Foam block differs from other finishing materials in its increased vapor permeability, as a result of which it requires a special approach to finishing. If done incorrectly, the problem of dampness and rapid destruction of the walls will arise. Therefore, I want to share with you several modern finishing options that are great for foam block walls.

Finishing a house made of foam concrete requires a competent approach

Features of foam concrete and finishing requirements

Foam blocks have a special cellular structure, which provides for the presence of small pores. They are closed and filled with air. And it is known to be the best heat insulator. Therefore, buildings made of foam concrete are very warm. This material has a special relationship with moisture. It has low water permeability compared to aerated concrete. But the vapor permeability of all cellular concrete is the same. The walls of such houses breathe, so a normal level of humidity is maintained inside the premises.

When facing external walls, you need to be guided by one rule - do not exclude the escape of steam to the outside. If you finish without neglecting this requirement, the surface will deteriorate over time due to accumulated moisture. It will freeze when the temperature drops and will destroy the structure of the cells. As for the premises, they will experience increased humidity. Therefore, the exterior decoration of a house made of foam blocks must be done with vapor-permeable materials or use cladding, which forms the basis of a ventilated facade.

Video description

About finishing a house with fiber cement in the following video:

Vinyl siding

Plastic (vinyl) panels are a popular way of arranging a ventilated facade. Siding panels consist of two layers: the inner layer gives strength, keeping the geometry of the material unchanged; the outer, thinner layer provides protection from precipitation and ultraviolet radiation. The facing material is characterized by many advantages:

- Resistant to a wide range of influences

, including temperature fluctuations and moderately acidic and alkaline environments. The original color and shape are maintained throughout the entire service life. - Budgeting

. Vinyl siding has an optimal price/quality ratio. - Variety

. On the construction market, you can choose a material to match any color palette. You can decorate your home in any style. - Easy installation

and maintenance.

The disadvantage of low-quality vinyl siding can be its cracking when exposed to low temperatures. In addition, violation of the installation technology can lead to tearing of the skin in strong winds.

Vinyl siding Source www.yugkrovlya.ru

Features of finishing materials

If you are thinking about the question of how to clad the outside of a house with foam blocks, you should know that special requirements must be met for the materials purchased.

- Firstly, they must be vapor permeable. This property is important, since if the exterior decoration is not properly organized, the humidity level inside the house will be disturbed.

- Secondly, materials for working with the facade must be waterproof. They are installed not only for external decoration of the house, but also to protect foam concrete from exposure and contact with moisture.

- Thirdly, the exterior decoration of a house made of foam blocks must be done with frost-resistant materials that will be able to undergo many cycles of freezing and thawing.

When consumers think about the question of how to decorate the facade of a house made of foam blocks, they usually pay attention not only to the type of materials, but also their price, as well as the complexity of the work. The simplest option in terms of power costs would be plaster and paint. They do not require complicated preparation, and application can be done independently.

If you cannot decide for yourself the question of how to decorate the outside of a house made of foam blocks, you should also consider the option with a ventilated facade. It allows you to improve the appearance of the building and additionally insulate it.

Video description

About facing the facade with stone in the following video:

The main limiting factor when choosing a brick finish is cost - the spectacular appearance of such a house will be quite expensive. A common drawback of low-quality brick is the appearance of efflorescence (salt stains), which significantly worsens the appearance.

Finishing foam concrete walls with stone is carried out only if there is a strong foundation. The house, lined with natural stone, has an unusually attractive appearance. There are many colors and textures of stone finishing, which is not only aesthetically pleasing, but also practical, since it will last as long as possible without much hassle. Poor-quality installation can briefly overshadow the choice of stone cladding - individual stones can lag behind the foam concrete, which, however, can be easily corrected.

Brick finishing Source svarnayasetka.by

To finish a facade made of foam blocks, you can use clinker, ceramic and porcelain tiles, for which you will need to perform the following preparatory work:

- Prime the wall surface

with a waterproofing compound. - If necessary , insulate the walls

(the standard choice is mineral wool or fiberglass). - Install a frame

made of aluminum profiles and secure sheets of drywall to it. Foam concrete walls will be provided with effective ventilation. - Cover the prepared surface

using an adhesive solution.

The tiled facade will be a practical protection of foam blocks from moisture and temperature fluctuations. This finishing option is common due to its good price/quality ratio and aesthetic possibilities - imitation of ceramic brick or natural stone would be ideal. The main disadvantage of tiled cladding is the financial and time costs of preparing the walls.

Finishing with artificial stone Source uf.ru

Exterior materials

Before cladding a house with foam blocks, you should consider the features of the materials offered by the modern market. Among the less common are façade cassettes. They are more often found on industrial and industrial buildings, but if they suit you, there is nothing stopping you from installing them on a country building or a permanent home. This cladding is wear-resistant and lightweight, and can perform two functions at once - insulation and decoration.

