Artificial brickwork is often used when decorating residential premises. When you want to have a brick wall, but it’s impossible to lay a real one, they resort to imitation. There are several ways to do this. In this article we will look at how you can create a textured decorative finish yourself using polystyrene foam.

What does a foam wall look like in the interior?

A brick wall is found in styles such as “loft” or “Provence”; it can be painted white or have a natural shade. False bricks are suitable for the interior of a kitchen, bedroom or living room. As a rule, decorative finishing of one wall is carried out, the rest are left for painting or wallpaper.

The calm, repeating texture of the brickwork serves as a good backdrop for various decorative items mounted on the wall.

If there is a wall with a TV in the center of your living room, then polystyrene foam for finishing it as a brick would be perfect, because this material is a good sound insulator. This is important if there is good audibility in the apartment, and you do not want the sounds of the speaker system to be transmitted to the next bedroom or disturb the neighbors.

Comparison of polystyrene foam and polyurethane foam panels

In the production of panels, the insulating layer can be polystyrene foam or polyurethane foam. Each of the materials has positive qualities.

Mold and moss do not grow on polyurethane foam. No structural changes are observed, even with temperature fluctuations. But the material can self-oxidize with further formation of peroxide. If the temperature increases to +80°C and higher, mechanical destruction with the release of phenol is possible. Polyurethane foam can last at least 60 years.

Expanded polystyrene is environmentally friendly for humans. It is used to fill furniture and pillows. It is not destroyed by microorganisms. Fungi do not grow on it and colonies do not develop. The structure of the material is porous. It has a relatively high percentage of moisture absorption, so it can be destroyed by negative temperatures.

Finishing features

Let's consider the properties of polystyrene foam (polyurethane foam) as a material for decorative finishing.

First of all, it is worth remembering that it is produced for insulation and soundproofing of walls, has different densities and strengths, so you need to be careful when choosing sheets of foam plastic to imitate brick.

The advantages of the material include:

- light weight, false brick adheres well to the wall;

- easy to cut and process;

- does not create dust and dirt, this is important when working indoors;

- polystyrene foam is cheaper than plaster, brick tiles or high-quality wallpaper, but the cost of paint and glue must be added to its cost.

The disadvantage of a foam wall is its low strength. Even if you choose sheets with a high density that hold their shape well and do not crumble, dents may still remain on such a finish from impacts and careless movements. Therefore, it is not recommended to make decorative brickwork from foam plastic in places with high operational load: in hallways, at the table in the dining area, in the children's room.

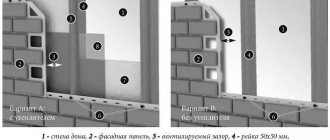

Design of facade thermal panels

Ready-made blocks of thermal panels are intended for external decoration of buildings. But sometimes designers use them in interior spaces. Ready-made panels do not weigh down the walls and do not create excess pressure on the foundation.

Structurally, thermal panels have the appearance of a layer cake.

- The top layer is decorative. The layer pattern repeats brick or stone masonry. It also performs the protective functions of the main layer from the actions of nature.

- The main layer serves as thermal insulation. Expanded polystyrene and polyurethane foam are used for its production.

The panels are manufactured at the factory using the latest technology, using special matrices. High-precision connection of panels masks possible installation defects. Cold bridges are never created in the panels. The fastening is reliable and can withstand even the force of slanting rain.

Decorative panels with imitation stone or brick are in demand by consumers due to their decorative qualities. Imitation of natural stone is difficult to distinguish from masonry. And it is easy to care for - just clean it from dust once a year with a damp sponge. The panels have beveled hidden edges that provide a seamless finish. The type of stone finish is resistant to fading in bright sun. There are no scratches on it.

Brick-like thermal panels are popular and considered traditional. They are suitable for many structures and buildings. There are many proposals for choosing the color and texture of bricks. The color of the brick can be white, yellow, gray, red, terracotta. In appearance, aged or burnt, with a rough or smooth surface.

The panels are joined together using the tongue-and-groove method. This ensures the rigidity of the skin, which holds wind loads.

What do you need for work?

To make artificial bricks you will need sheets of dense polystyrene foam. We call it foam plastic in general, it can be:

- "Penoplex" used for insulation of buildings. The thinnest one will do - 20 mm.

- Styrofoam. It is better to take with high density (for example, PPS-35).

- PVC sandwich panels with expanded polystyrene, which are used for finishing slopes. This sandwich brick needs to be cut lengthwise into two parts. On one side there will be foam plastic, on the other there will be a PVC base.

In order to glue foam bricks to the wall, the following is suitable:

Glue “liquid nails” such as “Moment Installation” or “Titanium”. Liquid nails are needed when brickwork is laid out one element at a time, i.e. foam rectangles are glued 1 piece at a time.

