The Block House was initially made exclusively from wood; later its analogues appeared from more modern materials. The parameters that a modern Block House has: sizes, types of raw materials, coloring - are very diverse, as they say, to suit all consumer tastes.

The type and size of a wooden Block House depends on the diameter of the log.

Block House made of wood

Block House for interior decoration

The use of such finishing material indoors replaces ordinary lining. But in this case the appearance of the walls is more impressive, as if your house was built entirely from logs. And it can be foam block, brick or just frame. But, due to the decoration of the walls with a narrow wooden Block House, the house seems very cozy and warm.

Decorative lining – narrow Block House.

Dimensions of a wooden blockhouse for interior decoration:

- width – 96 mm;

- height – 22 mm.

There are four types of lining in length:

- 3m:

- 2.7m;

- 2.4m;

- 2.1m.

One cubic meter of decorative lining of the Block House covers an area of 45.4 m2.

Block House universal

This type is used for interior and exterior decoration. It will look equally good on the facade of the house and on its interior walls.

Universal Block House, dimensions.

Dimensions of the Universal Block House:

- width –142 mm;

- height – 36 mm.

There are two types of lining in terms of length:

- 3m:

- 6m.

One cubic meter of the universal Block House covers a wall area equal to 27.8 m2.

Important!

When calculating the required number of boards, you need to take into account that the width of the board after joining, that is, its visible part, will be 135 mm.

Block House for interior and exterior decoration of the house - wide

This type of material is used for cladding the walls of buildings on the inside and outside. It is considered the most advantageous in size for interior work.

Block House – “Classic” The size of a Block House can be as follows:

- width –142 mm;

- height – 28 mm.

There are two types of lining in length:

- 3m:

- 6m.

Important!

When choosing a Block House, please note that with the same width of the board, the universal Block House is higher in the ridge, therefore there will be fewer boards in m3 and the price of m3 will be higher for the universal one than for the “Classic”. That is why “Classic” is considered the most beneficial for interior wall decoration. In addition, it hides less area of the room being finished.

One cubic meter of the wide Block House “Classic” covers a wall area of 35.7 m2.

Wide Block House made of wood for exterior decoration of the house

The photo shows the façade of the Block House. This type of Block House is used exclusively for finishing facades. It is easy to assemble, durable, and adds real shine to the facade of the house. It is very often used for finishing facades in frame housing construction. Wide blockhouse size for facade work:

- width –193 mm;

- height – 36 mm.

This type of Block House can only be six meters in length. After joining the boards, the net width will be 185 mm. One m3 of this material covers 27.75 m2 of façade area.

Installation

Before installation begins, they calculate the need for materials, purchase them, store them, and prepare the wall surface. Cracks and crevices are sealed, leveled, and wooden structures are treated with antiseptics. Further work is carried out in 3 stages:

- Leveling system device. The lathing is made of galvanized metal profiles or wooden blocks 40-50 mm thick with a pitch of 500-800 mm. They are vertically attached to the wall with brackets using polyamide dowels with screws or anchor bolts at intervals of 1000 mm along the guides. Matings of elements along the length are made taking into account temperature deformations, leaving a gap of 10 mm. To prevent cold bridges from arising, gaskets 3-5 mm thick made of paronite are installed under the fasteners. The geometry is controlled by a building level, a plumb line with a cord.

- Insulation. The house is protected from energy loss with thermal insulation materials with a density of at least 80 kg/m³. The thickness is determined by thermotechnical calculation. If it exceeds 150 mm, it is recommended to lay the insulation in 2 layers with bandaging of the joints. The material adjacent to the wall may be less dense - 40 kg/m³. The slabs are mounted after installing the brackets; glass-amide dowels are used. Consumption - on the facade at least 5 pcs/m², in corner areas - 12 pcs/m². The heat insulator is first covered with a wind- and moisture-proof membrane to prevent moistening and blowing out of the fibers. A ventilation gap of 40-100 mm is left between the metal siding and the insulation to allow condensate to escape into the atmosphere.

- Installation of block house. Install a horizontal starting strip, corner elements, platbands, slope strips of openings, flashings for the planned joints. The position is controlled by geodetic instruments, slats or plumb lines. The panels are laid from bottom to top, inserting into the hook along the entire length. Fastening is carried out with self-tapping screws from the middle to the edges. A gap of 5-10 mm is left between the vertical components and the end of the metal strip. The siding around windows and doors is finally cut off after fitting, since the openings do not always have a strict configuration. The installation is completed by installing the top element - the inner corner, ebb or other components. The fastening pitch is 400-500 mm, it is advisable to select it in accordance with the color of the closing profile.

