Vadim

26417 1 4

Vadim October 4, 2016

Each owner has his own idea of what his garage should look like. For one, a simple metal box is enough, and for the other, he strives to create a comfortable and warm home for his car, in which he can park the car, knock down a shelf if necessary, and meet with friends, a kind of mini-club of interests. Accordingly, the decoration of the garage inside and outside will be different. In this article I will try to highlight the most popular options for finishing garages today, with the emphasis on self-development.

External cladding of the garage.

Entrance to the garage made of paving slabs

In principle, any area finished with paving slabs is formed in the same way. First of all, prepare the site itself:

- They mark and dig a pit.

- Fine crushed stone 10-15 cm thick is poured into it, which is leveled and compacted.

- A cutting material is laid on top of the crushed stone layer: geotextiles, polymer film, roofing felt or other rolled materials.

- Fill the sand with a layer of 10-15 cm. It is also leveled and compacted, pouring water.

- Then they move on to laying paving slabs.

Attention! For the garage entrance, you must use tiles with a minimum thickness of 60 mm. Lay it only on a cement-sand mixture, which is prepared in proportions 1:3

Paving slabs 60 mm thick Source stpulscen.ru

Important points when laying paving slabs:

- the sand cushion is moistened before installation;

- masonry mortar is applied 1-2 cm thick;

- the tiles are leveled, leveling is also done between the cladding elements using the rule;

- leveling is carried out by hitting a rubber hammer; if one of the tiles is located lower than the others, a bonding solution of greater thickness is placed under it;

- installation is carried out from the garage door towards you.

The last stage is sealing the seams between the paving slabs. To do this, use the same masonry mortar.

The area in front of the garage made of paving slabs Source han-stroy.ru

No. 1. Plaster

This is one of the most budget-friendly, and therefore most popular, ways to decorate a garage space. This cladding method is almost ideal for the requirements described above. The list of advantages is significant:

- relatively low cost , and this is what you need for a garage;

- the ability to level and hide minor imperfections in the base, so preparatory work is greatly simplified;

- plaster does not take up useful space , unlike finishing that must be mounted on the frame, for example, drywall;

- wear resistance , strength, relative resistance to mechanical damage;

- fire and mildew resistant;

- resistance to temperature changes , moisture resistance;

- durability;

- application speed;

- simple but cute appearance .

No matter how much you would like to, it is still impossible to call plaster an ideal coating for finishing garage walls, and the following disadvantages :

- complexity of application and “dirty” installation process. You should only undertake finishing work yourself if you are 110% confident in your own preparation. Otherwise, it is better to entrust the work to specialists. If mistakes are made during installation of the plaster, then in the first winter, due to temperature changes, cracks will appear on the surface, and some areas will begin to peel off;

- The surface of the plaster gets dirty quickly , and it can be difficult to wash off the dirt. But this drawback can be easily eliminated. After applying a layer of plaster and drying it, the surface is treated with facade paint, which provides additional resistance to moisture, dirt-repellent properties and simplifies maintenance. You can choose any color, thus also solving the issue of the aesthetic side of the cladding.

Plaster can be applied to almost any base , but it will stick most firmly to walls made of brick, as well as aerated concrete and other concrete blocks. For work, it is better to take a cement-sand based composition.

Interior decoration of garage walls

Proper cladding of wall surfaces will eliminate the accumulation of excess moisture and mold. A wide variety of materials can be used for these purposes. The choice of finish depends on the base from which the walls are made:

- They try to plaster brick walls and additionally finish them with putty or bark beetle.

- Constructed partitions made of foam concrete or block are best sheathed on the inside with clapboard. Installation must be carried out by those who have the skill.

- Ceramic or ceramic tiles. These materials are considered the most practical, as they last a long period of time. This coating is easy to care for.

Neat shelvingSource stroy-frost.ru

For the garage, it is necessary to use raw materials that meet the following conditions:

- be fire resistant;

- durable;

- resistant to certain mechanical factors.

In case it is not possible to find a material suitable for its characteristics, it is necessary to treat the existing one with an anti-flammable composition. In most cases, this applies to plasterboard coverings, insulation and any plaster.

Please note that the selected finishing material should not absorb the odors of oils, gasoline, diesel fuel and other technical means.

