Building material for dry premises is widely used in finishing work. Gypsum fiber sheet does not have a cardboard covering, which is resistant to moisture and is also hard. We also suggest that you understand the advantages of gypsum fiber boards, the features of moisture-resistant panels, as well as which of them are best to use. Read on and you can learn about the technical characteristics, qualities, main differences between panels and gypsum plasterboard and methods for installing moisture-resistant gypsum board.

Material characteristics

Drywall must withstand the minimum permissible loads. The main supplier of drywall is Knauf. The sheets can withstand loads of 730 N. The weight of one sheet is 29 kg. Fire resistance of drywall is 20 min.

Knauf has developed products for interior decoration with fire protection.

Knauf panels in stock Source alicdn.com

Knauf FIRELINE has released a line of materials that include:

- raw panels;

- coated sheets.

The material has acoustic properties such as reflection, absorption, vibration. Fire-resistant products contain the following components:

- drywall;

- decorative surface (veneer, varnish, laminate);

- substructure.

What is the difference between GKL and GVL?

Let's look at regular gypsum plasterboard, what it is, and how it differs from gypsum plasterboard. Drywall consists of gypsum with additives and cardboard lining. Depending on the area of application, the material has different composition and properties. For visual distinction, products are painted and marked. There are the following types of drywall:

- GKL.

- GKLV.

- GKLO.

- GKLVO.

GKL can be wall or ceiling. GKLO is a fire-resistant material that contains reinforcing additives. Sheets are used only in dry rooms. The color of the cardboard marking is red.

GKLV is a moisture-resistant material that is impregnated with hydrophobic and antibacterial compounds. Water-repellent compounds have been added to the gypsum layer, so it is used in rooms with high humidity. The cardboard is green and the markings are blue.

GKLVO sheets are moisture and fire resistant. The product combines the properties of GKLO and GKLV, adding hydrophobic components.

The color of the sheets is green, the markings are red Source srbu.ru

GVL has a density of 1250 kg/mᶟ. The panels are made from gypsum, reinforced cellulose and additives. GVL Knauf differs from drywall:

- strength;

- frost resistance;

- absorption of excess moisture;

- creates a healthy microclimate.

See also: Catalog of companies that specialize in finishing materials and related work.

Comparison of GVL with analogues

First, let's figure out what GVL is. It differs from standard drywall mainly in its manufacturing technology. If the sandwich principle is used in the production of plasterboard (that is, two layers of cardboard and a gypsum layer between them), then in the case of gypsum board, manufactured fibers are mixed into the gypsum mixture and pressed into the form of a sheet. This results in increased strength and excellent fire performance.

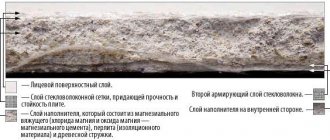

An analogue of GVL SML is a fairly new finishing material made in China. The glass-magnesium sheet contains in its structure magnesium oxide, finely dispersed shavings, perlite, magnesium chloride and binder composite materials. One of its good qualities is its non-flammability. In this regard, none of the currently known materials can compare with LSU. GVL is also inferior to it in fire resistance.

It is impossible not to note the moisture resistance. LSU perfectly withstands high humidity conditions. Test results have proven that even after immersion in water for several hours, the LSU does not lose its shape. It is also not susceptible to mold, deformation, does not contain harmful substances, flexible, durable, lightweight and quite easy to use. But in our country this material has not yet been studied enough, so not everyone risks getting involved with it, preferring GVL or GCR.

GCR is the most common option. This is a composite finishing material that is traditionally used for finishing residential and office premises. Drywall is environmentally friendly and does not contain any harmful impurities. Excellent soundproofing characteristics and non-flammability make it the most common and versatile material for constructing interior partitions, leveling walls and installing ceilings. This property is interesting when there is high humidity in the room: the material absorbs excess moisture, and when the air is dry, it releases it.

GVL is, in fact, an improved version of gypsum plasterboard, superior to it in some respects. For example, increased strength and fire resistance. In general, GVL has a huge list of advantages:

- Excellent heat and sound insulation.

- Environmental friendliness and safety.

- Increased strength.

- Easy to use.

- Low amount of waste during installation.

- Possibility of mounting on both wooden and metal frames.

- Another quality that can be noted is the ease of processing of joints.

- It is not necessary to use special tools to cut gypsum fiber board.

The list of shortcomings is not so impressive. It is limited by a large mass that prevents deformation and stretching. You won't be able to bend it like drywall. And the second drawback is the high cost compared to the same drywall.

