Wanting to quickly and beautifully cover the facade of their home, private developers prefer siding. The finishing material is characterized by ease of installation, allows you to achieve effective and aesthetic results, equip a ventilated façade and save significant money. In addition, it can be used to disguise uneven and crooked sections of walls and other imperfections. The material is made in different types, one of which is metal siding under timber.

About metal siding

Steel (metal) siding belongs to the category of facing materials. Most often it is used to decorate the walls of residential and public buildings. The material, in the form of panels, is used in facade systems (ventilated facade technology). The physical parameters of metal siding can be described by the following provisions:

- Appearance . Products are manufactured in the form of profiled panels with a perforated edge intended for fastening. The surface of the panels is painted in any color or imitates a natural (for example, wooden) texture.

- Material . The panels have a multilayer structure and are made of hot-dip galvanized cold-rolled steel. A layer of primer is applied to the steel base, protected by zinc. Then the front side is covered with polymer, the back side with a layer of paint.

Close-up Source tr.decoratex.biz

- Profile . Metal siding manufacturers offer several shape options. Popular ones include: eco-beam siding (ship plank, the most common option), L-beam (imitation of double timber), eco-beam (timber siding that imitates the surface of a timber wall), metal blockhouse (siding with log-like geometry), Christmas tree - identical to lining . Vertical siding is mainly used for finishing industrial buildings.

- Polymer coating . The pattern, which replicates the wood texture, is applied using photo offset printing, which gives the panels a realistic look. The cladding so successfully imitates the geometry and color of wood that the difference is only visible upon closer inspection.

- Variety of textures . Manufacturers develop an original palette of colors for each profile: uniform or simulating various types of wood. You can choose not only classic options (pine, larch, cedar, walnut), but also, if the design requires, the colors of stained or bleached oak, cherry or rowan. The color scheme of some collections is complemented by a pattern simulating a stone or metal surface.

Samples of textures Source tr.decoratex.biz

See also: Catalog of companies that specialize in facade materials.

What is better to choose: imitation or natural wood

Even if we take into account that imitation timber is a specially processed and prepared board, it has a huge number of differences from siding.

- Natural wood is considered a completely safe material. Vinyl or metal panels also do not harm human health.

- Siding has a lower cost. It does not need to be treated with special solutions all the time, unlike natural wood.

- Installation of a structure made of natural material is more complex and requires more time. The main advantages of wood are that it retains both heat in the room and the necessary climatic conditions well.

Pros and cons of metal siding

Metal siding is a popular building material due to the following advantages:

- Durability . The guaranteed service life of polymer-coated material is from 10 to 15 years. The actual (predicted) operating time is estimated at 40-50 years.

- Wide temperature range of use . Metal siding retains its properties at temperatures from -50 to +80°C.

- Physical parameters . The panels do not deform over time and are resistant to mechanical stress and the formation of chips and cracks. The material is environmentally friendly and non-flammable, resistant to temperature changes and corrosion.

- Fade resistant . Throughout the entire warranty period, the panels do not change their characteristics under the influence of solar ultraviolet radiation.

- Slight thermal expansion . The coefficient of thermal expansion is less than that of vinyl analogues.

- Design possibilities . A wide range of shades and textures allows you to choose metal siding for cladding a house in any architectural style.

Fragment of a facade with an additional element Source stroidomsait.ru

Professional builders note the following advantages of the material:

- Manufacturability . Siding panels can be installed year-round. The material is convenient to use for cladding facades with external insulation.

- Easy installation . The work is characterized by ease of assembly and minimal time expenditure.

- Light weight of panels . Finished cladding does not create excessive load on the walls of the house.

- Possibility of recovery . If the polymer coating has received minor damage (chips, scratches, abrasions), you can restore the original appearance by selecting paint from the catalog.

- Decent appearance of the facade . The panels are equipped with fastenings for hidden fixation; The finished facade made of metal siding does not require special care and maintenance.

Installation features

To cut siding, use a circular saw.

To cut siding, use a hand saw for iron, scissors for steel, or a circular saw with an appropriate blade. You cannot use a grinder, because the protection melts at the cut site, and flying sparks melt points on the surface.

Step-by-step installation procedure:

- Preparing the facade, filling cracks.

- Marking and installation of sheathing with simultaneous installation of insulation and film.

- The starting strip is installed first at the bottom of the frame posts, and the bottom of the first siding panel is inserted into it.

- The board is pulled up, snapped in place until it stops, and the top edge is secured to the stand with self-tapping screws.

- The panel is fixed starting from the center, then moving to the edges.

- Self-tapping screws are placed in the center of the hole to provide the siding with the opportunity to expand and contract with changing temperatures; for the same reason, the hardware is not screwed in depth by 3 - 4 mm.

The following strips are similarly snapped and fixed to the sheathing. Before installing the last panel, a finishing strip is placed at the top. The top of the board is inserted into it and, if necessary, cut to width.

The windows are framed with special additional trims, and decorative overhead corners are used on the internal and external corners.

Video description

About finishing a house with metal siding in the following video:

In general, the practical material also has some disadvantages that you need to be aware of when choosing facade cladding. The disadvantages of the material are:

- Price . If you compare the prices of metal and vinyl siding under timber, the price of metal panels will be higher.

- Need for careful handling . This applies to both installation work and subsequent operation. If the polymer layer is damaged down to the metal, this may cause corrosion in the future. A strong blow to the surface will leave a dent (no marks are left on elastic vinyl siding).

