Expanded clay has excellent heat-insulating properties. It is actively used in the process of constructing foundations, constructing floors between floors, and even for constructing attics. Just 10 cm of expanded clay crushed stone layer is warmer than 30 cm of wood and 100 cm of brick wall. Expanded clay is also ideal for installing heated floors. It is only important to use this unique material in a screed technologically correctly - and there are three such options.

To get started, here are a couple of introductory videos:

- 2 Types of expanded clay backfill for screed

- 3 We use expanded clay in the screed: 3 options

3.1 Semi-dry screed with expanded clay: insulate and raise the floor

- 3.2 Concrete screed with expanded clay, or expanded clay concrete

- 3.3 Dry screed with expanded clay: modern technologies

Advantages of expanded clay screed

If you compare expanded clay screed with traditional concrete, you can find only one serious drawback: the impossibility of laying a thin layer, which can be important for low ceilings. The disadvantages could also include lower strength than concrete, but it is quite sufficient for residential premises.

But screed with expanded clay has many advantages. These include:

- floor insulation on any base - soil, reinforced concrete slab, wooden flooring. And, as a result, increased comfort and reduced costs for heating the house;

- ensuring sound insulation between floors;

- the ability to level out any level differences;

Such a screed can cover differences of up to 10 cm or even more Source chonemuzhik.ru

- reducing the cost of leveling the base;

- the possibility of laying on insufficiently strong and reliable foundations, since expanded clay screed is much lighter than cement screed and therefore does not create a large load;

- the possibility of laying communications under the floor in a thick layer of screed.

All this together makes expanded clay rough coating much preferable to concrete. There is only one limitation for its use - this is the high probability of moisture getting into the thickness of the dry screed. That is why it is not recommended to install a water heated floor in it. Expanded clay gets along well with electric and infrared.

For reference! Expanded clay itself is not afraid of water and is not destroyed by its influence. But stagnation of moisture is dangerous due to the appearance of dampness in the house and the formation of mold.

What kind of material?

Expanded clay is understood as porous granules of fired mineral material. Such granules are obtained by sharply heating the raw material - clay. When quickly heated, the moisture and dissolved gases contained in the clay expand sharply, creating a foaming effect. As they harden, pieces of pore-filled clay acquire a kind of crust, which reduces the hygroscopicity of the material.

The advantages of expanded clay include:

- low cost due to cheap raw materials and simple manufacturing technology;

- light weight, which is extremely important when installing screeds on floors with weak load-bearing capacity;

- ability to use on floors with significant height differences;

- high thermal insulation properties;

- fire safety;

- durability;

- environmental friendliness.

In addition, expanded clay floor screed perfectly cuts off extraneous sounds.

The only disadvantage noted is the need to backfill with a thick layer of expanded clay filler. This leads to the need to raise the floor level.

Varieties of expanded clay

Floor screed with expanded clay is performed in different ways, which can be divided into dry, wet (traditional) and combined. For each of them, the material is selected individually. More on the methods below, but for now let’s figure out what expanded clay is and what properties and characteristics it has.

Expanded clay granules: dense on the outside and porous on the inside Source ec-nn.ru

The basis of the material is clay with special additives. The raw material is subjected to high-temperature firing, as a result of which it swells with the formation of many small closed voids inside and a dense crust on the surface. This porous structure allows the use of expanded clay as insulation with unique properties. With a sufficiently high density and strength, it is lightweight and resistant to moisture.

Depending on the production method, shape and size of individual particles, the material is divided into 3 types:

- expanded clay crushed stone, the main difference of which is the irregular shape of particles 0-40 mm in size, obtained by grinding large stones;

- expanded clay sand, consisting of round granules less than 5 mm in diameter;

- Expanded clay gravel is also a mixture of oval or round granules with a diameter of up to 40 mm. It can be homogeneous, from granules of 5-10, 10-20 or 20-40 mm, or it can consist of elements of different sizes.

Some types of expanded clay Source 1nerudnyi.ru

Note! Grain sizes and other characteristics of the material are regulated by GOST 32496-2013. Manufacturers producing it according to their own specifications cannot guarantee quality.

This bulk material also differs in density, which depends on the size of the granules and voidness. The lower these indicators, the greater the weight.

For thermal insulation, expanded clay flooring in the form of crushed stone or gravel is used. Sand is not suitable for this, as it has a high density. It is used when it is necessary to level bases with large differences in level or damaged surfaces as a material that gives less shrinkage.

Dry floor leveling

Dry floor leveling

This is perhaps the easiest and cheapest way to level floors using expanded clay. Compared to the previous ones, when all the work had to be done quickly, in this case you can interrupt as much as you like, make corrections, and you won’t have to wait for the screed to dry.

