In some cases, for finishing, in addition to decorative and leveling plaster solutions, special ones are required that perform specific functions. These include barite plaster, designed to protect personnel in rooms adjacent to the X-ray room from radiation. What it is, its advantages, calculation methods and application technique are discussed in this article.

Scope of application

Due to the use in some institutions and industries of technical equipment that is a source of radioactive radiation, barite plaster is used:

- at industrial enterprises for premises where radioactive substances and materials are used in production processes;

- in laboratories and research centers where technology emitting gamma rays is used or radioactive materials are studied;

- in tomography and x-ray rooms, where equipment generating ionizing radiation (IR) is used;

- in dental clinics where dental photographs are taken;

- in residential buildings located where the natural level of radiation is unfavorable, or located in industrial areas with an increased level of radiation (in this case, it is necessary to install a protective coating over a layer containing barite);

- in sarcophagi and storage facilities for radio emission sources.

Scope of application of barite plaster

To shield X-ray and gamma radiation, expensive lead shields were previously used.

An alternative to lead protection has become X-ray protective plaster, the magnitude of the shielding effect of which depends on the proportions of the composition and thickness of the coating. An alternative to barite plaster coating is barite slabs.

Safety precautions

It is important to use personal protective equipment when applying plaster. Barite is poisonous, and its dust should not enter the body! Respirators, protective clothing, special glasses and gloves are required. A reliable finishing layer is always applied on top of the dried coating.

Barite plaster is a high-quality and effective means of protecting people from ionizing radiation. It is considered a highly specialized composition, therefore it is rarely used in everyday life. In order for the result of using the material to be complete, correct application and the choice of only certified plaster are extremely important.

Components of barite plaster

The main substance that gives the coating the ability to reflect gamma rays and x-rays (XR) is barite sand. The mineral component (sulfate salt BaSO4) in the form of sand, granules (fraction up to 1.25) can constitute up to 95% of the solution (at least 85% by weight in the dry mixture). The size of the fractions depends on the required thickness of the coating - the thicker the layer, the larger the grain size barite sand can have.

Barite dust is used very rarely due to its harmfulness; it is most often used to shield residential premises from natural background radiation. The substance is toxic, therefore, when applying the coating, protective agents are used to prevent dust from entering the respiratory tract, and a layer of ordinary or decorative plaster is applied on top of the protective coating.

Barite sand is white in color and has a specific gravity of 4.48 kg/cm3, which explains the higher weight of the X-ray protective composition compared to other plasters.

The binder in the solutions is high-quality cement (not lower than M300), since barite sand adheres less reliably to low-grade cement. In the latter case, the mixture crumbles, crumbling even when laid. The compositions harden slower than mixtures made with ordinary sand. If it is necessary to accelerate hardening, and the water resistance of the coating does not matter, use magnesia cement.

Thus, X-ray protective compounds are:

- cement-barite;

- magnesium-barite;

- barite concrete.

Polymers or other plasticizers are added to the composition to increase the working properties of the mixture - plasticity, workability. When making the composition with your own hands, use PVA less than 3% of the weight of the SS (per 1 kg of mixture - 30 g of glue).

Factory SS is diluted as follows - 200 ml of water per 1 kg of powder. The mixture, compiled independently, is diluted gradually, bringing to the desired consistency by adding liquid.

