Today, the construction of buildings can be made from various materials. New, cost-effective construction technologies from combined materials are gaining popularity, but despite all the new products, brick construction is considered the most reliable, and buildings are warmer and more durable.

An important element of brickwork is the mortar, which is used to create a durable structure from individual elements.

Requirements for mortar for bricklaying

The main requirements for the solution are the requirements for strength and durability.

Based on strength, solutions are marked from M4 to M200. Frost resistance - from F10 to F200.

Important!

In terms of strength, the solution must meet the requirements of the project, and in terms of durability - the operating conditions of the structure.

It is interesting that the strength of brickwork on fresh, unhardened mortar is 3 times less than the strength of the same masonry on hardened M100 grade mortar.

In addition to strength and durability, an important requirement is sufficient mobility of the solution and its moisture-holding capacity.

The point is not only that a mobile solution that is not prone to delamination is more convenient to work with and saves time, but also that such a solution compacts and fills the seams better, as a result of which the strength of the masonry can increase by 1.5–2 times .

Characteristics

When plastering using a mechanized method, the degree of stratification of the mixture is very important, since if its value is high, the hoses will constantly become clogged.

The main parameters that determine the properties of the prepared solution are:

- ability to retain water;

- mobility;

- degree of delamination;

- average density;

- temperature conditions of use.

Freshly prepared mixtures are tested for water retention ability by factory laboratories. These figures should not be less than 95% in winter and less than 90% in summer.

Important. As a result of transportation to construction sites, the water-holding capacity of the finished solution may decrease, but should not become less than 75% of the value that was established by the laboratory. It is strictly forbidden to add water to already set solutions.

The low degree of stratification of the finished compositions is very important, as it reduces the possibility of separating it into liquid and solid fractions during transportation and pumping through hoses.

The main properties of the composition in hardened form are:

- frost resistance;

- its compressive strength;

- density.

All these properties must be acquired by the hardened composition at the design age, which is determined at 28 days. The only exceptions are mixtures with gypsum binders.

Ready-made lime finishing heavy mortar according to GOST 28013-98 must have an average density of at least 1500 kg/m3.

The strength of finishing ready-mixes is much lower than that of concrete or masonry mixtures. The fact is that plaster compositions carry virtually no load.

What are the types of masonry mortars?

The main component in masonry mortar is the binder. Solutions can be prepared on the basis of cement, lime, clay, gypsum. In low-rise construction, as well as in cases where there is no need to use high-grade mortars, local binders are used, widely available in the region, for example, lime-slag or lime-ash cement.

Since each binder has its own advantages and disadvantages, complex mortars are also prepared using several types of binders, for example, cement-lime, cement-clay mortars.

In addition to the binder, the composition of the masonry mortar includes:

- sand,

- water,

- additives of mineral or chemical nature.

For brickwork, mortars mixed with sand with a maximum particle size of 2.5 mm are used.

Important!

The composition of the solution is selected depending on the following factors:

- bearing capacity of the structure,

- operating conditions of the product.

The solution recipe takes these factors into account and is selected depending on the selected type of binders and sands.

Main types of masonry mortars:

- cement;

- lime;

- cement-lime;

- cement-clay.

Types of masonry mortars

In low-rise construction, for the most part, only three types of solutions are used:

- Lime masonry mortar is very plastic, inexpensive, easy to install, and is perfect for materials where low shrinkage is required. Durability is average, poor tolerance to humid environments. Another disadvantage is the long setting time, which significantly slows down the construction of houses, walls, and installation of elements. It can only be used in the above-ground part of the building; it is most often used for the construction of partitions and other planning structures inside the house. It does not tolerate high stress; load-bearing walls cannot be built from this material. Very sensitive to the quality of lime used and storage conditions.

- Cement-sand mortar is the most common and is used for laying load-bearing walls, partitions, creating a waterproofing layer, and for installing reinforced concrete products and load-bearing structures. It is characterized by high strength, water resistance, ease of use. Average setting speed, universal use, and low labor costs have made this type of masonry mortar the most suitable for low-rise construction.

- Cement-lime masonry mortar is also a universal mixture that has high strength and can be used on underground structures, in the construction of load-bearing structures, walls experiencing low and medium stress.

Important! The mobility, setting time, and strength of solutions are determined by their composition. Carefully study the technical characteristics of building materials before purchasing them. Ready-made mixtures should not be mixed with other components to prevent loss of strength.

Cement masonry mortar

The cement mortar is prepared on the basis of cement (Portland cement), which is a water-hardening binder. Cement forms a strong material in the presence of water through hydration reactions.

Typically, cement mortars are used where the structure is exposed to aggressive environments (including humidity). Foundations and plinths are always made with cement mortar.

