is resistant to moderate mechanical damage. It can be cleaned using a vacuum cleaner or sponge.

- It has standard colors, however, if the owners want to get other shades of the material, then it can be mixed with the necessary dye or painted after application and complete drying on the site.

- It is easy to buy at an affordable price at any hardware store. If necessary, the material is ordered for delivery to the site where the work is being carried out.

Preparatory process.

If you want plaster that retains its original appearance for a long time, you need to know how to make bark beetle plaster with your own hands and at the same time with high quality. First you need to diligently prepare the base by cleaning it and plastering it as follows. The process goes like this:

- First, all possible remnants of the previous coating are removed, cleaned of dirt and grease stains. If necessary, the wall is leveled using sand-cement raw materials.

- If bark beetle plaster is applied in a place where the moisture level is constantly elevated, then the wall is treated with a specialized antifungal solution.

- Any gaps are cut out and treated with gypsum putty.

- If you apply bark beetle plaster indoors with your own hands, know that the minimum thickness should be 2 cm, after which grouting is carried out. When application is carried out on external coverings or walls that are plastered with a mixture of lime and cement, no primer is needed. It is enough to thoroughly moisten the surface with plain water.

- The walls must be completely cleaned, degreased and leveled before application.

When all the above requirements are met, you can prepare a decorative solution.

Preparatory stage, surface treatment

Before applying the plaster layer, the walls are prepared. To do this, perform the following manipulations:

- Initially, it is necessary to remove the old coating, remove any remaining wallpaper and paint.

- Cracks and other defects in the walls should be eliminated so that the solution is evenly distributed over the surface.

- Before coating, the walls should be primed to ensure good adhesion of the material. In this case, a composition with the addition of quartz sand is used.

- If necessary, you can insulate the room using sheet material with additional mesh.

Preparation of raw materials.

Before making bark beetle plaster, you need to carefully follow the instructions so as not to spoil the raw materials.

The powder is added in minimal portions to running water heated to room temperature, and mixed during the process with a special “mixer” attachment, which is fixed in the drill chuck (such mixing will help avoid the formation of unwanted clots).

Then the whipped mass must be left under the lid for 15 minutes so that it “infuses”, and after the specified time, beat the control time with a drill until smooth (it resembles the composition of mashed potatoes with a uniform shade, if color was used). It is advisable not to add excess water, as there is a possibility of the solution stratifying.

It is allowed to add a small amount for the convenience of preparing raw materials. The finished mixture must be used within three hours. Do-it-yourself decorative bark beetle plaster is applied to a previously prepared wall. 6 hours before application, it is advisable to cover the surface with paint - primer (for example, ST - 16) in one tone of the mixture. This way the base will not be illuminated.

How to make a bark beetle

Making bark beetle plaster with your own hands

Bark beetle plaster is widely used in wall decoration

Recently, finishing facades and residential premises using plaster has been rapidly gaining popularity. One of these is the bark beetle. The surface covered with this type of plaster looks like wood eaten by bugs, hence the name. How to make bark beetle plaster with your own hands? This will be discussed below.

Advantages of coating and its properties

In addition to its decorative function, bark beetle plaster has a number of other advantages, which have made it quite popular:

- This coating is highly resistant to weather conditions. It is not afraid of exposure to the sun, humidity, frost and snow.

- A facade or wall treated with this composition is highly resistant to chemicals - acids, alkalis and other harmful components.

- The plaster coating is quite elastic, so it does not wear off over time. This finishing method is ideal for areas such as the kitchen where frequent cleaning of the walls is required. The bark beetle will retain its appearance at its original level for a long time.

- Decorative bark beetle plaster can be called a completely safe material - it does not emit any harmful fumes at high temperatures. This is important if the room’s windows face south or the room is well heated in winter.

- And finally, the last plus is that the bark beetle cannot be scratched. It can be easily washed and rubbed with a medium-hard sponge. The walls can be cleaned with a vacuum cleaner and then wiped with a cloth very often - there will be no defects.

- The plaster is quite easy to apply. Even a beginner can cope, provided that he does everything carefully and studies the technology in advance.

- building level;

- rule about 2 meters long;

- bucket or other container for finished plaster;

- drill and nozzle for mixing solutions;

- spatula for applying plaster to walls;

- plastic grater;

- paint brushes and rollers.

