"Slobodskoy Les" © 2012-2021.

Wood finishing is in demand today and will remain relevant at all times. Because natural materials have a basic value other than price. Always different, for every taste. As unedged boards to imitate a “careless” rough antique finish.

Finishing with an ordinary unedged board, with the right approach, can effectively change the perception of a home or bathhouse. Specially selected and prepared lumber allows you to decorate the interior space in an original, unique style.

Until people learned to work with unedged boards, finishing was mostly simple. The lack of strict geometry and the presence of a wane was critical for modern residential premises. Low-processed lumber was used for outbuildings, firewood sheds, and wooden sheds. Now the area of application of unedged boards covers the finishing segment.

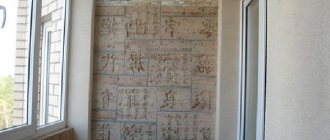

A characteristic feature of unedged boards is uneven edges of a free cut (in the shape of a tree trunk), uneven “floating” width along the entire length. Due to this, the installation of fragments during finishing serves as an interesting decor with a pronounced individuality. The designs shown are mainly used on the ceiling or wall.

The advantages of the material lie, first of all, in its naturalness and availability if you want to use unedged boards for interior decoration. Fit of elements, direction, location may not be ideal. Greater width + thickness means increased weight. Therefore, unedged boards need reliable installation on a flat base.

A simple finishing material can be easily planed and polished. Only a low grade can become a hindrance: cracks on unedged boards, resin pockets, biological damage, tobacco and fallen knots.

It is better to purchase lumber of natural moisture in advance and keep it under a canopy in gentle conditions (atmospheric drying) for several months before installation. Perform culling.

In addition to grade, there are options for wood species. The house mainly uses pine and spruce. Less commonly, beautiful cedar. Linden, larch in the bathhouse. In any case, an unedged board will need reliable protection with an antiseptic or wood varnish. Choose a good composition. For example, Finnish Tikkurila differs from those made in the Russian Federation.

Long service life, frost resistance of wood, the possibility of use in any climatic zones of the Russian Federation, ease of partial replacement without major rework, make it possible to use wavy edges on the facade of a building. With horizontal installation overlapping or in rows. Thanks to its natural beauty and texture, a simple unedged board will decorate platbands (windows), country furniture, and a fence.

Decorating the inside of the house with unedged boards, lining, imitation timber and other materials can significantly transform the appearance of the walls. In addition, the use of wooden blanks makes it possible to improve the heat and sound insulation of the room, which will have a positive effect on the level of comfort of the residents.

In our article we will tell you what parts can be used for the internal and external cladding of buildings, and also provide an algorithm for installing finishing materials.

The use of natural wood in interior decoration

Material characteristics

Sheathing options

People started using wooden parts for both interior and exterior decoration of their homes a very long time ago. At the same time, technology has constantly developed, because today there are many materials that can be used to solve this problem.

Below we provide brief characteristics of those that are used most often:

- Unedged board - parts obtained by sawing logs into plates without aligning the edges. Despite the rather sloppy appearance, the material can be used for decoration, especially if the entire interior or exterior of the building is stylized as antique (rustic and country styles).

The use of unedged boards in exterior finishing

Advice! Before installation, be sure to clear the unedged board of bark, and then trim off the thin edges to avoid cracking.

- Edged boards are used a little less frequently as a finishing material, but they allow you to create a smooth surface suitable for painting or applying decorative plaster. The main disadvantage of this design is that when drying, the dimensions of the board decrease, and quite large gaps form between the parts.

- Wooden lining, block house and imitation timber are materials that are aimed specifically at covering surfaces. Their design provides for the presence of locks - protrusions and depressions at the ends of the panels, which, when connected, overlap the seams and form an almost airtight connection.

Material Dimensions

Finishing is carried out with unedged boards of 16, 19, 22 and 25 mm in thickness, there are also thicker ones - 32-75 mm.

Specialized stores are replete with a variety of choices of this material, which is explained by the frequent finishing work with its use.

The creation and uniqueness of the play of chiaroscuro is the effect obtained thanks to the horizontal cladding. For facades, it is recommended to purchase unedged boards 30 cm wide.

Preference is given to high-density wood of northern species, which is characterized by a beautiful texture. I would especially like to note the selected butt wood and Siberian larch, which come without defects.

Installation method

Regardless of which board you chose for wall covering, such products are installed according to a similar algorithm. The main difference between the procedures is the need for insulation or waterproofing of wooden parts, as well as in the method of fastening the parts.

The general scheme of work is as follows:

- First, we prepare the base by cleaning it, and then treat it with moisture-proof and antiseptic components.

- Then we install the sheathing on the base - a frame made of beams or a steel profile, to which the sheathing itself will be attached.

Sheathing made of steel profile

- If necessary, we lay insulation between the cells of the sheathing - polystyrene foam, polystyrene, mineral wool, etc.

Note! Cellulose wool can be blown under the boards after they are installed, but then the thermal insulation process must be planned in advance, specifically leaving holes to fill cavities in the frame.