Room for two carsSource garagetek.ru

Installation technology

Be careful during installation. When you use plastic lining, it is mounted with a tongue and groove, but wooden planks are secured with layering. Remember the algorithm.

- First of all, you need to make the crate. A wooden beam or a galvanized metal profile will suit you as the main material.

- Consider the placement of the slats. It depends on the method of laying the lining. When the planks are laid vertically, the sheathing should be horizontal, and if the lining is attached horizontally, the lattice should be made vertically. You can fasten the sheathing with self-tapping screws and nails.

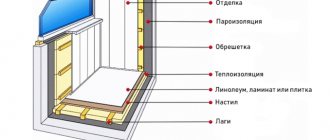

- Are you planning additional insulation? Then a layer of thermal insulation must be fixed between the slats. First, waterproofing is laid, then insulation, and only then vapor barrier. A good insulation option is mineral wool.

- Start sheathing from bottom to top.

- Try to fit the plates together tightly. When using wooden lining, craftsmen advise additionally filling the seams with a sealing compound.

- Wooden cladding must have a finish coat of fire-resistant varnish.

Stage 2. Inspection hole

Inspection hole

To repair a machine, it is advisable to equip an inspection hole. Even the most minor breakdown becomes a serious test if it is impossible to reach it without an inspection hole. In such cases, you have to go to a service station and pay a considerable amount for repairs.

In a word, the arrangement of the inspection pit will soon pay off. Below is the sequence of actions.

Step 1. First, the dimensions of the future pit are determined and markings are made. In this case, you need to maintain a balance - firstly, the pit should be spacious enough, and secondly, its width should be such that no problems arise when entering the garage.

Planning

The required width is 0.7 m; it will allow you to feel comfortable when carrying out repairs and at the same time leave enough space for parking maneuvers.

Planning

Regarding the depth, it depends on your own height, but again it is better to make it a little deeper than required - it is much easier to equip additional flooring than to redo the floor when deepening it.

Step 2. Once the marking is completed, you can begin excavation work. The most difficult thing is to dig a hole, because you will have to remove more than 9 cubic meters of soil.

Once the marking is complete, you can begin excavation work.

Step 3. The floor is leveled and covered with a 25-centimeter “cushion” of crushed stone. It is noted where the niches for the tools will be located.

Step 4. The walls can be poured with concrete or lined with brick. Concrete is more reliable, so it will be considered.

Brick wall laying

First, the floor is poured; a thickness of 7-8 cm will be quite enough. For reliability, you can pre-lay the reinforcement. Next, a wooden formwork is constructed, which will be gradually filled with mortar in tiers of 40 cm. The upper edge is reinforced with a metal structure, and lamps are installed.

Installation of formwork

Pouring concrete

Finishing the pit with tiles and installing lamps

Coating care

Caring for such a coating is easy. When work was carried out in the heat, it is necessary to moisten the surface of the coating for three days, the cracks are rubbed with a trowel. Further care is reduced to wiping the surface with a rag, vacuuming, and in case of dirt, cleaning with a damp sponge.

When work was carried out in the heat, it is necessary to moisten the surface of the coating for three days, the cracks are rubbed with a trowel.

Before plastering the inside of the garage, you need to decide on the choice of mixture and carefully prepare the base. Such finishing can significantly improve the appearance of the garage and its climatic conditions. It's easy to do it yourself.

Floor finishing

The floor in garages is precisely the surface that is always in use. Therefore, it must constantly withstand heavy loads from the car and heavy objects accidentally dropped from the hands. At the same time, not a single chip or crack should form on the floor. Requirements for fire and moisture resistance, of course, come first. Typically, a modern garage floor is multi-layered.

A self-leveling mass of sand-based concrete with reinforced mesh in the top layer and waterproofing is a practical and most commonly used garage flooring option.

Stronger, but a little more expensive than concrete, are paving slabs on a dense sand-gravel bed or road paving stones. For additional moisture resistance of paving stones, impregnants (special impregnations that have a water-repellent effect) are used.

An alternative to concrete mixtures is elastic polyurethane, epoxy or acrylic resins. Impact-resistant floor tiles laid out with black and white checkers will look very stylish.