“Bark beetle” plaster in the interior

How did manufacturers achieve such high technical qualities? The bark beetle coating is made from a mixture of acrylic, cement and marble chips. Acrylic gives resistance to weather conditions, cement gives elasticity, and marble gives unprecedented strength.

The consumption of plaster, which is indicated on the packaging, depends on the size of the marble chips. The composition, made with your own hands, can be applied to brick, concrete, sandwich panels, polystyrene and wood.

Tools and materials for application

To make decorative bark beetle plaster, you need to prepare the following tools:

Surface preparation

To make high-quality bark beetle plaster, you need to know how to properly prepare surfaces for application:

- remove the old paint and clean the surface. All old stains and other contaminants must be removed;

- if the room is damp enough, then it is necessary to impregnate the walls with a special composition against fungus and mold;

- all cracks should be repaired. To do this, they are deepened a little using a grinder and thoroughly coated with a gypsum putty mixture;

- The interior walls are covered with a couple of layers of base plaster. As for the external walls, their concrete surfaces are only moistened with water. The same applies to those cases where the outer parts of the building were treated with cement mortar;

- internal walls must be almost perfectly smooth. You can check this using a level. Don’t be lazy to treat them with regular plaster, because leveling with textured plaster will be very expensive. In addition, such a decorative coating does not look very aesthetically pleasing on curved walls.

Preparing the surface for plaster

Preparing the solution

To make a high-quality coating with bark beetle plaster, you also need to know how to make a solution.

So, take the container we have chosen and fill it with water at room temperature. Add the powder in small portions and mix constantly using a mixing attachment on a drill. Once the entire mixture is poured in, continue kneading for a couple more minutes. Let the plaster rest under the closed lid.

Under no circumstances should you fill the plaster with water! This will lead to the appearance of lumps that will be extremely difficult to stir.

Now beat the mixture again. If necessary, add paint and a little water for ease of application. In addition, a couple of hours before applying the mixture, professionals recommend painting the walls using primer paint of the same color as the plaster. This will improve the appearance and remove the effect of the base showing through. The finished mixture for plastering can be used for 3 hours; it cannot be stored longer. Otherwise, it will thicken and will be unsuitable for finishing - you cannot add water to the thickened mixture.

In the store today you can find both a dry mixture and a ready-made solution. It is worth noting that it costs significantly more.

The solution must be mixed with a mixer

We begin processing the walls

Having learned how to make bark beetle plaster with your own hands, it would be useful to dwell on the technology of wall processing.

Rubbing in a circle

What kind of drawings can you make?

“Rain” pattern – move the grater up and down and slightly diagonally. It gives the effect of window glass after rain.

Carpet pattern - alternate movements diagonally perpendicular to each other. It turns out to be a very interesting drawing.

Lamb pattern - circular movements with a grater of the desired size. By making circles of different diameters, you can create completely different effects.

You can come up with any pattern yourself. You just need to practice on an inconspicuous area of the wall and proceed to further finishing. It is better, of course, to invite an assistant. After all, it is important not to let the mixture harden, so the process must move quickly. For example, you apply plaster, and your partner creates a drawing.

Decorative bark beetle plaster finishing is ready! For a more detailed study, you can watch videos of professionals finishing the premises. This will allow you to delve into some important details. Good luck!

Technology for applying decorative plaster Bark beetle

When it comes to Bark Beetle plaster, one immediately imagines something unimaginable, covered with numerous chips. Indeed, this mixture got its name because of the unusual pattern, which resembles the work of a wood beetle, leaving numerous passages in the wood. It can be used for external and internal work. Naturally, you need to know some rules that will help you get a truly individual texture and not disappointment.

What is a "bark beetle"?

It should be understood that the appearance of the bark beetle depends solely on its composition. The general part can be acrylic or gypsum, which makes this plaster similar to other types. But additives, in the form of fine mineral chips and marble, distinguish it from others. It is their use that is the key to obtaining an indescribable drawing. Of course, application technique is also important. Thus, only the combination of all necessary indicators gives the desired result.

Indescribable pattern of bark beetle plaster

Each manufacturer tries to make an individual composition. Therefore, it is necessary that the name be on the label - textured bark beetle plaster (the last word is the main one). There is also roller plaster, but it differs slightly in the resulting pattern. Although many people don’t pay much attention to this.

The pattern of roller plaster is very similar to the bark beetle

On a note! It is better to make purchases in specialized construction stores. Now there are many fakes that may be unsafe for health.