When a consumer decides what is the best way to cover the outside of a foam block, they also consider corrugated sheeting. It is also rarely found on residential buildings, but it looks quite attractive, and can also have a special coating with anti-corrosion properties. You can cover your house with this material by choosing one of the many colors in which the canvases are painted. Additional advantages include fire resistance and airtightness of the new façade. During the entire period of operation, the walls will be easy to care for.

Production of textured blocks

Types of texture of facing foam blocks

For the production of decorative foam concrete, special automated lines, universal forms, original facing mixtures and painting methods are used.

- A solution is mixed from sand, cement and special foam.

- The mixture is poured into molds.

- Place on a vibrating table and vibrate to distribute air evenly.

- Leave until completely hardened.

- The finished foam block is lowered into a mold with a decorative mixture and again placed on a vibrating table, where the textured layer fuses with the surface of the block through the process of diffusion.

- Double processing of products helps to harden the surface and improve the adhesion of the decorative mixture.

Today, the invention of universal mold equipment makes it possible to reduce the manufacturing time of products by pouring foam blocks in one stage, which significantly reduces the cost of the material.

Some manufacturers are producing a completely new type of facade foam block with the front side covered with artificial stone. This cladding reliably covers the structure of cellular concrete from moisture penetration.

Foam blocks with a finished facade

A wall thickness of no more than 0.45 m can preserve all the important parameters of foam concrete, such as sound absorption, thermal insulation, and reliability.

Decorative foam blocks can be used to construct not only walls, but also internal partitions, fences, and foundations. A building made of cellular concrete will not require a powerful foundation, as it is a lightweight building. In addition, there is no need to create a multi-layer wall structure, which also reduces the cost of construction.

The blocks are available in two modifications:

- Facade – for walls and partitions (they have one textured surface).

- Corner – for finishing corners, wall and door openings (they have two adjacent decorative surfaces).

The variety of textured layers allows you to decorate the walls of a house with imitation stone, marble, brick, wood, and a wide palette of colors will help you choose a shade to suit any architectural style.

Color palette of decorative foam blocks

When building walls, the same instructions apply as for simple foam concrete - the blocks are placed on a special glue, laid in a thin layer. The verticality and horizontality of the masonry is strictly observed, otherwise the flaws cannot be hidden behind additional cladding.

Combining different textures on the facade will turn your house into an original and sophisticated masterpiece of architecture.

Modern methods of painting facade foam concrete make the cladding wear-resistant, capable of resisting environmental influences and negative atmospheric phenomena for a long time. A house built from decorative foam concrete will always look stylish and modern.

The video in this article will clearly show the benefits of using this unique building material.

Ventilated facades

You don’t have to decide what to use to clad the outside of a house made of foam blocks if you choose a material with a facing side. Its outer surface can imitate natural stone, brick and other materials. Products can have not only a decorative, but also a functional purpose, because sometimes there is insulation between the outer and main layers.

The parts are connected to each other by plastic, which does not conduct heat well, so the thermal insulation properties of the final product remain high. Foam blocks with a facing side can have different colors, so the design of the house can be done based on the features of the exterior of the site.

Facade cassettes

Before you start decorating a house, you need to familiarize yourself with the features of a particular material. If we are talking about façade cassettes, here are products based on:

- copper;

- stainless steel;

- brass;

- steel sheet;

- aluminum.

As for the steel sheet, it is covered with a layer of paint or plastic on top. Among the advantages of such cladding are an excellent degree of protection of the facade, environmental safety of the material and the absence of the need for subsequent maintenance. After finishing, the walls look aesthetically attractive, and such decorative elements can be combined with other facing materials.

This cladding method is very durable, provides design flexibility and is fire resistant. Installation can be carried out end-to-end or by combining. The latest work algorithm allows you to replace individual elements if they are damaged.

Corrugated sheet

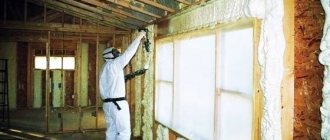

Before you start tiling your house, you must decide whether you will carry out the work yourself or entrust this task to professionals. Based on this, a material is selected that can be installed on your own or with outside help. When it comes to corrugated sheets, home craftsmen usually do not do the work themselves. Under the outer layer you can lay insulation, which is located between the sheathing elements.

The wall should be freed from protruding elements and measurements should be taken on the surface. Using a punch, holes for fasteners are made using the marked marks. Brackets are installed to secure the sheathing. The profile should be placed on brackets; these elements will act as the main components of the frame.

There is thermal insulation between the sheathing elements. On the surface of the mineral wool, if it acts as insulation, you need to mark points for installing fasteners. In these places, the insulation is drilled, and disc-shaped dowels are inserted into the holes. With their help, the insulation will be securely fixed to the wall. A windproof film is laid on top, which is attached to the upper part of the wall. It is fixed from below with roofing screws. The film is laid with an overlap. Next, you can begin covering with corrugated sheets. The material is cut using metal scissors, but it is better to avoid using an angle grinder. Fastening is carried out with roofing screws. Their color must be matched to the shade of the corrugated board.