- We lay membrane material on top of the insulation and sheathing, which will protect objects under the sheathing from moisture and condensation.

- We mount the finishing panels, fixing them to the sheathing using glue, self-tapping screws, nails or special clips - clasps.

Finishing with unedged boards: installation methods

The popularity of wall decoration with wood is due to the environmental friendliness of the material and its aesthetic qualities.

What are the features of this material, and how to beautifully decorate your home with wood? * RUSSIA IS OUR LIFE * Hace 2 meses

Alexander Alexander Hace 3 meses

A scooper is much faster

Thomas Hace 3 months

Just fire. Imitation timber or lining has become boring. I will use a very original solution. Definitely like

Alexey Voronov Hace 3 months

Alexander List Hace 7 months

Greetings! We made a cool façade from unedged boards! You can watch it on our channel!

Life Outside the City Hace un año

Vena Cherniakov Hace un año

Good idea. Like. Friendship.

Grigory Magdesyan Hace un año

Will pine and spruce “cry” at the temperature in the steam room? Maybe I missed something, but the only solution is impregnation, which will prevent this from happening? Aspen and linden lining are expensive here now, so I’m looking for a way out on a budget, especially since my bathhouse is experimental.

Alexey Voronov Hace un año

Grigory Magdesyan Everything is correct)

Mankind has been using board wall decoration for more than one century, so it can rightfully be considered a kind of eternal value. Today, using wood to decorate interior walls is a way to create an aesthetically pleasing, yet environmentally friendly and safe interior design for those present.

Finishing specialists identify at least five types of finishing boards for walls. Despite the fact that they have much in common, there are also differences, which in some cases play a decisive role. Before covering the walls with boards, you should understand each of the options.

In the interior of modern homes, among other types of boards, lining is most often found. This is the least expensive wooden finishing material, which, however, does not deprive it of most of the main advantages of wood finishing. The lining is strong and durable; it is often made with special grooves, which turn the installation procedure into a formality.

Lining is the most popular material for finishing interior walls and ceilings with wood.

The installation is carried out on top of the sheathing, which somewhat complicates the whole procedure, but allows you to hide communications, insulation or additional sound insulation in the resulting void. In general, the characteristics of the lining strongly depend on what type of wood was used for its manufacture.

Imitation of timber

This material is very similar to lining, both in appearance and in basic performance qualities and installation features. At the same time, imitation timber is relatively rare in the interior, since it is much more often used for exterior wall decoration. The visual difference from the lining lies only in the larger width, which inside the room would create an unnecessary effect of reducing the area. However, no one is stopping the consumer from using a board that imitates timber indoors.

Imitation timber is an analogue of lining, which is more often used for facade cladding, but interior decoration with this material creates the feeling of being in a real timber house

Some manufacturers initially treat the imitation timber with all the necessary compounds that protect the product from harsh street conditions. If the material is purchased for interior decoration, it may be worth taking a less protected option, because additional protection increases the price of the product, and snow and rain are unlikely to fall on the wall inside the building.

If you are really looking for a board for decorative wall decoration, then a block house is perhaps the best you can find. Visually, the interior will look like a natural wooden log house, with the difference that there is no question of using full-fledged logs. In essence, a block house is a log trunk from which the square core has been removed, leaving only a thin convex layer of wood on the outside, which was formed by cutting the log on four sides.

Block house finishing creates an imitation of a wooden frame

The block house is made from various types of wood and always has the most natural look. Preference is given to pine or spruce. Installation of the finish in this case will be a little more difficult, so it is advisable to seek the help of specialists. In general, the material is divided into two categories, and for use in the interior, that is, indoors, it is advisable to give preference to category “A”, since it has a smoother surface. The buyer has the opportunity to choose the diameter of the original trunks from which the block house is made.

Planken is an alternative to the materials described above, the only difference is the absence of a tongue-and-groove connection. It is used both for cladding facades and interior decoration of the house. Individual fragments of material have an oblong shape and are usually used to highlight a wall or some element in the interior. At the edges, it is most often equipped with sharp or rounded chamfers.

Due to its moisture resistance, planken is ideal for finishing wet rooms

Basically, planken is made from pine or larch, which is naturally very resinous, thanks to which it can withstand an almost unlimited amount of moisture.

When installing planken, it should be remembered that this material expands easily at high temperatures and humidity, so gaps should be provided between individual boards.

Parquet board

Parquet perfectly withstands the high loads constantly placed on the floor, and at the same time looks very aesthetically pleasing - so why not use it for wall decoration? Until now, few people do this, but that’s the trick – an unusual solution also allows you to stand out from the homogeneous crowd.

Parquet boards on the walls are stylish, original and practical

As with any other material of an elongated rectangular shape, the specific placement of individual finishing fragments allows you to change the perception of the room. If the parquet board is placed vertically, this visually makes the ceiling higher. Diagonal spatial orientation creates a complex geometric impression.

An interesting result is obtained if the parquet on the floor and walls is “directed” in the general direction - then the room seems more elongated and purposefully oriented.