Advantages and disadvantages

When giving preference to this composition, first of all, take into account its advantages:

- Due to the fact that the filler is mineral chips, the resulting layer is noticeably lighter. That is, the impact on the surface will be much less. The structure will not experience unnecessary deformation load.

- The mixture is completely safe; it does not emit substances harmful to human health.

- Finishing the facades of houses with bark beetle is an excellent solution. It is able to withstand a wide range of temperatures. Feels good under the influence of ultraviolet radiation and is resistant to fire. When heated strongly, it does not contribute to the formation of toxic substances.

- Features increased durability. Not exposed to fungi and mold. Not afraid of heavy precipitation.

- Withstands mechanical stress. Even light blows do not cause harm to the plaster.

- Due to the fact that the main color is white, it is possible to obtain a wide range of shades. The effect is achieved by adding color or dyeing.

- Finishing the facade with Bark Beetle costs much less than roller plaster.

The facade of houses with bark beetle decoration looks very impressive

- Working with this material is quite difficult. To get the desired surface you will have to try and make a lot of effort.

- Damaged areas are difficult to restore.

- Manipulations for applying bark beetle have seasonal restrictions.

It is not surprising that the work requires a certain skill. After all, in order to understand how to properly apply this or that composition, you need to have experience.

Material selection

Bark beetle facade plaster has a large selection. Even from the same manufacturer there may be different options. The differences lie in the physical appearance of the mixture and the grain size. These differences affect the resulting surface and texture of the pattern. Therefore, you should purchase the required amount of material at once. Even different batches from the same supplier may have some differences.

Bark beetle plaster has different grain sizes

It is very important to consider the grain size of the plaster. It affects not only the decorative qualities, because it is due to the pebbles that the grooves appear, but also the overall consumption of the solution. The larger the granules, the more bark beetles will be needed on the facade or walls.

With physical appearance, everything is much simpler. We are talking about the state in which the mixture is: ready or dry. Of course, purchasing a ready-made solution is quite profitable. But its price can be very high.

On a note! Ready-made roller plaster, replicating the effect of the bark beetle, costs an order of magnitude more. But there are construction stores where you can order the mixture to be made to order. That is, choose the components, decide on the size of the fractions.

Do-it-yourself decorative bark beetle plaster is made only from dry ingredients. The manufacturing process is quite simple. The difficulty lies in maintaining the required proportions, which is not always possible to do at home. Therefore, it is better to give preference to dry mixtures that were manufactured at enterprises.

Working with Bark Beetle

It’s worth mentioning right away that you don’t need complex tools and devices for the job. The set is quite simple:

Applying bark beetle plaster depends on the ability to use these devices.

Surface preparation

It is assumed that bark beetle plaster will be the final stage of surface finishing. Therefore, attention should be paid to the preparation process. After all, creating a beautiful top layer can be simple, but a lot depends on the base.

Finishing walls with bark beetle plaster requires a well-prepared base

Decorating a house with Bark Beetle begins with the following, regardless of the type of work:

- The surface is completely cleaned of all excess. Remove any dirt. If there are areas affected by fungus or mold, they are removed and etched with an antiseptic.

- Any cracks and chips are opened and filled with mortar.

- The starting composition (purchased or made independently) is applied to the wall. You should get a flat surface.

On a note! It is believed that applying decorative bark beetle plaster can hide some defects. Indeed, small differences will not be visible. But correcting the curvature of the walls, if this is not a design idea, will not work.

Preparing the mixture

To understand how to make bark beetle plaster more pliable to work with, you should follow the rules for diluting the dry mixture. Of course, every self-respecting manufacturer duplicates them on the packaging. So:

- Pour water into the container and begin adding the mixture.

- Pay attention to the temperature of the liquid; it should be within 20°C.

- The solution is gradually mixed. This must be done well. It happens that some fragments remain dry at the bottom.

- The composition is left for some time, after which the procedure is repeated.

Preparation of the solution

You need to dilute as much solution as necessary for the job. It cannot be prepared for future use. If it dries out, it will not be possible to return its properties.

Before we start talking about how to apply bark beetle, we should make a small remark. The fact is that there is roller plaster on the market; it has a similar pattern, but is slightly different in application. Therefore, you should carefully consider the choice of composition.

The process of transferring the mixture to the surface is no different from other types of decorative solutions:

Applying plaster with a trowel

On a note! Wall finishing can also be done with a special device that will automatically apply the solution. But how to apply the mixture is up to everyone to decide for themselves, based on the amount of work.