Polyurethane foam . With its help, you can glue a whole sheet of foam plastic on which imitation masonry is made. For individual bricks this method will be inconvenient. The foam adheres well to strong, rough substrates: concrete, aerated concrete, plaster, drywall. The polyurethane foam comes off from smooth PVC panels. When purchasing, look at the mass of polyurethane in the cylinder; with the same volumes of foam, it may be less. A good option is “Macroflex” (MAKROFLEX).

Adhesive for insulation . This option is also for installing foam plastic sheets directly under the brick. The adhesive that is used for constructing wet facades is suitable: Ceresit CT 85, Unis Warm Adhesive, Weber.Therm S100, Knauf Sevener.

Glue gun . It is useful for gluing decorative bricks from sandwich panels, i.e. with a smooth PVC base.

Do-it-yourself facing brick. Features and types of facing bricks

Along with plaster and siding, cladding a house with brick is often used.

The basis for the production of facing bricks is the same material that is used for the production of ordinary bricks. However, regardless of the material from which the facing product is made, it must meet the following requirements:

- correct geometric shape (the error in length cannot exceed 4.4 mm, in width – 3.3 mm, and in height – 2.3 mm);

- clear and smooth edges;

- rich, uniform color;

- the product should not have any defects in the form of chips, cracks and delaminations (the surface can be smooth, glazed or textured);

- facing bricks can have frost resistance within F 25 - F The marking value indicates the number of freezing and thawing cycles that the material can withstand without visible damage and a decrease in compressive strength of no more than 20 percent;

- water absorption should be below 6%.

Important: if you are laying facing bricks with your own hands, then you should know the following concepts: the long side of the product is called the spoon, the end part is called the butt, the supporting plane (the largest surface) is the bed.

How to make foam bricks

To imitate a brick wall, you need to mark out the foam, cut bricks according to a template or make masonry joints on a sheet, and give the surface a texture. The decorative trim is then glued to the wall and painted.

Let's take a closer look at the entire brick decoration technology.

- Marking . If the expanded polystyrene sheets will be glued entirely without cutting, then you need to draw brickwork on them with a marker or pencil. To cut out individual false bricks, you can make a cardboard template.

The size of a regular single brick is 250*120*60 mm. Those. To mark foam plastic, you need a 250*60 mm template. One-and-a-half bricks are often used for cladding; their height is 88 mm. The thickness of the masonry joint is the distance between the bricks = 1 cm.

- Slicing . Expanded polystyrene can be easily cut with any construction knife with a retractable blade. There are also no problems with cutting sandwich panels; the top PVC layer is cut together with the foam layer, and the bottom plastic layer is then broken along the cut line.

Decorative bricks can be chamfered on all sides with a knife for beauty.

If the imitation of masonry is done on the entire sheet, then the seams are easiest to form using a soldering iron ; the foam melts easily. The soldering iron is guided along the line of the masonry seam, controlling the pressure and depth. First, horizontal grooves are made from edge to edge parallel to each other. There should be a distance between them equal to the height of the brick (60 or 88 mm). Then the vertical seams are burned out and the contours of the artificial bricks are finally formed.

Attention! Expanded polystyrene is toxic when burned. Burn only in a well-ventilated area and wear a mask to protect your breathing from smoke.

- Creating an invoice . To make a decorative wall look like a real brick wall, you need to give it the same rough texture. This can be done with a brush with metal bristles. It is pressed onto the sheets and passed along the surface, creating pits and grooves on the foam. You can also give relief to bricks with a soldering iron or lighter. This will be shown in more detail later in the video lesson.

- Installation of bricks. To secure the made decor, you need “liquid nails”, foam glue or other glue mentioned above. The prepared rectangles are glued directly to the wall along a horizontal line, leaving a gap of 1 cm - a masonry joint. After laying the first row, move half a brick to the side and glue the second row. Then the process is repeated.

Another installation option is to imitate masonry not on the wall, but on a large sheet, for example, plasterboard or plywood. The advantage here is that the gypsum board lies on the floor, and gluing in this position is sometimes easier than vertically. After finishing the decoration, these sheets are attached to the wall or frame using self-tapping screws.

- Painting the wall. To complete the finishing, the decorative coating must be painted. Which color to choose depends on the overall style of the room. A popular option is a pure white wall. If you want to create a brick color, you will have to tint the paint in a red-brown shade. Artificial masonry joints can be made white or the color of gray cement-sand mortar.

Important! To paint polystyrene foam, you need to choose paints without solvents, otherwise they will ruin the material. Water-based emulsions and acrylic paints in jars or spray cans are suitable.