Baryte sand

About barite Barite is natural barium sulfate (BaSO4). The main technological properties that determine a wide range of industrial uses of barite are high density (4.3-4.6 g/cm3), chemical inertness, low hardness (low abrasiveness), the ability to absorb X-rays, high barium content, and whiteness. Barite is used mainly as a weighting agent for drilling fluids (70% of world consumption); serves as the best basis in the production of color paints; special cements that are resistant to aggressive environments; “heavy” concrete used in the foundations of heavy structures when laying pipelines in wetlands and under water; in road construction; to provide a durable and flexible surface layer for airport walkways. The chemical industry uses barite in the production of barium salts used in various industries. In addition, barite serves as the cheapest protective material in the construction of “burial grounds” and reactors in nuclear energy (Akhmanov et al., 1995). The product offered by Chemical Industry CJSC is barite concentrate (sand), produced at processing plants from mono-barite ores, crushed and enriched by the dry method (gravity barite) or the flotation method (flotation barite). Application of our products Oil and gas industry and geological exploration - weighting agent for drilling fluids for deep and ultra-deep drilling. Cement industry – production of highly sulfate-resistant, heat-resistant and weighted oil well cements. Chemical industry – production of all barium-containing compounds, salts and preparations of barium. Glass industry - production of special glasses. Barite glasses are very clean, transparent, shiny and have good optical properties. Metallurgy - an intensifier of the process of obtaining ferroalloys, an additive for the smelting of barium-containing alloys, as a flux in the smelting of yellow copper and in the aluminum industry in the production of pure alumina oxide. Road construction - filler. Ground barite is used in a mixture with latex (6%) and hot asphalt (47%) as overlays for runways and general roads to provide a durable and flexible layer. Paint and varnish industry - production of white pigment (lithopone), high-grade zinc (mixed with ZnO and ZnS) and lead white and other paints, white-burning products, tiles, etc., in high-grade enamels used in reactors for anti-corrosion protection. Rubber-technical - an inert or weakly active filler. Asbestos industry - production of friction materials. Nuclear industry - shields for radiation protection: barite concrete, including 80% barite and 10% iron oxides, is a good protective material against gamma radiation. Being an integral part of plaster for the walls of X-ray laboratories, it acts as protection against the harmful effects of X-rays (barite plaster).

Manufacturers and characteristics of ready-made mixtures

The number of manufacturers of materials containing barite is not as large as manufacturers of other types of plaster compositions.

The main ones are:

- Alphapol.

- Aksit.

- Flagship.

- Reference.

- Sorel.

- Roshi.

- Barite concrete.

- Runit.

More often, batches of ready-made SS barite concrete are produced for individual orders.

Dry mixtures offered by manufacturers differ in composition, properties, and price:

- Sorelbarit - contains a magnesium binder, barite chips, plasticizers (sold as a two-component material - CC + hardener), reinforcement due to basalt fibers, application of a layer of up to 3 cm per pass is allowed.

- FullMIX – M400 cement, barite chips, plasticizers, per pass – up to 10 mm.

- Radiation protection Russia.

- Runit.

- Alfapol SHT-Barite – barite crumbs with magnesia

Dry mix options

Currently, industrial companies produce several types of barite plaster, differing in composition, price and physical properties.

| Brand name | Chemical composition | approximate price |

FullMIX | Barite chips, cement and plasticizers | Bag 25 kg – 64–70 rub. |

| SOREL BARIT M150 | Barite chips, magnesium binder, polymer plastic additives | 5 liters of hardener + 25 kg of mixture – 1200 rubles. |

| Roshi | Barite chips, cement and plasticizers | Bag 25 kg – 750 rub. |

| RUNIT | Barite chips, cement and plasticizers | Bag 25 kg – 780 rub. |

| ALFAPOL ST-BARIT | Barite chips + magnesia | Bag 25 kg – 900 rub. |

To protect against strong radiation, Baritobeton M200 is used; the maximum thickness of a disposable layer increases to 6 cm; it can be used both for plastering walls and ceilings, and for pouring floors and creating interior partitions using formwork.

Barite concrete M200

Prices for popular types of plaster

Plaster

Advantages of barite plaster

Main advantages:

- the ability to screen different types of AI;

- low cost of coverage;

- availability of components on the market;

- ease of application;

- solidity of the coating;

- possibility of making it yourself;

Almost all of the disadvantages are easily overcome:

- with a large thickness of the protective layer, additional preparation will be required (production of formwork);

- toxicity of the main component;

- high specific gravity of the coating;

- manual application only (mechanical excluded);

- the need to install reinforcing mesh;

- the need for additional coating of a layer with barite;

- Each previous plaster layer is primed to increase adhesion.

Material advantages

This material has many advantages, so it is an excellent replacement for lead sheet.

Among the main advantages are the following:

- high protection of people from X-ray radiation;

- availability - you can buy the mixture at any hardware store, so there is no shortage of it compared to lead sheets;

- low cost - this mixture costs much less than lead panels, which makes it more affordable.

As for the disadvantages, this material can be considered almost ideal, since there are no particular disadvantages. The exception is that to obtain good protection from harmful radioactive radiation, the thickness of barite plaster must be quite large. In the case of X-ray rooms, the finishing layer must be at least 25 millimeters, while lead panels can be only 1 millimeter.

How to prepare barite plaster

You can prepare a protective composition at home yourself. Fortunately, all components (including barite sand) are available in stores.