This is the first stage, the effect that should be achieved is not yet visible.

Getting the pattern

The technology for applying bark beetle plaster is generally clear, but the further process will be determined by the factor. Manipulations are carried out with a plastic or wooden spatula. The main thing is that work should begin immediately after applying the composition. How to do:

- The tool is slightly moistened so that nothing sticks.

- He is pressed against the wall.

- Produce forward movements. The pebbles begin to move and grooves appear.

Obtaining a drawing depends on translational movements

Some ways to obtain different patterns:

- If you make movements along a small radius, you get short curls.

- When the trajectory is made in the form of parallel lines, the bark beetle finish will resemble dashes. Their length can be made different.

- By making movements perpendicular to each other, you get a grid. The lines are made of different lengths.

One of the ways to apply bark beetle plaster

A few secrets about how to apply bark beetle plaster:

Rules for tinting and staining

Of course, how to plaster with bark beetle is not an entirely easy question. In order not to spoil the surface and not to redo everything again, it is better to practice a little. You need to understand: how to distribute the layer and how to form the desired pattern. Although the decorative appearance will also depend on the coloring.

Painting bark beetle plaster can be done with a roller

- It is difficult to add pigments to dry solutions. Therefore, it is better to buy ready-made formulations in which the manufacturer himself has calculated the required proportions. Subsequent coloring will also help to make the bark beetle the desired shade.

- When you buy a ready-made solution, everything can be simpler. Often stores offer, for a small fee, adding color and mixing - using an automatic machine.

But a truly decorative surface can only be achieved in one way - double painting. This technology looks like this:

Contrasting coloring of bark beetle plaster

Modern possibilities provide a wide choice of materials, especially for painting walls. Therefore, imagination depends only on taste.

How to make bark beetle plaster yourself if you have no experience at all

Photo of the facade of a house finished with decorative plaster

Decorative structural plaster is no less popular than hinged ventilated facades. It allows you to give houses an individual look and not return to the problem of repair and reconstruction of external walls for many years. And most often, developers and owners of private houses are interested in the answer to the question of how to make bark beetle plaster yourself.

Why Bark Beetle? Because this is the simplest and most affordable coating for self-execution. Today many people have to save money, and the services of professional finishers are quite expensive.

What is this plaster?

Decorative plaster is a plastic granular mass based on polymer or mineral binders with various insoluble fillers. They are the ones responsible for the future texture of the finished coating. Sand, stone chips or granules are most often used as filler.

The type and size of filler differs in different plasters

If you are wondering how to make bark beetle plaster with your own hands, you should know that it differs in the size of the filler grains.

- A grain size of 0.3-0.5 mm will give a texture that imitates sandstone;

- Larger grains with a diameter of up to 1.5 mm will make the coating look like untreated stone;

- And only granules 2-3 mm in size will allow you to achieve the effect of a surface eaten away by a bark beetle, since only sufficiently large grains will leave grooves in the plaster layer during the rubbing process.

Note. The larger the grain diameter, the more pronounced the texture will be. But granules larger than 3 mm already give an imitation of rough tree bark, and not the texture we need.

Also, the thickness of the layer and the amount of mortar required to finish each square meter of area depend on the grain size. Before making bark beetle plaster, you will have to calculate how many bags or kilograms of material to buy, and this parameter is one of the main ones.

Decorative plaster from Ceresit

But the pattern on the surface is determined by the finisher himself, the direction he gives to the granules when grouting a fresh plaster layer.

Bark beetle can be produced in the form of a dry mixture or a ready-to-use solution. The price of the latter is higher, but it saves you from the need to knead and select the optimal consistency and saves time.

Process description

Before reading further, watch how to make bark beetle plaster video. This will give you a better idea of the process.

How to prepare the base

The first thing you need to know: decorative plaster is applied in a layer, the thickness of which should not exceed one and a half grain diameters, otherwise the granules will simply drown in the solution, and the texture will turn out fuzzy. But such a thin layer will not hide large surface defects.

This means it should be fairly even:

- Leveling, if necessary, is most often done with cement-sand plaster or putty.

- Quite often, before bark beetle plaster is made, the outer walls are insulated with foam plastic (see Facade insulation for plaster: types, characteristics, rules of application). If the installation of insulation is done efficiently, then leveling plaster is not required; it is enough to simply rub the seams between the slabs.