To prevent slipping, the tiles should be slightly rough. It is better not to buy tiles with any pattern, as over time it will become very worn out and will not look aesthetically pleasing at all.

No. 8. Concrete

The most affordable option for finishing garage walls is to use concrete. True, provided that concrete was also chosen for the floor covering, you will end up with a not very attractive gray box, but the arrangement will not cost a pretty penny, everything will be reliable and durable.

Advantages:

- high strength ;

- resistance to fire ;

- high level of maintainability , so the occurrence of cracks and other defects should not upset you;

- low cost ;

- acceptable frost resistance ;

- normal moisture resistance , which can be increased by covering the walls with varnish or paint;

- resistance to oil , fuel and other liquids;

- high adhesion to brick and concrete blocks.

Minuses:

- complexity of work , labor intensity. In addition, the lack of necessary skills in finishing work can result in the appearance of cracks in concrete;

- installation of concrete pavement is a “dirty” process ;

- dubious aesthetics , but in a garage you can put up with this drawback.

About the ceiling and roof

We will definitely take on the floor and walls again, but first let’s talk about something else. Decorating the inside of a garage usually begins with the ceiling surface. This is where the water will drip if it rains well outside.

It is important to make a high-quality ceiling in order to have guaranteed protection against leaks

Let's talk in more detail:

- Waterproofing is especially important for garages that have a flat roof. And for brick garages, for standard concrete structures, it has exactly this shape (if we talk about standard garage cooperatives);

- It is logical that if the owner built a separate garage for himself on the territory of his own household, which immediately had a pitched roof, waterproofing work was also carried out during the roofing work;

- If the roof is flat, moisture can stagnate here. Because of this phenomenon, the owner will have to frequently replace roofing roll materials (these are used most often).

- How to cover the inside of the garage so that there are no problems with moisture? You can always use a special waterproofing compound that is designed to interact with the seams;

- Such compounds are used to treat joints on floor slabs, those places where these elements adjoin the walls. When applying the composition, the adjacent surface is also covered (100-150 mm is enough);

- After this, the joints should be glued with fiberglass reinforcing tape;

- Now the entire ceiling surface in the garage must be treated with a penetrating primer, which is universal. If necessary, this composition can also be used to treat the concrete base of a floor or wall;

- This waterproofing needs to be done only once - it will be enough for the entire period while the building is in operation;

- The composition itself can be either dry or completely prepared for use. In the first case, the substance is diluted with water - before doing this, you must carefully read the instructions, where everything is explained in detail.

You can decorate the inside of a garage with different materials

- You can easily achieve any decorative coating using such waterproofing. In cases where there is no need to insulate the ceiling, you can always use ordinary panels for cladding. Even simple polystyrene tiles will work perfectly here. And if you have the means, you can use ceramics (it costs a little more);

- Today there are options when ceramic tiles are used not only for covering the ceiling, but also for finishing the floor and walls. Concrete slabs are usually smooth, so applying this finishing material will be easy;

- Ceilings in garages are often painted (as are the walls - we already wrote about this) and plastered.

So, we advise you to study our material to the end - we will also consider a lot of interesting options for what the interior decoration of the garage can be like

.

Finishing materials: 6 operational requirements

The modern construction market is overflowing with a variety of finishing materials, with a wide range of prices and characteristics. When choosing how to decorate the inside of the garage walls, it is important to remember that the garage is a technical building, therefore the cladding is selected in accordance with its specific use. Materials intended for interior decoration must meet the following operational requirements:

- Mechanical strength . The coating of walls and ceilings must be as resistant as possible to mechanical loads of any type, both impacts and deformations (weight loads).

- Resistance to chemical agents . A garage is a place for storing and using a variety of fuels and lubricants (fuels and lubricants) intended for car repair and maintenance. Most of them (acids, oils, lubricants, fuels) are chemically active compounds and dirty the floor and walls more often than we would like. Resistance to chemical influences is an important condition for choosing a material.

The garage is a place to store a variety of auto chemicals Source me.ayokonseling.com

- Fire resistance . Most products used to service a vehicle are flammable. The logical step would be to choose the most fire-resistant cladding.

- Resistant to temperature fluctuations . A particularly important parameter if the owner does not plan to install heating. In this case, the cladding will have to withstand repeated vibrations during one season, which not all materials can do.