Unedged board

The most natural effect will be obtained if unedged boards are used when creating an interior design. This solution is more often used for exterior decoration, since inside it looks rough and even brutal, but on the other hand, it allows you to create a unique design, which in certain situations will also be appropriate.

For finishing, unedged boards are often used in gazebos or buildings for household needs, that is, where some wildness in design seems quite appropriate. They do not refuse this material when decorating the interior to give the home a primitive style. With a lot of effort, unedged boards can be installed without gaps, and then the structure will look as if it was built entirely from untreated wood. The most “wild” option does not even involve removing the bark.

Like any other wood for finishing, an unedged board must be impregnated with protective compounds that protect it from moisture and pests.

Wood fits well into most interior variations and combines well with all popular styles. At the same time, there are styles in which wooden wall cladding will look as harmonious as possible:

- Styles aimed at environmentally friendly finishing - from a typical country or village house to Japanese classics. In this case, wood is generally appropriate in any quantity, and all that remains is to choose a specific material, which can be either carefully processed or, conversely, extremely wild.

Eco-style in the interior of the bedroom

- In general, any ethnic style is best combined with wood, because national styles originated at a time when plastic and other modern building materials did not yet exist. Country does not even require serious processing - only maximum naturalness. In other cases, the finished wood surface can be painted if the original actually uses this approach.

- Nowadays, everything that is done “antique” is very popular, and renovation is no exception, the main thing is that it looks neat and is new. To create interiors in a retro style, designers specially “age” the material, making it heterogeneous in shape and size, adding small cracks, chips and other artistic defects.

Retro style interior design

- Wooden finishing boards are also relevant where the old is combined with the modern, which is typical for such styles as eclecticism and vintage. In this case, a wall covered with wood will not become the central element of the design, but it can look very harmonious against the backdrop of the latest inventions of mankind, such as a huge liquid crystal display. Despite their heterogeneity, such elements can be perfectly combined, but it can be difficult to find the necessary balance between them. To implement such ideas, it makes sense to turn to professionals.

When arranging private houses and decorating them, many owners give preference only to environmentally friendly materials. The most popular type of wall cladding for a residential building is finishing the facade with boards or other products based on natural wood.

This choice is determined not only by environmental friendliness, but by physical properties, since wood always has a beautiful appearance, is resistant to mechanical stress, retains heat and makes it possible to partially replace individual planks in case of damage.

Finishing the ceiling in a wooden house: unedged and floorboards, lining and plank

A board as a finishing material for the ceiling of a house made of chopped logs can become a real “highlight” of a log house. Ceiling cladding made of boards can be of any kind; let’s look at the most popular types.

There is no specialized board for the ceiling; modern finishing technologies have made great strides forward and any type of board can be mounted on the ceiling - unedged, classic flooring, thermowood boards.

Unedged board - antique finish

An unedged board is obtained by cutting a log lengthwise, the edges are not cut off, so the top and bottom surfaces are smooth, and the edges follow the natural curves of the workpiece. To decorate the ceiling, use an unedged board with barked and unbarked edges.

Stages of preparing unedged boards

- Logs of natural moisture are used to make boards 25 mm thick;

- If you decide to use a debarked board, then manually remove the bark from the edges using a scraper or a landing stage;

- The cleaned workpieces are stacked to dry in natural conditions;

- The required number of boards for cladding the ceiling are processed on a planing machine, after which they are carefully sanded;

- After installation, the boards are cleaned and treated with protective compounds.

An unedged board is indispensable when implementing a design project in any ethnic style.

Country and Russian, rustic and chalet, the “antique” concept – a ceiling made of uncut boards is appropriate everywhere.

The boards are stuffed in two layers so that the gaps in the first row are covered with the sheathing from the second. Beams in such an authentic interior are most often made from untreated logs or rough-hewn beams.

The cost of unedged boards for finishing the ceiling

The cost of unedged boards made from coniferous wood is less than from “durable” deciduous trees (for example, oak). Also, the price depends on the type of lumber, of which according to GOST 5. On average, the cost of 1 m3 of unedged boards is from 2 thousand rubles. up to 5 thousand rubles

Lining

Lining is a classic for the ceiling in a house made of chopped logs. Lining comes in several categories; the “extra” class material includes lumber of excellent quality. Such lining costs a lot, but the ceiling finish is very smooth, without flaws.

A tongue-and-groove board is lumber with a tongue-and-groove fastening, which is called “tongue and tongue.” When installing such cladding, there are practically no gaps left; if there are any, they are formed due to the profile.

You can diversify the appearance of a ceiling trimmed with clapboard using the following techniques:

- Partial ceiling finishing;

- Installation of lining in different directions;

- The use of two or more types of lining of different colors;

- Installation of decorative beams.

Which wood to choose to cover a house with unedged boards: how to do it yourself

More recently, such material as unedged boards was used for cladding buildings for utility purposes. But today this option is also common among residential buildings. To give the house originality and style, it is sheathed with unedged boards.

What is the attractiveness of this finishing method and how to do it yourself, these are the questions that those interested will receive an answer to today.