Metal siding - imitation timber

Dimensions of a metal block house. The main advantages of an iron Block House are:

- its high strength;

- resistance to fading;

- durability;

- fire safety;

- resistance to temperature changes;

- ease of care;

- ease of installation;

- environmental Safety.

Metal imitation timber is produced in the form of double boards imitating a wooden Block House.

Application options for a metal Block House

Metal Block House finishing of the fence. Their metal siding imitating timber can be used not only for finishing facades, but also for finishing various auxiliary buildings. For example, fences, fences, technical buildings, bathhouses or industrial premises. The simplicity of the design of metal siding allows you to do this work yourself; it is only important that you carefully study the installation instructions.

Sheathing a house with imitation wood timber

It is not difficult to complete this work and you can do everything yourself. First, the wall is cleaned of dirt , dust and previous finishing material.

Then they make the lathing , install a vapor barrier, insulation and wind protection, make a counter-lattice and after that, you can proceed to the direct installation of the block house.

The fastening of metal panels begins from the bottom ; for this, starting strips are installed along the entire perimeter of the house, everything is controlled using a level, since all the facing material will be leveled against them.

The first panel is inserted into the starting strip; at the top of the house block there are mounting holes through which it is attached to the sheathing using nails or self-tapping screws. If there are not enough holes, they are made with a punch or drill.

You cannot tighten the screws too much or drive the nails in completely; you must leave a small gap so that during expansion, the panels have the opportunity to move a little.

There is a lock on the panels with which they are connected to each other; you do not need to press very hard until you hear a click. Thus, the installation of all subsequent panels is carried out.

If the length of the house block is not enough, the panels are joined using special H-profiles, or this can be done with an overlap with the panels overlapping at least 25 mm.

To hide the outer sides of the panels at the corners of the house, special corners are used; the same corners are also available for internal corners.

In places where obstacles arise, for example a pipe, the trim panel is cut out so that a gap of about 5 mm is formed. After this, all gaps, including those around door and window openings, are closed using J-planks.

It remains to install profiles or ebbs , with the help of which the distance between the block house and the sheathing is closed, and the finishing strip is mounted at the top.

Block House made of vinyl plastic

Wall cladding with Block House vinyl is the most popular type of finishing the facades of country houses. Consumers are attracted primarily by the relatively low price and excellent quality of the material . The starting raw material for the production of vinyl Block House is PVC, the composition of the mixture was invented by German specialists. Today this material is produced in many countries around the world, including Russia.

Color solutions for vinyl Block House.

Advantages of a Block House made of vinyl plastic:

- high resistance to mechanical stress;

- the impossibility of the appearance of mold and mildew;

- low toxicity in case of fire;

- high degree of resistance to changes in temperature and humidity;

- long service life of the Block House - 50 years;

- It does not require special care;

- very wide temperature range for operation (from -50C to +60C);

- not difficult installation.

Important!

Installing vinyl siding with your own hands is not very difficult. To understand the installation technology, just watch the video on our website and everything will become clear.

Block House vinyl panels are a unique combination of the natural beauty of wood and excellent quality for many years.

Panel sizes from different manufacturers may vary slightly. Here is the most popular size:

- Block House panel length – 3.66 m;

- Block House panel width – 0.24 m;

- The thickness of the Block House panel is 1.1 mm.

Types of metal siding

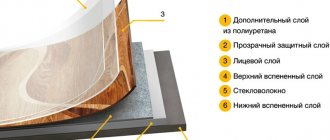

Metal siding has a multilayer structure, the base of which is galvanized steel, it is covered with primer, a base polymer, a protective coating and a film that protects the products during transportation, and is removed after installation.

By size

Depending on the manufacturer, the sizes of the panels may vary; some of them have the ability to produce a block house according to your dimensions. The length of the panels ranges from 50 cm to 6 meters, the profile height is in the range of 4-26 mm.

More rounded panels are used to decorate the outside of the building, and in order not to take up useful space inside the room, products with a lower profile height are used.

Please note that the overall size of the panel does not coincide with its installation area, since they have locking devices; this must be taken into account when calculating the required amount of material.

The total width of a single panel is 211 mm, double - 390 mm. The working width of a single panel is 188 mm, a double panel is 360 mm. Metal elements also differ in the type of coating, since each company tries to create its own original, reliable and high-quality coating.