The floor is suitable for full use almost immediately. It is necessary to note one more advantage of the method. The finished structure does not contain cement or sand at all, and therefore has the least weight. This leveling is ideal for old houses with wooden floors, in which the weight of the screed is critical.

A layer of unfixed expanded clay allows you to lay telephone and electrical wires, “warm floor” systems and any communications in it. There are two more advantages to this method of floor leveling: better sound insulation and heat retention, and the only disadvantage is that the coating sheets are susceptible to moisture.

The execution steps are very simple. The dry expanded clay mixture is scattered on the floor, compacted and leveled along the beacons. You can not level the entire floor at once, but in fragments, since you will still have to walk on the backfill. As for the thickness, it is determined by the specific situation. Already 3-4 centimeters of filler allows you to create a fairly dense and stable coating, but you should not make it less thick.

The dry expanded clay mixture is scattered on the floor, compacted and leveled along the beacons

Sheets of flooring material are laid on the compacted cushion. It can be gypsum fiber board, OSB, fibreboard, chipboard or just plywood. The sheets are placed relative to each other according to the principle of brickwork, that is, the side of each sheet is in contact with the halves of the sides of the other two.

GVL sheets

The folds of the slabs are usually glued together, and a second layer is laid on top, attached to the first with self-tapping screws. The resulting coating should not reach the wall by about a centimeter; these gaps will be hidden later by baseboards. All joints of the resulting structure are puttied, and the finishing coating is laid on top of the finished floor.

Methods for installing expanded clay screed

Expanded clay for leveling and thermal insulation of bases can be used in bulk form or as a filler for a pouring mixture. Depending on this, the technology of work also changes.

Wet method - traditional screed

Expanded clay concrete screed is made in exactly the same way as a classic screed, from a sand concrete mixture. It’s just that not ordinary crushed stone or gravel is used as a filler, but expanded clay. It allows you to seriously lighten the load on the floors when the thickness of the screed is needed: about 50 kg for every square meter with a thickness of 5-6 cm.

Finished rough coating Source chudopol.ru

See also: Catalog of house projects presented at the Low-Rise Country exhibition.

In this case, the fractionation of the material is not particularly important, since the voids will be filled with sand, and all components of the solution will be bound into a monolith. Therefore, you can take both crushed stone and gravel, focusing on the availability and cost of the filler. Typically, crushed stone is cheaper due to its lower density and weight.

It is also worth considering that the smaller the size of the aggregate granules, the smoother the surface will be. The layer with large crushed stone will probably have to be leveled additionally with cement mortar, making a finishing screed. A layer of gravel may well serve as a ready-made base for laying tiles, but you cannot lay linoleum or laminate on it - you will also need to level the surface.

Advice! When using coarse aggregate for screeding on the ground, its surface must first be leveled and compacted, without leaving significant unevenness and dips.

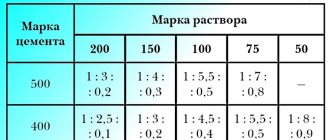

The composition of expanded clay concrete, the proportions per 1 m3 depend on the brand of cement used and the requirements for the strength of the base. For a house or apartment, an approximate ratio of M400 cement, sand and expanded clay is usually used: 1: 3: 2. This composition provides a grade of screed M50-M100 sufficient for domestic conditions, taking into account the laying of the finished floor covering.

Video description

You can study the technology of installing a screed made of expanded clay concrete using the video:

The work consists of several stages.

- First, the level to which the floor rises is marked along the walls. To do this, it is most convenient to use a laser level.

- After removing the old floor covering and clearing away the debris, the holes in the ground are filled and compacted, large cracks, gaps along the walls and joints between the slabs are sealed - the preparatory work depends on the material and condition of the base.

- The next stage is waterproofing. It is needed so that moisture does not leave it during the hardening process of expanded clay concrete. And also to prevent leaks from wet mortar to the lower floors. In the case of a ground screed, the waterproofing also serves as a barrier to groundwater. It is made from thick film, roofing felt or fiberglass, always laying the material with an overlap of at least 10 cm and gluing the joints with tape. Concrete bases can be insulated with liquid compounds - waterproofing, liquid rubber, etc. The waterproofing layer should be continuous and extend vertically onto the walls above the marking level.

Waterproofing under screed Source sam-sebe-dizainer.com

See also: Catalog of companies that specialize in the design and construction of turnkey country houses.

- If electrical cables are laid along the floor, they are also wrapped in film and wrapped with tape.

- Next, the beacons are installed, fixing them with cement mortar or alabaster. The distance between beacons should be no greater than the length of the rule.