- Easy to care for . Heavy contamination is not uncommon for a garage space, so weak absorption of dirt, auto chemical products and odors, as well as ease of care for the surface of the floor and walls (and sometimes the ceiling), become a valuable quality.

- Easy to update . It’s good if it is possible to update or additionally protect the wall material using paints and varnishes.

Finishing materials should not create problems during maintenance Source roomadness.com

See also: Catalog of garage projects presented at the “Low-Rise Country” exhibition.

Arrangement plan

Car owners spend at least a couple of hours caring for them almost every day. If we talk about some major work, then you can generally hang out in the garage for the whole day, or even several. This is a serious argument to make the environment in the garage comfortable to stay in.

the garage is equipped with a mobile closed rack for tools

To do this, the internal space is divided into conditional functional zones. This process is much easier in two-story garages and buildings with basements, but in a small room you will have to think through every little detail. If you calculate everything correctly, then the car and things stored in the garage will never interfere with each other, the tool will always be at hand, and a child’s bicycle poorly secured to the wall will not damage the body. To make the event even more successful, it would be a good idea to draw up a plan for arranging your garage.

spacious garage equipped with hanging furniture and automatic gates

What questions should be displayed in it?

- Sketch a 3D drawing of a building structure.

- Select the type of gate with the opening method that suits you.

- Plan a place to park the machine in such a way that access to its systems and parts is unobstructed from all sides. To do this, you will need to organize fairly free passages.

- Look where you can put workbenches, shelving, a sink, a sofa.

- Think about finishing materials.

- Calculate the approximate costs for all items.

Now you are ready to start work and can safely start purchasing supplies and furnishings.

monolithic concrete floors for the garage are the most successful solution

Price for finishing a garage in Moscow and the Moscow region

It is much more difficult to independently choose, buy and bring the right reliable materials for finishing the garage and perform installation work yourself, although, of course, cheaper than entrusting all the work to professionals. But “cheap” has never been GarageTek’s motto, but quickly and efficiently – yes.

We work with projects starting from 100,000 rubles. Our clients usually invest from 0.5 million rubles in the complex turnkey finishing of a garage for 2 cars. Whether it is expensive or inexpensive, of course, is up to you to judge. We understand that not everyone is ready to spend a lot of money on decorating their garage, but we are glad that every year there are more and more people who are ready to invest in comfort and order.

Beautiful and convenient, in a word, the ideal garage from GarageTek is not that expensive, considering all the benefits that you get for this price. See this for yourself by ordering a clean garage from us right now, or first read the reviews about GarageTek that our clients left.

Stage 4. Shelves

Shelves in the garage

Like shelving, it is better to make shelves yourself.

Step 1. First, the number of shelves, their sizes and installation locations are determined.

Step 2. In accordance with the calculations, everything necessary is prepared:

- boards;

- hacksaw;

- bolts;

- level;

- iron pendants;

- hammer;

- dowels;

- screwdriver;

- electric drill.

Shelves in the garageShelves in the garage

Step 3. Using the mounting level, the mounting locations are determined. Next, holes are made and dowels are driven into them.

Step 4. With a certain step (in accordance with the holes made earlier), hangers with eyes are fixed on the shelf. They can be nailed with ordinary nails. The assembled shelves are hung on dowels.

It is worth remembering that hanging shelves should not be too long, otherwise they will break under the weight.

Shelf in the garage

Shelf in the garage

Stage 3. Shelving

Shelving

For ease of use, each tool should have its own place. Shelves and racks can be purchased ready-made, but they are quite expensive and do not always meet the needs of the car owner. Therefore, it is better to make the rack yourself. It seems difficult, but only at first.

Step 1. First, the dimensions are marked. Most “store” racks are equipped with shelves 1 m wide. This is not enough for spare parts, so the width needs to be made larger.

Rack dimensions

You also need to leave a gap of at least 20 cm from the floor so that there are no difficulties with cleaning the floor. It is advisable to perforate all shelves - this will give two advantages at once:

- this will make it easier to get rid of dirt and dust;

- The holes will provide good ventilation, which will prevent corrosion or moisture damage to the tools.