The advantages of cement masonry mortars are:

- strength;

- durability;

- water resistance, frost resistance;

- resistance to the development of fungus and mold;

- no restrictions on use (can be used, for example, for structures that will be used in conditions of high humidity, exposure to low temperatures or aggressive environments);

- rapid strength gain, which is especially important in multi-story construction.

Among the disadvantages of cement mortars are their high specific gravity, rigidity, and low mobility, which affects not only ease of use, but also how well the work will be carried out and, ultimately, how durable the structure will be.

To make the cement mortar more mobile and workable without adding excess water (which entails a loss of strength), plasticizing additives are used.

Important!

The depth of immersion of the cone in cement mortars for brickwork is from 9 to 13 cm.

The cheapest additives of this kind are slaked lime and clay. But their use is not always convenient. The lime must be slaked, that is, mixed with water and left for several days while the reaction occurs. Clay must have certain characteristics.

Special plasticizing additives are very convenient to use, for example, CemStone, which completely replaces clay and lime in cement masonry mortars. The supplement is laboratory tested and comes with clear instructions for dosing and use. It provides masonry mortars with all the necessary properties:

- increases the “lifetime” of the solution (up to 5 hours), thus allowing you to mix it in large quantities at once and save time or order it at a mortar unit;

- eliminates the delamination of the solution, as a result of which it does not require constant stirring;

- increases the efficiency of cement, allowing the use of even stale cement;

- does not cause corrosion of metal embedded parts and fittings;

- reduces the time for full strength gain (7 days instead of 28 days, which is required for a solution without additives);

- gives the solution increased characteristics of water resistance and frost resistance.

Hardening of the cement mortar occurs within 28 days, after which the mortar gains its design strength. The strength gain does not occur linearly: the fastest rate of hardening is observed immediately after laying the mortar, then it gradually slows down. Therefore, the more time has passed, the less adverse external influences affect the hardening process.

Adverse effects include too high or too low ambient temperatures and low air humidity. The optimal air temperature is +18–22° C and almost one hundred percent humidity.

Important!

The lower the ambient temperature, the slower the rate of strength gain, as can be seen in the table. At temperatures below +5°C, strength growth stops. Subsequently, when the air temperature rises, the solution gains strength, but is less durable than when cured under optimal conditions.

Obviously, it is impossible to avoid the work of laying bricks at low and subzero temperatures, because in this case it would be necessary to postpone construction for several months, which is not economically feasible.

In these conditions, masonry work can be carried out without compromising the strength of the structure if you use anti-frost additives, for example, CemFrio and HotIce from CEMMIX, which not only allow you to work at negative temperatures (down to –20°C), but also have plasticizer properties, as well as provide the following benefits:

- saving cement up to 10% without loss of strength;

- increasing the mobility of the solution;

- elimination of solution delamination during transportation and storage.

Additives CemFrio and HotIce are compatible with any type of cement and are safe for humans.

What are masonry mortars?

Ready-made cement masonry mortar can be used for the following types of work:

- Laying brick, gas silicate, cinder block, shell rock;

- Installation of reinforced concrete products of various sizes (slabs, blocks, floors, flights of stairs);

- Manufacturing of various products for construction (vibrobrick blocks, panels, tiles) using the vibration casting method;

- Installation of decorative elements, load-bearing structures, metal structures;

- Repair work (sealing cracks, fixing objects);

- Protection of materials and substrates from negative external influences (mechanical damage, rain, abrasion).

Masonry mixtures are characterized by ease of preparation, plasticity, long pot life, and fine-grained filler. After setting, masonry mortars are resistant to frost, tolerate short-term contact with water, and can be used in a humid environment, as well as in places where temperature changes are observed. It is very important to follow the manufacturing technology and use of masonry mixtures to ensure the strength of the entire structure. Very often, problems arise on construction sites when the technology for preparing the mixture is violated, it is used on an unprepared surface, without quality control of the masonry, and so on. As a result, the masonry joint may have high strength, but the entire plane of the wall will be covered with defects or may have a loose structure. In some cases, it is appropriate to use masonry mortars as a facing mixture. The material provides good tightness, does not change appearance for a long time, and provides water resistance.

Lime mortar for masonry

Our distant ancestors used lime masonry mortars to erect magnificent buildings that have stood for centuries and are still standing.

The fact is that slaked lime, an air-curing binder, gains strength in air, and this process continues for a long time. Even after years, such a solution continues to gain strength.

But for construction work, such a slow increase in strength is rather a disadvantage, because we want to get a strong structure not in 100 years, but in a few weeks. The use of lime masonry mortars in multi-story construction is especially inconvenient, since you have to wait a long time before starting the construction of the next floor.