- Along the entire perimeter of the walls along the marking line, damper tape is glued or secured in any other way. It neutralizes the thermal expansion of the screed and serves as sound insulation. You can use either ready-made self-adhesive tape or other suitable materials - for example, strips of polystyrene foam.

- Then expanded clay concrete is prepared, the proportions of which are selected in accordance with the strength requirements. In the case of an insulating screed and laying a hard floor covering on top of it, it is allowed to double the amount of expanded clay.

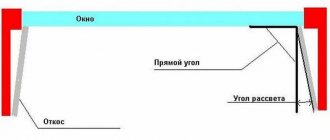

Proportions of components for obtaining a solution of different brands Source remoo.ru

- When making a solution, it is recommended to first fill the expanded clay with water so that it absorbs moisture and does not float to the surface of the screed and does not pull it out of the solution. Then add the remaining components - cement and sand or a ready-made sand-cement mixture.

- If the thickness of the screed exceeds 60-100 mm, then it is poured in 2 layers with a minimum soak time between layers. It is best to divide the room into squares and fill each area in 2 steps, then move on to the next one.

- If the screed is without a leveling layer, then the solution is pulled out according to the beacon rule. In the case of a cement screed, leave space for it - at least 2-3 cm to the upper level of the beacons, and the expanded clay concrete is leveled by eye.

- After the initial setting of the solution, the beacons are removed, and the resulting depressions are sealed with fresh solution.

Beacons are removed until the solution has completely set Source polonest.ru

Kinds

To screed floors in residential premises using expanded clay, including in new buildings, three methods can be used:

- semi-dry;

- dry (backfill floors);

- wet (expanded clay concrete).

Each of the listed methods has its own characteristics and subtleties when carrying out work. But the base of the floor is always first cleaned of debris and dust. If the floor has unevenness, then they are eliminated, and the old screed is also dismantled. For waterproofing purposes, bitumen mastic or special roll material is often used, which is laid overlapping on the floor. Its sheets are connected to each other using masking tape.

Semi-dry method

The semi-dry method is the only one that does not require meticulous preparation of the floor before applying the screed. After cleaning up the garbage, you can immediately get to work. If wires or communications pass under the floor, they are insulated and pressed tightly to the base of the floor. Installation using the semi-dry method consists of two successive stages:

First, the floor is covered with expanded clay

It is important that its level is 2-2.5 cm below the future base of the floor. The floor is then filled with cement mixed with water. After the granules have set together, the surface is additionally filled with sand concrete and allowed to dry thoroughly.

Dry method

The dry method is very popular because it is the simplest and does not require the purchase of cement. To install such a screed, the previously prepared floor is covered with a vapor barrier film, and the required layer of expanded clay is poured onto it and carefully leveled using a level. GVL slabs are laid on top.

Wet method

The wet method involves the independent production of expanded clay concrete. You can also purchase ready-made mixtures, for example. Purchasing a ready-made expanded clay mixture makes the work easier, but it should be taken into account that it hardens much faster than self-prepared expanded clay concrete.

The ratio of the components of a self-prepared solution is individual; it depends both on the quality of the concrete and on the characteristics of the room where the screed will be installed. The solution is poured between pre-installed beacons and carefully leveled.

Whatever method is chosen, it requires strict adherence to the steps and technology, and then a high result can be achieved.

Video description

The entire process from backfilling to laying the coating is shown in the video:

Advice! It is better to start backfilling from the far wall and move towards the exit, and laying gypsum fiber boards in the reverse order. But you can carry out the installation in small sections or move along a temporary gypsum fiber board flooring thrown onto the expanded clay.

Combined method - type-setting screed

Something in between the described options is a screed on expanded clay, poured onto the base in a thick layer. To ensure effective thermal insulation, the thickness of the backfill layer must be at least 100 mm and consist of gravel of different fractions. If only leveling with raising the floor level is required, the layer of dry expanded clay may be smaller, and the backfill may consist of fine crushed stone and sand.

Installation of a wet screed over a dry screed Source www.baurum.ru

So, screed with expanded clay – the technology for its production with all its variations:

- as usual, the first step is to mark the level and prepare the base;

- expanded clay is poured and distributed so that there is room for a cement screed (usually at least 20-30 mm);

- so that the backfill does not float up into the screed, the expanded clay layer is filled with cement laitance - a liquid solution that should seep between the granules and hold them together;

- a day later, beacons for a wet screed are installed on the set layer;

- Between the layers you can lay a reinforcing mesh, which is important for large areas, or a thick polyethylene film, which will prevent the expanded clay from sucking water out of the solution. In this case, there is no need to spill the backfill with liquid solution.