However, it should be borne in mind that home-prepared/made X-ray protective compounds have disadvantages:

- the consumption of materials will be large, and there will be a lot of waste;

- the protective properties will not be the same across the entire plane of the wall;

- difficulty in caring for each layer, and the technology must be followed, following each point of the instructions, otherwise cracks or peeling will appear;

- making the solution, applying the coating, and caring for each layer takes a lot of time.

There are few advantages:

- low cost;

- possibility of self-production from available materials.

If possible, it is more rational to purchase ready-made formulations that just need to be mixed before use.

Certificates are not issued for homemade protective plaster. For a ton of solution with a density of 2700 kg/cm3 take:

- Portland cement – 60 kg;

- barite (dust, sand) – 800 kg;

- regular sand – 55 kg;

- PVA glue – 5.5 liters;

- water in the amount necessary to create the desired consistency (per 1 kg of cement no more than 0.9 l).

Composition of components for preparing barite plaster

If calculations show that the layer should be more than 50 mm, it is more rational to use a barite plate for protection. Dry components (barite sand and others) are mixed, then added to water in which PVA is dissolved.

The procedure for preparing a mixture of barite concrete m200

The protective mixture is used for:

- pouring floors;

- production of blocks for laying partitions and production of protective fences for X-ray equipment;

- performing a protective coating using formwork;

- plastering works.

The barite concrete mixture goes on sale in the form of two components:

- liquid hardener;

- barite concrete powder, which contains polymers.

The components are placed in a concrete mixer container and mixed by adding water. The amount of water depends on the purpose of the solution. The solution is made thinner for plastering, and thicker for floors and walls.

The prepared mixture is used for 45 minutes before the start of polymerization, so the amount of concrete and the workers involved in laying it is determined in advance.

Making your own barite mixture

To reduce costs, you can prepare a protective mixture for finishing walls and floors yourself. You will need:

Barite concentrate (barium sulfate) grades KB-3 or KB-5. Sold in bags of 20-25 kg or in big bags of 1t.

Cement M400

Water

Concrete mixer or drill with mixer attachment + mixing container

Proportions of barite plaster: mix 1 part of cement with 4 parts of barium sulfate, add water in a ratio of 0.2 liters for each kg of cement. Mix the solution in a concrete mixer or using a drill. It is allowed to add lime paste (up to 25% of the volume of barite) to improve the mobility of the solution.

Important! During work, use a respirator to protect your respiratory tract.

The properties of the prepared solution are retained for 1-2 hours, so the composition is mixed in portions that can be consumed during this time.

Requirements of sanitary authorities for the application of barite plaster

X-ray protective plaster is a special composition that protects the health of people in the room with the equipment and in those adjacent to it, therefore, according to SanPin 2.6.1.1192–03, it is subject to certain requirements that it must meet.

Firstly, during design, the thickness of the protective lead screen is calculated and taken according to the coefficient of attenuation of radiation radiation at the maximum power of the equipment beams. According to this thickness, the thickness of the protective plaster layer with barite is determined. Approximate data are given in the table.

Since protective mixtures of different modifications differ, an individual approach is needed in each case. For example, at a voltage of 100 kW at the anode of the emitter, the lead equivalent thickness of magnesia-barite plaster in the X-ray room is:

The parameters of the lead shield are specified in the project. If the equipment used changes, recalculation is carried out. Any changes must be agreed with the supervisory organization. According to the requirements of GOST 12.4.217–2001, tests are carried out for each batch of protective mixtures (in production) and for laid plaster coatings, information about which and the results are recorded in protocols.

General concepts

This type of finishing material is a dry mixture, the components of which are:

- barite sand (produced by grinding the protective mineral into sand, where the grains have a maximum diameter of 1.22 mm);

- finely ground cement of the highest category, which acts as a binder;

- plasticizers.

Barite plaster has the property of protecting against radioactive radiation.

It is the presence of such a specific mineral (can reach 95% of the total composition, the rest is replaced by silicon sand) that determines the specific protective properties of blocking X-ray radiation. Lead has the same characteristics, but this resource is much more costly in financial terms. That is why in rooms with the presence of X-rays, walls and other surfaces are plastered with barite solution.

There are certain conclusions that indicate the harmful effects of barium sulfate on the human body, in particular leading to diseases of the pulmonary system. However, it should be understood that barite dust is dangerous. Therefore, to work with such a resource, it is necessary to attract highly qualified workers who have experience in this field and can reduce the danger of the mineral to a minimum.