The advantages of lime mortars include their low thermal conductivity, good plasticity, and high hygienic properties (they “breathe”). However, they are quite fragile and unstable to high humidity.

They are used only for masonry that is located above ground level and is not in contact with the ground.

Cement-lime masonry mortars

Cement-lime mortars are prepared from cement, sand and lime paste with the addition of water.

As a result, we obtain a solution that is more plastic than cement (since lime works as a plasticizer) and more durable, waterproof, and resistant to fungus than lime. Cement-lime mortars are also frost-resistant.

The proportions of cement and lime in solutions may be different; Depending on the formulation, such solutions can be used for both above-ground and underground parts of buildings.

Important!

In cement-lime mortars, plasticizers are also used to reduce the consumption of cement and lime.

We recommend studying: Plasticizers

Cement-clay masonry mortars

Cement-clay masonry mortars are stronger than cement-lime mortars and set faster. Typically, in such solutions, cement is mixed with finely ground clay in various proportions, and the solution also includes sand and water.

Due to the fact that clay retains water well, this solution can also be used at low temperatures.

Important!

Masonry mortars, depending on the composition, may have special properties, for example, they can be heat-insulating, heat-resistant or decorative, colored, allowing to achieve an aesthetic effect.

Watch the video: Laying bricks with Perel colored mortar

Cement mortar proportions

First I would like to understand the types of cement mortar itself . They come in several types:

- normal;

- skinny;

- fatty.

This classification is a consequence of the different amount of liquid that is used to dilute the dry ingredients of the solution.

The greasy solution is obtained by using a small amount of water. On the one hand, the mixture sets very quickly, but on the other hand, after hardening, the mixture may crack over time, which negatively affects the life of the building.

A lean solution, on the contrary, is prepared with a large amount of water. The characteristics of the finished solution leave much to be desired, and the setting time of the mixture increases significantly.

The best option is a normal solution, in which the harmonious proportions of all components are observed - cement, sand and liquid. After hardening, such a solution does not crumble or crack, which makes construction projects quite durable.

Proportions

The most common solution is a combination of cement and sand (1:3). Do you want to know how to mix such a solution? There is nothing complicated about this. Taking three parts of sand, mix them with one part of cement in a separate container.

Mix thoroughly until the dry mixture becomes the same shade . Then you can start adding water while stirring the mixture using a shovel or electric drill with an attachment.

Preparation of the solution

The finished solution should resemble thick sour cream in consistency, so after mixing the dry ingredients, add water in small portions. On average, the volume of liquid leaves half the volume of cement, but this is an approximate proportion.

It is also worth noting the fact that the brand of ready-made cement mortar and the brand of cement are different concepts.

The grade of mortar is the grade of cement divided by the volume of filler used, i.e. sand

So, to mix the M100 brand solution we will need the following components:

- cement grade M300;

- three buckets of sand.

But this does not mean that M100 grade cement mortar is prepared only from M300 grade cement.

M300

If M400 cement is available, then to prepare the solution you will need four buckets of sand (ratio 1 to 4). If the cement is M500, then five buckets (ratio 1 to 5), etc.

We have already said that cement mortar is used for a wide variety of construction purposes. Accordingly, the proportions of sand and cement , as well as other components of the solution, will be different for each of the specific areas of application. Let's look at each of them in more detail.

How to knead for the foundation

The foundation is a defining moment in the construction of any construction project, on which the operational life directly depends. That is why it is very important to strictly observe the proportions of the foundation solution.

For the foundation

A high-quality foundation should consist not only of traditional mortar components - sand, cement and water, but also crushed stone. It should not be limestone, because this does not increase the strength of the finished solution. Also, do not replace crushed stone with expanded clay, gravel and other similar materials.

In most cases, cement grades M400 and M500 are used to make the foundation. Strength is extremely important for the foundation of a building, so the use of high grades of cement is fully justified.

M500

As for sand and water, the requirements are absolutely identical to those for ordinary cement mortar used for plastering walls, laying bricks, etc. Water should not contain impurities, oils or foreign objects.

Bathroom wall panels are quite easy to install, they are quite durable, can easily cope with temperature changes and have a long service life. It's all about this wonderful material.

With the help of a self-leveling floor screed, you can minimize all the difficulties of floor leveling. Here you can learn about the different types and costs of self-leveling screed.

Quarry sand has become widespread due to its low cost and excellent natural qualities. By clicking on the link, you will become familiar with the technical characteristics of this material.

The sand must be washed and sifted so that there are no traces of clay, stones, silt formations, etc.

The proportions of sand and cement for preparing mortar for the foundation are as follows - three buckets of sand are taken for one bucket of cement.