Cardboard brickwork

Imitating a brick wall in the interior does not require much expense. Creating artificial masonry is easy if you have the following materials and tools:

- corrugated cardboard;

- PVA glue;

- hot glue gun with rods;

- brushes for applying it;

- multilayer paper napkins;

- rulers;

- pencil;

- scissors or stationery knife;

- paints;

- varnish

Imitation of brickwork in decoupage

Having stocked up with everything you need, you can get to work. First of all, you should prepare the surface: clean it and coat it with a primer. Bricks cut from cardboard are glued to a pre-marked wall. To firmly fix them to the wall, it is recommended to use PVA and hot melt adhesive at the same time. The main part of the brick is processed first, and the second is applied pointwise only in the corners. Hot-melt adhesive quickly fixes the cardboard to the surface; using PVA allows you to save on expensive rods.

Next comes the turn of decoration. That's what paper napkins are for. The technique is called “decoupage”. To do this, you need to peel off one layer of the napkin, crumple it in your hands and place it on a surface greased with PVA. Carefully apply another layer of glue on top, and at the last stage paint and varnish.

Imitation of brickwork made of cardboard

Brickwork can be used in the design of a room in different ways. You can decorate an entire wall with it or use it only as a decoration element. For example, in the kitchen, special tiles laid out like real masonry look great as an apron. False bricks are often used to frame arched openings, fireplaces, mirrors and paintings.

Facade cladding panels

At the end of our article, we note that for cladding facades, brick-like wall panels are produced from polystyrene foam. They not only decorate the building, but also serve to insulate it. Such panels are attached to a frame or glued to the wall. The sheets fit together well, and after installation there are no visible seams. There is no need to paint them, they already have the texture and color of a real brick wall.

We hope that the article was useful to you. Leave your feedback and questions in the comments below.

Source

Imitation of a brick wall using polystyrene foam. Master Class

Just look at the idea! Having seen a photograph with a brick wall for the first time, I would never have guessed in my life that it was just foam plastic) The idea is suitable for those who are interested in photo shoots, for creating a pseudo-fireplace or for decorating a wall to give the interior a creative twist) It’s up to you to decide whether or not no, bring the idea to life. Maybe you can try it at the dacha? But this pseudo-wall can be painted a brighter color? For example, the color of red brick. My daughter, when she saw this, wanted to urgently redo her room)))) Well, I like it) What about you?

Listen! I need advice from the experts! It dawned on me just before publication))) In my dacha, the ceiling is made of pieces of plywood, such bullshit. We covered it and plastered it with whatever we could. The cracks show up every year. What if you stick foam plastic to this plywood in this way? What will happen? If anyone knows, please write.

So, for work you will need polystyrene foam, plywood for the base, a knife for cutting polystyrene foam, a soldering iron, glue (construction PVA is suitable) and spray car paint.

Cut the foam into bricks measuring 20 by 6 cm (you can set the dimensions yourself)

Lubricate the plywood with glue and glue the foam bricks, leaving equal gaps

Installation, texture processing

To reliably attach individual blocks, you will need an adhesive composition and cement mortar. Foam bricks are selected to be the same size. Laying begins from the corner of the wall, then around door and window openings. Upon completion of the installation of corner points, it is recommended to form the first horizontal line. After completing the installation work, the wall surface is treated with a protective agent.

Installation work

Decorative bricks are attached directly to the base of the wall. Sometimes plywood sheets are used as a base. Upon completion of work, fixation is performed with standard fasteners. A sheathing is first created on the wooden flooring. Initially, the polyurethane wall is completely painted. The primer composition is diluted with a dye of the desired shade. When the previous layer is completely dry, you can begin painting each individual brick in the desired color. The gaps between the decorative stones are made to match the color of the cement composition.

5 days after installation of the elements, the wall is treated with aerosol acrylic paint. After a week, you can apply matte acrylic varnish.

If the foam structure is not reinforced with protective agents in the form of varnishes and paints, it will collapse under the influence of moisture.

Cutting and lining the base from sheets

For this method of making foam bricks with your own hands, it is best to choose a material with a fine grain. It will not crumble, release harmful substances and burn when exposed to heat. To achieve this effect you will need the following arsenal:

- knife;

- finely dispersed foam;

- paint, primer and varnish;

- soldering iron;

- special glue.

Brick imitation is performed as follows:

- Blanks with the required dimensions are cut out of foam plastic.

- The blanks are fixed to the wall with glue. This should be done so that there is a distance of 10-15 mm between the tiles.

- When the entire wall is covered, finishing is carried out. Use a soldering iron to burn out the irregularities characteristic of a brick surface.

- The treated surface is covered with putty.

- When the putty hardens, a primer is applied to the wall.

To make the brick imitation look believable, you need to decorate it.

To do this, you need to cover the entire surface with paint diluted in a primer until it dries. The protruding areas also need to be painted over, but the gaps should not be touched. It is better to apply paint on them the color of cement with a thin brush so as not to affect the protruding rectangles.

5 days after decoration, it is recommended to cover the surface with a layer of aerosol acrylic paint. After another 7 days, the wall should be treated with matte acrylic varnish. (Fig. 1)