This type of plaster is not environmentally friendly

Technology of plastering with barite plaster

In general, the process is carried out in several stages:

- preparation of the base;

- installation of reinforcing mesh;

- installation of special beacons that allow the solution to be applied evenly to the entire surface, or formwork;

- plastering;

- maintenance of installed finishes;

- finishing coating.

Such features of the coating with barite, such as high specific gravity and high cost, require saving the solution and ensuring the strength of its adhesion to the base, so the preparation of the base is carried out especially carefully:

- remove all old coatings;

- repair potholes and large cracks;

- After cleaning from oil stains, fungus, grease, removing unnecessary metal products and dust, the base is primed twice, drying each layer.

After the primer has dried, the walls are measured. Determine the thickness of the coating and calculate the required amount of materials.

Barite X-ray protective plaster is applied:

- manually;

- at a temperature of +15 – +35°С,

- at humidity up to 75%,

- layers no more than 10 mm.

The place of plastering work is shaded and protected from precipitation.

Plastering walls

To obtain a high-strength coating, reinforcement is used. The mesh is attached to the base with screws or dowels. When installing and fastening the mesh, stretch it as much as possible, avoiding sagging. Every 15 mm of the thickness of the X-ray protective composition must be reinforced.

Main stages of plastering:

- Apply a starting layer of 10 mm evenly onto the base using a wide spatula. Having applied a layer, “line” the surface with the corner of a spatula to increase its adhesion to the next one. Dry, cover with a primer, which is dried for 3 - 4 hours.

- Perform a second layer of 5 mm (all subsequent layers will be the same thickness). After partial hardening, a second reinforcing network is attached to the wall.

- Further layer-by-layer application of the solution is carried out, reinforcing and drying in time, until the coating reaches the specified value.

The finish is dried until it gains strength for at least 7 days, ensuring that the surface remains moist (covered with film) to prevent the formation of shrinkage cracks.

Technology of work execution

The peculiarity of barite coating is its large thickness: from 1 cm to 0.5 m or more. If barite plaster is used, the technology for applying the protective layer depends on its calculated thickness. The work is carried out in the sequence established by the regulations in stages. As when laying ordinary plaster, the surface to be covered is prepared: cleaned of nails, screws, dirt, deposits, cracks and potholes are sealed with cement-sand mortar. There are features that need to be taken into account when laying a barite screen.

Main stages

The prepared surface is cleaned of dust and degreased. For better adhesion of the solution, the base is primed.

Stages of work:

- Mesh reinforcement. Required for multi-layer plastering. The frequency of installation is 15 mm of barite layer, the fastening pattern with self-tapping screws and nails is 50x50 cm, without sagging.

- Applying the first layer. Its thickness is up to 1 cm. The material must be distributed evenly, avoiding gaps. For better adhesion to the other layer, you can use a spatula to draw stripes along the freshly laid mixture. Allow time to dry, coat with primer and leave for 2-3 hours.

- Application of the second and subsequent layers with a thickness of 5-10 mm. They are also applied with periodic laying of the plaster mesh and primer treatment.

- Laying the finishing layer. Strengthening lasts 7 days, after which the surface is sanded for decorative finishing: paint or wallpaper.

The drying time of the layers depends on the ambient temperature and the thickness of the applied layer.

Features of applying plaster

The technique and technology of applying barite plaster differs from laying simple mortars for leveling surfaces. The specificity is due to the large specific gravity of the dry mixture and the need to form multilayer coatings.

Features of applying barite plaster:

- optimal conditions: ambient temperature +15…+35°C, humidity level 75%;

- the mixture is applied in a layer of up to 1 cm without the use of equipment for spraying the solution, i.e. manually;

- the place of plastering work is protected from precipitation and shaded;

- the use of formwork technology is required if the design thickness of the coating is ≥2 cm;

- You need to install a concrete screed on top of the concrete barite floor to strengthen the base for X-ray equipment.

When plastering the floors, the barite solution is introduced into the next room by 2 cm. The minimum layer for ceiling surfaces is 50 mm.

Finishing the walls

After gaining strength, the surface is sanded with sandpaper or a grinder (protecting the respiratory tract with a respirator). In addition to decorative functions, the finishing serves the purpose of protecting the room from barite dust entering the air. Wallpapering, thin-layer decorative plaster, painting, and plastic panels are used as finishing materials.