- Rigidity . It is impossible to cover rounded façade elements with metal siding panels.

- High thermal conductivity . Like any metal, the material heats up in the sun, which is sometimes an obstacle to use.

Panel parameters Source montazh-zaborov.ru

Decorative coating for stone, plaster and other types of finishes

Wood-look metal siding for walls

Related article: Bedside tables. Photo

Siding designed to look like aged masonry will help turn an old wooden house into an ancient castle. You can make the building stylish and sparkling with newness with panels on which imitation brickwork or polished stone is applied.

For combined façade finishing, panels imitating large stones are mounted on a plinth. Then the house looks more massive and solid. The walls are covered with a profile for rounded timber, solid boards or brickwork.

Specifications

Metal siding has the following parameters and technical characteristics (average indicators are given, which may differ between different manufacturers):

- Dimensions. Many manufacturers make panels to order, according to the size of the house. The length range can vary from 0.5 to 8 m, installation width - from 22 to 36 cm, overall width - from 26 to 39 cm. Profile height can vary within 12-15 mm, metal thickness - from 0.5 to 1 .1 mm.

- Weight of 1 m2 of material. Steel siding - 5-6 kg, aluminum - 1.7-1.9 kg.

- Color spectrum. Determined by RAL and RR classifiers. The color range of metal siding has brighter and more saturated shades than its vinyl counterpart.

- Lock system. A common design that controls the evenness of joints is a latch lock. Some panels have an additional element of rigidity, which increases the reliability of fixation of the façade cladding in heavy winds.

- Protection. To reduce the likelihood of damage during storage and transportation, metal siding panels are stacked one-on-one and secured with stretch film.

Additional elements Source 100-dom.ru

- Equipment . To make the house cladding look neat, additional elements are used in the design of corners, window and door openings in addition to the main panels. These include corner, starting and finishing strips, slopes, soffits and other components.

Price

The construction market demonstrates a continuous increase in consumption of the material, which is facilitated by its performance qualities. Metal siding is considered an advantageous option for finishing the facade of a country house, since it is made to individual sizes (installation takes place with minimal trimming). Manufacturers are improving popular brands and constantly updating the range of metal siding for timber. The price of the material is determined by the following parameters:

- Origin of the metal . It can be Russian or imported (for example, from China, Finland or South Korea).

- Type of metal . Siding is offered not only from steel, but also from aluminum, copper or zinc-titanium.

Larch finish Source mn.unistica.com

- Type of polymer coating . Popular coatings are polyester (regular and matte), plastisol and polyurethane coating (twice as thick as polyester). Printek coating is applied using photo printing; It is precisely this that imitates natural textures. The front surface can be powder painted; Powder-coated metal siding costs 20% more than polymer-coated analogues.

The average price for some types of metal siding for timber in Moscow and the region is as follows (per 1 m2):

- Metal siding ECOBRUS GL VELUR 0.5 mm: from 520-530 rub.

- Soffit LBRUS perforated MP ECOSTEEL T. 0.5 mm: from 650-660 rub.

- Metal siding ECOBRUS GL PURAL 0.5 mm: from 775-785 rub.

- Siding Grand Line Eco-timber Colority Print 0.5 mm (golden oak, cutting): from 575-580 rub.

- Siding Grand Line Eco-timber (white oak) : from 680-685 rub.

- Siding Grand Line Shipboard (cherry, cutting): from 560-570 rub.

- Siding Grand Line Shipboard (white oak, cutting): from 565-575 rub.

- Siding Grand Line Block House (antique oak): from 575-583 rub.

Finishing in two textures Source sd.tierient.com

Installation material

The installation instructions for all varieties are almost identical, although they may have some nuances depending on the specific manufacturer. Installation begins with high-quality preparation of the base, insulation and creation of sheathing.

The same fittings are used for installation of all metal siding models

Installation instructions for metal siding "Ekobrus"

Step-by-step instruction:

- Parts must be mounted from top to bottom, and not vice versa. The starting bar and corner elements are installed. Everything is carefully leveled.

- The first panel is inserted into the corner groove and raised until it is fully connected. For fixation, self-tapping screws are used, screwed in increments of 40 mm with a mandatory gap of 1 mm.

- The next element is laid in a similar way and beaten with a mallet, which will provide the required rigidity.

- If the part does not fit, it is trimmed and the edge is treated with a protective compound.

You should know! To obtain a more attractive appearance, it is recommended to begin attaching Ecobrus siding from the back of the house and move towards the gable.

Features of fastening “L-beam” siding

To sheathe the outside of a residential building with Elbrus, no special skills are required.

Work algorithm:

- Due to the special geometry of the locking connection, the parts are installed from top to bottom. The initial profile and corners (if they are not overhead) are fixed, and the finishing fragment is attached below.

Most models of metal siding under timber are mounted from top to bottom - The planks are laid according to the manufacturer's recommendations until they are securely connected to the initial element.

- Parts are placed under the finishing profile carefully and only after measurements.

There are some differences in working with the plinth structure: for this process, a special Z-bar is used, mounted under the ebb.

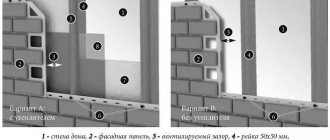

General diagram of installation of “L-beam” siding on a vertical sheathing