Back to contents↑

Moisture-resistant GVL and GVLV

GVL and GVLV can be used in rooms with a humidity of 60%. GVL is a dense material made from gypsum and fluffed cellulose fibers. GVL panels are low-flammable materials of class G1. The products are used in fire-resistant structures. Panels can have straight (PC) and folded (FC) edges.

GVLV can be used in unheated rooms. The panels are treated with a water repellent. GVLV material weighs 32-44 kg. Main characteristics of sheets:

- ultimate bending strength – 6.0 – 5.5 MPa;

- humidity – less than 1%;

- vapor permeability;

- low thermal conductivity;

- hardness – more than 20 MPa.

The use of gypsum fiber panels allows you to reduce finishing work. GVL and GVLV Knauf slabs are used to insulate the floors, walls of rooms, attics, verandas, and attics.

Among the advantages of the material:

- sound insulation, fire resistance;

- reliability of the panels (withstand heavy objects);

- water resistance;

- does not emit harmful substances.

To better understand what GVL is, you should know the panel manufacturing process.

Details

Moisture-resistant GVLV and GVL

Moisture-resistant GVL for flooring can be used in a room with a humidity of 60%. GVL is a dense material made from fluff cellulose fibers and gypsum. GVL panels are low-flammable materials of class G1, and the products are used in fire-resistant structures. Panels can have straight (PC) and folded (FC) edges. GVLV can be used in unheated rooms, and the panels are treated with a water repellent. GVLV materials can weigh from 32 to 44 kg, and the main parameters of the sheets are:

- Hardness more than 20 MPa.

- Low thermal conductivity.

- Vapor permeability.

- Humidity less than 1%.

- The bending strength limit is from 5.5 to 5 MPa.

The use of gypsum fiber panels makes it possible to reduce finishing work, and GVLV and GVL Knauf slabs insulate floors, room walls, verandas, attics and attics. Among the advantages of the material are:

- Does not emit harmful substances.

- Water resistant.

- The panels are extremely reliable (able to withstand heavy objects).

- Fire resistance and sound insulation.

In order to understand as best as possible what GVL is, it is also important to know about the panel manufacturing process. You should watch the video for a clear overview of plasterboard production.

Sheet creation process

Drywall is made using injection molding technology, and a cardboard strip will go along the conveyor, onto which a binding liquid substance is poured. From above, everything is rolled into a cardboard sheet and rolled out. After this, when the binder has set, the material is cut to size on a guillotine, and then the product is sent for drying. Gypsum fiber materials are made by semi-dry pressing. A 5-7 cm layer of a binder containing cellulose is poured onto the molding table. All this will be pressed to a thickness of 1.2 cm, and after the press you will get a hard surface that will dry. The processes for creating drywall and fiberboard are very different. Moreover, the materials are finished differently. Drywall can be puttyed immediately, but gypsum plasterboard does not have a perfectly smooth surface, and for this reason finishing and base putty are applied. It is not difficult to figure out from the GVLV marking that such a material is resistant to moisture. Here are some examples of markings: GVLV-PK-2.5*1.2*0.1 meter, or GVL-FK-2.5*1.2*0.1 meter.

Working features with moisture-resistant drywall

GVL is ideal for work indoors where the environment is aggressive:

Swimming pools.- Showers.

- Bathrooms.

- Kitchens.

The edges and joints of the panels are treated with moisture-proof specialized solutions. Impregnation is carried out before finishing work so that moisture does not get inside the material. Installation work begins with making a frame, for which metal profiles are used. We suggest considering gypsum fiber sheets for the kitchen and bathroom, and Knauf offers decorative and design options that are specially designed for wet use. Complete Knauf Dry Construction systems for interior finishing are recognized as advanced.

Video description

For a clear overview of the production of drywall, watch this video:

Sheet manufacturing process

Drywall is produced using injection molding technology. Along the conveyor there is a strip of cardboard onto which a liquid binder is poured. The top is rolled into a sheet of cardboard and rolled out. Then, once the binder has set, the material is cut to size using a guillotine. Next, the product goes to drying.

Gypsum fiber material is made by semi-dry pressing. A 5–7 cm layer of binder with cellulose is poured onto the molding table. All this is pressed to a thickness of 12 mm. After the press, a hard surface is obtained, which goes into drying.

GVL production line Source prom.st

Features of working with moisture-resistant drywall

GVL is suitable for work in rooms with aggressive environments:

- kitchens;

- bathrooms;

- showers;

- swimming pools.