Technology of pouring barite plaster in a thick layer

When the thickness of the barite plaster finish is > 2 cm, the application technology using formwork allows the work to be completed faster, better and more reliably. Formwork panels are made from sheet plywood or boards. The installation of formwork is preceded by the installation of reinforcing mesh. In this case, the height of the caps of the fastening elements is taken equal to the total thickness of the coating, in other cases - close to the height of the mesh installation.

Board formwork

To fill the plaster coating of the wall, you can make panel formwork from boards (edged) about 20 mm thick.

Manufacturing sequence:

- Measure the wall to calculate the dimensions of the formwork panels. If the length of the wall is up to 3 m, you can make one long shield. If the wall length is 3 meters or more, two panels are made, for example, one and a half meters long. The rational height of the shield is up to 100 cm.

- 30 x 50 mm slats are used as vertical stiffeners, installing them no further than a meter from each other. Attach the slats, pressing the boards tightly against each other. For pressing, stops and wedges are used. Diagonal slats are added to the vertical slats to give rigidity to the shield.

- After assembling the shield, the formwork is turned over with the front (working) side up to check the formed plane. If the boards do not form a single, even plane, they are unfastened and, after correcting the position, fixed again.

- The manufactured shield(s) are installed against the wall, resting on the dowels to which the mesh is attached. Check verticality with a level.

- Fix the position using corner supports.

- The plaster solution is poured into the formwork from above, making sure that it fills the cavity evenly. It is advisable to use vibrators. If they are absent, tap the formwork boards with hammers from the outside. This is how the air bubbles formed during pouring are “expelled.” This is done until the settling of the poured mixture stops.

- The formwork panels are removed when the poured mixture has hardened (not earlier than in a week). Doing this earlier is risky, as peeling or cracks may occur. The removed formwork panels are raised higher and fixed. Then the next section is filled with barite composition.

- The very top of the wall is plastered by hand, applying layers with a trowel or spatula.

- The resulting protrusions of the solution are rubbed or chipped off.

Floor protection

Since the strength of the concrete floor is less than that required for installing heavy X-ray equipment, a concrete screed is made on top of the X-ray protective monolith. This is a feature of barite concrete floors. Before starting work, the floor surface (usually reinforced concrete slabs) is leveled, cleaned, and beacons are installed. The applied solution is leveled using the rule.

Plastering the ceiling

It is better not to take on this work for people without experience.

The use of goggles is mandatory to protect your eyes. Plastering is performed sequentially:

- The reinforced concrete floor slab is prepared for plastering, cleaning it from dirt and dust. Cement mortar is used to seal cracks.

- After drying, prime the surface twice with a roller, rolling in transverse directions. To increase adhesion, add a ladle of cement lait, which has a consistency similar to liquid sour cream. After hardening, the milk has a fringed bottom surface that increases adhesion.

- Beacons are made from a mass of solution with barite on the ceiling or metal slats are installed on dowels.

- Plastering is done in the same way as plastering a wall.

sealing cracks in the ceiling

priming the ceiling with a spray gun

installation of beacons

plastering the ceiling

Expert advice

Expert recommendations.

- Barite mortar, the coating technology of which involves the use of reinforcing mesh due to its high friability, is applied in layers when plastering rooms with a high radiation rate.

- The size of the layers must be at least 12 mm.

- The reinforcing mesh is applied in a couple of rows with different cell sizes.

- Floors and walls are plastered with a maximum thickness of 30 mm, ceilings - 50 mm. The walls need to be lined on all sides.

- When finishing the floors, the material is introduced into the next room by at least 20 mm.

- When using reinforced concrete slabs, a protective layer of 65 mm is applied.

The working process is carried out at 15 degrees and high humidity. After finishing, these requirements are maintained in the building for 2 weeks. This will create a consistent acquisition of strength and will not allow the layers to crack and crumble.

Since the barite composition is used to protect people from radiation, you must strictly follow the working technology when applying it, buy only proven materials with a proven effect, and do not use plaster without experience and training.

Barite plaster: consumption and calculation methods

The main protection against radiation sources is lead shields. Their thickness is calculated during design and indicated in the project. The thickness of barite plaster and the consumption of materials are recalculated based on these parameters (in lead equivalent). And here you need to be careful, since the mixtures differ in the content of barite sand (its content in the composition is from 85 to 95%).