For reference. Foam plastering technology involves the use of a reinforcing mesh, which is fixed with a special adhesive solution. In our case, we can do without it, since the bark beetle has good adhesion and usually holds up well even without reinforcement. But the mesh will protect the coating from possible cracks.

- The next step is priming the leveled surface (see Why a primer is needed: technological nuances of finishing work). It is applied to a dry base, free of dust and dirt. It is highly advisable to use the leveling mixture and primer from the same manufacturer. If for some reason this is not possible, then do not skimp on the primer and purchase a high-quality composition that will penetrate deep into the base and strengthen it, and create a rough layer on the surface for better adhesion to the decorative coating.

Primer Ceresit with quartz sand, which gives roughness to the base

- It is recommended to prime the walls shortly before making bark beetle plaster, so that dust does not have time to settle on them. In warm and dry weather it dries quickly, after half an hour you can begin finishing.

Advice. If you are using colored plaster or are going to paint the walls after finishing, then the primer can be tinted to the desired tone, since the base in the grooves can show through.

How to mix the solution

If you bought a ready-made mixture, all you have to do is open the bucket and stir its contents well. With dry plasters, everything is not so simple, although you are unlikely to encounter any particular difficulties if you have a drill and a mixer attachment for it.

Just carefully read the instructions on the package so as not to make a mistake with the proportions of dry mass and water, and act in accordance with the description. The scheme is standard: pour water at room temperature into a clean bucket, then add the required amount of plaster, wait until it settles slightly, and mix with a mixer at low speed until a homogeneous mass without lumps is obtained.

You can start working in 5-10 minutes after one more stirring.

It is important! The finished solution quickly loses its viability, which is not restored by repeated addition of water and stirring. Therefore, the portions should be such that you have time to process them within the time specified by the manufacturer.

It is possible to tint mineral plaster, but it is not advisable. If you still decide to do this, then use mixtures based on white cement and make sure that the volume fraction of pigments does not exceed 5%.

How to apply plaster

If the base is level and well primed, then plastering is easy even for beginners. The solution is applied to the wall with a wide spatula or grater and “spread” over it in an even layer. The residues are collected with a smaller spatula and transferred again to the working tool.

There are several mandatory rules for how bark beetle plaster is made:

- The layer of plaster must correspond to the grain diameter. Do not rub the solution too hard, otherwise the protective properties of the finish will deteriorate, but also do not make a thick layer - its decorative effect will suffer;

- It is advisable to cover the wall from corner to corner in one go, without allowing the already applied strip to dry, since the border between different grips will be noticeable;

- If you do not have an assistant preparing a new batch of plaster, stick masking tape on the wall and plaster in strips, going over it. And before finishing the next strip, remove the tape along with the mixture adhering to it.

How to give the desired texture

You create the drawing on the surface with your own hands. It will depend on the direction of movement of the grater, under the influence of which the filler crumbs will move through the thickness of the solution, leaving behind characteristic traces.

- If you rub the plaster up and down or diagonally, you will get a “rain” pattern;

Advice. In order for the oblique “rain” to look neat, you need to constantly maintain one rubbing angle. Masking tape applied at a given angle will help you stay on course.

- If you alternate movements up and down and from right to left or diagonally in mutually perpendicular directions, you will get a cross-shaped “carpet” pattern;

You can come up with your own design options by practicing on an inconspicuous area of the wall. You can start grouting 15-20 minutes after applying the solution, when the plaster dries and stops sticking to the tool.

Conclusion

If you carefully watched the video in this article, you probably noticed that the work is done quite quickly, since all the described operations must be completed before the plaster finally sets. Not all professionals can do this alone, so you will need an assistant to mix the solution and carry out the grouting “hot on your heels.”

Graduated from the Faculty of Architecture of the Penza State Institute of Architecture and Construction. For the last ten years, he has been a leading specialist in a large construction company in Penza, engaged in the construction of multi-storey residential buildings. Total work experience in the specialty is 18 years. Consults on design issues, selection of materials for interior and exterior decoration, and technology for finishing work.

- How to make a tamper with your own hands? There are a number of tools that have to be purchased one-time for a specific situation. After finishing work, such...

- How to make Venetian plaster with your own hands Venetian plaster with your own hands If you are tired of the usual wallpaper, it’s time to learn a new finishing technique...

- How to make a drill from a hammer drill? Video Why do you need to make a drill from a hammer drill? It's simple, drill bits cannot be used in a hammer drill...