Prefabricated rack - drawing

Step 2. To make a rack, use a metal frame from a profiled pipe or a 30x30 corner. The parts are welded or bolted together, then the shelves are cut out. Usually they take boards for this, but the best option would be moisture-resistant plywood - it costs more, but will last a long time.

Shelving

Required tools and materials

To apply the coating you will need the same tools that plasterers use:

- trowel or trowel;

- ladle if the surface needs to be leveled);

- spatulas;

- brushes;

- plumb line, level;

- roller;

- mixer;

- rule;

- roulette;

- pencil;

- grater;

- masking tape.

You also need to stock up on the required amount of materials themselves:

- primer;

- dry or ready-made plaster mixture (or starting components).

Among the auxiliary devices you will need beacons, containers, construction cord, self-tapping screws, and protective equipment.

Layout inside the building

For the correct distribution of free space into areas for recreation, work, entry and exit, etc., a detailed plan is drawn up, in which all the details must be thought out.

There is no need to try with all your might to create something like a service station, or a warehouse for large spare parts, out of a mostly small premises.

Aisles should not be secured with empty cans and other containers for oil, gasoline, spare parts and other unnecessary debris.

You need to approach the arrangement of a workplace in the garage with special scrupulousness, caution and due attention to detail.

The inspection pit must be equipped with drainage along the walls and ends to collect condensate and melt water in winter. At the far end of the hole, make a small depression for general collection of water.

Cement plaster has proven itself well in finishing walls and ceilings. It is better to put something rubber on the floor screed; tiles, tape, etc.

To fix the plaster and give it aesthetic properties, it would be a good idea to prime it and paint it with facade paint. PVC panels or wooden lining can be used to decorate the ceiling.

Garage racks can be either metal or made of wood. Make a workbench and a small table from similar material.

In the recreation area, place an ottoman, or a corner kitchen set to which you can add a couple of stools or a bench.

Shelves in the garage can be made open, closed or combined and placed on them a TV, radio, electric kettle, the required minimum of dishes and other household utensils.

Garage drawers can be placed under tables and workbenches. This form will give them more functionality and make them more accessible for storing all kinds of small items.

Video description

About finishing walls with wooden lining in the following video:

- Simple installation with a minimum of construction waste (compared to classic plaster).

- Use as a base . Ceramic tiles can be fixed to the material (if it was used to level the walls) or relief plaster can be applied.

- Use as a partition . Drywall attached to a frame is suitable if you want to allocate space in the garage for a mini-warehouse or locker room.

- Changing shape . Drywall is suitable for forming not only flat, but also arched structures (after preliminary preparation).

Cladding garage walls and ceilings with plasterboard installed on a frame has its disadvantages:

- Unprofitable for a small room. The frame reduces the already small free space.

- Low impact resistance of walls. If it is planned to cover the plasterboard with a durable material (for example, ceramic tiles), the disadvantage disappears.

Sheathing with moisture-resistant plasterboard Source koon.ru

Sheathing with OSB sheets

As an option for finishing garage walls, you can find plywood and other wood-based materials. OSB (oriented strand board) sheets, which are made from a mixture of crushed wood and various binding additives, are well suited for constructing insulated walls. For covering garage walls (and ceilings), the best option is sheets marked OSB-3 or OSB-4. OSB-3 material is the most common choice for finishing a garage. It is characterized by good strength and average moisture resistance, therefore it requires additional moisture-proof treatment. OSB-4 is a more durable option with the following advantages:

- Long service life.

- Durability and resistance to temperature changes.

- Good moisture protection . The material does not deform in conditions of high humidity.

- Resistant to mold (contains antiseptic additives).

Types of repair work in the garage

Garage buildings need repairs, since this structure is negatively affected by many environmental factors:

atmospheric precipitation accumulates on the roof, leading to its damage; high humidity, sudden changes in temperature outside lead to damage to wall decoration and corrosion of metal gates; More and more inventory and equipment accumulates inside the building, so it is important to update storage systems from time to time.

How often do we repair a motorhome, and where do we start? First of all, it is important to determine what type of restoration will be required: major or cosmetic. Both of these types of operations have their own characteristics, which are extremely important to take into account in order to achieve the highest quality result on your own.