In the accompanying documentation for plaster mixtures, manufacturers provide data for conversion to lead equivalent and the approximate consumption of the mixture accordingly. For preliminary calculations, take a mixture consumption of 20 kg per square meter. m of coverage with a layer of 1 cm.

If the thickness of the barite plaster layer is 25 mm, the consumption will be 20 kg x 2.5 = 50 kg. The total area of the wall is calculated simply. The total consumption is obtained by multiplying the number of squares of area by the resulting composition consumption per 1 m2.

Properties and technical specifications

The main property of all types of barite plasters is the ability to block harmful gamma rays and X-rays. The average technical parameters of barite plasters are as follows:

- color - gray or white;

- binder - cement;

- minimum layer thickness - 0.5 cm;

- moisture-holding capacity - up to 90%;

- application time of finished plaster - less than 2 hours;

- radiation safety standard - class 1;

- drying time (depending on the thickness of the layer) - from 7 hours;

- flammability class - NG.

General recommendations

There is no rush to perform special protective barite plaster. The work is carried out carefully, responsibly following technology.

It is important to ensure a uniform strength gain, for which there must be enough moisture in the solution for the entire hardening and strength gain process so that cracks do not occur. To do this, porous substrates, such as brick walls, are wetted before plastering.

At air temperatures above 22°C, the plastered surface is also moistened overnight after completion of work.

It is forbidden to use a fan when plastering

Do not use fans or other drying methods. You cannot make grooves in plaster finishing with barite, otherwise the protective functions in these places are impaired. All communication wiring is done before applying the mixtures.

When preparing the mixture, it is advisable to first test its ability to adhere to the walls. If the solution does not adhere well to the base, a small dose of cement is added to it.

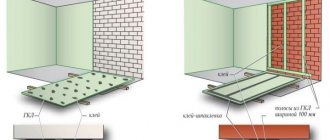

Barite plasterboard

Special plasterboard sheets are also used as radiation protection in medical offices. The base is a plate made of a mixture of gypsum and barium sulfate, covered on both sides with thick cardboard.

Such gypsum boards are produced under the Safeboard brand. Dimensions – 2500*625, thickness – 12.5 mm. Each sheet is tested in production to ensure compliance with the declared protective properties.

Barite plasterboard is used for leveling walls, erecting partitions, and installing suspended ceilings.

The advantages of this solution:

- Putty Knauf Safeboard

speed and ease of installation;

- light weight compared to lead plates and less load on the walls;

- material efficiency confirmed by factory control;

- environmental Safety;

- lower cost than lead;

- improving sound insulation in the room;

- the ability to create curved surfaces.

Expert opinion

Sergei Shablovsky

Plasterer

To seal the joints between the sheets, you should not use ordinary plaster, but a special gypsum mixture, for example Knauf Safeboard Spachtel (pictured above). Each joint is sealed, even if several layers of gypsum board are installed.

X-ray protective plaster

Together with other types of protective materials, for example, sheet lead, antistatic linoleum, X-ray protective rubber, X-ray protective plaster is used to ensure that workers and visitors to X-ray rooms, as well as employees working in adjacent rooms, are not harmed by radiation.

Materials containing barite sand are capable of absorbing scattered radiation and serving as a screen around the perimeter of rooms where there are radiation sources.

Barite plaster, the quality of which is achieved through strict adherence to the technology of preparing the solution, applying the composition to the base, and hardening conditions, will be an affordable, cheap alternative to expensive lead screens.

Plaster for X-ray rooms

Protecting medical workers and clinic visitors from the harmful effects of gamma rays is the main purpose of coatings based on barite sand. X-ray protective plaster is a finishing material that protects against penetrating rays.

X-ray rooms and adjacent rooms are plastered with concrete barite if the following conditions are met:

- the thickness of the protective layer is not less than 2.5 cm, which corresponds to covering the surfaces with 2 mm lead plates;

- strict adherence to the instructions for preparing the barite mixture, technology, and application regulations.

The health and lives of people who, by virtue of their profession, are near radiation sources for a long time depend on the fulfillment of these conditions. From an economic point of view, barite plaster has an advantage over lead screen. With equal protective properties, concrete barite is cheaper, despite its greater consumption.

Market offers and price range.

Without exaggeration, the sales leader among such mixtures is fullmix barite plaster from the Runit company. Its cost is the lowest in the price range. Despite this, fullmix special X-ray protective barite plaster is of sufficient quality, and its composition is based on a concentrate of ground barite with large fractions, which indicates the safety of the composition. Among other market representatives, we can highlight mixtures from brands:

- Aksit;

- Flagship;

- Alphapol;

- Sorel;

- Reference;

- Roshi.