The joints and edges of the panels are treated with moisture-proof compounds. Impregnation is carried out before finishing so that moisture does not get inside the material.

Making the frame Source izgipsokartona.com

Installation work begins with the manufacture of a frame, for which metal profiles are used.

Let's look at the GVL sheet and what it is for the kitchen and bathroom. Knauf offers decor and design options that are specially designed for wet use. Complete Knauf Dry Construction systems for interior finishing are recognized as advanced.

Sequence of GVL putty for painting and wallpaper (putty secrets)

Before applying GVL putty for painting, the surfaces are primed. The procedure is necessary to improve the binding properties of the putty with gypsum fiber. The primer is applied using a roller with a small pile, carefully covering all seams and corners with the composition. Hard-to-reach places are treated with a paint brush. After the walls have completely dried, proceed to the next stage.

The places where the screws are fastened and where the gypsum fiber sheets are glued together are first covered with starting putty. To prevent cracks and better retain the mortar, apply a self-adhesive mesh to the seams. The putty solution is diluted according to the instructions and applied to the mesh using a spatula.

In the corners, treatment is carried out first on one side and then on the other. The thickness of the putty layer should not exceed 1.5 mm. To seal deep cracks or dents, the layer may be thicker. If minor roughness and irregularities remain, they can be eliminated using a grinding device.

The finishing putty for GVL is selected especially carefully. When painting walls, you will need a good quality polymer mixture to create a thin layer. If the pre-treatment of the walls is of poor quality, the lighting will show all the bad places.

The finishing putty mixture is carefully applied with a spatula, spreading in the direction from the stroke made towards the dry, untreated sheet.

Professionals have some secrets for puttingtying gypsum fiber sheets:

- Before gluing paper or non-woven wallpaper, the walls are primed twice. After 1 layer has dried, the primer is applied again so that the wallpaper lasts for a long time.

- In order to save putty, it is applied only to the joints and fastening screws. After drying, the surfaces are coated with a primer of a dense white consistency. After this treatment, the color of the gypsum fiber sheets is evened out and they will not be visible under light wallpaper.

- All obvious unevenness of the dried putty should be sanded before applying paint or before gluing wallpaper.

- Work on applying putty mortar for each area is carried out without interruption.

- After drying, each layer of putty is treated with a primer.

- Using a small spatula, remove the mixture from the bucket and apply it to a large spatula, with which the solution is distributed evenly over the entire surface.

- It is necessary to use the entire prepared solution; after hardening, the putty loses its properties.

- When processing seams, the spatula is moved from bottom to top.

- When installing the mesh at the corners, you must ensure that it does not bend too much. Otherwise, the mesh will spring back and come unstuck from the solution.

- When sanding walls, you must wear personal protective equipment on your face to prevent abrasive dust from getting into your lungs.

Puttying will correct all aesthetic deficiencies in fastening gypsum fiber board sheets and increase the service life of the final wall finishing.

Application of panels in construction

Laying gypsum fiber board on the floor

Installation of a “dry” slab floor is quick and simple.

Work order:

- Cover with waterproofing.

- Apply edge tape around the perimeter of the room.

- Lay a layer of expanded clay with a fraction of no more than 0.5 cm.

- Installation of the 1st layer begins from the wall opposite the door.

- The laid row on top is covered with glue, and the 2nd row is covered.

- Seal the joints.

- Lay the finished floor.

If the GVL is 1200x1500 in size, use the bricklaying method.

Attention! The second row is laid out carefully so as not to displace the bottom layer.

Builders call the technology waste-free; the trimmings are transferred to the next row. GVL is connected depending on the size. All products are glued. Large formats are secured with screws over the entire area every 30 cm, small ones - every 20 cm.

Small sizes are suitable for household purposes, since large products are inconvenient to work with.

Laying gypsum fiber board on the floor Source rovpol.ru

How to paint drywall yourself

Well, we got to the actual painting. Painting drywall is not as difficult as installing and preparing it, but it also has its own subtleties and nuances. Again, I suggest → ordering painting work (via the link, again in Moscow) in order to make your life easier. Painting work also includes sealing plasterboard joints, so you can order as a whole, a partition or ceiling, or leveling gypsum plasterboard walls for painting.

If you have decided on all this and think that the installation of drywall was carried out correctly, the joints are sealed correctly, let's start painting it.

What paint to use

Almost any water-based paint can be used. The main thing is that the label says that you can paint the walls and ceiling. These can be acrylic, latex and other paints. But only water-based! There is no need to use any smelly enamels for drywall; that is not what they are intended for in the age of water-based paints.