Coverage

The main types of coatings used for metal block houses:

- Polyester , it has a glossy surface, its thickness is up to 25 microns and its cost is low. The surface may be matte, but then the coating thickness will be 30 microns.

- Plastisol , it has a large thickness, it is up to 200 microns, which allows you to imitate the structure of wood, but such material is afraid of high temperatures.

- Pural is a new coating, the thickness of which is up to 50 microns, it has high resistance to fading in the sun, high anti-corrosion qualities, and therefore is durable.

- PVDF is a material made from a combination of acrylic and polyvinyl difluoride, it is glossy, has a long service life, can be self-cleaning, and is therefore ideal for finishing the facade of a building.

Most manufacturers offer painted panels in accordance with the international RAL classification, but some can create exclusive colors.

Manufacturers

World brands:

- Alcoa (American);

- Ruukki (Finnish metal siding);

- Flexospan;

- Corus Group (British-Dutch);

- Grand Line (Grand Line);

- Gentek Building Products.

Russian manufacturers:

- Lipetsk roll forming equipment plant;

- SeverStal;

- INSI Holding;

- OMI.

How to paint imitation logs outside and inside

It’s worth clarifying right away that painting panels for interior decoration is not always advisable. However, if such a need arises, you can use dyes used for external coloring. At the same time, for interior work, fewer layers of paint will be required.

On the outside, a wooden Block House is usually painted in order to increase its service life. The following compositions can be used here:

- Impregnations . These are substances with a transparent texture that prevent the appearance of fungus and mold. It is worth noting that impregnation can serve as an antiseptic or primer layer; accordingly, other coloring compounds can be applied on top.

- Varnish or stain . These compositions allow you to preserve the wood texture and give the panels a bright, expressive color.

- Azure . The dye can replace impregnation and varnish; in addition, it gives the panels an attractive shine.

If there is a need to completely change the color of the Block House, you can use water-soluble paint or acrylic, polyurethane and oil-based compounds.

Material calculation - how many pieces are needed?

The block house should be calculated in square meters, because when finishing, you will cover exactly a certain number of square meters of area with panels. Accordingly, before going to the market, you should calculate this very area. The formula is incredibly simple - the height of a wall or other surface is multiplied by its length.

If there are windows and doors, their area is calculated using the same formula and then subtracted from the total area. If there are several surfaces and they are different, calculations must be carried out for each separately, but if their number is the same, the figure obtained as a result of the first calculation should be multiplied by the number of surfaces.

Then you should calculate how much area is covered by a particular block house sample. The working width for calculations should be taken, that is, without taking into account the tenon, since it fits into the groove. For example, our sample has a width of 100 mm without a tenon, and the length of the board is 5 meters. Therefore, the panel area will be: 0.1 (panel width in meters) * 5 m = 0.5 m2.

Therefore, for cladding 10 sq.m. surface we need:

10: 0.5 = 20 boards.

Numbers should always be rounded up. When you change the board parameters, the required number of panels will also change. Knowing the number and parameters of boards in a package or cube, you can easily calculate how much area they can cover. For example, a package contains 100 pieces of boards 90 mm wide and 4.5 m long. In this case, the calculations will look like this:

Advantages:

- creates individual style and comfort of a real wooden house;

- practical, reliable, safe (environmentally friendly);

- long service life;

- The tongue-and-groove system ensures quick installation. The work can be done by both experienced builders and novice craftsmen;

- It is not recommended to process it when decorating the interior of a house. Saving special products, varnish and mastic;

- the opportunity to purchase taking into account financial capabilities: you can buy expensive and cheaper products (depending on the type of wood used);

- light in weight;

- relatively inexpensive finishing;

- wide choice in terms of design solutions. Analogs of different length, width and thickness.

Dimensions

Block house dimensions:

Wooden. The length of the parts depends on the logs used for production, so it can range from 1.5 to 6 m. The thickness varies from 2 to 4 cm.

The maximum width is 19 cm, the minimum is 9.6 cm. The division into external and internal cladding in the wooden version is conditional, in this case it all depends on the height of the ceilings and the overall design of the building. Metal. The size of such a block house depends on the manufacturer. Standard parameters: width – 211 mm; thickness – 0.5 mm; length - 6 m. The size ranges of metal and plastic siding for logs are similar, but as such there is no single standard; each reputable brand develops its own technical specifications. Vinyl. These materials have a narrower range of sizes. There are widths of 232 and 240 mm; length – 366 cm and 381 cm, thickness – 1.1 mm.