Vinyl siding

If you still haven’t decided for yourself the question of how to clad the outside of a house made of foam blocks, you should consider vinyl siding. It is very common today because it is easy to install, has little weight, which means it does not put a load on the foundation, and in addition, it looks very attractive. Installation of products is carried out on the lathing. To do this, you can use a galvanized steel profile or wooden blocks.

If the facade is covered with plaster, the walls should be rid of crumbling areas. The frame provides for the installation of a starting strip, on which the quality of the cladding will depend. The fastener heads should be positioned in the center of the perforated hole. Nails or screws are not fully embedded to allow for thermal expansion. Once the starting strip is on the wall, you can begin attaching the corner profiles. Siding extensions are carried out overlapping or lengthwise.

Fiber cement boards

Walls made of foam blocks are often covered with fiber cement boards. They can be produced in brick imitation. In order to ensure the escape of steam from the interior, work should be carried out according to the principle of a ventilated facade. An additional layer will be mineral wool sheets. However, you can choose insulation as desired. These may be solutions that do not require such careful protection from moisture as mineral wool. This will reduce the cost of the process and make it less time-consuming.

A frame should be installed, which is made from profiles. For fastening, brackets will be used, which are separated from the main wall with cushioning material. Installation of brackets must be carried out in a certain step. In order to prevent the foundation from getting wet, an ebb tide should be installed. The first row is fastened with clamps, which are located above the ebb. With their help, decorative products are attached to vertical profiles with self-tapping screws.

Types of foam blocks with decorative coating

Facade decorative block with cladding comes in several types:

- Simple. A simple wall foam block with a finished facade has become widespread in the field of country and cottage construction. Its main advantage is that after the walls are erected there is no need to carry out facing work. The outer surfaces of the blocks are initially covered with a layer of high-quality finishing, making the façade look beautiful and respectable. The facing coating applied to the front side of each block not only gives the materials excellent aesthetic qualities, but also protects it from external influences (since it has a high degree of moisture resistance).

- Angular. Unlike a conventional facade block, this material has two adjacent decorative surfaces. It is used for arranging door and window openings and finishing corners.

- Thermoblock. Structurally, such blocks consist of several layers. On the front side of the material

There is a facing facade layer that gives the foam block an aesthetic appearance. Behind it is a thick layer of heat-insulating filler designed to reduce the thermal conductivity of the blocks. On the inside there is a load-bearing layer, which gives the building material sufficient strength and resistance to mechanical loads. Thermoblock is one of the best thermal insulating materials. Thus, a 0.4 m thick thermoblock wall is identical in thermal insulation quality to a 2.4 m brick or 4.6 m concrete wall. Therefore, it is often used to fill the walls of buildings that require effective thermal insulation.

Plaster and paint

When thinking about the question of how to cover the outside of a house made of foam blocks, you can choose budget options - plaster or paint. Before applying the first wall, the walls are leveled and primed. When decorating external walls, the thickness of the plaster layer can vary from 5 to 10 mm. You can use cement mortar, which is prepared using sand and lime. About 5% chalk is added to the composition, which will increase the plasticity of the mixture. Cement mortar is cheaper than others, but working with it will require skills and knowledge from the master.

Leveling walls with plaster mortar

Any option for indoor wall cladding first of all needs to provide a flat surface, which is especially important for block construction. The surface is leveled by plastering. Such work is carried out in the following order:

- Surface preparation. This preliminary procedure includes thoroughly cleaning the wall from dirt, adhering mortar, grease and oil stains. If there are large defects, they must be repaired.

- Primer. The special composition is applied with a paint brush or roller in a thin layer over the entire surface of the wall. It is important that it penetrates inside the foam blocks to a depth of about 3-5 mm. Wide seams between blocks are treated with adhesive.

- Mesh installation. After the primer mass has completely hardened, the entire wall surface of the foam blocks is covered with a mounting mesh. The most commonly used mesh is fiberglass mesh. This element strengthens the finishing coating and, most importantly, ensures adhesion of the plaster.

- Plastering. The purpose of this operation is to perfectly level the surface. For plastering, it is recommended to use ready-made dry mixtures for interior work based on gypsum or cement. Craftsmen often use their own sand-cement mortar. In this case, they usually stick to a 3:1 ratio. The plastering technology depends on the subsequent cladding. So, when preparing a wall for tiling, one layer of plaster is considered sufficient. If you plan to paint or wallpaper, we recommend two-layer plaster with an outer, finishing layer that provides an ideal surface. In this case, the first layer (main) has a thickness of 2-3 cm, and the leveling, top layer is 10-12 mm.