As for crushed stone, in most cases it is identical to the amount of sand. If you measure everything in buckets, then for one bucket of M400 or M500 cement you will need three buckets of crushed stone and three buckets of sand.

Crushed stone

Water must be diluted carefully so as not to make the solution too liquid. It is very important here how dry the sand we have is available, i.e. if it is wet, it is advisable to dry it before mixing with the rest of the ingredients.

Composition of mortar for floor screed, how to mix

The proportions and consumption of cement mortar for screed are determined based on the grade of cement available. The minimum acceptable grade of mortar for floor screed is M 150 (dry mix), but grade M200 is used quite often.

M200

In general, sand-cement or concrete screed can be used as an independent floor covering in certain rooms. As a rule, these are garages and other non-residential buildings. In most cases, the screed is used as a basis for linoleum, parquet and other coatings.

Cement mortar for floor screed includes three main components - sand, cement and liquid.

Concrete screed is also supplemented with crushed stone, but it is practically not used for residential premises, so we will not consider it.

For floor screed

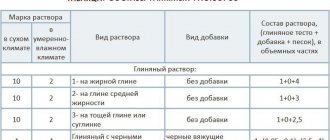

Recipes for masonry mortars

The solution recipe is selected depending on the desired characteristics and is determined by the design documentation.

One of the most common cement mortars in construction, grade M100, for brickwork includes (per 1m3):

- cement – 250 kg;

- sand – 1580 kg;

- water – 140 l;

- CemStone additive – 1.25 l.

Solutions of different brands are used for different types of structures. Grades M150 and M200 are used for hydraulic structures.

Scope of application of masonry mortars

Mark 75

- Preparation of grounds;

- Providing a waterproofing layer;

- Protection of materials under the solution;

- Prevention of moisture loss due to evaporation (vapor barrier);

- Zabutovka;

- Filling seams, decorative repairs;

- Laying natural stone.

Mark 100

- Assembly of reinforced concrete products;

- Providing external wall coverings;

- Laying brick, gas silicate, cinder block;

- Leveling walls and floors;

- Construction of load-bearing columns;

- Preparation for soft roofing.

Mark 150

- Application in the field of complex construction, work with increased loads;

- Construction of foundations, laying on foundation blocks;

- Installation of high-strength floor screed;

- Construction of hydraulic structures;

- Construction of swimming pool bowls.

Employees of the AlfaCem group of companies will help you choose the optimal masonry mortar for your operating conditions, goals and objectives. We will organize delivery to any region of Russia and supplement the order with related products and building materials.

Very often, manufacturers label their products differently, for example, “installation adhesive,” “masonry adhesive,” “universal mortar,” and so on. This is due, of course, to marketing, but also to the changed formulation of the solution. Adding components significantly expands the scope of application:

- Increased heat resistance for the construction of stoves, chimneys, fireplaces;

- Elasticity of the solution to prevent the formation of cracks;

- Adding dyes improves the aesthetics of masonry;

- The addition of polymers increases resistance to UV radiation and prevents dirt from penetrating into the masonry joint;

- Thermal insulation properties reduce heat loss through the masonry.

Previously, construction sites used factory-produced mortar, which was delivered in pears, poured into special containers, and all construction teams had to manage to work it out during the viability of the masonry mortar (several hours). Today, mixtures are supplied in convenient bags of 25-50 kg, therefore, the mason does not have to knead a lot of material, and then rush to work it out. The mixture can be prepared in a regular bucket or tub with a whisk, even without the use of concrete mixers or other mechanisms.

How to mix masonry mortar with your own hands

Unlike large-scale construction, for which masonry mortars are ordered from mortar units, in private construction they often prefer to mix the mortars themselves.

Construction mixers and concrete mixers are used to mix solutions. In this case, it is especially important to use plasticizers in order to achieve an ideal solution and, if possible, eliminate shortcomings.

The order in which the components are mixed may vary. Some craftsmen mix dry ingredients and add water to them, others first pour water into a concrete mixer, then add sand to the water and only then cement. Lime dough is mixed with water to obtain lime milk, then it is used instead of water.

One of the mistakes when mixing masonry mortars with your own hands is adding detergents to them instead of a plasticizer. Since the exact composition and recipe of liquid soap are not known to us, we, in fact, do not know what we are adding to the solution and how this will affect the strength of the future structure. Adding a plasticizer in this case is the right step, which leads to predictably good consequences.

How much solution will be needed

Before starting construction work, it is necessary to carefully calculate how much materials will be required. The consumption of mortar for brickwork is calculated per 1 m2 and also depends on the thickness of the brick and the thickness of the walls in the bricks. It can be viewed in the table.

Based on the required amount of solution, you can calculate the amount of necessary consumables.

We advise you to study: For plastering and masonry work