In any case, it is necessary to carefully analyze the condition of the building:

- the roof is subject to rotting, mold, mildew and other structural elements of the building;

- the walls are analyzed both from the outside of the structure and from the inside, because the updated repair of the walls will make the motorhome attractive, neat, and comfortable;

- the basement, pit, caisson are repaired when the first signs of fungus and mold appear, because these problems make storing food and preservation inside the building unsafe;

- the floor can also rot, become moldy, or sag under the weight of the car;

- The ceiling crumbles over time and the plaster chips off.

Choosing the best option

A special façade composition is suitable for exterior finishing.

Since the ceiling is usually not subject to impact loads and abrasion, it does not require a high-strength coating. But it is more difficult to plaster it than walls, so it is more convenient to use a composition that is easy to apply. If the room is heated, a gypsum mixture will do.

For walls you can purchase acrylic composition. The lower parts should be coated with a product with waterproofing properties.

For exterior finishing, a special façade composition is purchased. You can paint walls with universal products suitable for exterior and interior use. Indicators of moisture and frost resistance are selected taking into account the climate in the region.

How to repair a garage yourself - fill the floor

Repairing the flooring is an important step. The most common type of flooring used in garages is concrete because it is economical and durable. But still it has its drawbacks.

Concrete coating is not resistant to stains and wears out quickly over time.

To combat this problem, special paints and impregnating agents are used. Such protection for floors must be carried out at least three times a year.

To make the coating last a long time:

- Lay the concrete foundation:

- Clean and level the soil;

- Make a cushion of sand and crushed stone, carefully compacting the base;

- Concrete pouring is carried out using one part of cement and two parts of sand, adding the same amount of gravel to them.

To make the coating even, fill it along the beacons. To do this, you need to pull the cord and align them. Additionally, reinforcing mesh should be laid.

Once the mixture begins to set, it will need to be rubbed in. The final coating is allowed to be done only after a month. Some craftsmen advise making a blind area over the entire area of the garage and outside.

Advantages of lining

Let's pay attention to the key advantages of lining as a finishing material for a garage.

- The lining is environmentally friendly. It does not emit toxic compounds and is completely safe for health.

- The material is easy to process. For example, the lining is tinted, giving it almost any desired shades.

- This finish attracts with its durability. It practically does not rot. Even wood planks are not afraid of moisture, since they are subjected to special treatment.

- There is no need to specially prepare the surface for clapboard covering. However, craftsmen still advise making a special frame to speed up the installation process and make the final surface more durable.

- You can easily install hidden communications, such as wiring, under the material.

- If you finish it with clapboard, the room will acquire good sound and thermal insulation properties. Moreover, the method is economical. You immediately receive a finishing layer, as well as properties that are useful from a practical point of view.

It is noteworthy that almost anyone can handle the installation of lining, without special training or professional skills. The main thing is to remember useful recommendations. Now we will learn how to line a garage with clapboard correctly.

Tools for full work

Well, the decoration of the garage with your own hands is completed, all that remains is to select the working equipment. If for simple work you need: a basic set of keys and a jack, then for more complex work you will need special equipment. This includes:

- workbench with the required number of drawers;

- welding machine;

- an apparatus that separates air from oil, small particles, water and vapors;

- washing

This is just a preliminary set; everything you need to set up a garage with your own hands is up to you.

Separately, it can be noted that decorating the interior of a garage with your own hands is not the final chord in the work of “building a garage with your own hands.” The final stage can be the outer cladding of the building with cladding materials. Which ones? You decide. There are many options on the market and the final result depends entirely on you.

We really hope that we helped you deal with such a sensitive issue - how to arrange the inside of a garage with your own hands and now you can easily cope with it.

Characteristics of plastic lining

Plastic lining appeared on the market not so long ago, but has already gained popularity and trust. Such plates are made from polyvinyl chloride. Here are its main technical properties.

- The lining is not afraid of rotting, mold and mildew.

- The material is not dangerous for rodents, and microorganisms do not grow in it.

- Plastic provides a decent level of fire safety.

- This type of finish is easy to care for: the plastic lining is easy to clean, you can simply wipe it down or do a wet cleaning.

True, if we talk about thermal insulation and noise protection, plastic lining is significantly inferior to wooden finishing material.

We set aside a corner for storage

When arranging a garage, it is recommended to designate separate areas for storing certain items.