When choosing, you should pay attention to the manufacturer; from different companies, the sizes of parts can vary significantly. This is taken into account if it is necessary to purchase additional elements or special linings.

In appearance, a block house resembles an ordinary lining, so they are often confused, although there are some differences. These products are ideal for situations where it is necessary to sheathe a house so that the facade imitates the laying of timber.

Advantages:

- creates individual style and comfort of a real wooden house;

- practical, reliable, safe (environmentally friendly);

- long service life;

- The tongue-and-groove system ensures quick installation. The work can be done by both experienced builders and novice craftsmen;

- It is not recommended to process it when decorating the interior of a house. Saving special products, varnish and mastic;

- the opportunity to purchase taking into account financial capabilities: you can buy expensive and cheaper products (depending on the type of wood used);

- light in weight;

- relatively inexpensive finishing;

- wide choice in terms of design solutions. Analogs of different length, width and thickness.

Recommendations from experts

- All work on installing metal siding must be carried out in accordance with developed technologies, carefully and slowly.

- In addition to the panels themselves, you need to purchase additional elements: starting and finishing strips; H and J-profile, ebbs, external and internal corners. Without them, you will not be able to give the building a finished and beautiful look.

- It is very easy to care for this coating; to clean it, just wipe it with a damp cloth or brush.

- If damage suddenly occurs to the outer protective layer of the panel, it must be immediately painted over using an aerosol of the appropriate color.

Application

Using a blockhouse, you can cover walls made of brick, wood or foam blocks. Blockhouses are equally effectively used for interior decoration of steam rooms and dressing rooms, kitchens, terraces, verandas, and residential premises. Read more about installing a block house..

Almost any type of wood is suitable for cladding a house (here, it’s not so much the characteristics that matter as the appearance of the covering). But for a bathhouse and especially a steam room, a blockhouse is required that is resistant to rot and warping. Aspen and birch are most suitable. Coniferous species are not used when finishing a steam room due to the resin content (when heated, it comes to the surface, gets very hot and sticks).

Painting can improve the characteristics and appearance of the board. It can be performed not only on the construction site, but also in the factory. In this case, the material is coated with paint evenly over the entire surface, which extends the life of the wood. To paint a blockhouse in a steam room, special water-based varnishes are used that are odorless at high temperatures. The use of such a blockhouse can significantly reduce installation time. Various color effects are available, including artificial aging. There is also a block house for interior work, painted in the color of valuable wood.

Panel categories

Any elements of a block house have a certain category, according to which the quality of the finishing material is determined. Wooden lining is characterized by definitions of class A, B, C. The non-standard category includes the category of extra class (E) . Extra-class products are usually made to order, since the production of these products requires careful processing of wood and special equipment.

Products are labeled according to quality related to a particular category. Sometimes you can find the markings AB, BC, which means that they belong to two categories at once in relation to the existing flaws.

- Category A includes boards with knots up to 1.5 cm , end longitudinal slots up to 95 mm, color loss of the coating no more than 10%. This category includes the highest quality materials, made from good raw materials and carefully processed;

- Category B includes boards with knots up to 5 cm , end longitudinal slots up to 30 cm, unlimited loss of color fastness. The cost of material in this category is slightly lower than products of category A due to permissible errors;

- In category C, panels have an unlimited number of cracks and knots , while color changes are allowed without limitation. Products in this category are low-grade, but the material is strong, durable, and wear-resistant.

NOTE!

The standardization of panels for each manufacturer may differ, with higher quality panels classified as Category A.

The best quality is only the extra varieties, but they do not belong to mass standard production . Extra panels are ideal in shape, carefully processed, made of high-grade wood, and have increased external design and wear resistance.

Advantages

The appearance of the finish can be attributed to its main advantages. A house made of timber or logs, namely such variations of the material are on the market, looks cozy and warm both inside and outside. In addition, wood finishes are always in trend. The material has a pleasant pine aroma, and wood resin creates a natural layer of protection from rain in summer and snow in winter. Its antiseptic properties are also a big advantage.

The block house is highly resistant to impacts and scratches. If the integrity of the canvas is nevertheless compromised, this can be easily corrected by sanding and painting such an area. Over time, cracks and distortions do not appear in the boards thanks to modern drying and processing methods.

The lightness of this material allows you not to worry about the weight of the structure. And simple and convenient fastenings make it possible to do sheathing without special skills.