- A mirror in a baguette and with lighting for the hallway are many ways to make the interior special. A woman is beautiful in herself, but it cannot be denied that the appropriate outfit emphasizes and...

How to use raw materials?

"Bark beetle" can be used for various purposes. As already mentioned, it is used to decorate walls and facades. The result that the owner of the object can achieve depends only on him.

They can be used to decorate part of the room (apply plaster to the ceiling, walls). Naturally, it should be taken into account that applying raw materials to surfaces with which it will have poor adhesion (glass, walls of a metal garage) is not advisable. But with brick, concrete, and drywall, the material will have excellent adhesion.

Important! This type of plaster is an independent coating finish. Therefore, they need to decorate the walls. The material is not suitable for filling deformations or holes in the coating.

Consumption of raw materials for facades per 1 m2.

If you need bark beetle plaster, how is it done, the material consumption per 1 square meter will be from 2.5 to 4 kg. Such figures directly depend on the volume of filler and the thickness of the layer applied by the master. For an accurate determination, you can rely on the data indicated by the manufacturer per square meter. But it is advisable to make calculations with a small margin (up to 10%).

Consumption also depends on the manufacturer. At first glance, the differences in parameters may be minimal, but if the raw materials are used for large areas, the difference can be quite significant.

For example, the Volma company provides a consumption of 6 kg/m2 for a 10 mm layer thickness. For] “Prospectors”[/anchor] the consumption is 9 kg per square meter. m. As a result, when finishing a medium-sized object with a coverage area of 30 m2 and a thickness of 3 cm, the difference in volume will be about 270 kg.

Popular plaster mixtures and cost of work

The construction market offers consumers many options for bark beetle plaster. However, not all manufacturers have earned trust among the majority of buyers. Only a small number of companies produce truly high-quality mixtures:

- Alpina - a German company produces a universal product for facade and interior decoration. These are professional mixtures that require appropriate experience to work with. Customers' feedback is positive.

- Ceresit is another German brand that is popular in the Russian market. High quality, durability, ease of use - all these and many other properties relate to Ceresit plaster. The compositions are suitable not only for facade cladding, but also for internal surfaces.

- Prospectors are a domestic manufacturer whose quality is in no way inferior to foreign companies. The assortment mainly contains dry mixes.

When choosing a building material, it is first of all important to pay attention to the production date. If 3 months or less have passed, the plaster can be purchased. As for retail outlets, it is better to visit large supermarkets that sell professional materials for building houses. Here the risk of purchasing a craft is minimal. It is also advisable to inquire from sellers about the availability of certificates for materials.

The proportions of ingredients, temperature conditions and sequence of actions should be strictly observed.

To create a decorative Bark Beetle covering, it is not necessary to hire specialists, since the work can easily be done with your own efforts. But the result depends on personal skills and abilities. However, if you follow the technology, you can avoid many mistakes.

Was this information useful to you? Share in the comments!

Progress.

Apply decorative bark beetle plaster yourself using a special grater. It is given an angle of 60 degrees to the plane and the composition is smeared.

The thickness of the applied layer depends on the grain size of the material. When the raw material stops sticking to the working tools, the required pattern is created on the treated surface with a grater.

When bark beetle plaster is applied with your own hands, lines of any inclination can be created (horizontally, vertically, diagonally or in a circle), the result of the work will correspond to the imagination of the master.

It is advisable to complete the entire process at once, without interrupting for lunch. The material will dry within three days, so if exterior finishing is involved, it is advisable to check the weather forecast in order to know how long the bark beetle plaster will take to dry under normal climatic conditions.

If the work is done correctly, glossy areas and joints should not be noticeable. The wall looks monochromatic and uniform.

Features of painting a plastered surface

There are two options for painting the decorative surface:

- Adding coloring pigment directly to the finished mixture.

- Painting a plastered and hardened wall.

The first option is more acceptable when using a ready-made mixture, to which a certain amount of dye should be added to obtain the required shade. When a dry mixture is used, it is very difficult to calculate the dosage of color. In this case, it is better to paint the finished base.

To paint the finished surface, you should use acrylic, silicate or water-based paint, which is applied with a brush or roller. The acrylic composition should be applied no earlier than two weeks from the date of finishing, and silicate paint can be used after three days.