This is also barite plaster, which you can even buy online. The price for 1 kg of the mixture varies depending on its composition, so you can find different options.

Since the demand for this type of building material is modest, buying it in a regular retail chain or on the construction market is a real problem. It is much easier to order a whole batch from a manufacturer or distributor. At the same time, you can be confident in the protective properties of such a composition, in the fact that it was not a falsified product that was purchased, but barite plaster. The price for it will most likely be wholesale.

The total cost per m2 of coverage depends on many factors, taking into account not only the cost of raw materials, but also the work of specialists, consumables, including painting mesh, and depreciation of the equipment used. In addition, the price range in different regions per sq. m. m. may differ dramatically.

For example, in the metropolitan area, for a square meter of treated surface they will demand an amount of 10 USD, in the outback the payment will be much lower. Moreover, the technology for applying barite plaster does not require specific professional construction skills.

Application area

The main components that increase adhesion and increase the required viscosity are ground barite, as well as specialized polymers. This composition resists high humidity well, lays smoothly and easily on the walls.

There is also a significant drawback to barite plaster - toxicity

Most often, barite plaster is used in medical institutions where CT, MRI and X-ray machines are installed. Such surface finishing is necessary to protect the human body from X-ray radiation.

The use of barite plaster is mandatory:

- In industrial premises.

- In research centers.

- In radiochemical laboratories.

Years earlier, it was replaced with special lead plates, but they are difficult to install and have a fairly high cost.

The most common places where barite mixture is used are medical institutions

Sometimes plaster is applied to the facades of houses that are located in areas with high radiation, as well as in industrial areas. X-ray protective plaster contains barite.

This component itself is toxic, for this reason its use near people’s places of residence is considered unsafe. If the composition is nevertheless used in such places, then the application of a special surface protective layer is required.

Flaws:

- Weight. The weight changes especially dramatically in the finished form - after applying the composition to the wall surface.

- Typically, a large amount of waste is left behind.

- Requires a large number of layers to be applied to the walls.

- The protective layers may be distributed unevenly, which reduces the level of protection.

- A large amount of cement is required.

- If not properly maintained, plastered walls are subject to deformation and visible changes.

When applying barite plaster you need to wear a respirator.

Which mixture to choose

Consumer demand for this finishing material is low, but the most popular brands can be identified:

- Aksit.

- Alphapol.

- Flagship.

- Reference.

- Roshi.

- Barite concrete.

- Runit.

A large number of companies produce barite mixture, but few follow the technology

The basic rule is that you need to buy only certified products. This is the only way to reduce the risk of purchasing a counterfeit.

Pay attention to the amount of barite in the plaster; the higher the percentage, the better. Some manufacturers' mixtures consist of 95% barite, which is a good indicator.

In order to correctly calculate the required amount of plaster, it is important to determine its consumption per square meter. And the consumption of the mixture for each square meter completely depends on the intensity of the specific radiation.

An average thickness of wall material of 3 cm will require 50 kg of plaster mixture for 1 m². To accurately determine the thickness of the applied material, you can use special tables that present the parameters of the lead equivalent.

Features of working with the material

If any equipment that emits a large amount of radiation is used in the room, then the walls should be treated in several stages. In this case, each subsequent layer should be applied only after the previous one has completely dried. In addition, the thickness of each layer must be at least 12 millimeters. All work should be carried out very carefully, since due to the high flowability of the mixture, the protective layer can turn out to be quite fragile and short-lived. Also, do not forget to use protective equipment and special clothing when preparing the mixture and working with the solution. The thing is that barite is a toxic substance, so you should be extremely careful with it.

Tips for choosing

By what criteria are barite plasters selected? There are no special recommendations, since the finished mixture is prepared at the factory by mixing all the components, which makes it impossible to determine the quality of the material. It will also not be possible to purchase all the components and prepare the mixture yourself at home, because it will be very difficult to calculate the exact proportions of the components yourself.

The best option would be barite plaster, the quality certificate of which comes with the mixture and confirms that it was manufactured in accordance with all standards. If you decide to make the mixture yourself, then in this case the optimal proportions should be determined based on the thickness of the layer you want to obtain. It must be remembered that the minimum thickness is 25 millimeters.