Fishing rods and tackle

The rod rack is made in two stages. First, a PVC pipe is attached to the wall below, inside which holes for handles are formed every 10 centimeters. Then foam rubber (or other similar material) with slots for fixing the rod is mounted on top.

It is recommended to use organizers to store gear.

Canisters and other containers

Cans and other similar containers are usually stored in a corner of the garage. But there is another, more interesting solution for storing such items. Under the canisters, you can organize a hanging shelf located above the level of the car owner’s head. This approach to arrangement will free up space inside the garage.

Construction materials

It is optimal if building materials are stored upstairs. Thanks to this, free space is not cluttered. To quickly organize a place to store building materials, just attach several metal beams or PVC pipes to the ceiling.

How to calculate mixture consumption

To calculate the flow rate, you first need to install three beacon strips on the wall; it is better to choose the most protruding place, the smallest and any other. Their distance from the wall is added up and divided by the number of selected beacons. This figure is multiplied by the area of the room, then the resulting number must be multiplied by the average consumption, which is indicated on the packaging of the mixture, often this is the number 10. As a result, you get a figure in kilograms, but you still need to add about 20% to it for reserve.

To calculate the flow rate, you first need to install three beacon strips on the wall; it is better to choose the most protruding place, the smallest and any other.

How to decorate the inside walls and ceiling

There are various options for materials that are used for interior wall decoration with your own hands. Therefore, they choose in advance what to paint the walls with, and also determine what is suitable for their cladding.

Plaster

Many people prefer to decorate their walls with plaster, as it can last for several decades. Its advantages include heat resistance and low cost.

Before applying the plaster mixture to the surface, you need to check the temperature inside the garage. It should not be lower than five degrees, since at low temperatures the plaster adheres less well to the wall.

PVC panels

Wall panels made of plastic are considered universal, as they are used for external and internal finishing work. The advantages of PVC products include a high level of protection against mechanical damage, as well as ease of maintenance and installation. Such panels can be installed in two ways: on a wooden frame or directly to the wall.

Tile

To create an attractive interior inside the garage, its walls are tiled. When arranging a garage, some people use tiles, as they cope with high humidity and temperature changes. The tiles are also easy to clean from dirt and do not become deformed. Its only drawback is considered to be low strength.

Plywood sheathing

Builders recommend using plywood only for interior decoration of garages, since the material is poorly protected from high humidity. To increase its moisture resistance, you will have to pre-treat the plywood with special protective agents.

Wood finishing

Among the most famous facing materials is wood. For cladding the walls in the garage, choose wood that does not contain toxic substances.

Drywall

Some use plasterboard systems with increased fire resistance and moisture resistance for cladding. Among the advantages of drywall are its low cost, ease of installation, flexibility and light weight. The main disadvantage of the material is considered to be its poor impact resistance, due to which the plasterboard surface is subject to mechanical damage.

Lining

When covering the walls of a car garage, some people use clapboards made of plastic or wood. The advantages of this facing material include:

- possibility of horizontal and vertical mounting;

- ease of installation of the product on a frame or wall;

- resistance to temperature changes.

Made of metal

The metal profile is considered durable and strong. It also copes with mechanical stress and temperature changes. However, despite all the listed advantages, builders do not advise using the material in high humidity, as it quickly rusts.

Corrugated sheet

This is a good material that is often used for interior wall cladding in garages. It, like metal, is susceptible to corrosion and therefore cannot be used at high humidity levels.

No. 2. Ceramic tile

Ceramic tiles are another material that almost completely meets all the requirements put forward, which is why this type of cladding is often found in garages. Its main advantages include:

- resistance to moisture and frost resistance , so that harsh garage operating conditions will not particularly damage the coating;

- fire resistance;

- hygiene . Dirt does not stick to the surface, and if something happens, almost any dirt can be washed off the wall with minimal effort;

- sufficient strength ;

- durability;

- wide choice and aesthetics. Ceramic tiles are produced in almost all colors, shapes and sizes, and manufacturers’ collections are replenished every season, so it will not be difficult to find a suitable material in this variety. Even the simplest plain tile will look great. From an operational point of view, it is best to go with clinker - it is stronger than ordinary tiles, although it does not have such a wide variety of colors.