Textured bark beetle plaster can be painted with silicone, acrylic and silicate paints, which apply well and dry quickly

Coloring can be carried out in two stages. The first time, the entire surface is carefully covered, including the grooves of the texture. After the surface has dried, a second layer of a lighter or darker shade is applied, which involves painting only the upper part of the coating, excluding paint from getting into the grooves. This effect can be achieved by using a semi-dry roller, which must first be rolled on plywood. Also, it is advisable to use special dyes with reflective properties.

Helpful advice! If you don't paint the grooves, you can get the illusion of depth of coverage.

Instead of painting the surface, you can glaze the coating with acrylic varnish, to which you can add mother-of-pearl or color. This mixture should be applied using a steel spatula, completely filling all the grooves on the wall surface.

Surface application of paint on textured plaster allows you to get the effect of depth due to the fact that the grooves are not painted over

Strict adherence to the sequence of actions when covering the surface with textured bark beetle plaster will allow you to obtain a high-quality, durable, attractive and aesthetic coating that will delight the eye for many years without losing its original appearance.

Using plaster on foam plastic.

To apply bark beetle plaster to polystyrene foam, you need to stock up on the following construction attributes:

- Bark beetle

- Reinforcing mesh and glue.

- Primer paint.

Bark beetle plaster is often used for exterior decoration of buildings. Foam plastic is usually used to insulate objects, so you need to know about all the nuances of applying bark beetle to this insulation.

Important! If the bark beetle is applied to foam plastic in the standard way, then as a result the coating will be deformed and the plaster will begin to crumble.

First, you need to apply reinforcing glue and mesh to the foam. In order for the coating to dry, it is enough to wait a day. Next, you can apply primer paint, which will provide good adhesion to the foam and prevent the layer from “sliding.”

Before application, the bark beetle must have the recommended consistency. If the choice fell on an unfinished mixture, then after preparing it you can begin the work process.

Important! Any facade work associated with surface treatment with plaster must be carried out at above-zero temperatures.

Which mixture to choose

Plaster or bark beetle putty is produced by a large number of manufacturers due to the high popularity of decorative finishing of houses or apartments. In order not to make a mistake with the choice of the necessary material, you need to pay attention not to the brand, but to take into account two main criteria:

- composition type;

- grain.

The plaster goes on sale in ready-to-use form (in plastic containers) or as a dry powder (usually packaged in bags). The former are always more expensive than the latter; they contain special additives. It is recommended to buy ready-made mixtures in the required quantity, since they cannot be stored for a long time. And if not all the plaster was used, the remains will have to be thrown away, because the frozen solution is unsuitable for further work.

Dry mixtures do not have this drawback. The powder does not lose its properties throughout the entire storage period. But there is a limit here too - expiration dates are indicated on the packaging. The only difficulty is associated with preparing the solution, however, if you follow the instructions, there are no difficulties.

Note!

The texture of the surface, including the consumption of plaster, depends on the size of the grains. The thickness of the layer should be comparable to the size of the filler granules. The larger the fraction, the thicker the coating and, accordingly, the greater the consumption.

When choosing a coating, you need to focus on the type of composition, its grain size, and the pot life of the solution

Painting bark beetle plaster.

Before you paint the bark beetle plaster, you need to decide on the color. Before this, you can paint the entire mixture using color, pouring it in and mixing thoroughly (this can be done when purchased in specialized stores). This will help create a uniform color for the mixture.

To paint bark beetle plaster in two colors, you need to stock up on a roller with a small pile. A velor tool is ideal. This is necessary so that the paint does not penetrate into the recesses. It is enough to dip the roller into the paint and, without applying too much pressure, walk over the surface. The result is a very original and aesthetic tone.

When a person wants to achieve a three-dimensional effect of bark beetle coloring, before painting the bark beetle plaster in two colors, you can take shades that differ in saturation. The bark beetle itself is painted dark using a fluffy roller so that the paint penetrates into the cracks. Then the same velor roller is taken and the surface is painted with light paint. The result is an original and voluminous textured pattern.

If a person came up with the idea of painting plaster immediately after applying it to the wall, without first adding color, then you can use another painting method that will help change the shade and the inner part of the texture.

To do this, you can take a primer (acrylic or latex) and add color directly to it. Then you need to treat the entire plastered surface with a painted primer. Since the composition of the primer is liquid, this will allow it to penetrate into the cracks and pores left by the bark beetle pebbles.

During drying, an indelible layer is formed.

At first the result may not be as expected, but after re-painting in a second tone, the end result will be a very impressive surface appearance. It is almost impossible to distinguish whether it is painted plaster or primer painting. In order to apply the bark beetle and subsequent painting, it is not necessary to hire a team of craftsmen, since a similar procedure can be performed with your own hands, guided by the above tips. data-matched-content-ui-type=”image_stacked” data-matched-content-rows-num=”2″ data-matched-content-columns-num=”3″ data-ad-format=”autorelaxed”>

Types and composition

Plaster mixtures with the Bark Beetle texture are produced on the world market in various versions. In most cases, manufacturers position their product as universal, but some differences are still present. Typically these include grain size and fillers. The result is a different effect under different environmental conditions.

Acrylic

The mixture, produced on the basis of acrylic resins, is elastic, strong and durable. Marble chips with a fraction of no more than 2.5 mm are used as filler. Due to the fine grain size, a thin layer of material is laid on the walls, which reduces the load on the walls.

Acrylic compositions have a high cost. However, this price is justified by increased moisture and heat resistance, and high decorative qualities.

Note!

It is worth considering that the main components are flammable, and therefore this option is not recommended for use on walls that are in contact with open fire.

The acrylic composition is suitable for interior work in hallways, kitchens, toilets, and bathrooms. Sometimes plaster is used to create special coziness and comfort in living rooms. The plaster mixture is supplied to markets in finished form. If necessary, it can be easily cleared into the desired shade, although there is a rich color palette, which allows you to choose the desired tone in each specific case.

The acrylic composition of the mixture is sold ready for use.

Mineral

Mineral mixtures are called cement-lime mixtures and in most cases are used for application to building facades. But also suitable for interior surfaces. The plaster is created on a cement base and is sold in the form of a dry powder, which subsequently requires the addition of water to mix the solution. The manufacturer does not provide color variations and therefore the finished coating requires painting.

Plaster can be applied to surfaces either manually or mechanically. In the latter case, labor productivity increases and work time is reduced. In this case, you should prepare exactly the amount of mixture that will be used at a time. For this reason, you should be guided by how much area will be involved, and only then prepare the solution.

The main disadvantage of all mineral plasters is hardness. If the building has not yet shrinked, the walls treated with this composition will be covered with cracks. This is not the best choice when the house is located in close proximity to the railway tracks. The same applies to seismically unstable areas of the country.

When work is carried out in bright sunny weather, the treated surfaces must be covered with plastic film until they dry. The drying time can take up to 4 days, depending on external conditions.

Mineral bark beetle plaster consists of a mixture of cement and quartz chips

Silicone

Silicone-based mixtures have the highest elasticity. However, the coating is durable. The material is supplied ready for use. With all the advantages, there is one significant drawback - high cost. But the long service life successfully compensates for this disadvantage. The color of the plaster is white; it easily acquires any other shade during tinting (before work begins).

Silicone - expensive and very high quality coatings

Silicate

Silicate plaster is sold only in a ready-to-use state. The material is based on liquid glass, due to which a hard and durable coating is formed that is impervious to moisture. The surface is easy to clean, but there is a risk of cracks.

The material is not suitable for interior work, since harmful substances are released after drying. The filler is marble and granite chips. Coarse sand and granules of artificial materials (ceramics, synthetics) are also used. The size of the fractions is 1-3.5 mm.

Silicate plaster is a good solution for busy streets where there is a lot of dust in the air. The finished coating is not afraid of this type of contamination.

Plastic, vapor-permeable silicate mixtures are easy to apply and do not retain water

Plaster

The gypsum version of the bark beetle plaster is painted in the desired color only after the composition has been applied and the surface has dried. The purpose of the gypsum-based mixture is to cladding internal surfaces. It is highly not recommended to treat external walls and facades with plaster.

The building material is sold in the form of a ready-made dry mixture in bags. The solution is mixed in a plastic bucket. Water temperature is from 23 to 25 °C. A construction mixer is used for mixing, which allows you to quickly obtain the desired consistency. But if the plaster is used for external work, it is better to mix the mixture with a wooden stick.

If you plan to plaster the walls with a decorative gypsum mixture, the solution is applied only after pre-treatment with a cement-sand composition or covering with plasterboard sheets. When the surface is dry, you need to walk over it with an abrasive mesh. In order to increase adhesion, the surface is treated with a penetrating primer.

Gypsum compositions are less suitable for external cladding