There were some downsides :

- the cost of the material, as well as the need to pay for its proper installation if you can’t do it yourself;

- weight . Tile is a heavy material, so the optimal base for it would be brick walls;

- relatively long installation .

Since the main deterrent to the widespread use of tiles in garages is their price, you can use a trick by combining materials . The lower part of the walls is the most vulnerable, so clinker can be used here, and the rest can be made from cheaper tiles. You can make the bottom of tiles and finish the top with plaster. In this case, we get all the benefits inherent in tiled flooring, but we can save a lot.

Can a garage be beautiful inside: the rules of true masculine design

For those who are really involved in arranging the interior space of the garage, you can choose quite attractive ideas for decoration. With their use, the room will not lose its intended purpose.

Closed shelvingSource smyrnaviningsyellowpages.com

If the garage is finished with clapboard, then all wall brackets must be mounted with additional fastening. As for concrete partitions, this rule may not be followed. You can decorate the setting in absolutely any way. For example, in rooms with high ceilings, hanging technical furniture is installed. It is mainly made of steel. Thanks to the corrugation of the facade, the headset produces a good garage design.

Large garage as part of the houseSource desertstarconstruction.com

If you have a large garage, then it can be decorated in a variety of ways. Natural wood cladding is allowed. The walls can be left brick without finishing. This will create a “loft” garage interior style. For modern art connoisseurs, even in a technical room this option will be to their liking. A minimum of furniture and plenty of free space are welcome.

Large spacious garageSource wethepeopleoklahoma.com

Let's assume that there is a small garage. To prevent it from being too cramped, you have to think through different options for arranging the headset. Metal or wooden racks are used for this. In some cases, special brackets are installed in the ceiling that will securely hold light vehicles: a bicycle, a hoverboard.

No. 3. Drywall

Drywall has conquered not only residential premises, but also technical ones. So sheets of plasterboard are now often used to decorate garage walls. Naturally, only those that have additional protection from moisture and fire . You can recognize this material by its gray-green color, red markings and the name GKLVO.

Advantages:

- low cost ;

- light weight of the material , relatively simple and quick installation , absence of dirt, dust and debris during the installation process (not like plaster);

- thorough preparation of the base is not required - all holes, cracks and other defects will be hidden behind even and smooth sheets of drywall;

- when installing drywall on a frame, free space is created between the base and the sheets themselves, which can be used to place insulation ;

- fire and moisture resistance.

Flaws:

- when installing sheets on a frame, the area of the room will be reduced , so if the garage is small, carefully carry out the calculations and try to assess how the room will change after finishing. There is also an adhesive installation method, then the area of the room is not reduced, but the possibility of insulation disappears;

- the need for additional cladding , since the surface of the plasterboard is not very attractive, given the presence of seams. In addition, finishing will improve some of the performance qualities of the material;

- low impact resistance , but this disadvantage can be negated by using ceramic tiles as finishing - drywall will withstand such a load;

- to wash the surface of plasterboard from contaminants , so it is better to paint it with moisture-resistant washable paints - this is the simplest and most cost-effective option for finishing plasterboard walls.

Drywall in a garage can be used not only for finishing walls, but also for constructing partitions, as in apartments. If you need to allocate, for example, an area for a storage room or workshop, then you will only need to build a frame and cover it with sheets.

Stage 5. Garage workbench

The most convenient workbench for a garage would be one that combines shelving and a work surface. This way, the tools will always be at hand, which will significantly reduce the time spent searching for one or another of them.

Garage workbench

To make a workbench, a metal frame is assembled, on which a wooden tabletop with shelves is installed. The tabletop is covered with sheet steel so as not to damage the structure during operation.

The workbench must be equipped with several sockets for electrical tools, and also a fluorescent lamp must be installed, equipped with iron brackets for this.

Features of performing work using a robot plasterer

Some professional builders use a robotic plasterer to apply the compound. With the help of this modern invention, it is possible to significantly speed up the process of plastering a garage.

The advantages of the equipment include its simple operating principle. Before starting work, the robot is installed near the wall. Then the plaster mixture is poured into it, after which the robot is turned on. He will perform all subsequent actions independently.

The only thing that is required from a person is to timely fill the robot with the working mixture.